Using essential skills: On the job with an industrial mechanic (millwright)

Alternate formats

Using essential skills: On the job with an industrial mechanic (millwright)[PDF - 506 KB]

Large print, braille, MP3 (audio), e-text and DAISY formats are available on demand by ordering online or calling 1 800 O-Canada (1-800-622-6232). If you use a teletypewriter (TTY), call 1-800-926-9105.

Are you starting an apprenticeship as an industrial mechanic (millwright) or are you thinking about a career in this trade? Pursuing a career as an industrial mechanic (millwright) requires strong essential skills such as reading, document use, numeracy and critical thinking.

Use this booklet to:

- learn how industrial mechanics (millwrights) use essential skills

- follow the daily routine of an industrial mechanic (millwright)

- find out how your essential skills compare to those of an industrial mechanic (millwright) journeyperson

How industrial mechanics (millwrights) use essential skills

Industrial mechanics (millwrights) use essential skills to perform a variety of job-related tasks, for example:

- document use to read tables, drawings and specifications

- numeracy to take accurate measurements using precision instruments

- critical thinking to evaluate the condition of machines and their components

Industrial mechanics (millwrights) install, maintain, troubleshoot and repair stationary industrial machinery and mechanical equipment. Industrial mechanics (millwrights) work in manufacturing plants, utilities and other industrial establishments.

A day in the life of an industrial mechanic (millwright): Ron’s story

Taking apart a turbine

Ron is an industrial mechanic (millwright) working at a waste-to-energy facility. He is part of a crew of industrial mechanics (millwrights) assigned to perform maintenance on a turbine that has been running continuously for the past five years and is due for an overhaul. The crew will need to take the turbine apart, inspect all the components to make sure they are in working order, make repairs where necessary, clean the parts and reinstall the turbine.

Attending a toolbox talk

Before starting work for the day, Ron attends a toolbox talk where the supervisor gives the crew members their tasks for the day, goes over any safety issues and addresses worker concerns. The supervisor cautions the crew that, due to the weather conditions, ice has built up on the floor. The supervisor also reminds the workers to report any hazards they may notice. At the end of the talk, Ron raises a concern about the lack of lighting in the work area (oral communication). The supervisor tells Ron that he will set up additional lighting. Ron and the other workers sign the attendance list at the end of the talk to show that they were at the meeting and that they understand what was discussed and what they have to do that day (document use).

Daily toolbox talk

Customer: Waste to energy facility - TG inspection

Date: April 15

Project# 11960

Attendance list: (to be signed by all attendees)

Jack Sinclair _______________

Gary Lew _______________

Sean Whitaker _______________

Ron Morison _______________

Adam Desousa _______________

Taking off the turbine cover

Ron’s first task is to take off the turbine cover. The supervisor tells the crew which tools they will need and Ron gets them from the tool storage drawers (oral communication). Each drawer is labelled so that the industrial mechanics (millwrights) can easily find any tool they need (document use).

Ron will use a socket wrench and ratchet to unbolt the cover before it is lifted off. All bolts must be identified and labelled before disassembly. Labelling the bolts ensures that each bolt will be installed in the right place and that each nut will be installed on the right bolt when the turbine is reassembled. This will make it possible for other industrial mechanics (millwrights) to take over the task of reassembling the turbine. Ron marks each bolt and puts the bolts in a bag (writing). He labels the bag and places it in the bin for bolts from the turbine cover.

Getting the rigging hardware

Once he has finished removing the bolts, Ron reports to the supervisor. The supervisor reviews the blueprints and tells Ron how heavy the turbine cover is and what rigging hardware is needed to lift this load (oral communication). An overhead crane will lift the cover, and ropes and shackles will be used to help stabilize it.

All of the heavy equipment at the plant, such as the cranes, is inspected by engineers before a job is started to make sure the industrial mechanics (millwrights) will be safe. However, it is important for Ron to watch out for faulty equipment and know what to do about it. Ron notices that one of the shackles is damaged (thinking skills – critical thinking). He knows that he has the right to work under safe conditions, so he tells the supervisor about the damaged shackle (oral communication). After speaking to the supervisor, Ron refers to the working loads table to find out what size rope he needs. He then gets the other supplies and hooks the rigging up to the turbine cover (document use).

Lifting the turbine cover

Performing a lift is dangerous and requires precision; the horizontal joints on the cover must be kept parallel to one another to avoid damage. The lift requires a team (working with others). Ron and the supervisor monitor the load and use a level to make sure it is being lifted evenly (numeracy). The supervisor communicates any adjustments that need to be made during the lift to the crane operator using hand signals. It is important for all industrial mechanics (millwrights) to know these signals. Workers receive an occupational health and safety manual with standard procedures on the first day they arrive on the site (reading). From this training and his experience on the job, Ron knows how to use and interpret the signals.

-

Text version

An image illustration the hoist and lower movement hands signal for lifting the turbine cover.

Hoist: with forearm vertical, forefinger pointing up, move hand in small horizontal circle

Lower: with arm extended downward, forefinger pointing down, move hand in small horizontal circle.

Checking inside the turbine

Once the cover is off, Ron can start the maintenance work on the inside of the turbine. This involves a variety of tasks, such as measuring the internal alignment of the components (numeracy). To do this, Ron takes readings with precision measuring tools such as micrometers. He records all of the readings and gives this information to the supervisor (document use). Ron sometimes asks his partner to double-check his readings (oral communication, working with others).

Performing non-destructive testing

Next, Ron checks for defects (cracks or damage) in the turbine using non-destructive testing techniques. He needs to choose an appropriate technique before carrying out the inspection (thinking skills – decision making). He decides to do a dye penetrant inspection. In this test, the surface of the component is coated with a dye that penetrates any defects, making them visible under ultraviolet light. When he inspects the test, Ron notices a slight change in colour on a journal bearing, which is a component that surrounds a rotating shaft to support and guide it. He concludes that the bearing has overheated due to a lubrication problem (thinking skills – critical thinking). He reports this to the supervisor, and they decide to replace both bearings (oral communication, thinking skills – decision making). Ron goes to the storage area to find the new bearings and checks the reference catalogue to make sure he gets the right ones (document use).

Referring to material safety data sheets (MSDS)

Ron needs to clean and prep the shaft for the new bearings. To do this, he uses industrial solvents and cleaners. Before he uses any chemical, especially one he has never used before, Ron makes sure he knows the health and safety risks associated with it. He looks at the MSDS for the product to see what the risks are and how he can protect himself (document use).

After cleaning the shaft and installing the bearings, Ron returns all the tools to their proper place and updates the supervisor on the tasks he has completed (oral communication)

Do you have the essential skills to be an industrial mechanic (millwright)

Complete the following questions to see how your skills compare to those of an industrial mechanic (millwright) journeyperson.

1. Noticing a hazard

It is important for industrial mechanics (millwrights) to evaluate the safety of their work environment. An industrial mechanic (millwright) is working at a site where the supplies are kept in a trailer outside. On her way to get a socket wrench, she notices that a lot of ice has built up on the steps. She decides that this is a potential hazard. What should she do?

2. Selecting rope for lifting a load

Industrial mechanics (millwrights) refer to working load limits to make sure that the load they need to lift does not exceed the safe working load for the equipment they are using. Look at the working loads table. The supervisor tells his crew to use a basket hitch configuration to lift a 42000 pound load. What size of wire rope should be used?

-

Text version of working loads for wire ropes

Performance series ABC weight in LBS Rope size

(in.)Vertical lift Choker hitch Basket hitch 1/4 1300 960 2600 5/16 2000 1450 4000 3/8 2800 2200 5800 7/16 3800 2800 7800 1/2 5000 3800 10200 9/16 6400 4800 12800 5/8 7800 5300 15600 3/4 11200 8200 22000 7/8 15200 11200 30000 1 19600 14400 40000 Performance series XYZ weight in LBS 1 1/8 24000 18200 48000 1 1/4 30000 22000 60000 1 3/8 36000 26000 72000

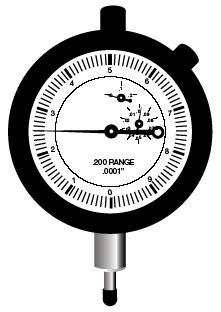

3. Dial indicators

Once turbine maintenance is complete, industrial mechanics (millwrights) use a dial indicator to align the turbine shaft with the generator shaft so that they form a straight line. What is the reading on this dial indicator?

Hint: each tick mark on the dial is 0.0001 inches.

4. Material safety data sheets (MSDS)

Industrial mechanics (millwrights) refer to MSDS for information about handling hazards, personal protective equipment (PPE) and first aid procedures for the materials they use. According to section 8 of the MSDS below, what types of PPE are required for handling this material?

| Engineering controls | Provide exhaust ventilation or other engineering controls to keep the airborne concentrations of vapors below their respective threshold limit value. Ensure that eyewash stations and safety showers are proximal to the workstation location. | |

|---|---|---|

| Personal protective equipment | Eyes | Safety glasses. |

| Body | No special protective clothing is required. | |

| Respiratory | Wear appropriate respirator when ventilation is inadequate. Be sure to use an approved/certified respirator or equivalent. | |

| Hands | Gloves (impervious). | |

Answers

-

Noticing a hazard (thinking skills – problem solving)

-

The industrial mechanic (millwright) can try to solve the problem by removing the hazard. For example, she could chip off the ice or add salt to melt the ice.

-

If the problem can’t be solved, the industrial mechanic (millwright) should report the hazard to the supervisor.

-

-

Selecting rope for lifting a load (document use, numeracy)

The industrial mechanic (millwright) needs a 1 1⁄8 inch rope.

-

Dial indicators (numeracy)

The reading on the indicator is 0.0025 inches.

-

Material safety data sheets (document use)

Safety glasses, an approved/certified respirator or equivalent, and impervious gloves are needed.