Care of Plastic Film-based Negative Collections – Technical Bulletin 35

Greg Hill

CCI Technical Bulletins

Technical Bulletins are published at intervals by the Canadian Conservation Institute (CCI) in Ottawa as a means of disseminating information on current techniques and principles of conservation of use to curators and conservators of Canada’s cultural artifacts and to collection care professionals worldwide. The author welcomes comments.

Abstract

This Technical Bulletin provides a comprehensive look at photographic negatives on plastic film bases made up of cellulose nitrate, cellulose acetate and polyester, and covers issues related to material composition, mechanisms of deterioration, access, handling and storage.

Author

Greg Hill was the Senior Conservator of Archival and Photographic Records at CCI from 2006 until 2020. Prior to this, he worked at Library and Archives Canada (LAC) as a conservator, conservation manager and preservation advisor. Greg has presented numerous workshops and has spoken and published on a range of conservation activities, including photograph preservation, storage of cellulose nitrate-based negatives, disaster preparedness, treatment and research. He has also supervised many interns from Europe, North America and the East. He has been the president of the Canadian Association of Professional Conservators, a board member of the Canadian Association for Conservation, the chair of the Photographic Materials Group of the American Institute of Conservation of Historic and Artistic Works and the coordinator of the Photographic Materials Working Group of ICOM-CC.

Disclaimer: The information provided here is based on the current understanding of the issues presented. The guidelines given in this Technical Bulletin will not necessarily apply to all possible scenarios related to the long-term preservation or stability of plastic film-based negatives.

Table of contents

- List of abbreviations

- Introduction

- History and chronology of photographic negatives

- Understanding plastic film-based negatives

- Identifying and differentiating plastic film-based negatives

- Health and safety concerns related to degrading plastics

- Treating plastic film-based negatives

- Storing plastic film-based negatives

- Condition monitoring

- Preparing collections for cold or sub-zero storage

- 1. Survey the collection

- 2. Segregate plastics

- 3. Implement a copying plan

- Value of the collection

- Condition of the collection

- Intended use of the collection

- Existence of high-quality duplicates or digital copies

- Seven critical considerations for copying or scanning projects

- 3.1. Use high scanning standards

- 3.2. Consider digital scanning before making physical copies

- 3.3. Develop a plan before copying or scanning

- 3.4. Prioritize the collection before copying or scanning

- 3.5. Use the copying or scanning project as an opportunity for re-housing negatives

- 3.6. Consider surface cleaning and/or treatment of cellulose acetate films before copying or scanning

- 3.7. Follow resources and guides on the planning of copying or scanning projects

- 4. Evaluate enclosures

- Options for cold or sub-zero storage

- Humidity control in sub-zero storage

- Preparing collections for cold or sub-zero storage

- Conclusion

- Acknowledgements

- Bibliography

- Endnotes

List of abbreviations

- µm

- micrometre

- CCQ

- Centre de conservation du Québec

- HEPA

- high efficiency particulate air

- RSAPAQ

- Regroupement des services d’archives privées agréés du Québec

- Tg

- glass breaking point

- w/w

- weight to weight

Introduction

Photographic film negatives represent the artist’s or photographer’s intent and are a very significant part of our visual history. Their value is generally based on historical significance, though monetary value and donor agreements can also play a significant role in the decision to accept and preserve these collections. This Technical Bulletin will look at numerous aspects of the conservation and care of plastic-based negatives made from cellulose nitrate, cellulose acetate and polyester, with the intent of guiding curators, custodians and non-photograph conservation professionals to the successful preservation of their collections over the long term.

Collections of photographic negatives on plastic film bases, large and small, present many challenges for their custodians. Inherent vice, mishandling and adverse storage materials and environments all contribute to the degradation and destruction of plastic negatives, but all of these issues can be managed with the proper tools, as outlined in this Bulletin. Whatever the reason for holding a negative collection, preserving it can require a serious commitment. For example, facilities storing large quantities of negatives made of cellulose nitrate film may be required to comply with the National Fire Prevention Association Standard 40 (NFPA 40), Standard for the Storage and Handling of Cellulose Nitrate Film, a universally adopted American standard for storage and handling of nitrate film, which can be costly.

Identifying and understanding the mechanisms of deterioration for these materials is the first step to preserving them, followed by the segregation of the plastic types. Deteriorating collections can also contribute to the destruction of other collections and objects located in proximity to them. Surveying for numbers and condition, developing copying strategies and securing appropriate housing and storage environments all contribute to managing a collection for both access and preservation. Information on the preservation of negative collections is available in a variety of published sources; this publication brings together the salient points on the topic for the benefit of conservation professionals, collections managers, curators and archivists responsible for the care of negative collections.

History and chronology of photographic negatives

Pre-plastic film bases

Throughout the latter half of the 17th century and the early 18th century, numerous scientists and researchers across Europe investigated the potential of light-sensitive materials to permanently capture images. Though Louis Daguerre’s 1839 introduction of the daguerreotype process to the scientific community is most often touted as the official launch date of photography, much investigation preceded it. It was, in fact, French scientist Joseph Nicéphore Niépce who, in 1826, successfully captured the first photographic image by placing a polished pewter plate coated with bitumen of Judea (an asphalt derivative of petroleum) within a camera obscura. After an eight-hour exposure, he washed the plate with a solvent mixture that dissolved away parts of the bitumen that had not been hardened by the action of light, which rendered visible the latent image of the view from his window. The result was a permanent direct positive picture.

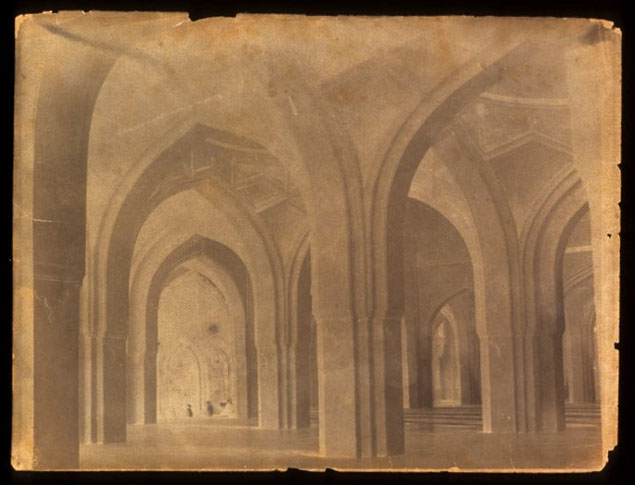

Light-sensitive metallic salts, specifically silver halides, proved to be the most viable option for capturing images and was the basis for the work of Daguerre and most subsequent innovations, resulting in the mass of photographic technologies developed throughout the 19th and 20th centuries. Daguerre’s invention was closely followed by William Henry Fox Talbot’s negative/positive process, which, again, was the culmination of many years of experimentation. Talbot is also credited with the introduction of the calotype (Figures 1a and 1b), generally known as waxed paper negatives, which is a more complex paper negative process, later refined by photographers in France.

From the moment the negative/positive process was introduced to the community at large by Talbot in the mid-19th century, it was embraced as the dominant method of capturing images and formed the basis of the vast majority of the photographic technologies that followed, up to the present day. By the end of the 19th century, mass-produced pre-sensitized negatives that could be easily inserted into a camera behind its lens, exposed, removed from the camera, processed and then made permanent were commercially available. An unlimited number of prints could then be printed from the negative at a relatively low cost.

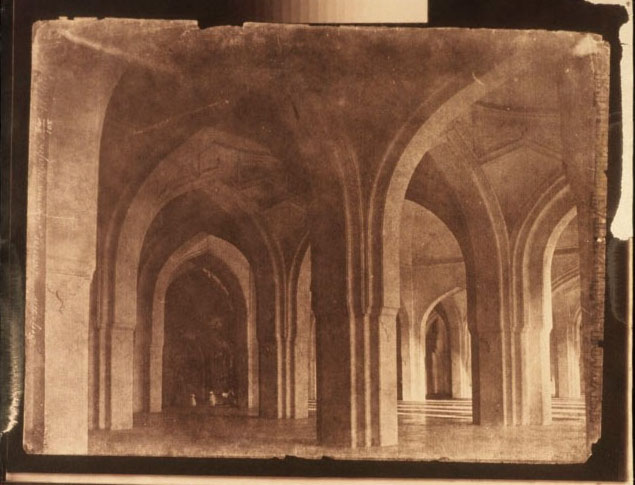

Paper was initially used as a substrate for negatives because it is easy to handle, coat and process. In order to increase its translucency and to facilitate the subsequent printing of the positive image, it was often oiled or waxed. Yet, its lack of transparency and the loss of detail due to the presence of the paper fibre prompted the search for a clear substrate. Glass was the most obvious choice for its absolute clarity, dimensional stability and chemical inertness, although its weight and fragility posed great challenges. Though many different image binders were experimented with on glass, wet collodion plates were the first negatives that employed glass as a substrate on a very large scale, with millions in production throughout the world (Figure 2).

© Greg Hill

Figure 2. A collodion wet glass plate negative under reflected light with a black paper underlay beneath the left half to show the conversion of the negative image to a positive image.

Introduction of plastic film bases

In the 1830s, the development of the cellulose-based plastics industry began in France with the discovery by chemist Henri Braconnot that cellulose in the form of starch or wood fibre combined with nitric acid could produce a lightweight combustible material. Others, looking to exploit the explosive nature of this mix, experimented with a range of cellulose fibres and different formulations of nitric and sulfuric acids. In 1846, the German-Swiss chemist Christian Friedrich Schönbein developed a somewhat more stable product called “gun cotton,” using cotton fibre with a more precise formulation. It was suitable for use in blasting since it was more powerful and produced less smoke and heat than traditional powders. However, it remained too volatile and unstable a material to be put into practical use.

Gun cotton, which at the time was also known as either cellulose nitrate, flash paper or pyroxylin, continued to be experimented with, and by the early 1850s, collodion was produced by dissolving the gun cotton in a mix of ether and alcohol. A British sculptor and photographer named Frederick Scott Archer, in his quest for a suitable binder for photographic silver salts, successfully created the collodion wet plate by pouring the freshly prepared collodion onto a piece of glass, allowing it to set and then sensitizing it with silver nitrate. Using collodion meant that the negative had to be prepared on-site just prior to exposure and be processed immediately following exposure in order to minimize exposure times. Photographers were obliged to carry their entire darkroom with them wherever they chose to capture images, which was an arduous task. Nevertheless, the collodion wet plate was widely popular until the end of the 19th century. The same materials were exploited for use in the production of ambrotypes and tintypes—in-camera positive images often found in small cases. Collodion was used as a binder for silver salts on photographic positive print papers called “collodio-chloride prints” from the 1880s and continuing through to the 1920s. It competed with gelatin for supremacy in the photographic binder market until it was discontinued in the 1930s.

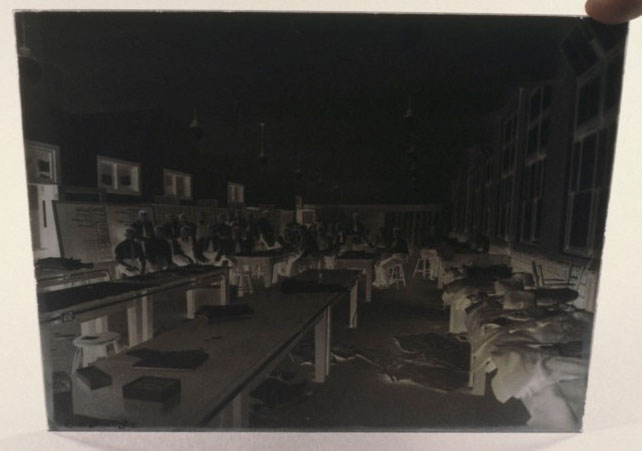

In 1871, Richard Leach Maddox, a physician and photography enthusiast, developed an emulsion using gelatin as the binder. Subsequent refinements by Charles Bennett greatly increased the light sensitivity of the emulsion, allowing exposure times of well under a second. Although experimented with beforehand by others, gelatin was not widely used until this time. It became the predominant binder for glass plate negatives, positive printing papers and plastic-based negatives. Its benefits were many: it was chemically stable, non-reactive with image silver, water clear and colourless; it conformed readily to any textured surface; and it swelled in aqueous solutions without dissolving immediately, allowing processing chemicals to reach silver salts, followed by drying down to a tough compact surface. The emulsion was industrially coated onto glass plates and commercially available by 1879 (Figure 3). Protected from light, the plates could be processed much later, thus eliminating the need to have a dark room and chemicals on hand when taking pictures. Photographers could now purchase the plates and expose them up to months later.

© Greg Hill

Figure 3. A gelatin dry plate under transmitted light.

In 1873, again following much investigation of cellulose nitrate by British and American scientists, the product Celluloid was trademarked by John Wesley Hyatt of the Celluloid Manufacturing Company in New Jersey. Celluloid, or cellulose nitrate, was plasticized with camphor, which proved to be the critical component. The plasticized cellulose nitrate, often referred to as French ivory, is considered the first industrially produced and marketed plastic. Employed as a substitute material for ivory and tortoiseshell, it was widely used in the production of combs, billiard balls, shirt collar stays and many other household items.

English photographer John Carbutt is generally recognized as the first to produce a film base that was lightweight and flexible. He founded the Keystone Dry Plate Works in 1879, although he was unable to standardize his process until 1887. Plasticized with camphor, large blocks of cellulose nitrate acquired from Hyatt’s Celluloid Manufacturing Company were cut into thin sheets, 1/100th of an inch (0.25 mm) thick. The sheets were then heated and pressed between metal plates to eliminate cut marks, followed by the application of a photographic emulsion to one side using gelatin as the binder. Though limited in size and not very flexible, the sheets were successfully used as photographic negatives (Figures 4a and 4b). In fact, the name “Celluloid” became widely used as the popular or generic term for motion picture film in the early years of the movie industry.

Shortly thereafter, Eastman Kodak Company obtained a patent to produce cellulose nitrate negatives by casting the nitrate onto large glass tables, forming long sheets of film that were strong and extremely flexible. This coincided with a patent obtained by Hannibal Goodwin for the same process. The Ansco Company acquired Goodwin’s patent upon his death and was able to successfully fight copyright infringement against Kodak in 1905. Long before this, though, in 1889, Kodak became the first to market a roll film, revolutionizing the photographic industry. With this innovation came the birth of the motion picture industry and an explosion of the amateur still photographic market. Photographers and non-photographers alike were able to take pictures under a much greater variety of conditions. Kodak wisely manufactured cameras, sold the film and processed and printed the negatives all for a price that was affordable to the middle class. Photography became ubiquitous.

The production of cellulose nitrate was finally discontinued in 1951 because of its chemical instability issues and in light of the development of new plastic film bases. Cellulose acetate film bases came into production in the mid-1920s, followed by polyester in the mid-1950s, both of which remain in production today.

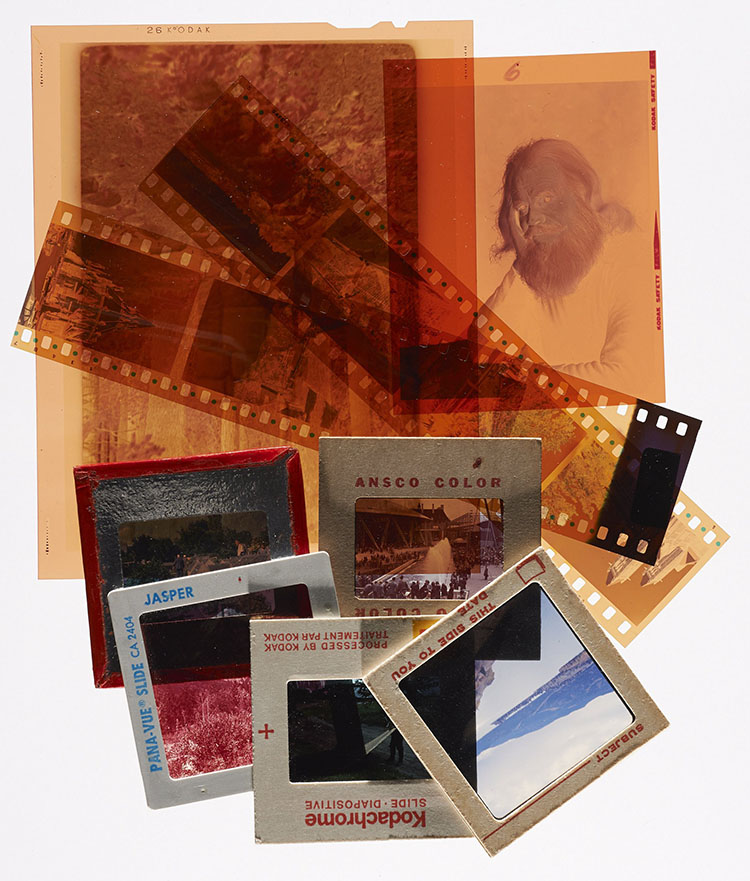

The photographic industry has continued to employ the silver-based chemistry and the technology that started it. The vast majority of black and white or monochrome materials in the early years of the industry were silver-based. Chromogenic colour materials, which became the predominant colour technology of the 20th and 21st centuries, exploited silver halide chemistry as well, though the final negatives and prints contain only dye layers. The first chromogenic negative material was produced by Agfa in 1939, followed by Kodak in 1942, but the cost was prohibitive until the late 1960s and early 1970s. However, by the mid-1990s, it accounted for over 80% of all film sales. Chromogenic films have a characteristic orange base tone and their images contain very muted blues, greens and reds. Chromogenic technology was employed in the production of positive images on clear film bases, referred to as reversal films, slides and transparencies, widely used in the 1980s and 1990s (Figure 5). They were initially produced on cellulose acetate, but polyester was eventually employed for use in more technical photography and the professional market due to its greater dimensional stability.

© Government of Canada, Canadian Conservation Institute. CCI 122361-0088

Figure 5. A composite of negatives (above) and chromogenic slides (below).

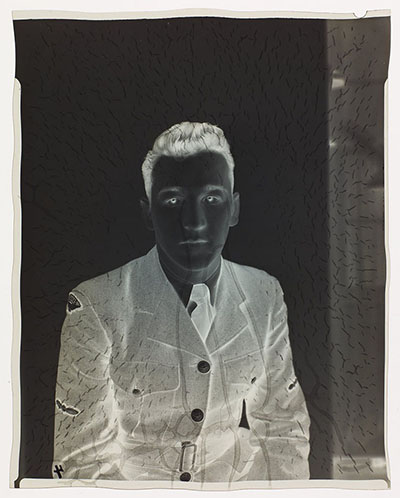

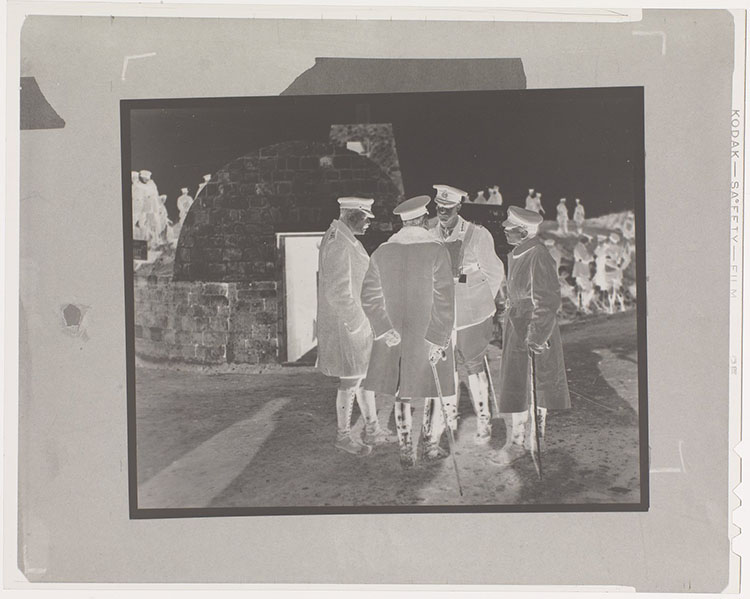

Negative retouching

Retouching of photographic negatives was a common practice in the early and mid-20th century, employed primarily to enhance studio portraits (Figure 6). One can often find oiled or waxed areas on the emulsion side of a negative onto which the retouch medium has been delicately applied. Graphite pencil was the predominant medium for black and white negative retouching, requiring great skill in its application in order to ensure that it would not be detectable on the final print. Occasionally, one finds opaquing applied to the emulsion, designed to completely block out extraneous information; it is usually black or red (Figure 7). All retouch media tends to be somewhat water soluble.

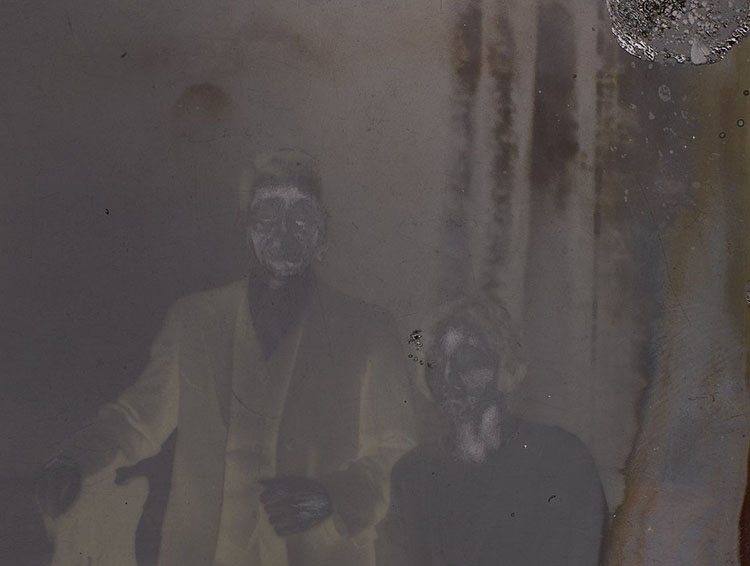

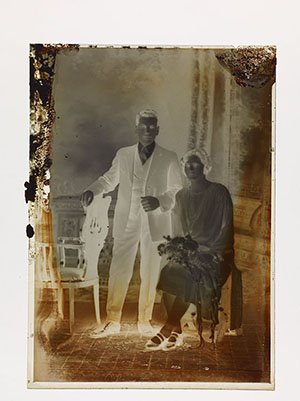

© Government of Canada, Canadian Conservation Institute. CCI 122361-0038

Figure 6. A retouched studio portrait negative. Graphite pencil was applied to the emulsion, appearing as hand-drawn marks on the faces of the sitters.

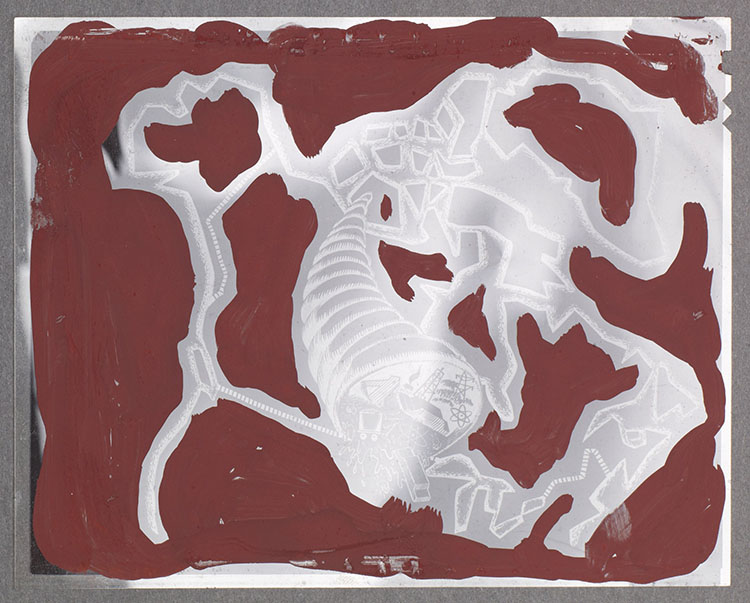

© Government of Canada, Canadian Conservation Institute. CCI 122361-0031

Figure 7. Large parts of this negative have been blocked out using an opaque added to the emulsion.

Until the advent of digital output media, where inkjet printers are used to produce negative images on clear plastic sheets, non–silver-based technologies were never used for negatives. Overall, throughout the late 19th century to now, paper, glass and a variety of plastic-based negatives have all been commercially available, each with specific desirable properties. Paper, being flexible and very lightweight, was used at various times from the first in-camera image to remote field work. Glass, with its great clarity and dimensional stability, was later employed in the sciences, particularly astronomy. Plastics, the most widely employed for their light weight and flexibility, allowed a myriad of formats and great convenience in both the professional and amateur markets.

Understanding plastic film-based negatives

Cellulose nitrate film base

| Cellulose nitrate film formats | Available sizes |

|---|---|

Film packs

|

Various sizes up to 5 in. × 7 in. |

| Microfilm | 35mm film (available from 1930 to 1940) |

Motion picture film

|

35mm film Amateur film stocks (such as 17.5mm cut down from 35mm film) |

| Roll film | 70mm Many different amateur film stocks cut down from 70mm |

| Sheet film | 4 in. × 5 in. 5 in. × 7 in. 8 in. × 10 in. 11 in. × 14 in. |

X-ray film

|

Various large formats |

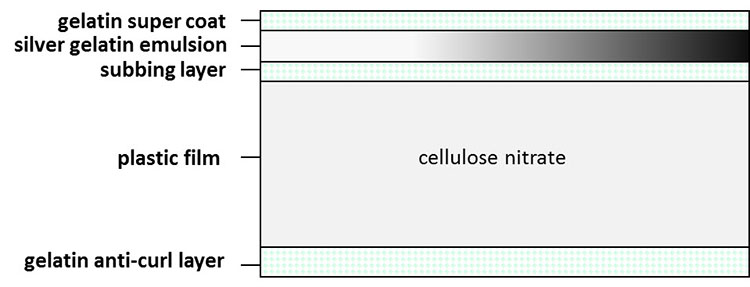

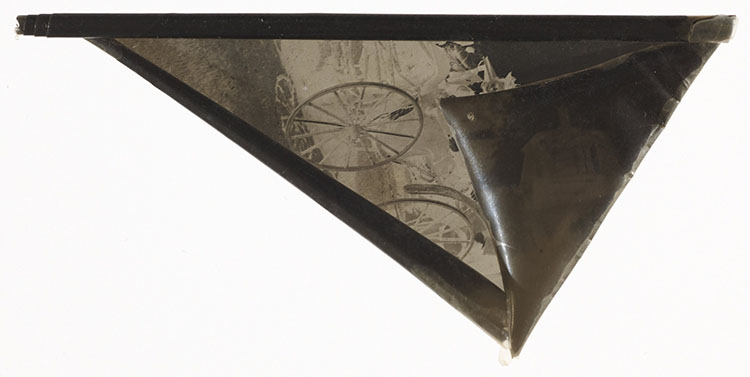

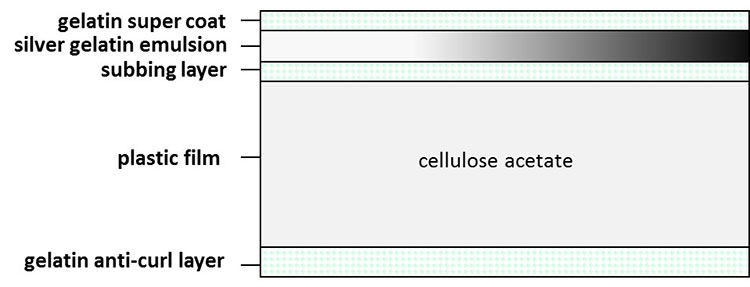

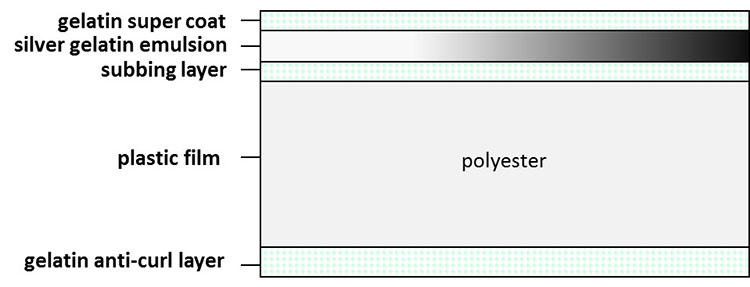

Cellulose nitrate film can be found in a large range of formats. The basic structure of the film (Figure 8) includes the plastic film base, an emulsion of gelatin and silver halides adhered to the base with a subbing layer and, in later films, an anti-curl layer on the opposite side of the base from the emulsion, stabilizing the sheet against curling up. Early nitrate sheet film contained no anti-curl layer, often resulting in the sheet curling into a very tight roll (Figure 9). Beginning in 1935, with the introduction of Kodak’s Technicolor process, colour emulsions were also applied to cellulose nitrate film bases, followed by chromogenic emulsions in the 1940s.

© Government of Canada, Canadian Conservation Institute. CCI 122361-0111

Figure 8. Typical structure of cellulose nitrate film.

© Government of Canada, Canadian Conservation Institute. CCI 97858-0008

Figure 9. Curled nitrate film (from the Annie McDougal collection, McCord Museum).

Degradation of cellulose nitrate film base

In spite of the great conveniences afforded by nitrate flexible film bases, there was a monumental problem: they proved to be chemically unstable. As there were no standards organizations or quality controls at the time to dictate minimal acceptable standards for the production of nitrate film, there was, consequently, a broad range of stabilities. Some survived only a few years, while others remain viable to this day. The stability is dictated partly by the manufacturing process and partly by the environments in which the negatives have been stored across their life span. Most highly unstable cellulose nitrate film has already deteriorated and no longer exists. Although often unidentified, cellulose nitrate film currently in public and private collections is generally stored in better preservation environments, which helps to mitigate deterioration. Table 2 provides discontinuation dates of cellulose nitrate products from the market. Though the final production date of nitrate motion picture film was 1951, it is possible that stockpiles of raw film stock resulted in its continued use through to the mid-1950s; however, this is difficult to verify.

| Type of film | Last year of cellulose nitrate manufacture |

|---|---|

| X-ray filmsTable 2 Footnote 1 | 1933 |

| Roll films in 35mmTable 2 Footnote 2 | 1938 |

| Portrait and commercial sheet filmsTable 2 Footnote 3 | 1939 |

| Aerial films | 1942 |

| Film packsTable 2 Footnote 4 | 1949 |

| Roll films in sizes 616, 620, etc.Table 2 Footnote 5 | 1950 |

| Professional 35mm motion picture filmsTable 2 Footnote 6 | 1951 |

Table 2 Notes:

|

|

As cellulose nitrate negatives age, degradation proceeds along several paths, including acid and alkaline hydrolysis, and photochemical and thermal degradation. These processes are accelerated in the presence of high humidity and temperatures. The degradation processes result in the breaking off of the nitrate groups from the cellulose nitrate molecule, which forms nitrous oxides and, in the presence of humidity, nitric acid. As the level of acidity increases, so does the rate of deterioration. This autocatalytic reaction can very quickly lead to the total destruction of the negative. This will also catalyze rapid destruction of other items in the vicinity of degrading cellulose nitrate, most notably cellulose acetate films.

Thermal degradation of cellulose nitrate involves the breaking off of nitrate groups in the cellulose nitrate molecule, which produces nitrous gases (Reilly 1991).

Another side effect of degradation is the significant lowering of its temperature of combustion. Whereas newly produced nitrate film may have a combustion temperature of around 150°C, the lowest recorded temperature of combustion of degraded film is 41°C (Cummings 1950). Storage facilities with no insulation in summer months can easily exceed this temperature, potentially leading to spontaneous combustion. When cellulose nitrate film is stored in large quantities, the results can be, and have been, devastating. Motion picture film vaults were particularly vulnerable to combustion, as were the projection booths in movie theatres.

When cellulose nitrate burns, chemically bound oxygen is released. This means that the resulting fire becomes self-sustaining and no attempts to smother and control the combustion of the film will be successful. It will continue to burn until completely consumed. With the evolution of combustion gases, it burns at approximately 15 times the rate of a wood fire (though not as hot), causing explosive-type forces. Toxic gases are released in the beginning stages of combustion; indeed, in most cases where deaths have occurred in nitrate fires, they were due to gas poisoning. Many high-profile, well-documented fires, such as the National Film Board fire in Beaconsfield, Quebec, in 1967, have informed the public of the dangers of nitrate.

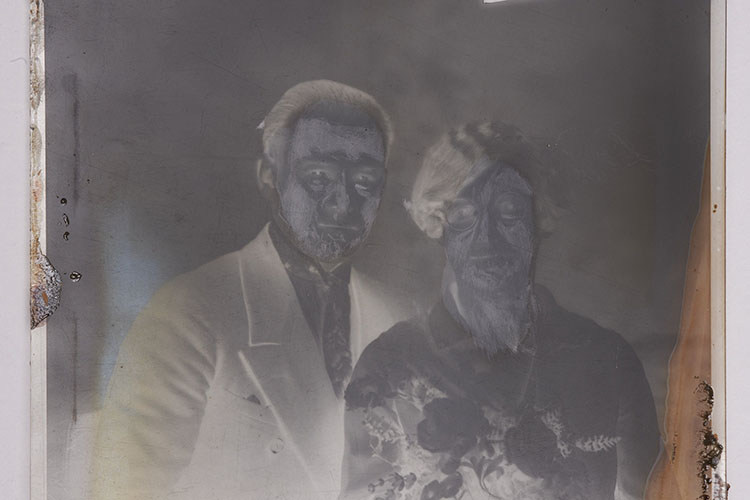

Stages of deterioration

The deterioration of cellulose nitrate film is divided into six different stages, described in Table 3 and illustrated in Figures 10a, 10b, 11a and 11b. The stages are broadly agreed-upon levels of deterioration, not a universal standard classification system. However, they do allow the collections manager to characterize the degree to which their collection is degraded and to take appropriate measures for treatment and storage. The rate of deterioration is affected by temperature, humidity, storage enclosures and the current state of degradation of the film. The higher the temperature and humidity, the faster the rate of deterioration.

| Stage | Description | Recommendations |

|---|---|---|

| 0 | No deterioration. | Segregate from rest of collection. Place in cool or cold storage. |

| 1 | The film turns yellow and the image exhibits silver mirroring (Figure 10a). | Segregate from rest of collection. Place in cool or cold storage. |

| 2 | The film becomes sticky and gives off a strong nitric acid odour (Figures 10b). | Segregate from rest of collection. Place in cool or cold storage. |

| 3 | The film turns an amber colour and the silver image begins to fade (Figures 11a and 11b). | Segregate from rest of collection. Place in cool or cold storage. |

| 4 | The film becomes soft and may adhere to adjacent materials, and the image becomes indistinct. | Send for destruction by specialist. |

| 5 | The film breaks down completely, turning into a brown powder. | Send for destruction by specialist. |

Note: Any deterioration between levels 1 to 5 presents health and safety concerns.

Cellulose acetate film base

| Cellulose acetate film formats | Available sizes |

|---|---|

| Microfilm | 35mm |

| Motion picture film | 35mm 8mm Super 8 9.5mm and 16mm movie film (always manufactured on cellulose acetate base/safety base) Edison 22mm Pathé 28mm films |

Roll film

|

4 in. × 5 in. 5 in. × 7 in. 8 in. × 10 in. 11 in. × 14 in. 16 in. × 20 in. |

Sheet film

|

4 in. × 5 in. 5 in. × 7 in. 8 in. × 10 in. 11 in. × 14 in. 16 in. × 20 in. |

The chemical instability issues associated with cellulose nitrate film became evident shortly after its introduction in the late 1800s. The often rapid deterioration and associated flammability issues resulted in devastating fires and deaths. Extensive research eventually identified an alternative in the form of cellulose acetate. It was first used as a coating for airplane fabrics, but its potential for forming thin flexible sheets was investigated and, by 1909, a plastic film base was fashioned by Kodak. Wood pulp and cotton linters were the source of the cellulose fibres used in its production; the addition of acetic acid, acetic anhydride and a catalyst, such as sulfuric acid, allowed for cellulose diacetate to be derived. Technical problems delayed its commercial production until 1923, at which point Kodak produced 16mm amateur motion picture film on a cellulose diacetate base. As with cellulose nitrate film, all iterations of cellulose acetate film relied on gelatin/silver halide technology in both black and white and colour emulsions.

In 1925, Kodak became the first manufacturer of sheet film on cellulose diacetate. In contrast to nitrate, it was not highly flammable and was known as “safety film.” Beginning with Kodak, the words “Safety” or “Safety Film” were printed on the edge of most cellulose acetate sheet film and many roll films. Agfa, Defender, Dupont Defender and Hammer began manufacturing safety film on supports made from cellulose diacetate by the mid-1930s, and both Agfa-Ansco and Defender continued to use cellulose diacetate until switching to polyester in 1955 (Horvath 1987). A number of early large-format roll films from this period (1930–1940), however, contained no edge printing, which makes identification of plastic film bases difficult today.

Within a few years of the first production of cellulose diacetate, Kodak opened a research lab dedicated to the development of other cellulose esters that could optimize strength and moisture resistance as well as dimensional and chemical stability. Cellulose acetate propionate, developed in 1927, and cellulose acetate butyrate, developed in 1936, were both used throughout the following decades, with the latter still in production by Eastman Chemical Company, though not for photographic negatives.

Cellulose triacetate came into production in 1948. It was developed as a more stable alternative to earlier acetates. It is still in wide use today for all types of films. It continues to be the preferred film base above polyester in the motion picture film industry because of its working properties. For example, it has much less strength than polyester, so when projectors jam, the film breaks rather than the costly equipment. Splicing broken acetate film is also much less problematic than polyester. Currently, much of the still photographic negatives continue to be produced on cellulose triacetate, a cheaper alternative to polyester.

Table 5 shows the time frames for the production of each type of acetate, from 1925 to today.

| Acetate type | Dates | Film type | Manufacturers |

|---|---|---|---|

| Diacetate | About 1923 to about 1955 | Roll, sheet | Agfa, Ansco, Dupont, Defender, Kodak |

| Acetate propionate | 1927 to about 1949 | Roll | Kodak |

| Acetate butyrate | 1936 to today | Sheet, X-ray, aerial maps | Kodak |

| Triacetate | About 1950 to today | Roll | Almost every film manufacturer |

Degradation of cellulose acetate film

Although the flammability issue of negatives was eliminated with the introduction of cellulose acetate, significant instability issues soon became apparent. Being inherently unstable, particularly in elevated temperature and humidity, the films began to deteriorate within a matter of years in some cases.

The mechanisms of deterioration take the form of two separate reactions. The first is the de-esterification of the molecule, which means the acetyl groups attached to the cellulose molecule break off and, in the presence of moisture, create acetic acid, releasing the characteristic smell of vinegar, hence the name “vinegar syndrome.” The second reaction, due to high acidity, is the breaking of the cellulose acetate polymer bonds that reduce the base viscosity and cause brittleness and shrinkage. As the acetate deteriorates, it becomes increasingly acidic. The heightened acidity, in combination with ambient moisture in the environment, causes an ever increasing rate of deterioration. This auto-catalytic reaction is exacerbated by elevated temperatures.

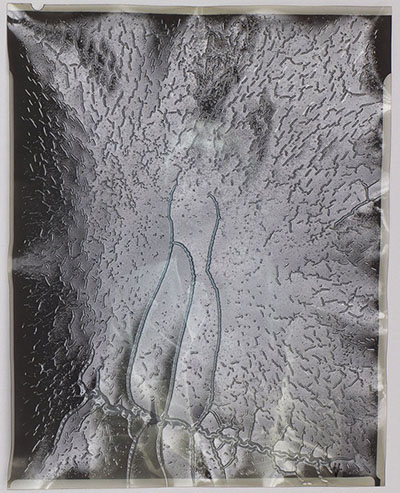

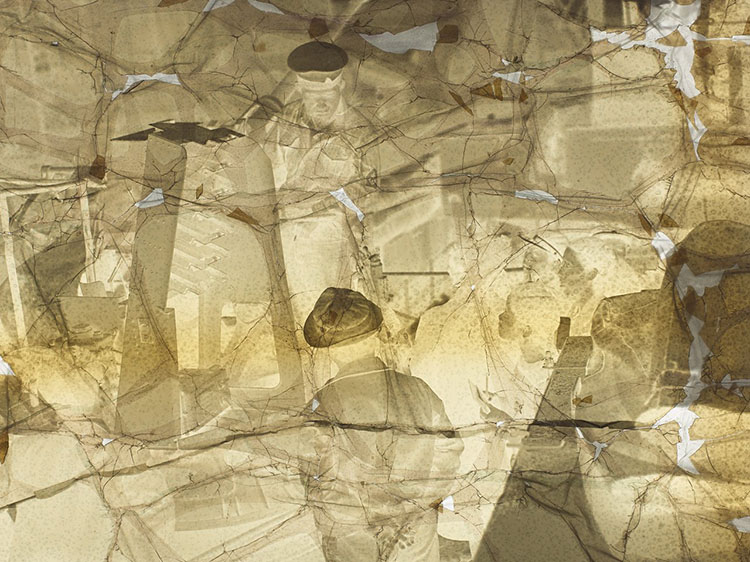

Plasticizers, such as glycol phthalate, tributyl phosphate or dibutyl phthalate, are added to cellulose acetate to increase flexibility. As the cellulose acetate ages, the plasticizers can migrate to the surface and produce an oily film. Their loss from the matrix results in dimensional changes: the plastic base shrinks, causing the attached emulsion and anti-curl layers (Figure 12) to channel and blister. The entire sheet warps and cockles, eventually obscuring the image. Any shrinkage of the base is particularly devastating for motion picture films, as sprocket holes are precisely placed to feed through projectors (Figure 13). Whitish accretions are often found along the edges and in the blisters of the film and, occasionally, the blister contains a clear liquid. Once the vinegar smell is apparent, the process of deterioration is well on its way and action must be taken to slow or stop the process.

© Government of Canada, Canadian Conservation Institute. CCI 122361-0106

Figure 12. Typical structure of cellulose acetate film.

The various stages of deterioration are outlined in Table 6 and illustrated in Figures 14 through 16. Again, this is not a universal standard but rather a guide for collections managers as to the state of their collections. Once these symptoms begin to appear, even at stage 1, there really is only one course of action. These items should be segregated from the rest of the collection, copied if at all possible and then placed in cold storage. This will be fully discussed later in the text.

| Stage | Description |

|---|---|

| 1 | Vinegar odour |

| 2 | Shrinkage |

| 3 | The film retains a curve when cupped. It will not lie flat and instead appears wavy. |

| 4 | Crazing: the emulsion cracks and the image appears as a fragmented mosaic. |

| 5 | Appearance of white powder on edges (from binder deterioration, this is the plasticizer separating from the film); occasionally liquid-filled bubbles. |

| 6 | Film embrittles and cracks, becoming square on the reel (Figure 13). Referred to as “spoking.” |

| 7 | Film is no longer flexible and the emulsion flakes off from the base. |

© Image Permanence Institute

Figure 13. Motion picture film reel becoming square on the reel (spoking).

Further deterioration results in the complete loss of the film’s physical integrity. The base and the gelatin layer—the entire matrix—crumble under any physical pressure.

Another phenomena related to the deterioration of the film is the reforming of the anti-halation dyes. Incorporated into the anti-curl layer, anti-halation dyes absorb the light passing through the emulsion and film base so that it does not scatter back into the light-sensitive emulsion during the exposure and cause a halo effect. Rendered colourless during the processing of the negative, their presence is not evident in the final processed negative. However, their characteristic blue or red colour can reappear in the acidic environment of the degraded film (Figure 17).

© Government of Canada, Canadian Conservation Institute. CCI 122361-0107

Figure 17. Anti-halation dyes appear blue in degraded cellulose acetate film, as shown in this example.

There are techniques for re-dimensioning film (restoring it to a less-shrunken state), but these are temporary measures that can permanently damage the film and should only be done in a laboratory situation as a final recourse to enable a new negative or print to be made. Refer to Treating plastic film-based negatives for a further discussion on treating degraded cellulose acetate-based negative films.

Polyester film base

| Polyester film base formats | Available sizes |

|---|---|

Microfilm

|

35mm |

Motion picture film

|

35mm |

Roll film

|

4 in. × 5 in. 5 in. × 7 in. 8 in. × 10 in. 11 in. × 14 in. 16 in. × 20 in. |

Sheet film

|

4 in. × 5 in. 5 in. × 7 in. 8 in. × 10 in. 11 in. × 14 in. 16 in. × 20 in. |

There are many polyesters, both natural and synthetic, though the term polyester most commonly refers to poly(ethylene terephthalate) (PET). It is a clear, colourless, thermoplastic long-chain polymer developed in the late 1940s that incorporates no plasticizers. Polyester sheeting is formed by extrusion. The continuously heated polymer is extruded through a slot and stretched in a longitudinal direction while at the same time being pulled in a widthwise direction. After this, the molecules are oriented in two different directions, with different refractive indices in each of these directions. This creates a birefringent sheet, which means that when a ray of light enters the film, it decomposes into two separate rays that have different refractive indices, with perpendicular directions of polarization.

Polyester has been used for a limited number of sheet-film bases since the 1950s and, since the 1990s, for the base of release print materials in the motion picture film industry. It is strong, tear-resistant and both chemically and dimensionally stable, and it can be formed into sheets of varying thicknesses, from 1 to 350 µm. This extreme resistance to tearing makes it an ideal film base for the rigours of commercial cinema projection. However, splicing polyester film is problematic as adhesives will not hold to the surface. Heat-welding and tape splicing have addressed this problem, yet acetate films are still preferred in many cases. Due to polyester’s extreme tear strength, when jams in projectors occur, it is usually the equipment that suffers as the sprocket holes in the polyester film hold fast.

Additionally, the smooth slick surface of the polyester was cause for concern in the beginning of its use as a film base, as emulsions would not stick to the film. As a result, additives were designed to create texture or tooth to the surface in order to allow the emulsions to adhere adequately. Throughout their history, polyester-based films have depended on the use of gelatin/silver halide emulsion technology (Figures 18a, 18b and 19).

© Government of Canada, Canadian Conservation Institute. CCI 122361-0109

Figure 19. Typical structure of polyester film.

Degradation of polyester

Due to the extreme chemical stability of polyester in a broad range of test environments, few statistics are available regarding its rate of degradation. Tests carried out at the Image Permanence Institute indicate that the expected life of polyester is in excess of 1000 years; in the 60 or so years that polyester film has been on the market, there have been no documented cases of its degradation in any collections, regardless of environments (P.Z. Adelstein, J.M. Reilly, D.W. Nishimura and C.J. Erbland 1995, p. 141). Optimal storage environments would, of course, increase the projected life of the film.

Photographic gelatin has the capacity to be very chemically stable, making the image silver the weakest part of the film base as it is subject to oxidation from atmospheric pollutants. Post-processing treatments, such as selenium or sulfur toning of the image silver, will provide much greater stability, rendering the polyester negative much less susceptible to deterioration of any kind.

Identifying and differentiating plastic film-based negatives

As cellulose-nitrate- and cellulose-acetate-based films begin to deteriorate, they volatilize specific products of decomposition. The impact of the volatiles on other material stored in proximity can be devastating. This is particularly true when cellulose nitrate and cellulose acetate are stored together, as this can accelerate their deterioration. In these cases, segregation projects are essential to preservation, particularly if telltale signs of decomposition are evident, including characteristic odours followed by base shrinkage, warpage and/or discolouration.

The capacity to differentiate one type of plastic film base from another can be critical to the long-term survival of a negative collection. Many plastic film bases, when not in a deteriorated state and without visible indicators as to material type, can be very difficult to distinguish. Image and film base tone, base thickness and formats often provide few clues as to the plastic type and date.

Faced with three different types of plastic—cellulose nitrate, cellulose acetate and polyester—and a limited number of tests that can be performed in most collections, the following steps will aid in differentiating one film base from the others (each step is described in detail in the next sections):

- date the material

- examine the edge marks

- examine the notch codes

- perform a light polarization test to identify polyester

- perform a diphenylamine (DPA) test to identify cellulose nitrate

If the results for steps 4 and 5 are negative, the film base is neither polyester nor cellulose nitrate and, therefore, must be cellulose acetate.

Step 1: date the material

If the negative can be positively identified as having been produced between 1889 and 1920, it is cellulose nitrate.

If the negative can be positively identified as having been produced after 1955, it is cellulose acetate or polyester.

If the film can be positively identified as having been produced after 1920 but no other information is available, proceed to Step 2.

Step 2: examine the edge marks

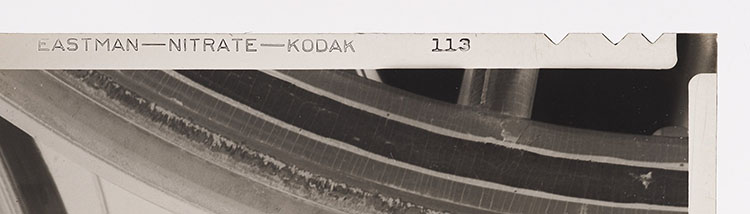

Early cellulose nitrate film produced by Kodak had the word “Nitrate” printed on the edge of the negative (Figure 20a). If this appears on a negative, segregate it from film marked as “Safety” or “Safety Film” and any unmarked material.

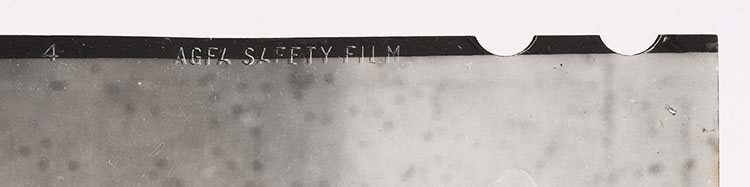

Alternative materials to cellulose nitrate were generally edge printed with the word “Safety” or “Safety Film” (Figure 20b). Safety film edge marking can be found on both cellulose acetate and polyester. If one of these terms appears on a negative, segregate the material from known cellulose nitrate film.

If no edge marking is evident, proceed to Step 3.

Step 3: examine the notch codes

Many early roll films and sheet films from various manufacturers contained no edge marking. However, all manner of sheet film—black and white, colour, positive transparencies, etc.—regardless of the manufacturer, contain a series of notches in the upper right corner when the emulsion is facing the viewer (Figure 20a and 20b). The intent was to help the darkroom technician in identifying the type of film, in the dark, by feeling the notches and in orienting the film properly in the processing tanks so as to maximize the film’s contact with the processing chemicals and washing products.

These notches can provide clues as to the identity of the film, though it is unfortunately not entirely reliable because various notch codes were reused by manufacturers for different types of film bases. Notch codes are found only on sheet film, not negatives cut from a roll of film, and can be very useful, particularly if the manufacturer is known. Several notch code guides are included in the Bibliography (Horvath 1987, Eastman Kodak Company 2004, Morrisson 2005–2010).

If you are able to positively identify the film type from the notch code, segregate the film from the collection and store it appropriately.

If identification of the notch code is impossible or if the results are questionable, proceed to Step 4.

Step 4: perform a light polarization test to identify polyester

The light polarization test is designed to positively distinguish polyester film from cellulose nitrate and cellulose acetate films. Polyester film is known as a birefringent material, meaning that when a ray of light enters the film, it decomposes into two separate rays that have different refractive indices, with perpendicular directions of polarization. This is due to the manner in which polyester is produced. The continuously heated polymer is extruded through a slot and stretched in a longitudinal direction while at the same time being pulled in a widthwise direction. After this, the molecules are oriented in two different directions, with different refractive indices in each of these directions. This creates a birefringent sheet.

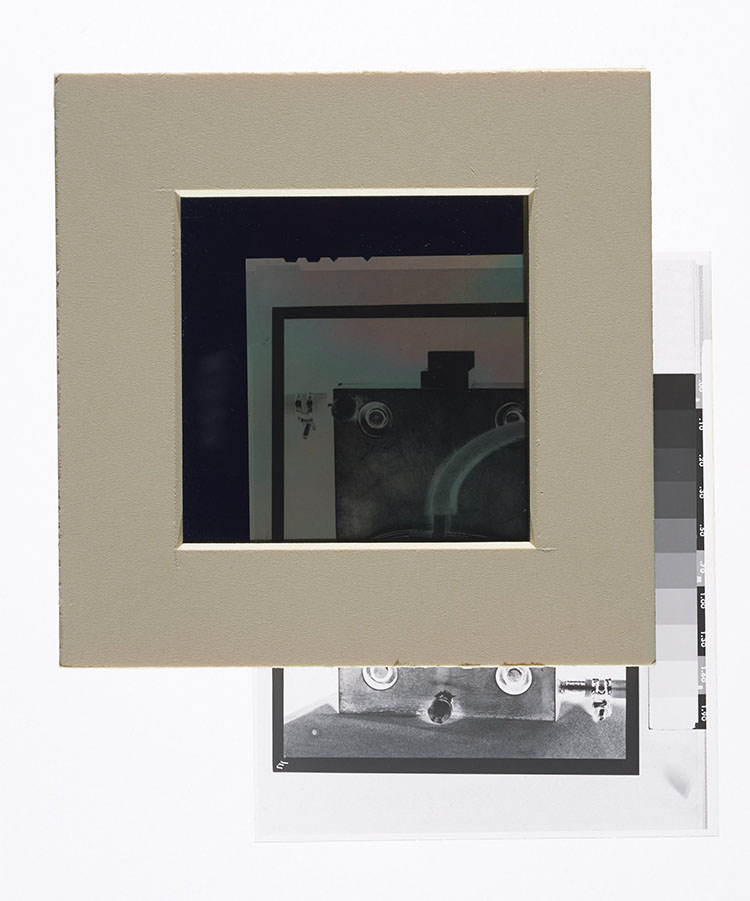

Two polarizing filters are said to be crossed when one is rotated relative to the other until no light passes through the combination (directions of polarization are perpendicular or crossed). Sandwiching a clear, transparent non-image area of the polyester film or clear film base between crossed polarizers will rotate the direction of polarization so that it is no longer perpendicular to the second polarizer, allowing light to pass through and create interference colours in the pink and green range that are visible in the non-image areas (Figure 21). The results should be unequivocal, though using a part of the negative that contains little or no image silver is essential. This phenomenon will not occur with either cellulose-nitrate- or cellulose-acetate-based films.

© Government of Canada, Canadian Conservation Institute. CCI 122361-0072

Figure 21. When polarizing filters are crossed with a piece of polyester sandwiched between the two filters, the negative becomes visible. Light is allowed to pass through and pink and green interference colours appear, illustrating birefringence.

If the material is not birefringent, proceed to Step 5.

Step 5: perform a diphenylamine (DPA) test to identify cellulose nitrate

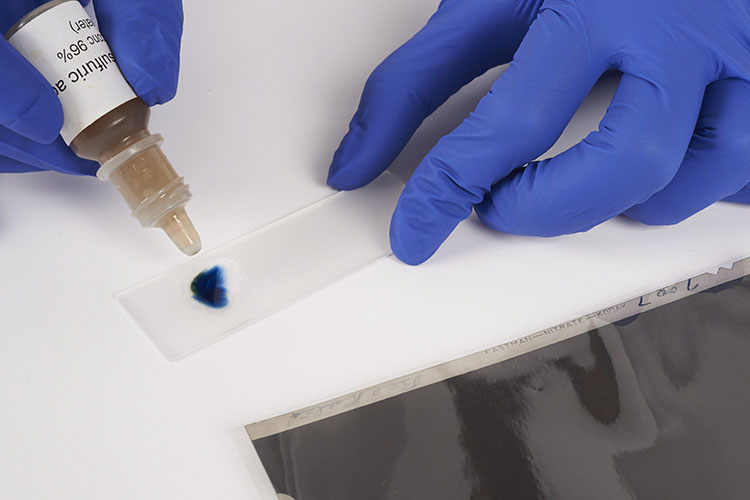

The DPA test depends on the release of nitrate ions from the plastic by hydrolysis in a sulfuric acid solution. The reagent stains a very characteristic indigo blue colour in the presence of the nitrate ions. Non-cellulose-nitrate film material will remain colourless in the presence of the test solution. Sometimes, a greenish-brown stain will appear, but this is not a positive test result and the sample is, therefore, not nitrate.

The currently recommended test reagent for detection of cellulose nitrate in photographic materials is 0.8% diphenylamine (DPA) in 80% sulfuric acid. A ready-made stock solution of 1% diphenylamine (DPA) in concentrated sulfuric acid is available in Canada from Fisher Scientific and in the U.S. from LabChem Inc. Although the acid concentration is too high to allow the use of this stock solution directly as received, dilution of four volumes of the stock solution with one volume of water produces a test solution of 0.8%.

Prepare the test solution

This reagent is prepared from the stock solution as follows:

Add 80 mL of stock solution to 20 mL of water in a large container while stirring. Since only one drop is used per test, 100 mL will provide sufficient test reagent for hundreds of tests.

Caution

- The solution is highly corrosive and must be handled with great care and proper personal protective equipment, including gloves and goggles.

- Always add acid to water. Adding sulfuric acid to water will generate a lot of heat, so stirring is required to prevent localized boiling and spattering.

- Do not store the solution in bottles with cap liners or bulbs made of rubber, paper or metal. Store the prepared reagent in polyethylene dropper bottles, which provide a convenient method of dispensing a single drop of reagent to samples.

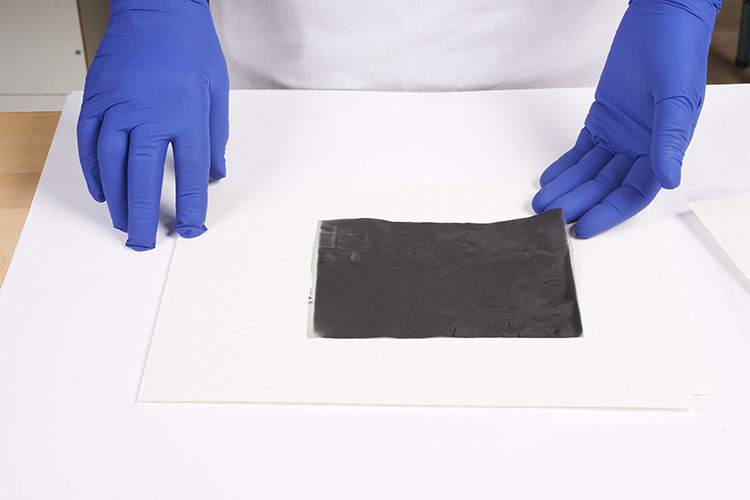

Prepare the test sample

The DPA test is considered a destructive test. However, the sample amount required is very small. Using a frosted microscope slide, sand the very edge of the film sample against the slide. To do this, hold the film edge perpendicular to the slide plane and rub the slide back and forth against the film edge. The resulting loss of original material is virtually undetectable (Figures 22a, 22b and 22c).

Test the sample on the slide

Place a tiny drop of the DPA solution on the frosted microscope slide, where it made contact with the film edge. If the solution immediately turns a dark indigo blue colour, the test result is positive for cellulose nitrate. If there are other colours present (out of the blue range towards green or very pale), it should be considered a negative test result.

Testing for cellulose nitrate subbing layers on early safety films can be accomplished using a microscope. While observing the film through the microscope, deliver a small quantity of the DPA solution to the film base using a fine glass rod and look for the blue colour to appear.

The DPA test for cellulose nitrate is outlined in CCI Note 17/2 The Diphenylamine Spot Test for Cellulose Nitrate in Museum Objects.

Health and safety concerns related to degrading plastics

Adhering to trusted guidelines for storage and handling of cellulose nitrate and cellulose acetate is very important not only for the long-term preservation of the associated collections but also for the health and safety of the people handling them.

The only existing standard addressing these concerns, including proper storage of cellulose nitrate film, is NFPA 40, Standard for the Storage and Handling of Cellulose Nitrate Film. The destructive by-products of cellulose nitrate film decomposition and its high flammability rating make its immediate identification, separation from the collection and proper storage imperative. Disposal may be required, based on the level of deterioration of the film and this, too, must be done within strict guidelines. Degraded cellulose nitrate films have a very low temperature of combustion, requiring vigilance in ensuring that storage temperatures do not rise above 30°C and that environments are free from the risk of fire.

There is no equivalent standard to NFPA 40 for cellulose acetate film. Though it does not pose the same flammability risk as cellulose nitrate, it does still present a significant health risk. Chronic respiratory and dermatological ailments can result from prolonged exposure. Proper storage and handling requirements for cellulose acetate are discussed in the following International Organization for Standardization (ISO) standards:

- ISO 18901:2010, Imaging Materials – Processed Silver-Gelatin-Type Black-and-White Films – Specifications for Stability

This standard covers requirements for the film base, emulsion and backing layers, and image stability for cellulose acetate film. - ISO 18906:2000 (reviewed in 2012), Imaging Materials – Photographic Films – Specifications for Safety Film

This standard gives requirements and test methods for ignition time and the burning time of cellulose acetate film. - ISO 18911:2010, Imaging Materials – Processed Safety Photographic Films – Storage Practices

This standard includes topics related to enclosures, housings and environmental conditions for cellulose acetate film. - ISO 18916:2007, Imaging Materials – Processed Imaging Materials – Photographic Activity Test for Enclosure Materials

The photographic activity test described in this standard is a predictive test of interactions between the storage enclosure and the photographic image. It can also be used to evaluate possible photographic activity caused by components of enclosures such as adhesives, inks, paints, labels and tape. - ISO 18931:2001, Imaging Materials – Recommendations for Humidity Measurement and Control

This standard defines pertinent terms and different measuring systems for cellulose acetate film.

Products of polymer decomposition

The degradation of cellulose nitrate and cellulose acetate film bases involves the evolution of chemicals that can have serious negative health effects on the people responsible for ensuring the long-term preservation of such film.

Products of decomposition of cellulose nitrate film bases include nitrous oxides (NO, NO2). In the presence of moisture and humidity, these gases can form corrosive acid gases that will damage other materials in their proximity, including all organic and metal materials. Low odour warning properties of nitrate mean that concentrations of the gases can be high before the odour becomes apparent. The smell, when noticed, is acrid or pungent.

Degraded cellulose acetate film bases produce acetyl oxides that form acetic acid in the presence of atmospheric humidity. The volatiles are airborne and affect all materials in their proximity. The smell of decomposition resembles that of vinegar. Generally, the more pronounced the smell, the higher the levels of acidity. Decomposition of cellulose acetate is commonly referred to as “vinegar syndrome.”

Health effects of long-term exposure

Even short-term exposure to the decomposition chemicals of cellulose nitrate and cellulose acetate can provoke health issues, most notably respiratory and dermatological problems.

Chronic exposure to the decomposition products of cellulose nitrate film, especially nitrogen dioxide, can lead to headaches, blurred vision, loss of appetite, emphysema and other systemic damage. Chronic exposure can result in a heightened sensitivity to a broad range of environmental toxins, such as those found in new buildings, solvents and standard air pollutants. These effects can be serious, long-term and debilitating and are the same for both cellulose nitrate and cellulose acetate. Contact dermatitis and other skin diseases can also result from long-term exposure to cellulose nitrate and cellulose acetate and, in turn, lead to sensitivities to many other materials.

Mould

Gelatin, the primary component of photographic emulsions and anti-curl layers, is a rich source of nutrients for mould. Fingerprints in particular act as a focal point for the mould to start due to their high salt content, which makes them hygroscopic and a source of higher moisture. Mould germination and the extent of growth are dependent on relative humidity (RH), temperature, time, species of mould and the nutritious quality of the organic substrate. A precautionary limit to prevent mould is 65% RH at 20°C (Tétreault and Hagan 2012).

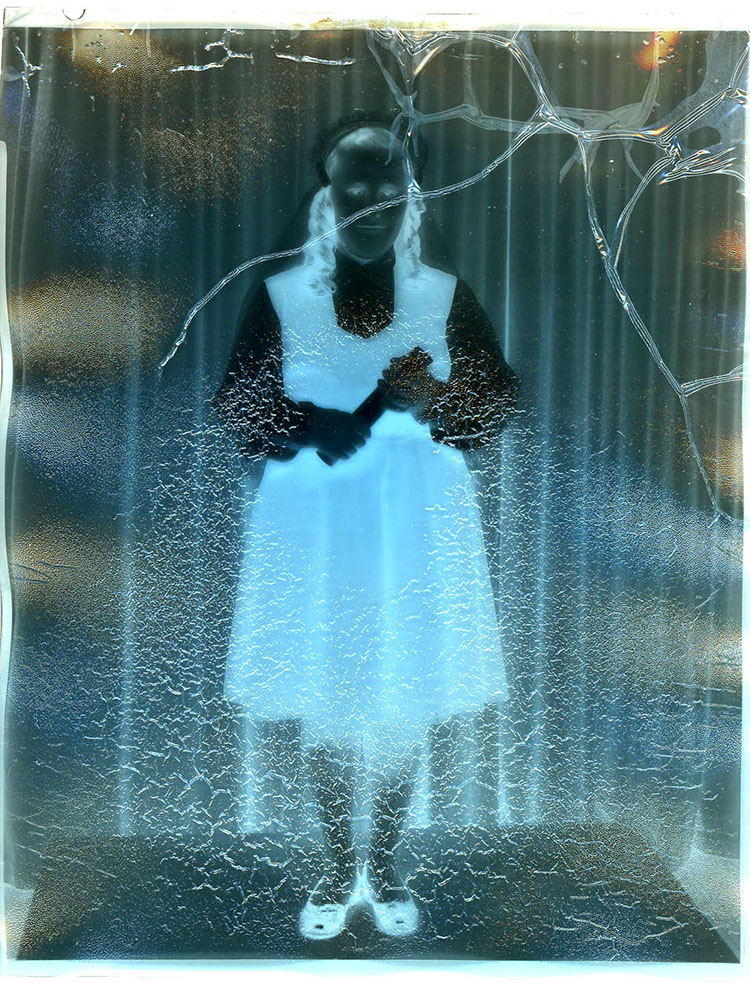

Mould will not grow in dry environments, but spores may remain viable even under extreme, dry conditions. It is not uncommon to find mould on negatives (Figure 23) since the environments in photo studios are rarely controlled. Fungicides are not recommended as they are generally detrimental to protein and collagen.

© g.samson-Hendriks

Figure 23. The white markings on this plastic-based negative are mould.

Mould is virtually everywhere and in normal background concentrations generally does not affect healthy individuals. However, prolonged exposure to higher than normal concentrations of mould can greatly increase the risk of severe illness. The degree of risk is dependent on the type of mould, the mould products and the susceptibility of the individual. Respiratory problems, compromised immune systems and allergies can be greatly exacerbated by mould exposure, and these conditions can compound the effects of the mould, resulting in severe chronic illness.

For mould infestations in heritage collections, particulate filters from the N series (N for “not-resistant to oil”) are generally appropriate. Filters described as N100 offer the greatest protection against particulate matter and are referred to as HEPA (high-efficiency particulate air) filters. Respirators, including disposable respirators, should be test-fitted by a qualified individual to ensure a proper fit.

Gloves should be worn at all times when handling mould-affected material. Disposable gloves, including nitrile, latex, nylon and polyethylene gloves, provide adequate protection. Eyewear should include goggles, even if you wear prescription eyeglasses. The appropriate, recommended goggles are not ventilated and must accommodate a disposable or half-face respirator. Outer disposable clothing that can be immediately removed following contact with mould-affected materials is recommended, such as laboratory coats, disposable aprons and sleeves.

There are no special requirements for discarding contaminated personal protective equipment, though it is important to exercise caution when handling and discarding these items. Place disposable clothing, gloves, etc. in thick (6 mil) plastic garbage bags or two layers of thin plastic garbage bags. Seal the bags and discard them in an outdoor garbage container.

Procedures for mitigating the presence of mould

- Once mould has been discovered in a collection of negatives, take defensive action immediately to protect staff. Staff with asthma or allergies should be immediately removed from the vicinity. Staff in the contaminated area or handling contaminated objects must wear the appropriate personal protective equipment.

- Isolate the affected negatives, including the envelopes and boxes in which they are housed. If the negatives are not wet or damp, put them into plastic bags and seal them thoroughly. If an entire collection is affected, the room in which it is housed should be quarantined. It is important to limit the spread of mould spores throughout the entire facility. Doorways should be covered with plastic sheeting and taped off, as should air vents and air return ducts.

- Determine the extent of the mould outbreak. Consider the available resources and determine whether the infestation can be handled in-house or if outside help is required. If the problem is extensive, professional mould remediation services should be called upon. They will have the equipment and expertise to deal with it. The area must be kept off-limits until the clean-up has been completed, whether it is extensive or small and contained.

- Determine the cause of the mould outbreak. Is it mould that developed in the distant past, when the negatives were stored in adverse conditions, or is it the current environment that needs to be fixed? Moving the material to a more appropriate space may be required if the environment cannot be brought under control.

- Control the spread of the mould. Before being removed from negatives, mould needs first to be deactivated. This may involve freezing the affected materials or thoroughly drying them by reducing the humidity, lowering the temperature and increasing air circulation. Negatives that are to be frozen must first be placed in plastic bags with tight seals that provide no air exchange. This ensures that the mould will not be spread around and that the humidity is controlled. Any condensation that forms when the bag is removed from the freezer will deposit on the plastic and not on the negatives. They therefore must be kept in the bag until the interior temperature climbs above the dew point. The dew point is described as the atmospheric temperature (varying according to pressure and humidity) below which water droplets begin to condense and dew can form. Once the object is dry, mould can be removed. Keep the dry object isolated and in a sealed container until it can be cleaned. This will prevent any inactive but still viable spores from dispersing.

- It is important that you know your capacity to manage the mould outbreak. Large-scale mould remediation projects should be carried out by companies that specialize in it. Small projects can be carried out on-site, provided the appropriate equipment is available. Class 1 biological safety enclosures are designed for cleaning mould-contaminated objects. Careful, thorough vacuuming of affected negatives is the best way to remove visible mould growth. Vacuum cleaners used indoors must contain HEPA filtration systems. Every item should be cleaned individually and new sleeves and boxes provided. Contaminated sleeves and boxes must be discarded. Further surface cleaning of negatives should be referred to a photograph conservator.

More information, including a detailed methodology for the removal of visible mould growth from objects, is provided in Technical Bulletin 26 Mould Prevention and Collection Recovery: Guidelines for Heritage Collections.

Health and safety guidelines for handling degrading plastics

Personal protective equipment

Use a respirator with chemical filters designed to remove organic solvents to protect the respiratory system. Use nitrile, polyethylene, neoprene, latex or nylon gloves when handling cellulose nitrate or cellulose acetate film bases to protect against contact dermatitis.

Ventilation

For short-term exposure, appropriate respirators can be used. For collections-processing and segregation projects where long-term, ongoing exposure is anticipated, fume extraction systems are essential, either permanently installed or portable. Extraction systems should be tested regularly to ensure their efficacy.

General

- Handle objects as little as possible, and use nylon, nitrile, neoprene or vinyl gloves.

- Keep objects in protective sleeves as much as possible to avoid contact.

- View objects in a well-ventilated area.

- When examining or surveying deteriorating collections, wear the appropriate respirator to minimize the ingestion of gases that have evolved due to the deterioration of the film base.

- If fume extraction equipment is available, make sure that it is properly positioned to maximize the removal of evolving gases.

- If the film is badly degraded, wear eye protection as the gases can become irritants to eyes. It is not advisable to wear prescription eyeglasses or contact lenses without goggles.

Safe disposal of film

Deciding on when a film should be destroyed is not always straightforward. With current, highly sophisticated digital copying technologies available, images can be resurrected from badly deteriorated films. However, there comes a point when saving the original is no longer an option as the risks posed by holding on to it outweigh its value as an artifact. If the film is badly degraded and a good copy has been made, even though cold storage may be an option, you must evaluate the long-term commitment to that negative, its value in its deteriorated state and how averse to risk your institution might be.

Disposal of deteriorated cellulose nitrate film must be done by a registered professional company that follows government-based guidelines for disposal. Cellulose nitrate film should never be discarded into ordinary garbage containers for standard disposal. Destruction must only be carried out by a certified agency, and the local fire commissioners should be consulted for information on any special regional requirements. You must handle unstable or deteriorated cellulose nitrate films much like you would handle explosives. The optimal approach is to keep such films underwater in a steel drum until disposal can be arranged.

Never attempt to burn cellulose nitrate film, even in the open. It is extremely dangerous, and burning it in an enclosed stove or furnace must never be considered. The rate of combustion of nitrate is 15 times that of wood, with the result that explosive-like forces can occur. As cellulose nitrate burns, it releases chemically bound oxygen that sustains fire. Therefore, attempting to extinguish it by depriving it of oxygen is futile as the fire will continue until the cellulose nitrate is completely consumed.

Unlike cellulose nitrate film, the disposal of cellulose acetate does not carry the same stringent requirements. Local waste disposal requirements should be consulted if large quantities are to be destroyed.

Treating plastic film-based negatives

Negatives represent the photographer’s intent. They are the camera originals and, as such, are unique, demanding very considered thought regarding their handling and treatment.

Surface cleaning

Often, negatives require surface cleaning to remove dust and accretions in order to maximize the quality of the print or scan. Dust removal is a process of little intervention, but it can result in surface damage. As tough as gelatin emulsions may appear to be, they are vulnerable to mechanical damage, such as scratching, particularly if degraded.

Prior to any re-housing or scanning projects involving negatives, provide as dust-free an environment as you possibly can. Surfaces need to be thoroughly vacuumed and wiped down to eliminate abrasive materials.

Start the cleaning process by putting on gloves. Fingerprints are very damaging to gelatin emulsions, often leading to permanent staining and etching of the gelatin. Lint-free cotton, nitrile, nylon, latex and polyethylene gloves all provide protection for the negative as well as for the operator or conservator.

Mould is occasionally found in photograph collections, whether they be prints, negatives, transparencies or glass plates. Gelatin is a rich source of nutrients and poor environments can promote the propagation of mould, which presents a significant health risk. If mould is found in a collection, the number one concern is human safety. Refer to the Mould section for more details on the presence and removal of mould in photographic negative collections.

Loose surface dirt and dust can be easily removed using compressed air delivered by a bulb blower, gas duster or compressed air duster (Figure 24). Do not attempt to blow off the dirt, as it will invariably result in the dispersion of minute dots of saliva.

© Government of Canada, Canadian Conservation Institute. CCI 122361-0094

Figure 24. A conservator dusts a negative with an antistatic brush and canned air.

Some physical manipulation may be needed to dislodge more tenacious particulates adhered to the surface. One can use soft bristle brushes as employed in watercolour painting or soft micro-fibre dusting cloths, provided they are clean and only light pressure is applied.

Static electricity can cause substantial dust build-up. Anti-static cloths and brushes can work very well for dissipating static charges. They must be kept very clean, and the bristles and cloth should not be touched with bare hands to avoid transfer of skin oils.

Grease on the surface of the negative, including fingerprints, can be removed using solvent cleaning fluids considered safe with emulsions and bases. There are numerous products on the market, such as PEC-12, a waterless emulsion cleaner. It is a blend of organic hydrocarbon solvents, has a neutral pH and is free from chlorofluorocarbons and chlorinated hydrocarbons. It dries instantly, leaving no residue, and can be applied with an accompanying product, PEC*PADS, which are lint-free cotton pads, or with cotton swabs (only to be used once per application). Solvent-based cleaners need to be used in well-ventilated areas. Respirators with organic solvent filters are recommended, along with protective eyewear and chemical-resistant gloves, such as nitrile gloves.

Grease or oil was often applied to the surface of the emulsion prior to retouching. This improved the adhesion of the graphite retouch medium to the emulsion surface (Figures 25 and 26). These areas of retouch can be vulnerable to solvent and aqueous treatment and should be avoided when cleaning the surface.

© Government of Canada, Canadian Conservation Institute. CCI 122361-0050

Figure 25. Graphite retouching media has been applied to the faces in this image. Grease has been applied to the surface of the emulsion to facilitate adhesion of the graphite.

© Government of Canada, Canadian Conservation Institute. CCI 122361-0030

Figure 26. The grease applied to the face of this sitter is matte compared to the glossy surface of the rest of the negative.

Do not use water-based cleaning methods unless you are an experienced photograph conservator. Water will soften the emulsion and greatly increase the risk of damaging it. As gelatin becomes more degraded, it tends to become more water-soluble. Depending on the degree of deterioration, clean cotton swabs dampened with a mixture of ethanol and distilled water can be gently rolled across the surface to lift tenacious water-soluble accretions. This should only be carried out by a trained conservator.

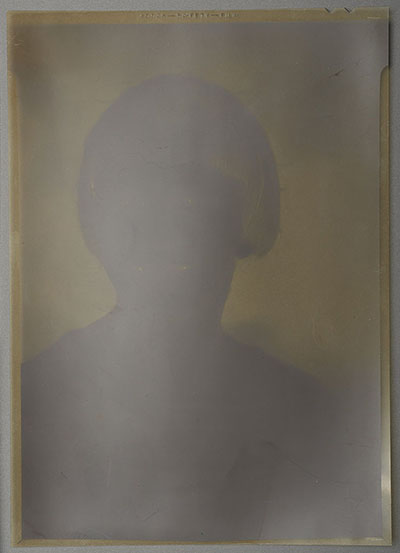

Separating the emulsion from the plastic base (stripping)

The deterioration of a plastic film base will eventually lead to the destruction of the gelatin emulsion and the image will be lost. This stands true for both cellulose nitrate and cellulose acetate.

In the case of cellulose acetate, before total destruction of the image occurs, the image gradually obscures as the plastic support shrinks, causing the gelatin layers to blister and channel (Figures 27a and 27b). As the levels of acidity increase, the gelatin becomes more and more brittle, eventually crumbling to the touch. Before the gelatin is weakened and embrittled by high acidity levels, it retains considerable strength, allowing for its removal from the plastic base. The separated emulsion layer, referred to as the “pellicle,” is strong and chemically stable, as gelatin is known to be. Ideally, a trained conservator will remove the emulsion intact and flatten it, then will scan the negative and place it in permanent storage in a paper or plastic sleeve. Though some small amount of damage often occurs during this treatment, it is generally considered preferable to an image being obscured by channels and blisters or to complete image loss.

Emulsion removal, or stripping, is a labour-intensive process and should be reserved for very significant items from the collection (Figures 28, 29, 30a and 30b). If the negative is of little value, it can be sent to cold storage where the degradative process will be slowed or stopped, and it can then be treated at a later date, as required.

© Government of Canada, Canadian Conservation Institute. CCI 122361-0058

Figure 28. The emulsion layer is removed from a cellulose acetate-based negative. A cellulose acetate film in a late stage of deterioration is treated in a bath of water/ethanol and/or acetone, depending on the solubility of the subbing layer, in order to remove the plastic layer.

© Government of Canada, Canadian Conservation Institute. CCI 122361-0059

Figure 29. Once removed, the emulsion layer is taken out on silicone-release Mylar.

This treatment is meant for cellulose acetate material only and is not a treatment that can or should be carried out by anyone other than a professional conservator. Every negative is different. Slight variations in manufacturing techniques and materials, age as well as storage and use history require adjusting the treatment, to some extent, with each negative or batch of negatives to ensure minimal impact and reduce risks. To handle and treat an object is to put it at risk. Consequently, one must clearly understand the implication of treatment and thoroughly analyze every aspect of it.

The manner in which cellulose nitrate film deteriorates generally does not allow for separation of the different layers. The removal of a cellulose nitrate film base from a negative can be accomplished by first carefully dissolving the anti-curl layer from the verso, followed by the dissolution of the cellulose nitrate base itself using strong, toxic chemicals (Hendricks 1991). This is rarely done, and only carried out by trained conservators, but would be a potential option for high-value items. The process of deterioration of cellulose nitrate differs from that of cellulose acetate in the sense that it does not blister and channel but rather dissolves into a sticky brittle mass. The more degraded it becomes, the more the image is obscured. However, the images are often salvageable through scanning, even in advanced stages of deterioration. Although the scanned image will show the damage of the negative, basic information will still be retrievable. Scanning followed by freezing is definitely the preferred option in the case of deteriorating cellulose nitrate.

Storing plastic film-based negatives

The chemical stability of cellulose nitrate and cellulose acetate is very much influenced by temperature and RH. Research has shown that the control of humidity alone can increase the longevity of the plastic film base by a factor of three to four. Controlling the temperature, on the other hand, can provide a much more significant benefit, particularly so when the humidity is also lower. Ambient to high temperatures and RH can greatly accelerate the rate of deterioration. Lower temperature and lower humidity storage is critical to the negative’s long-term survival. As for polyester, since it is extremely chemically stable, it requires less rigorous temperature and RH standards, though protecting the image silver from oxidation must always be considered.

Cellulose nitrate film is known to be highly flammable and, as a consequence, strict standards for storage are legally applied. NFPA 40, being the only existing standard for the storage of cellulose nitrate film, has been generally adopted internationally, though local jurisdictions can affect the degree to which it is implemented and alter its interpretation. Quantities of film exceeding 11 kg (25 lb.) must be stored in an NFPA 40-compliant manner. Lesser quantities can be stored in the same manner as other plastic films, though segregation is highly recommended.

International standards for the long-term preservation of collections of photographic materials recommend environmental set points for temperature, humidity, air purity and light. These standards, along with recommendations from scientists and other researchers as well as anecdotal information, guide contemporary decision makers on how to maximize the lifespan of these unstable collections through temperature and humidity control. Though 25 years ago the American National Standards Institute may have told us that an environment of 18°C and 25% RH was satisfactory for cellulose acetate film storage (ANSI 1985), experience has shown that, under these conditions, vinegar syndrome can appear and progress.

The recent relaxing or rationalizing of environmental standards for museums and archives has allowed for more flexibility and subsequent cost savings for most institutions. Unfortunately, when storing cellulose nitrate and cellulose acetate, rigorous conditions must continue to be applied, particularly if the process of deterioration has begun.

International Organization for Standardization (ISO) Standards ISO 18934:2011, Imaging Materials – Multiple Media Archives – Storage Environment and ISO 18911:2010, Imaging Materials – Processed Safety Photographic Films – Storage Practices provide recommendations for storage environments that include temperature, humidity and air quality. General temperature categories, taken from ISO 18934:2011, are shown in Table 8 and will be used throughout this bulletin.

| Condition* | Temperature range (°C) |

|---|---|

| Room | 16 to 23 |

| Cool | 8 to 16 |

| Cold | 0 to 8 |

| Sub-zero | -20 to 0 |

| *Assuming 30% RH to 50% RH for each condition | |

| Base material | Recording layer | Minimum RH% | Maximum RH% | Maximum temperature (°C) |

|---|---|---|---|---|

| cellulose nitrate | black and white photo | 20 | 30 | 2 |

| cellulose acetate | black and white photo | 20 | 50 | 2 |

| cellulose acetate | black and white photo | 20 | 40 | 5 |

| cellulose acetate | black and white photo | 20 | 30 | 7 |

| cellulose acetate | colour photo | 20 | 50 | -10 |

| cellulose acetate | colour photo | 20 | 40 | -3 |

| cellulose acetate | colour photo | 20 | 30 | 2 |

| polyester | black and white photo | 20 | 50 | 21 |

| polyester | colour photo | 20 | 50 | -10 |

| polyester | colour photo | 20 | 40 | -3 |

| polyester | colour photo | 20 | 30 | 2 |

Cold storage

Almost all photographic materials benefit from cold storage, including prints and negatives in both black and white and colour. The inherent chemical instability of cellulose nitrate, cellulose acetate and colour photographic dyes is the characteristic at hand in the most well-known and documented examples of the benefits of lower-temperature storage. Much research has been conducted in this area by the Image Permanence Institute, Wilhelm Imaging Research, Mark McCormick-Goodhart and others, all pointing to the essential need for temperature and humidity control in order to provide the highest standard of care.

In the case of deteriorating plastic film bases, humidity-controlled, sub-zero temperature storage is the only recourse to ensure the long-term viability of the material. Sub-zero storage essentially places the collection in a state of suspended animation. Though not strictly true, chemical activity slows down to a point where little degradation occurs. If a comprehensive copying program is implemented prior to the collection being placed in cold storage, it won’t be necessary to remove the material from storage, thus contributing to its long-term survival.

Cool, cold and sub-zero storage environments are expensive, with heavy resource implications. They can be scaled to the size of the collection, with lower-cost solutions often being found for smaller collections.

Important resources for planning cold storage include:

- The Conserve O Grams series from the National Park Service of the U.S. Department of the Interior:

- 14/10 “Cold Storage for Photograph Collections – An Overview” (2009)

- 14/11 “Cold Storage for Photograph Collections – Using Individual Freezer Unit” (2009)

- 14/12 “Cold Storage for Photograph Collections – Vapor-Proof Packaging” (2009)

- Cold Storage: A Long-Term Preservation Strategy for Film-Based Photographic Materials (online tool)

Acclimatization

When negatives that have been placed in cold or sub-zero storage are requested for viewing, they must be gradually warmed to ambient temperature prior to being unwrapped. Condensation can thoroughly wet an object transferred directly from cold storage to ambient room temperature. The air around the object is warm and therefore has a higher moisture content than the cold air. As the warm air contacts the cold object, the water condenses out of the air; liquid water is then deposited on the surface of the object. This occurs when the change in temperature from cold to warm crosses the dew point.

Items properly wrapped for humidity control in cold or sub-zero environments can be left wrapped in the warm air until the entire bundle has warmed to the ambient room temperature (4–24h). If the cold storage environment is fully humidity-controlled and the negatives are not wrapped, they must be bagged prior to being removed from the cold conditions and again allowed to sit until the entire bundle has reached room temperature. Alternatively, insulated and sealed picnic coolers can be used. Unwrapped items can be placed in a sealed cooler in the freezer; then, the cooler can be brought into the warm room and allowed to sit closed until its interior temperature reaches that of the room. Thermocouples with an external reader can be employed to monitor the interior temperature.

Without acclimatization, the photographic gelatin can become saturated with water, resulting in the softening of the gelatin, which, in turn, can precipitate sticking and blocking of the negatives. This is particularly devastating for degraded films where the gelatin may be already compromised and may be rendered more soluble.

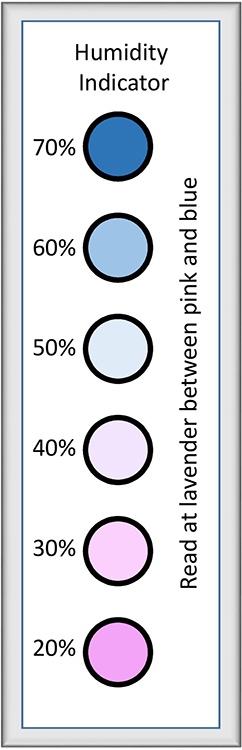

Humidity control in cold storage

The influences of—and the relationships between—temperature, RH, equilibrium moisture content (EMC) and atmospheric pressure must all be considered when investigating environments that promote the long-term stability of photographs.