Screening Assessment

Internationally Classified Substance Grouping

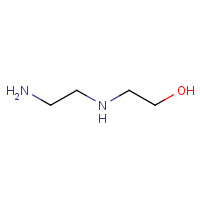

Ethanol, 2-[(2-aminoethyl)amino]-

(AEEA)

Chemical Abstracts Service Registry Number

111-41-1

Environment and Climate Change Canada

Health Canada

May 2016

Table of Contents

- Synopsis

- Introduction

- Substance Identity

- Physical and Chemical Properties

- Sources

- Uses

- Releases to the Environment

- Measured Environmental Concentrations

- Environmental Fate

- Persistence and Bioaccumulation Potential

- Potential to Cause Ecological Harm

- Ecological Effects Assessment

- Ecological Exposure Assessment

- Characterization of Ecological Risk

- Uncertainties in Evaluation of Ecological Risk

- Potential to Cause Harm to Human Health

- Exposure Assessment

- Health Effects Assessment

- Characterization of Risk to Human Health

- Uncertainties in Evaluation of Risk to Human Health

- Conclusion

- References

Synopsis

Pursuant to section 68 of the Canadian Environmental Protection Act, 1999 (CEPA), the Ministers of the Environment and Climate Change and of Health have conducted a screening assessment of Ethanol, 2-[(2-aminoethyl)amino]-, hereinafter referred to as AEEA. The Chemical Abstracts Service Registry Number (CAS RN) for AEEA is 111-41-1. This substance is part of the Internationally Classified Substance Grouping, which includes substances that were prioritised for screening assessment because they were classified by certain international agencies as potentially of concern for human health.

AEEA does not occur naturally in the environment. In Canada, AEEA is imported both as a pure substance and as a component of products. In 2008, a lesser quantity than the reporting threshold of 100 kg of AEEA was manufactured in Canada, and more than 500 000 kg of AEEA were imported into Canada. In 2011, AEEA was not manufactured in Canada, and between 100 000 and 500 000 kg of AEEA was imported into Canada in the same year. AEEA can be used as a chemical intermediate, a component of adhesives and sealants used in asphalt paving or patching, a curing agent for epoxy resins, in building products with mainly commercial applications, a component in super glue, and a component of corrosion inhibitors and lubricant additives. As a chemical intermediate, AEEA is used to manufacture surfactants which in turn have applications as industrial detergents and in consumer products such as cosmetics. AEEA is used as a component in food-packaging adhesives and inks with no direct contact with food, and as a component of an agent used in the paper manufacturing process. AEEA is also used as a component in additives for closed recirculating cooling systems where the water treated will not come into direct contact with food.

AEEA is characterized by a moderate vapour pressure, a very low Henry’s Law constant, and very low log Koc and log Kow values. AEEA is miscible in water. Monitoring data on AEEA in the Canadian environment have not been identified.

AEEA has a short half-life in air, and it is not expected to be present in the atmosphere. AEEA is readily biodegradable in water and it is not expected to remain in soil or sediments for prolonged periods of time. Based on the available empirical and modelled evidence, AEEA is expected to have a limited persistence in air, water, soil and sediments.

AEEA has a low bioaccumulation potential. This was evidenced by very low empirical and modelled bioconcentration and bioaccumulation values for fish.

Several studies have been conducted for AEEA to identify ecotoxicological effects of the substance on aquatic organisms, including micro-organisms, crustaceans and fish. Results of these studies indicated that AEEA has a low to moderate potential to cause acute toxic effects in exposed organisms. Longer-term ecotoxicological studies were not available for AEEA. It was noted that at higher exposure concentrations, AEEA increased the alkalinity of the aqueous test solutions, and this may have contributed to additional toxic effects to exposed organisms. Effects of AEEA on soil and sediment organisms have not been studied; however, such effects are not expected to be greater than those determined in aquatic species.

AEEA is imported as a minor component in products or mixtures that are used in industrial , commercial or consumer applications. Many of these products undergo curing. The potential for AEEA releases into the environment from these cured products as well as from AEEA applications in asphalt cement is not expected to be significant. AEEA can also be a minor constituent of imported solid products in building materials, but with very limited potential for releases. The main source of release of AEEA is expected to occur from industrial uses of the pure substance as a chemical intermediate. AEEA is assumed to be chemically converted during industrial processes, and it is expected that it no longer exists in its parent form. The only quantitative scenario considered was based on disposal of unreacted residual AEEA from the cleaning of empty transport and processing containers. Based on this scenario, and using conservative assumptions, exposure to organisms in the environment would be below levels expected to cause harm.

Considering all available lines of evidence presented in this Screening Assessment, there is low risk of harm to organisms and the broader integrity of the environment from AEEA. It is concluded that AEEA does not meet the criteria under paragraph 64(a) or (b) of CEPA as it is not entering the environment in a quantity or concentration or under conditions that have or may have an immediate or long-term harmful effect on the environment or its biological diversity, or that constitute or may constitute a danger to the environment on which life depends.

Critical effects for characterization of risk to human health for AEEA are developmental and reproductive effects in animal studies.

There were no reports of AEEA in environmental media identified for Canada. Exposure of the general population to AEEA from environmental media is not expected, given that it is not manufactured in Canada and its use is limited to a few industrial applications. Canadians are also not expected to be exposed to AEEA through food consumption or the use of consumer products. Accordingly, the risk to human health is considered to be low.

Based on the information presented in this Screening Assessment, it is concluded that AEEA does not meet the criteria under paragraph 64(c) of CEPA as it is not entering the environment in a quantity or concentration or under conditions that constitute or may constitute a danger in Canada to human life or health.

Conclusion

It is concluded that AEEA does not meet any of the criteria set out in section 64 of CEPA.

Introduction

Pursuant to sections 68 or 74 of the Canadian Environmental Protection Act, 1999 (CEPA) (Canada 1999) the Minister of the Environment and Climate Change Canada and the Minister of Health conduct Screening Assessments of substances to determine whether these substances present or may present a risk to the environment or to human health.

The Substance Groupings Initiative is a key element of the Government of Canada’s Chemicals Management Plan (CMP). The Internationally Classified Substance Grouping consists of six substances that were identified as priorities for action, because they met the categorization criteria under section 73 of CEPA and/or were considered as priority substances under the CMP based on human health concerns (Environment Canada, Health Canada 2013). Substances in this substance grouping have been identified by other jurisdictions as a concern for human health due to high hazard potential as recognized by international agencies.

The Internationally Classified Substance Grouping includes four cresols (phenol, methyl- substances), as well as two other substances, Ethanol, 2-[(2-aminoethyl)amino]- (CAS RN 111-41-1) and Carbamic acid, ethyl ester (CAS RN 51-79-6). These substances are not necessarily similar in terms of chemical structure, physical and chemical properties, uses, or other assessment parameters. For this reason, three separate Screening Assessments have been conducted within the Internationally Classified Substance Grouping, with one screening assessment for the sub-grouping of the four cresols, and individual assessments for Ethanol, 2-[(2-aminoethyl)amino]- and Carbamic acid, ethyl ester.

Screening assessments focus on information critical to determining whether substances within a grouping meet the criteria as set out in section 64 of CEPA, by examining scientific information to develop conclusions by using a weight-of-evidence approach and precaution.Footnote[1]

This Screening Assessment includes consideration of information on physical and chemical properties, hazards, uses and exposure, including additional information submitted by stakeholders. Relevant data were identified up to July 2013. Empirical data from key studies as well as some results from models were used to reach conclusions. When available and relevant, information presented in assessments from other jurisdictions was considered.

The Screening Assessment does not represent an exhaustive or critical review of all available data. Rather, it presents the most critical studies and lines of evidence pertinent to the proposed conclusion.

The Screening Assessment was prepared by staff in the Existing Substances Programs at Health Canada and Environment Canada and incorporates input from other programs within these departments. The ecological and human health portions of this assessment have undergone external written peer review and/or consultation. Comments on the technical portions relevant to the environment were received from Tim Fletcher (Ontario Ministry of the Environment) and Dr. Pamela Welbourn (Queen’s University). Comments on the technical portions relevant to human health were received from scientific experts selected and directed by Toxicology Excellence for Risk Assessment (TERA), including Dr. Sue Ross (TERA), Dr. Barry Ryan (Emory University), Dr. Pamela Williams (E Risk Sciences and University of Colorado) and Dr. Calvin Willhite (McLaughlin Centre for Population Health Risk Assessment and Risk Sciences International). Additionally, the draft of this Screening Assessment was subject to a 60-day public comment period. While external comments were taken into consideration, the final content and outcome of the screening assessment remain the responsibility of Health Canada and Environment and Climate Change Canada.

The critical information and considerations upon which the Screening Assessment is based are summarized below.

Substance Identity

The substance Ethanol, 2-[(2-aminoethyl)amino]-, (CAS RN 111-41-1), hereinafter referred to by its acronym AEEA, is a simple organic chemical that belongs to the class of organic substances known as ethanolamines. Information regarding substance identity of AEEA is summarized in Table 1.

| CAS RN | Chemical structure | Molecular weight (g/mol) | Chemical formula | SMILESFootnote Table 1 [a] |

|---|---|---|---|---|

| 111-41-1 |  |

104.15 | C4H12N2O | OCCNCCN |

Physical and Chemical Properties

A summary of experimental and modelled values of physical and chemical properties of AEEA that are relevant to its environmental fate and ecotoxicity is provided in Table 2.

Models based on quantitative structure-activity relationships [(Q)SAR] were used to generate data for some of the physical and chemical properties of AEEA. These models are mainly based on fragment addition methods, i.e., they sum the contributions of sub-structural fragments of a molecule to make predictions for a property or endpoint. Most of these models rely on the neutral form of AEEA as input (see Table 1 for SMILES sequence). Consequently, except where noted, the modelled values shown in Table 2 are for the neutral form of AEEA. It is noted that AEEA ionizes at environmentally relevant pH (ECHA c2007-2014b; ACD/Percepta c1997-2012; see Table 2), and consequently some of the substance could be present in the +1 and/or +2 ionized form, available to undergo electrostatic interactions in environmental media. Nonetheless, the modelled physical and chemical properties are considered relevant and predictive of its fate in the environment. Some AEEA is expected to be present in its neutral form at environmentally relevant pH. In addition, when ionized, AEEA behaves as a base. In aquatic toxicity studies, rapid increases in pH to as high as pH 10 were noted when AEEA was applied at high concentrations of approximately greater than or equal to 250 mg/L (ECHA c2007-2014b; European Commission 2000). AEEA exposure concentrations of less than or equal to 250 mg/L had no effect on pH levels of aqueous test solutions.

At room temperature, AEEA is a colourless to pale yellow liquid, and it has a mild ammonia odour (HSDB 1983– ; ECHA c2007-2014b). Generally, a very good correlation was found between the available empirical physical and chemical property values and the modelled values. AEEA has a moderate vapour pressure (less than or equal to 1 to 1.3 Pa at room temperature) (ECHA c2007-2014b; Hawley’s 2007; Sax’s 2012) and a very low modelled Henry’s Law constant (HLC) of 10-10 to 10-8 Pa·m3/mol (EPI Suite 2012). The empirical and modelled log Kow values for AEEA were determined to be negligible, at -2.13 to -1.37 (European Commission 2000; EPI Suite 2012; ACD/Percepta c1997-2012). The modelled log D values varied with pH and were found to be in the range of -4.46 to -3.26 for pH 6.5–8.0, respectively. The modelled log Koc values were very low, at 0.42 (based on the MCI method) and -0.359 (based on the Kow method) (EPI Suite 2012). AEEA is completely miscible in water (ECHA c2007-2014b; EPI Suite 2012; ACD/Percepta c1997-2012; Lide 2012). Lastly, the modelled pKa of the ammonium ion suggests that AEEA is an ionizing substance that is likely to exist primarily in either the 1+ or 2+ ionized form at a pH lower than approximately 9 (ECHA c2007-2014b; ACD/Percepta c1997-2012). Additional physical and chemical properties such as the melting and boiling points, density, and other partition coefficients are provided in Table 2 below.

| Property | Type | ValueFootnote Table 2 [b] | Temperature (°C) | Reference |

|---|---|---|---|---|

| Melting point (ºC) |

Experimental | -18Footnote Table 2 [a] | NA | European Commission 2000 |

| Melting point (ºC) |

Experimental | -38 (measured as pour point) |

NA | ECHA c2007-2014b |

| Melting point (ºC) |

Modelled | 9–58 | NA | EPI Suite 2012 |

| Boiling point (ºC) |

Experimental | 243.1; 243.7 | NA | ECHA c2007-2014ba; Sax’s 2012 |

| Boiling point (ºC) |

Experimental | 237–243; 140 (at 44 hPa) |

NA | European Commission 2000 |

| Boiling point (ºC) |

Experimental | 238–240[*] | NA | HSDB 1983– |

| Water solubilityFootnote Table 2 [c] (mg/L) |

Experimental | 1 × 106[*] (1000 g/L) |

20 | ECHA c2007-2014b |

| Water solubility[c] (mg/L) |

Modelled | 1 × 106 | 25 | EpiSuite 2012; ACD/Percepta c1997-2012 |

| Density (kg/m³) | Experimental | 1030 | 20 | European Commission 2000 |

| Density (kg/m³) | Experimental | 1024 | 25 | ECHA c2007-2014b |

| Vapour pressure (Pa) |

Experimental | 1.2; (0.012 hPa) 1.3[*]; (0.01 mm Hg) less than 1 (less than 0.01 hPa ) |

20 | ECHA c2007-2014b; Hawley’s 2007; Sax’s 2012 |

| Vapour pressure (Pa) |

Experimental | 1.09 (0.00819 mm Hg) |

25 | ECHA c2007-2014b |

| Vapour pressure (Pa) |

Experimental | 100 (1 hPa) |

83.8 | ECHA c2007-2014b |

| Vapour pressure (Pa) |

Modelled | 0.824 | 25 | EPI Suite 2012 |

| Henry’s Law constant (Pa·m3/mol) |

Modelled | 1.1 × 10−8[*]; (bond method) 6.2 × 10−10 (group method) |

25 | EPI Suite 2012 |

| Log Kow (dimensionless) |

Experimental | -1.46[*] | NA | European Commission 2000 |

| Log Kow (dimensionless) |

Experimental | -1.37 | 25 | European Commission 2000 |

| Log Kow (dimensionless) |

Modelled | -2.13; -1.4 |

NA | EPI Suite 2012; ACD/Percepta c1997-2012 |

| Log D (dimensionless) |

Modelled | -4.46 (at pH 6.5) -3.81 (at pH 7.4) -3.26 (at pH 8.0) |

NA | ACD/Percepta c1997-2012 |

| Log Koc (dimensionless) |

Modelled | 0.42 (MCI method) -0.359[*] (Kow method) |

NA | EPI Suite 2012 |

| Log Koa (dimensionless) | Modelled | 9.89 | 25 | EPI Suite 2012 |

| pKa (dimensionless) |

Experimental | pKa1 =6.49 pKa2 = 9.52 |

25 | ECHA c2007-2014b |

| pKa (dimensionless) |

Modelled | pKa1 = 6.1 (secondary amine) pKa2 = 9.6 (primary amine) pKa3 = 14.9 (primary hydroxyl) |

NA | ACD/Percepta c1997-2012 |

Sources

No natural sources of AEEA have been identified. Sources of exposure to AEEA are anthropogenic, primarily resulting from industrial manufacturing and processing activities.

Results from the DSL IU conducted under section 71 of CEPA (Canada 2009) indicate that for the year 2008, a quantity lower than the reporting threshold of 100 kg of AEEA was manufactured in Canada, and more than 500 000 kg of AEEA was imported into Canada (Environment Canada 2010). Based on the more recent voluntary information submitted to Environment Canada and Health Canada in 2012–2014 as a follow up to the DSL IU (Environment Canada, Health Canada 2012-2014), AEEA was not manufactured in Canada in 2011, while between 100 000 and 500 000 kg of AEEA was imported into Canada in the same year. Moreover, approximately one quarter of the total AEEA imported was in the form of a pure substance, with the rest imported as a component of products.

Globally in 2003, the production capacity for ethyleneamines, including AEEA, was estimated at 295 million kg (295 000 tonnes). In Europe, AEEA is identified as a high-production volume chemical in the Organisation for Economic Co-operation and Development (OECD) Cooperative Chemicals Assessment Programme. The production capacity was highest for Europe, followed by the United States and Japan; however, individual capacity data on AEEA were not available at that time (OECD 2006). In the United States, the national production volume of AEEA was listed as approximately 14.5 million kg/year (31.7 million lb/year) for the 2012 reporting year (CDAT 2013).

Uses

Globally, ethanolamines are used as chemical intermediates, corrosion inhibitors and cement additives. They can also be used in gas purification to capture carbon dioxide. As chemical intermediates, ethanolamines are widely used to manufacture surfactants with applications in lubricating fluids, detergents and fabric softeners (Frauenkron et al. 2001; Dow Chemical Company 2010; BASF AG 2013). AEEA is also used in the synthesis of adhesion additive for latex paints (BASF AG 2013).

Other specific uses of AEEA have been reported for the United States (Geosyntec 2012a), Europe and Japan (OECD 2006). In the United States, AEEA has also been used as a reactant in the production of an organic flotation agent used to process ground marble ore (Geosyntec 2012a). In Europe, AEEA is used in the production of polyurethane and hardeners for epoxy resins. In Switzerland, AEEA is reported as a constituent of soldering flux. In Japan, AEEA is primarily used as a chemical intermediate to produce surfactants and waxes for consumer uses (OECD 2006). Additional uses of AEEA identified by other jurisdictions include its application as an additive in textiles, fuel, 2,4-D-based herbicide salts, oils used in metal cutting, gas processing chemicals, resins, rubber products, insecticides and certain medicinal soaps (NJ Health 2008; HSDB 1983– ).

Most of the AEEA imported into Canada is used as a chemical intermediate (Environment Canada and Health Canada 2012-2014), a curing agent for epoxy resins (Henkel 2010, 2012a–c), used in commercial building products (Henkel 2013, Mapei 2013), and as a component of adhesives and sealants used in asphalt paving or patching (Environment Canada and Health Canada 2012-2014). AEEA may also be present in some epoxy adhesives, or super glues, used for small scale repairs or hobbies (Henkel Canada 2012b). AEEA can also be found as a component of corrosion inhibitors, lubricant additives, as a component of pigments used in fibres (e.g., carpets) (Environment Canada, Health Canada 2012-2014. AEEA can also be a minor constituent of solid products in building materials, with very limited potential for release (Environment Canada 2010).

Furthermore, in Canada, AEEA is used as a component in food-packaging adhesives and inks with no direct contact with food, and as a component of an agent used in the paper manufacturing process. AEEA is also used as a component in additives for closed recirculating cooling systems where the treated water will not come into direct contact with food (personal communication, 2011 email from the Food Directorate to the Risk Management Bureau; unreferenced).Based on notifications submitted under the Cosmetic Regulations to Health Canada, AEEA is not used in cosmetic products in Canada (2013 emails from the Consumer Product Safety Directorate, Health Canada, to the Existing Substances Risk Assessment Bureau, Health Canada; unreferenced). AEEA is not listed in the Drug Product Database (DPD 2013), the Therapeutic Products Directorate’s internal Non-Medicinal Ingredients Database, the Natural Health Products Ingredients Database (NHPID 2013), or the Licensed Natural Health Products Database (LNHPD 2008) as a medicinal or non-medicinal ingredient present in final pharmaceutical products, natural health products, or veterinary drugs (personal communication, 2011 emails from Therapeutic Products Directorate, Natural Health Products Directorate and Veterinary Drugs Directorate to the Risk Management Bureau; unreferenced).

Lastly, AEEA is a component of formulants that are used in four herbicides classified as commercial-use products by the Pest Management Regulatory Agency (personal communication; email from Pest Management Regulatory Agency, Health Canada to Ecological Assessment Division, Environment Canada, dated 18 September, 2013; unreferenced).

Releases to the Environment

Anthropogenic releases of a substance to the environment depend upon various losses that occur during the manufacture, industrial use, consumer or commercialFootnote[2] use, and disposal of a substance. In order to estimate releases to the environment occurring at different stages of the life cycle of AEEA, information on the relevant sectors and product lines, as well as emission factorsFootnote[3] to wastewater, land and air at different life cycle stages is compiled. This is done in order to identify the life cycle stages that are likely to be significant contributors to overall environmental concentrations. Recycling activities and transfer to waste disposal sites (landfill, incineration) are also considered. However, releases to the environment from disposal are not quantitatively accounted for because reliable specific information on the rate of (or potential for) release from landfills and incinerators is not available.

AEEA is used as a chemical intermediate and can also be a component of imported additives that are mainly used as a chemical intermediate (Environment Canada and Health Canada 2012-2014). The substance is also used as a curing agent for epoxy resins (Henkel 2010, 2012a–c), and as an anti-stripping agent to enhance adhesion properties in asphalt cement (Environment Canada and Health Canada 2012-2014).

AEEA has a limited potential for release to the environment. Expected environmental releases for AEEA stem mainly from its uses as a chemical intermediate. Potential releases may occur during handling of AEEA when it is added, as a pure substance, in industrial processes to prepare other chemicals. These releases are expected to result mainly from the cleaning operations of the transport and processing containers and could yield emission factors as high as 3% (OECD 2006).

Releases of AEEA from life cycle stages subsequent to its use as a chemical intermediate are not expected. Quantitative estimates of residual AEEA were not identified in published literature. However, given that AEEA is a reactive chemical (contains primary amine and primary alcohol functional groups), it can be expected that the majority of the substance would be fully chemically transformed (i.e., no longer existing in its original chemical form), and covalently bound, when used as a chemical intermediate. Under such conditions, releases of AEEA would not be expected.

Similarly, the potential for AEEA releases from cured products and its applications in asphalt cement is not expected to be significant, since AEEA is expected to undergo irreversible chemical reactions in these applications that would result in its full chemical transformation.

Other known uses of AEEA in Canada (e.g., minor constituent of solid products in building materials) (Environment Canada 2010) are estimated to have very limited potential of releases.

Measured Environmental Concentrations

AEEA is an anthropogenic chemical, and it is not found naturally in the environment. No data on the concentrations of AEEA in the Canadian environment have been identified.

In the United States, levels of AEEA in surface water and groundwater were reported in the industrial zone of Florence, Vermont, where ground calcium carbonate is produced from marble ore (Geosyntec 2012a, 2012b). It is noted that since 2010, tailings management practices at this industrial site have been improved, resulting in a decrease in the detection of AEEA in the water samples (Geosyntec 2012a). Based on the most recent 2012 monitoring data, AEEA was not detected above the detection limit of 0.002 mg/L in any on-site or off-site surface water samples (Geosyntec 2012a). In the past, on-site surface water concentrations of AEEA were measured to be as high as 0.3 mg/L in 2006, and the highest off-site concentrations were up to 0.009 mg/L in 2007 (Geosyntec 2012b). AEEA was detected in groundwater in one of ten monitoring wells at an estimated concentration of 0.016 mg/L (based on a measured concentration of 0.004 mg/L adjusted for 25% recovery), and at a concentration of less than 0.01 mg/L in the remaining nine wells. Historical groundwater concentrations of AEEA, adjusted for incomplete recovery, ranged from below the detection limit of less than 0.002 mg/L to 0.07 mg/L, and a decrease in concentrations has been observed over time (Geosyntec 2012a).

Environmental Fate

Fugacity modelling

Level III fugacity modelling (New EQC 2011) simulates the distribution of a substance in a hypothetical, evaluative environment known as the “unit world”. The EQC model simulates the environmental distribution of a chemical at a regional scale and outputs the fraction of the total mass in each compartment from an emission into the unit world and the resulting concentration in each compartment. The mass-fraction distribution results are used for general information on the environmental fate of a substance rather than the compartmental concentration results for the predicted environmental concentration (PEC) in a substance assessment. Some exceptions to this may occur, such as when a wide dispersive release of a substance suggests that regional-scale concentrations are appropriate for the PEC(s).

The mass-fraction distribution of AEEA is given in Table 3 below using individual steady-state emissions to air, water and soil. The Level III EQC model (New EQC 2011) assumes non-equilibrium conditions between environmental compartments, but equilibrium within compartments. The results in Table 4 represent the net effect of chemical partitioning, inter-media transport, and loss by both advection (out of the modelled region) and degradation/transformation processes.

| Substance released to | Air | Water | Soil | Sediment |

|---|---|---|---|---|

| Air (100%) | negligible | 19 | 81 | negligible |

| Water (100%) | negligible | 100 | negligible | negligible |

| Soil (100%) | negligible | 11 | 89 | negligible |

Model inputs: half-lives in air, water, soil and sediment were 1.1 h, 120 h, 120 h, and 480 h, respectively; log Koc = -0.359; log Kow= -1.46; water solubility = 1 × 106 g/L; vapour pressure = 1.3 Pa.

The results of Level III fugacity modelling (summarized in Table 3) indicate that AEEA is not likely to reside in air because of a very short predicted half-life, moderate vapour pressure and very high water solubility. When released to air, AEEA is expected to deposit to soil, and to a lesser extent to water, based on wet deposition from the atmosphere. Level III fugacity modelling indicates that if released to water, AEEA would remain in water. Similarly, when released to soil, AEEA is expected to remain in soil, and also, given its high solubility in water, run off soil to water. Partitioning to sediments was predicted to be negligible in all scenarios. However, given its high water solubility, AEEA could potentially be found in pore water, and thereby be found in sediment samples. It is also noted that AEEA ionizes at environmentally relevant pH (ECHA c2007-2014b; ACD/Percepta c1997-2012) (see Table 2). Therefore, AEEA may undergo electrostatic interactions in sediment as well as in soil that are not accounted for by the EQC modelling.

In summary, based on the results of Level III fugacity modelling, water and soil are the main receiving compartments of AEEA, depending on the compartment of release. Therefore, considering the physical and chemical properties and the associated predicted environmental fate of AEEA, aquatic and soil organisms could potentially be exposed to this substance. Exposure to sediment-dwelling organisms is not expected. Exposure to terrestrial organisms through inhalation is not expected, given that AEEA is not likely to remain in and/or partition to air.

Persistence and Bioaccumulation Potential

Environmental persistence

Relevant media and data sources

Based on the known uses, potential releases, and expected partitioning of AEEA, the environmental media of primary interest are water and soil. In order to provide the best possible weight of evidence for persistence of AEEA, empirical and modelled data for AEEA were considered. Available information is organized and presented based on the environmental compartment (i.e., air, water, soil and sediment). Available data are summarized in Tables 4a–c.

Data for persistence

Air – Modelled data

Empirical data for the degradation potential of AEEA in air were not available. Modelled results, based on the available (Q)SAR model, indicated a short half-life of 1.1 hours in air (AOPWIN 2010). It is therefore expected that the substance will be rapidly degraded by reaction with hydroxyl radicals in the atmosphere. In contrast, the ozone reaction half-life could not be modelled since chemicals of structural comparability to AEEA are not contained in the training set of the AOPWIN (2010) model. Nonetheless, based on the short half-life in air, AEEA is considered readily degradable and not persistent in this compartment. Modelled data in air are summarized in Table 4a.

| Fate process | Model and model basis |

Model result and prediction | Extrapolated half-life (days) |

|---|---|---|---|

| Atmospheric oxidation | AOPWIN 2010 | t 1/2 = 1.1 hoursFootnote Table 4a [a] | less than or equal to 2 days |

| Ozone reaction | AOPWIN 2010 | N/A | N/A |

Water – Empirical studies

Several ready and inherent biodegradation studies and one field study have been conducted for AEEA using activated sludge. Original unpublished studies were not available for review. However, study summaries prepared for the European Union Regulation concerning the Registration Evaluation Authorization and Restriction of Chemical Substances (REACH), available from ECHA (c2007-2014a) were considered. The summary of the more recent ready biodegradation study (performed according to OECD Guideline 301F) conducted in 2005 was comprehensive. The three other ready or inherent biodegradation studies are briefly summarized in the European Commission’s IUCLID Dataset for AEEA (European Commission 2000). However, given that no experimental details and methodologies were provided, little can be concluded based on the available study results. Finally, a field study was performed by Emtiazi and Knapp (1994) characterizing biodegradation of AEEA in water samples taken from the River Aire (located in Leeds, United Kingdom).

Overall, available biodegradation studies using activated sludge indicate that AEEA undergoes relatively rapid biodegradation in water. In addition, it is noted that more severe toxic effects on micro-organisms, including those in activated sludge, were observed at AEEA exposure concentration greater than 100 mg/L (ECHA c2007-2014b). The large extent of inhibition of sludge micro-organisms, which could affect the degradation of AEEA in studies using sludge, is not expected at substance concentration of less than 100 mg/L. OECD ready or inherent biodegradation study protocols specify that substance concentrations not exceeding 100 mg/L are applied (Environment Canada 2009). Biodegradation study summaries are provided below, and study endpoints are listed in Table 4b.

In general, ready biodegradability tests include the modified OECD screening tests, CO2 evolution test, manometric respirometry test, dissolved organic carbon (DOC) die-away test, closed bottle test, and the MITI(I) test, and measure mineralization over a 28-day period using a low concentration of a sewage or activated sludge as an inoculum and a high concentration of the test compound (2–100 mg/L). Inherent biodegradability tests are comprised of the Zahn-Wellens test, SCAS test and MITI(II) test, and are typically run with high microbial population densities, also using a sewage or activated sludge inoculum. In general, a substance is considered to undergo ready, ultimate biodegradation if at least 60% biodegradation has occurred in 28 days, and inherent, ultimate biodegradation if at least 70% has occurred in 28 days in an inherent test (Aronson and Howard 1999). Biodegradation above 20% but lower than 60–70% may be regarded as evidence of inherent, primary biodegradability (Environment Canada 2009).

AEEA was tested in 2005 using OECD Guideline 301F (Ready biodegradability, Manonmetric respirometry test) (ECHA c2007-2014b) at concentrations of 19 and 64 mg/L over 28 days. In this study, biodegradation was measured based on oxygen consumption, mineralization and DOC removal. Results from oxygen consumption tests indicated mean biological oxygen demand (BOD) values ranging from 66.3 to 109.6% of the theoretical oxygen demand (ThOD) after 28 days. Similar results, i.e., biodegradation values of greater than 60%, were obtained from measurements of CO2 evolution and DOC removal, thereby indicating mineralization of AEEA under these study conditions (ECHA c2007-2014b).

Other unpublished ready and inherent biodegradation studies are briefly summarized in the European Commission’s IUCLID Dataset for AEEA (European Commission 2000). Too few experimental details were provided to infer conditions of these studies and thereby to allow for interpretation of the test results. In one study performed according to OECD Guideline 301C (Ready biodegradability, Modified MITI Test I), 0% biodegradation in 14 days was reported for AEEA, tested at a concentration of 100 mg/L. In another study (according to a BSB-test method), less than 1% aerobic biodegradation was observed after 5 days, but sample concentrations were not provided. Finally, results from the 1977 inherent Zahn-Wellens study indicated 30–50% biodegradation (based on DOC removal) after 37 days, using a high concentration of AEEA of 400 mg/L (European Commission 2000). In addition, this study reported a 1% biodegradation of AEEA after 3 hours. Given that study duration was less than 28 days in two of these studies, it is difficult to extrapolate whether more complete biodegradation would occur if the studies were run longer. Results of the 1977 Zahn-Wellens (European Commission 2000) study suggested that AEEA biodegrades under inherent test conditions but did not pass the 70% threshold. In addition, it is possible that if applied at high test concentrations, AEEA may have caused toxic effects to bacteria found in the sludge, and consequently affected the biodegradation test results. Inhibitory effects in micro-organisms have been observed at concentrations of less than 400mg/L (ECHA c2007-2014b) (see the Potential to Cause Ecological Harm section).

A study using water samples from the River Aire located in central Leeds in the United Kingdom reported complete degradation of AEEA in 30 days based on a die-away test method (Emtiazi and Knapp 1994). It was noted that at the time of sampling, the river was recovering from the impact of treated domestic and industrial effluents emitted from the surrounding cities. Environmental samples containing activated sludge as well as soil suspensions were added to a sterile water solution containing AEEA, for a final concentration of approximately 100 mg/L (1 mM). It was observed that AEEA remained in aqueous solution and did not adsorb or partition into solids. Complete degradation of AEEA was observed in 8–30 days, based on 4 or 5 experimental determinations. The observed lag time was reported in the range of 3–12 days. Mean degradation value was also calculated by Emtiazi and Knapp (1994) based on individual results, and was reported as 20 days for complete degradation with a lag time of 6.5 days. The results of this study provide additional evidence that AEEA can undergo complete mineralization in a relatively short amount of time (less than or equal to 30 days). Available empirical biodegradation results are summarized in Table 4b.

| Fate process | Degradation endpoint / units |

Degradation value | Reference |

|---|---|---|---|

| Biodegradation (aerobic) | % BOD, % CO2 evolution, % DOC removal (28 days) |

greater than 60%Footnote Table 4b [a] | ECHA c2007-2014b |

| Biodegradation (aerobic) | die-away test (20 days) |

100 % | Emtiazi and Knapp 1994 |

| Biodegradation (aerobic) | % BOD NR (14 days) |

0% | European Commission 2000 |

| Biodegradation (aerobic) | BSB test NR (5 days) |

less than 1% | European Commission 2000 |

| Biodegradation (aerobic) | % DOCNR(37 days) % DOCNR (3 hours) |

30–50% 1% |

European Commission 2000 |

In summary, the available experimental data suggest that AEEA biodegrades relatively quickly in water. Two studies, the 2005 OECD 301F ready biodegradation study (ECHA c2007-2014b) and the field study by Emtiazi and Knapp (1994) indicate that AEEA undergoes complete mineralization in as little as 8 days and up to 30 days. The results of the 1977 Zahn-Wellens study suggest that AEEA has the potential for inherent biodegradation under favourable conditions (European Commission 2000). Available results from two other ready biodegradation studies indicate limited biodegradation of AEEA up to 14 days (European Commission 2000). However, given the lack of experimental details provided for these studies from the available source (European Commission 2000), the fact they were conducted for a period of time too short to evaluate biodegradation potential (i.e., less than 28 days), and may have used concentrations of AEEA high enough to cause toxic effects in sludge micro-organisms, little weight is placed on these results.

Overall, there exists compelling empirical evidence to support that AEEA is not persistent in water.

Water – Modelled data

In addition to the available empirical data for the degradation of AEEA in water, a (Q)SAR-based weight-of-evidence approach was also applied using the degradation models shown in Table 4c.

| Fate process | Model and model basis |

Model result and prediction | Extrapolated half-life (days) |

|---|---|---|---|

| Hydrolysis | HYDROWIN 2010Footnote Table 4c [a] | N/A | N/A |

| Primary biodegradation (aerobic) | BIOWIN 2010 Sub-model 4: Expert Survey (qualitative results) |

3.91Footnote Table 4c [b] “biodegrades fast” |

less than or equal to 182 |

| Ultimate biodegradation (aerobic) | BIOWIN 2010 Sub-model 3: Expert Survey (qualitative results) |

3.18[b] “biodegrades fast” |

less than or equal to 182 |

| Ultimate biodegradation (aerobic) | BIOWIN 2010 Sub-model 5: MITI linear probability |

0.83Footnote Table 4c [c] “biodegrades fast” |

less than or equal to 182 |

| Ultimate biodegradation (aerobic) | BIOWIN 2010 Sub-model 6: MITI non-linear probability |

0.84[c] “biodegrades fast” |

less than or equal to 182 |

| Ultimate biodegradation (aerobic) | DS TOPKAT c2005-2009 Probability |

N/A[c] | N/A |

| Ultimate biodegradation (aerobic) | CPOPs 2012 % BOD (biological oxygen demand) |

% BOD = 0 “biodegrades slowly” |

greater than or equal to 182 |

Modelled hydrolysis

Hydrolysis reaction half-life using the available HYDROWIN (2010) model was not calculable for AEEA, as chemicals of structural comparability are not contained in the training set of the model. AEEA is not expected to undergo hydrolysis, as the substance contains functional groups that typically do not hydrolyze (i.e., primary amine and hydroxyl functional groups) (Boethling and Mackay 2000). However, AEEA is expected to ionize, and the pka1 of 6.1–6.49 (see Table 2) suggests a potential for ionization at environmentally relevant pH levels.

Modelled primary and ultimate biodegradation

Results from the primary biodegradation (BIOWIN Sub-model 4), and most of the ultimate biodegradation models (BIOWIN sub-models 3, 5 and 6) (EPI Suite 2012) suggest that biodegradation is rapid and that the expected half-life in water would be less than or equal to 182 days. In contrast, results from the ultimate model CPOPs (2012) suggest that this substance does not biodegrade at all (0% BOD). However, the CPOPs model output also indicates that AEEA has a suspected BOD inhibition effect. It is noted that toxic effects to micro-organisms in sludge stemming from AEEA exposure have been observed at substance concentrations exceeding 100 mg/L. AEEA also contains structural features associated with chemicals that are easily biodegraded (e.g., primary amine and hydroxyl functional groups). Therefore, results from CPOPs (2012) are considered unreliable for AEEA. Lastly, results for AEEA were not available from DS TOPKAT (c2005-2009), as the model does not provide biodegradation estimates for this type of structure.

In summary, based on the reliable primary and ultimate modelled biodegradation results as well as the structural features of AEEA, there is sufficient evidence to indicate that AEEA undergoes mineralization in water and that its expected half-life would beless than or equal to 182 days in this compartment. Model results for AEEA support the available empirical biodegradation data (ECHAc2007-2014b; Emtiazi and Knapp 1994; European Commission 2000) described in the preceding section.

Soil and sediment

No experimental studies were found for the biodegradation of AEEA in soil or sediments. Limited modelling is available for these compartments. Therefore, an extrapolation ratio of 1:1:4 for water:soil:sediment biodegradation half-life based on Boethling et al. (1995) was applied. Consequently, given that the half-life of AEEA in water is less than182 days, it follows that the half-life in soil is also less than182 days and the half-life in sediments is expected to be less than 365 days. This indicates that AEEA is not expected to be persistent in either soil or sediment.

Conclusion

AEEA is not considered to be persistent in air, based on a model prediction (AOPWIN 2008). Available boidegradation studies as well as modelled data suggest that the substance boidegardes rapidly in water. AEEA is also expected to undergo rapid boidegradation in soil and sediment, based on the extrapolation criteria from the half-life in water (Boethling et al. 1995). Therefore, based on the empirical and modelled data (Tables 4a-c), AEEA is expected to have a limited persistence in environmental media.

Potential for Bioaccumulation

In order to provide the best possible weight of evidence for the bioaccumulation potential of AEEA, its physical and chemical properties as well as empirical and modelled data for AEEA were considered.

Physical and chemical properties of AEEA relevant to bioaccumulation potential

AEEA is completely miscible in water, indicating that the substance can be readily bioavailable for uptake in water. Experimental and modelled log Kow values (-1.37 to -2.13) for AEEA suggest that this chemical has a low potential to bioaccumulate in biota (see Table 2). In addition, a combination of log Kow of -2.13 and log Koa of 9.89 indicates that, given a terrestrial dietary exposure, AEEA is unlikely to have the potential to biomagnify in terrestrial food webs, as suggested by Gobas et al. (2003) and Kelly et al. (2007).

Information regarding molecular size and cross-sectional diameters is useful to consider as weight of evidence for bioaccumulation potential. Studies relating fish BCF data and molecular size parameters (Dimitrov et al. 2002, 2005) and the effects of cross-sectional diameter on passive diffusion (Sakuratani et al. 2008) suggest that the probability of a molecule crossing cell membranes as a result of passive diffusion declines significantly with increasing maximum and effective diameters (Dmax and Deff). It was observed that the probability of passive diffusion decreases appreciably for molecules with maximum diameters greater than 1.5 nm (Dimitrov et al. 2002, 2005), and that substances that do not have a very high bioconcentration potential (BCF less than 5000) often have a Dmax of greater than 2.0 nm and an effective diameter (Deff) greater than 1.1 nm. However, significant bioaccumulation potential may remain for substances that are subject to slow absorption processes, if they are slowly biotransformed or slowly eliminated by other processes (Arnot et al. 2010). Based on 3D analysis of AEEA conformers calculated using the BCFmax Model with Mitigating Factors (Dimitrov et al. 2005), the maximum and effective diameters of AEEA are 1.0 and 0.8 nm, respectively, suggesting that the probability that a molecule will cross cell membranes as a result of passive diffusion is high. This indicates that AEEA is not likely to experience restricted uptake from steric effects at the gill surface.

Physical and chemical properties of AEEA relevant to its bioaccumulation potential are listed in Table 5a.

| Molecular mass (g) | Water solubilityFootnote Table 5a [a] (mg/L) | Log Kow | Log Koa | Molecular diameter (nm) |

|---|---|---|---|---|

| 104.15 | 1 000 000 | -1.46 | 9.89 | 0.961 (Dmax), 0.792 (Deff) |

Empirically determined bioaccumulation

Bioconcentration factor (BCF)

One empirical bioconcentration study in fish was identified for AEEA. The summary of this unpublished study was available from ECHA (c2007-2014b). This study was performed in 1992 according to OECD Guildeline 305C (Bioaccumulation: test for the degree of bioconcentration in fish) in flow-through conditions. Carp (Cyprinus carpio) of about 30 g and 10 cm in length were used in the study, and fish lipid content was calculated at 4.8%. AEEA was tested at two concentrations, 0.1 and 1.0 mg/L, for 42 days. Bioconcentration factors (BCFs) were determined at both test concentrations as 2.1 to less than 3.7 at 0.1 mg/L and less than 0.2 at 1 mg/L. These results indicated that AEEA has a very low potential to bioconcentrate in fish. No data were provided regarding the elimination of AEEA by carp. However, as the substance is likely to undergo passive diffusion across the gills based on its small molecular size, cross-sectional diameters and unhindered structure, it is expected that the depuration rates in fish would likely be high. Study results are summarized in Table 5b.

| Test organism | Kinetic and/or steady-state value (L/kg)Footnote Table 5b [a] | Reference |

|---|---|---|

| Carp (Cyprinus carpio) |

2.1 to less than 3.7 (0.1) | ECHA c2007-2014b |

| Carp (Cyprinus carpio) |

less than 0.2 (1.0) | ECHA c2007-2014b |

Bioaccumulation factor (BAF)

Bioaccumulation factors are measured under field conditions as the ratio of the whole body burden of chemical taken up from all exposures to that of the ambient water concentrations. Measures of BAF are the preferred metric for assessing the bioaccumulation potential of substances because they incorporate all chemical exposures including the diet, which predominates for substances with log Kowgreater than ~4.0 (Arnot and Gobas 2003).

No empirical BAF values were available for AEEA at the time of this analysis, and therefore metabolism-corrected kinetic mass-balance modelling was used to fill this data gap. For chemical substances characterized by log Kow values of less than 3.5, BCF values tend to be equivalent to BAF values for chemical substances, due to lack of dietary uptake (Arnot and Gobas 2003, 2006).

Modelling of BCF and BAF

Since few empirical BCF and no BAF data were available, the BCF and BAF of AEEA were estimated using both structure-based models and a three trophic level kinetic mass-balance model. All estimates of BCF and BAF, [except sub-model 1 of the BCFBAF (2010) model in EPI Suite (2012)], were corrected for metabolism using the metabolism rate constant (kM) derived based on the fragment addition (Q)SAR within the BCFBAF model, a structure-based QSAR method. The (Q)SAR kM for a 10 g fish at 15oC reported in the BCFBAF (2010) model was17.58 days–1.

The results of the BCF and BAF modelling are given in Table 5c below. These results are reported for a middle-trophic-level fish representative of Canadian waters, based on a modification of the mass-balance model from Arnot and Gobas (2003).

| Log Kow | kM (days–1) |

Model and model basis |

Endpoint | Value wet weight (L/kg) |

Reference |

|---|---|---|---|---|---|

| -1.46 | 17.58 | BCFBAF Sub-model 1 (linear regression) |

BCF | 3.16 | BCFBAF 2010 |

| -1.46 | 17.58 | BCFBAF Sub-model 2 (mass balance) |

BCFFootnote Table 5c [a] | 0.93 | BCFBAF 2010 |

| -1.46 | 17.58 | BCFBAF Sub-model 3 (Gobas-mass balance) |

BAF[a] | 0.93 | BCFBAF 2010 |

| -1.46 | N/A | BCFmax with mitigating factors | BCFFootnote Table 5c [b] | 0.37 | Dimitrov et al. 2005 |

Modelled BCF values for AEEA ranged from 0.37 to 3.16 depending on the model used and application of the metabolic rate constant. These values are similar to the empirically derived BCF values of less than 0.2 to less than 3.7 in carp (see Table 5b), and point to a very low potential for bioaccumulation of AEEA. The modelled BAF value of 0.93 was also in agreement with modelled and empirical BCF values.

Conclusion

AEEA is water-miscible, has a very low log Kow and has a relatively small molecular diameter (see Table 5a). These properties suggest that it may easily diffuse across biological membranes such as gills. Empirical and modelled data indicate that AEEA does not bioaccumulate in organisms. Available empirical evidence in fish from exposure to AEEA over 42 days indicated very low BCF values (see Table 5b). Similarly, modelled BCF and BAF results, corrected for metabolism, also indicated a very low potential for bioaccumulation (see Table 5c). Overall, based on the available evidence it is considered that AEEA has a low bioaccumulation potential.

Potential to Cause Ecological Harm

Ecological effects assessment

Data sources

Ecological effects of AEEA in the aquatic compartment have been well characterized through empirical studies. In addition, modelled data for AEEA were considered for aquatic species. Studies addressing ecological effects in soil and sediment were not found, and suitable models are also not available. However, it is expected, based on the physical and chemical properties, use and release patterns, and results from fugacity modelling, that the majority of exposure to AEEA would occur in the aquatic compartment.

Empirical studies – in the aquatic compartment

Empirical studies describing the ecotoxicological effects of AEEA on aquatic organisms were available from published literature as well as unpublished sources. The majority of the available data were from unpublished aquatic toxicity studies performed according to internationally accepted standard protocols (such as OECD testing guidelines) and described effects of AEEA on micro-organisms (freshwater bacteria and activated sludge), algae (Scenedesmus subspicatus), invertebrates (Daphnia magna) and fish (three species). Effects studies on invertebrates and fish were limited to short-term AEEA exposures.

None of the unpublished aquatic toxicity studies was available for review; however, study summaries were found from sources including the European Chemicals Agency website (ECHA c2007-2014a) and a IUCLID Dataset for AEEA prepared by the European Commission (European Commission 2000). It is noted that study summaries provided in the IUCLID Dataset (European Commission 2000) are limited to study endpoints and provide minimal details; they therefore do not provide sufficient basis for scientific evaluation. Nonetheless, available endpoints are included for comparison with other available empirical data. A summary of the toxicological endpoints in aquatic organisms, such as lethal and effect concentrations, is provided in Table 6a. However, only those endpoints where sufficient experimental details were available were included in this table. Additionally, experimental observations including percent mortality are summarized in the text.

Effects of AEEA were studied in two species of freshwater Gram-negative bacteria, Pseudomonas putida and Pseudomonas aeruginosa, and in micro-organisms from industrial activated sludge (ECHA c2007-2014b; European Commission 2000; Emtiazi and Knapp 1994). The effects on P. putida were evaluated in 1988 in a study according to the Bringmann-Kuehn Standards (similar to the German Industrial Standard DIN 38412, part 8) (ECHA c2007-2014b; European Commission 2000). In the study, P. putida were exposed to AEEA at nominal concentrations ranging from 8 mg/L to 1000 mg/L. The 10% effects concentration (EC10), median effects concentration (EC50) and 90% effects concentration (EC90) values for growth inhibition were determined as 82.2, 134.8 and 231.3 mg/L, respectively, following 17 hours of exposure.

Growth inhibition of AEEA to P. putida and Pseudomonas aeruginosa was also observed by Emtiazi and Knapp (1994). Specific growth rate and growth inhibition were measured at AEEA concentrations of 1000 mg/L (10 mM) and 10 000 mg/L (100 mM). Following 8 hours of AEEA exposure, it was observed that the maximum growth of both P. putida and P. aeruginosa was reduced by 30% at 1000 mg/L, and by nearly 60% for P. putida and 40% for P. aeruginosa at 10 000 mg/L. Similar observations for specific growth rate were also made after 1-hour exposure to AEEA. Specific growth rate of P. putida was reduced by about 25% and 45% at 1000 mg/L and 10 000 mg/L exposure concentrations, respectively. For P. aeruginosa, the specific growth rate was reduced to a lesser extent, by 6% at 1000 mg/L, and by 11% at 10 000 mg/L. These results are not presented in Table 6a.

The effects of AEEA exposure on respiration rate were studied in industrial activated sludge in 1986, according to the ISO 8192 test protocol (Test for Inhibition of Oxygen Consumption by Activated Sludge) (European Commission 2000). AEEA was tested at the nominal test concentration of 1003 mg/L. It is noted that typically studies with activated sludge are performed using domestic sewage sludge rather than industrial activated sludge (OECD 2005). Following 30 minutes of exposure, no inhibition of respiration rate was observed; instead, observations of increased respiration activity of the industrial activated sludge when compared to the study control were made. These results are also not presented in Table 6a.

In algae (Scenedesmus subspicatus), AEEA was tested in two studies, dated 1989 and 1988 (ECHA c2007-2014b; European Commission 2000). The 1989 study was performed according to German Industrial Standard DIN 38412, part 9 with AEEA at nominal concentrations ranging from 8 mg/L to 500 mg/L for 72 hours(ECHA c2007-2014b). The addition of AEEA at 500 mg/L increased the pH up to pH ~9, and a subset of the test samples was pH neutralized to pH 7.8–8.2. Endpoints were reported based on measurements of the growth rate (growth inhibition) and biomass reduction.For biomass reduction, the EC10 and EC50 values were determined as 100, and 204 mg/L, respectively. For growth inhibition, EC10 was determined as 156 mg/L, and EC50 values were determined as 358 mg/L, and >500 mg/L from the pH-neutralized samples. Adverse effects were not observed in the neutralized, 500 mg/L-AEEA treatments. respectively.

The effects on S. subspicatus were also evaluated in a growth inhibition study in 1988 (European Commission 2000). This study was performed according to German Industrial Standard DIN 38412, part 8. EC20, EC50 and EC90 values for growth inhibition were determined as 130, 210 and 490 mg/L, following 72 hours of exposure to AEEA.

The ecotoxicological effects of AEEA were determined for the water flea (Daphnia magna) in short-term studies. In a 1993 study, acute ecotoxicological effects of AEEA to D. magna were determined according to OECD Guideline 202 (Daphnia sp. Acute Immobilisation Test) (ECHA c2007-2014b). AEEA was tested at nominal concentrations ranging from 1 to 100 mg/L for 48 hours. NOEC and EC50 values for mobility were determined as 10 and 22 mg/L, respectively. It was observed that at the three highest concentrations tested (32, 56 and 100 mg/L), the pH levels in test solutions increased to above the recommended pH maximum of 9, subsequently decreasing to pH below 9 during the 48-hour course of the test.. Nevertheless, as was noted by the study authors, the high alkalinity at these test concentrations may have exerted adverse effects on daphnids and contributed to the observed toxicity.

In another acute toxicity study performed in 1989 (according to Directive 79/831/EEC, Annex V, Part C), daphnids were exposed to somewhat higher nominal AEEA concentrations of up to 500 mg/L for 24 and 48 hours. At 24 hours, the NOEC, EC50, and EC100 values for mobility were determined as 125, 225 and 500 mg/L, respectively. At 48 hours, the NOEC, EC50, and EC100 values were determined as 125, 190 and 500 mg/L, respectively. Increases in alkalinity were also observed at AEEA concentrations greater than 250 mg/L, where pH values of test solutions increased to approximately 10, and subsequently normalized to about 8.5 after 48 hours. It was noted that this marked increase in alkalinity may have produced additional toxic effects in daphnids; however, observations detailing such effects were not provided.

In fish, the short-term toxicity of AEEA was established through a series of unpublished studies conducted between 1978 and 1994.These studies were short term, i.e., 48- and 96-hour studies, and the tested fish species included the rice fish (Oryzias latipes), rainbow trout (Oncorhynchus mykiss), and fathead minnow (Pimephales promelas). In the 1978 study, the effects of AEEA in the fathead minnow (P. promelas) were performed according to an industry protocol comparable to the accepted international standards (ECHA c2007-2014b). In this study, fish were exposed to AEEA at nominal concentrations ranging from 155 to 1150 mg/L for 96 hours. The NOEC (mortality), 10% lethal concentration (LC10), median lethal concentration (LC50), and 100% lethal concentration (LC100) were determined as 490, 514, 640 and 1000 mg/L, respectively. It was observed that at the four highest concentrations tested (i.e., 650–1150 mg/L), the pH of the test solutions increased, to values up 10.2, and increased the mortality of fish, ranging from 70 to 100%. It was noted by the authors that adverse effects due to alkaline conditions may have contributed to the observed mortality at these exposure concentrations. However, it was also pointed out that at the highest concentration of AEEA that caused no mortality (i.e., 490 mg/L), the pH of the test solution was similarly high, at 9.8. Overall, these results suggest that the combination of high and critical AEEA concentration (greater than or equal to 650 mg/L) together with the increased pH levels of water had the most detrimental effects on fish. It is noted that such high exposure concentrations of AEEA are not representative realistic environmental exposures.

Acute toxic effects of AEEA were also determined in the Japanese rice fish (Oryzias latipes), in a 1992 study (ECHA c2007-2014b). The study was performed according to Japanese Industrial Standard JIS K 0102-1986-71, in semi-static test conditions. Additional details of methodology and observations were not available. The LC50 value was determined as greater than 1000 mg/L following 48 hours of AEEA exposure.

Two other acute fish studies were also briefly summarized in the IUCLID Dataset prepared by the European Commission (European Commission 2000). In one study using fathead minnows, the 96-hour LC10, LC50 and LC100 values were determined as 617, 728 and 859 mg/L, respectively. Another study using rainbow trout listed the NOEC and LC50 values of greater than or equal to 100 and greater than 100mg/L, respectively (exposure time was not provided) (European Commission 2000). These endpoints are not listed in Table 6a.

| Test organism | Type of test | Endpoint | Value (mg/L) | ReferenceNAR |

|---|---|---|---|---|

| Bacteria (Pseudomonas putida) | Chronic (17 hours) |

EC10; EC50; EC90 (growth inhibition) |

82.2; 134.8; 231.3 | ECHA c2007-2014b; European Commission 2000 |

| Algae (Scenedesmus subspicatus) | Acute (72 hours) |

EC10; EC50 |

156; 358 greater than 500 (pH neutralized); |

ECHA c2007-2014b |

| Algae (Scenedesmus subspicatus) | Acute (72 hours) |

EC10; EC50 (biomass increase) |

100;204 | ECHA c2007-2014b |

| Algae (Scenedesmus subspicatus) | Acute (72 hours) |

EC20; EC50; EC90 (biomass increase) |

130; 210; 490 |

European Commission 2000 |

| Water flea (Daphnia magna) |

Acute (24 hours) |

NOEC; EC50; EC100 (immobilization) |

125; 225; 500 |

ECHA c2007-2014b |

| Water flea (Daphnia magna) |

Acute (48 hours) |

NOEC; EC50; (immobilization) |

10; 22 | ECHA c2007-2014b |

| Water flea (Daphnia magna) |

Acute (48 hours) |

NOEC; EC50; EC100 (immobilization) |

125; 190; 500 |

ECHA c2007-2014b |

| Japanese rice fish (Oryzias latipes) |

Acute (48 hours) |

LC50 | greater than 1000 | ECHA c2007-2014b |

| Fathead minnow (Pimephales promelas) |

Acute (96 hours) |

NOEC; LC10; LC50; LC100 | 490; 514; 640; 1000 |

ECHA c2007-2014b |

In summary, a number of ecotoxicological studies determining the effects of AEEA exposure were available for different aquatic organisms including micro-organisms, crustaceans and fish. Overall, based on the endpoints studied, AEEA has moderate to low toxicity to aquatic organisms based on short-term exposure. The lowest observed EC50 value was 22 mg/L for immobilization of daphnia, based on 48 hours of exposure to AEEA. A notable effect of AEEA at the highest test concentrations was the marked increase in alkalinity, to pH levels as high as 10. Increased fish mortality was noted at those high pH levels, but only when combined with the high AEEA concentrations of greater than or equal to 650 mg/L. Exposure concentration of 450 mg/L combined with a high alkalinity of the test solution (pH 9.8) did not induce mortality. In a study with D. magna, a neutralized AEEA test solution indicated approximately two-fold lower toxicity (for growth rate, an EC50 of greater than 500mg/L for a neutralized test was observed, compared to about 350 mg/L in the non-neutralized test). These results point to additional toxic effects induced by increased pH levels at high exposure concentrations of AEEA. However, these effects, and notably mortality, transpire in test conditions where high alkalinity occurs with highest AEEA exposure concentrations. Such high AEEA exposure concentrations are not representative of realistic environmental exposures.

Long-term studies characterizing the ecotoxicological effects of AEEA in aquatic invertebrates and vertebrates were not located in the published literature or in any unpublished materials.

Modelled results – in the aquatic compartment

In addition to the available empirical data for aquatic species, modelled data were also considered. The structural classes of ethanol amines are amenable to most model predictions.

Short-term aquatic toxicity values were obtained from the ECOSAR model in EPI Suite (2012) (see Table 6b). Predicted EC50 or LC50 values for fish, daphnids and algae estimated for short-term exposures fall in the range of 26–5555 mg/L. Model results for chronic exposure to AEEA were also generated; however, AEEA or similar substances were not part of the aliphatic substances training sets of ECOSAR (2012). As such, these chronic modelled results are not considered reliable for AEEA.

In general, model results generated for algae, daphinds and fish agreed with the available empirical results for these species, and pointed to a low toxicity potential of AEEA. Therefore, based on the model results, AEEA is not expected to cause acute harm to aquatic organisms at low concentrations [acute median lethal concentrations (LC50s) are greater than or equal to1 mg/L]. Modelled results are summarized in Table 6b.

| Test organism | Type of test |

Endpoint | Value (mg/L) |

Reference |

|---|---|---|---|---|

| Fish | Acute (96 hours) |

LC50 | 5555 | ECOSAR 2012 |

| Water flea (Daphnia magna) |

Acute (48 hours) |

EC50 | 238 | ECOSAR 2012 |

| Algae | Acute (96 hours) |

EC50 | 26.8 | ECOSAR 2012 |

Empirical studies – in other environmental compartments

AEEA effects studies were not identified in other environmental compartments, including soil and sediments. Suitable (Q)SAR models were not available for characterization of ecological effects in soil and sediment organisms.

Derivation of the PNEC

A predicted no-effect concentration (PNEC) was derived from the acute toxicity value of 22 mg/L, which was the most sensitive valid experimental value, determined for daphnids. This value was divided by an assessment factor of 100, to account for interspecies and intraspecies variability in sensitivity, and to extrapolate from acute to chronic exposure duration, to give a value of 0.22 mg/L.

Conclusion

Based on various lines of evidence, AEEA is unlikely to cause harm to aquatic organisms at low concentrations. Given that AEEA has low bioaccumulation potential characterized by factors such as BCF values of approximately 1 L/kg, and a negative log Kow, it has limited potential to be incorporated into organisms and thereby cause toxic effects. The available empirical and modelled data are in good agreement for all trophic levels (i.e., fish, daphnids and algae) in the aquatic compartment.

Ecological Exposure Assessment

No data on measured environmental concentrations (in water, soils or sediments) of AEEA in Canada have been identified. Therefore, environmental concentrations have been estimated from available information, including substance quantities, estimated release rates and characteristics of the receiving environment.

Identification of important exposure scenarios

Exposure characterization is focused on scenarios which represent the highest potential for environmental releases and exposure. In general, the magnitude of releases is a direct function of the quantity of a substance manufactured or used and its applicable emission factors. In cases where industrial releases are similar in quantities to consumer and/or commercial releases, the former typically result in higher levels of environmental exposure than the latter. This is because industrial releases are concentrated at a limited number of sites while consumer and/or commercial releases are dispersed across the country.

Asphalt

AEEA is used in asphalt as a component of an anti-stripping agent (additive). The role of this anti-stripping agent is to enhance asphalt-aggregate adhesion and reduce moisture damage on asphalt by improving the bond between the asphalt cement and the aggregates (Harnish 2010). The recommended amount of total anti-stripping agent in asphalt cement is 0.25% to 0.75% (based on the weight of the liquid asphalt cement). According to an industry product information sheet about anti-stripping products, one half pound of product per ton of asphalt can increase the lifespan of asphalt pavements (Unique Paving Materials c2013). The concentration of AEEA in asphalt should be well below the recommended concentration of the anti-stripping agent in the asphalt cement, because AEEA is only a minor component of this anti-stripping agent.

During the preparation of the asphalt, aggregates are dried to remove moisture, and the anti-stripping agent is added to asphalt cement through a pipe system. Asphalt cement is then transferred to an aggregates vessel and mixed for a short period of time. During this operation, volatile organic compounds (VOCs) can be released from organic compounds. The US EPA (2000) has estimated that releases of total semi-volatile compounds from mixing asphalt, unloading mixer and asphalt storage can be less than 2 lbs per 100 000 tons of asphalt made. This results in an emission factor of 1 × 10−8 (US EPA 2000). As AEEA has a moderate vapour pressure, it is possible that AEEA can be a minor component of these VOCs. Water is not used in this process, and therefore releases of wastewater containing AEEA are not expected.

Reclaimed asphalt pavement may be added into a new batch mix (US EPA 2000). Residues in mixing equipment are assumed to be cleaned and then are expected to be re-inserted in future batches.

In general, releases of AEEA from the process of asphalt paving are considered to be minimal. Releases of any remaining unreacted AEEA to air or adjacent soil are expected to be negligible. As wastewater is typically not produced during asphalt paving, releases of AEEA in water to the environment are also considered negligible from this operation (Lutes et al. 1994). In contrast, releases of AEEA from asphalt leaching are possible, as suggested by Lindgren (2011). Lindgren (2011) has studied leaching of emulsifiers from new asphalt wash down. The function of the emulsifier in asphalt is to increase bonding between asphalt cement and aggregates. This function is similar to an anti-strip agent as described by Harnish (2010); therefore, Lindgrens’ findings can be used for comparison. Lindgren (2011) found that retention of emulsifiers in asphalt was almost 100% with a fraction release of less than 0.005% that occurs primarily with the first rain events after application. Additionally, leachate will be highly diluted by water runoff (Lindgren 2011).

In summary, the potential for AEEA releases from the preparation of asphalt cement is considered to be negligible based on characteristics of the typical process in place (US EPA 2000). Release of AEEA from asphalt pavement is expected to be negligible based on the function of the additive to promote asphalt adhesion to aggregates and due to the known limited leaching potential of an asphalt product with a similar function as that of AEEA (Harnish 2010; Lindgren 2011).

Epoxy resins (component of imported additive)

In Canada, AEEA is also a component of imported additives, mainly used as a curing agent or chemical intermediate for epoxy resins (Henkel 2010; 2012a–c). These activities are discussed together because both imply that AEEA undergoes irreversible chemical reaction, with the subsequent chemical conversion of AEEA into another substance.

In some cases, AEEA is imported in products for commercial uses where AEEA is a minor component (Environment Canada and Health Canada 2012-2014). The function of AEEA in these products is not clearly understood but is often presented as a curing agent (Henkel 2010, 2012a–c). Therefore, in such applications, AEEA is assumed to be cured within the product. It is expected that any residual AEEA should be captured in the matrix of the solid material formed after the epoxy is cured. Under optimal curing conditions, which are known and specified by product use instructions, AEEA would be largely consumed by the reversible chemical reactions that characterize the curing processes. Therefore, the potential for releases from fully cured products is considered negligible.

Imported as chemical intermediate

Some companies reported imports of AEEA as a pure substance, to formulate as an additive for industrial uses, or to prepare other substances. In these cases, the function of AEEA was reported as a chemical intermediate (Environment Canada and Health Canada 2012-2014). When used as a chemical intermediate, AEEA is considered to be chemically converted during the process, and it is expected that AEEA no longer exists in its original chemical form. Therefore, the only potential significant releases for unreacted AEEA stem from the cleaning of empty transport and processing containers. This scenario is further developed to determine quantitative estimates for aquatic concentrations resulting from this activity.

Estimates for predicted environmental concentrations

The exposure to AEEA was estimated in the form of predicted environmental concentrations (PECs) for the cleaning of equipment scenario (when pure AEEA is used as chemical intermediate). These concentrations are based on available information on quantities of AEEA, sector-specific emission factors, the characteristics of wastewater treatment systems and the receiving environment.

The PECs estimated were focused on the aquatic compartment. This is because AEEA is primarily released to the aquatic compartment through wastewater treatment systems.

Given its high water solubility and low Kow, AEEA is not expected to reach the soil medium through the application of biosolids (resulting from wastewater treatment operations) to land.

Industrial releases to aquatic medium

As AEEA is used by industrial facilities and can be released to water, an aquatic industrial release scenario was developed. This scenario considered the release of AEEA at an industrial facility where pure AEEA is used as a chemical intermediate. AEEA is assumed to be fully chemically converted during the industrial processes. Therefore, only a scenario for release of residual AEEA resulting from cleaning of empty transport and processing containers was considered.

Industrial uses of pure AEEA in Canada have been reported (Environment Canada and Health Canada 2012-2014). To estimate the potential of AEEA releases to water resulting from its industrial use as a chemical intermediate (i.e., the applications of AEEA in its pure chemical form), conservative but realistic scenarios at several industrial facilities were developed. These scenarios were refined by applying the exact substance quantities reported for use in 2011 (Environment Canada and Health Canada 2012-2014), as well as considering the characteristics of the receiving water bodies, wastewater treatment, and industrial operations at each site. In the conservative scenario presented below, the exact quantity of AEEA between 1000 kg and 10 000 kg reported for 2011 (Environment Canada and Health Canada 2012-2014) for an industrial facility that discharges into a receiving environment with low dilution was considered.

Aquatic exposure to AEEA could occur if this substance is released from industrial activity to a wastewater system that discharges its effluent to a receiving surface water body. The concentration of the substance in the receiving water near the discharge point of the wastewater system is used as the predicted environmental concentration (PEC) in evaluating the aquatic risk of the substance. It can be calculated using the equation:

Cwater-ind = [1000 × Q × L × (1 – R)] / [N × F × D]

where

- C water-ind:

- aquatic concentration resulting from industrial releases, mg/L

- Q:

- total substance quantity used annually at an industrial site, kg/yr

- L:

- loss to wastewater, fraction

- R:

- wastewater system removal rate, fraction

- N:

- number of annual release days, d/yr

- F:

- wastewater system effluent flow, m 3/d

- D:

- receiving water dilution factor, dimensionless

Table 7 presents the inputs used to estimate resulting aquatic concentrations close to the industrial point of discharge. It is noted that the assumptions considered are conservative and provide a basis for a conservative release scenario.

| Input | Value | Justification and reference |

|---|---|---|

| Quantity (kg) | 1000–10 000 | Quantity of AEEA reported at one site in Canada for 2011 (Environment Canada and Health Canada 2012-2014) |

| Loss to wastewater (%) | 3% | Maximum residual in container that can be washed and released to wastewater (OECD 2011 |

| Wastewater system removal efficiency (%) | 60% | Model estimates of efficiency of a typical secondary wastewater plant; removal of AEEA will be between 60 and 80%. Models used are ASTreat 1.0 (2006), SimpleTreat 3.0 (1997), STP Model 2.1 (2006) and STP-EX (2011). Value of 60% is obtained from model ASTreat 1.0 (2006). |

| Number of annual release days (days) | 100 | Value based on estimated intermittent cleaning (2 days per week for 50 weeks) |

Based on these conservative realistic assumptions, this scenario yielded a predicted environmental concentration (PEC) of 0.11 mg/L. This PEC value represents the level of exposure in the receiving water near the point of the discharge of a small sized wastewater treatment system with secondary treatment characteristics.

Characterization of Ecological Risk