Risk management scope for TPHP, BPDP, BDMEPPP, IDDP, IPPP and TEP

Official title: Risk Management Scope for Phosphoric acid, triphenyl ester [TPHP], Phosphoric acid, (1,1-dimethylethyl)phenyl diphenyl ester [BPDP], Phosphoric acid, bis[(1,1-dimethylethyl)phenyl] phenyl ester [BDMEPPP], Phosphoric acid, isodecyl diphenyl ester [IDDP], Phenol, isopropylated, phosphate (3:1) [IPPP], and Phosphoric acid, triethyl ester [TEP]

Chemical Abstracts Service Registry Numbers (CAS RN):

- 115-86-6

- 56803-37-3

- 65652-41-7

- 29761-21-5

- 68937-41-7

- 78-40-0

Environment and Climate Change Canada

Health Canada

November 2021

Summary of proposed risk management

This document outlines the risk management options under consideration for substances in the Flame Retardants Group that have been proposed harmful to the environment and/or human health. The aryl organophosphate (OP) subgroup (TPHP, BPDP, BDMEPPP, IDDP, and IPPP) has been proposed to be harmful to the environment. IPPP has also been proposed to be harmful to human health. Additionally, one substance in the alkyl OP subgroup, TEP, has been proposed to be harmful to human health. The Government of Canada is proposing:

- The implementation of regulatory measures to minimize the release of aryl organophosphate subgroup substances from industrial processing activities and from products available to consumers via wastewater to the Canadian environment.

- The implementation of regulatory or non-regulatory actions to help reduce dermal exposure of infants and children to IPPP and of the general population to TEP in certain products made with polymeric foams such as polyurethane foam. These products may include upholstered furniture, mattresses, mattress toppers, infant or child restraint seats and other foam-based products to which prolonged skin contact may be expected.

Moreover, because certain data gaps remain, the following information should be provided (ideally on or before January 5, 2022) to the contact details identified in Section 8 of this document, to inform risk management decision-making:

- Quantity and current use of aryl OP subgroup substances by Canadian importers/exporters of the substances and products or manufactured items containing TPHP, BPDP, BDMEPPP, IDDP, and IPPP;

- The use of IPPP and TEP in textiles, including textile backings in furniture;

- The use of IPPP and TEP in polymeric foams other than polyurethane foams, which may be used in products such as furniture, mattresses, and other foam-based products to which prolonged skin contact may be expected;

- Changes to Flame Retardants Group (TPHP, BPDP, BDMEPPP, IDDP, IPPP, and TEP) use patterns and economic impacts; and

- Chemical and non-chemical alternatives to TPHP, BPDP, BDMEPPP, IDDP, IPPP, and TEP.

The risk management options outlined in this Risk Management Scope document may evolve through consideration of assessments and risk management options or actions published for other Chemicals Management Plan (CMP) substances as required to ensure effective, coordinated, and consistent risk management decision-making.

The Flame Retardants Group consists of ten substances. Two substances, TBOEP and TDBDPB, are associated with ecological effects of concern, but for which environmental exposure is not of concern at current levels. Options are being considered for follow-up activities to track changes in environmental exposure to these two substances.

Note: The above summary is an abridged list of options under consideration to manage these substances and to seek information on identified gaps. Refer to section 3 of this document for more complete details in this regard. It should be noted that the proposed risk management options may evolve through consideration of additional information obtained from the public comment period, literature and other sources.

1. Context

The Canadian Environmental Protection Act, 1999 (CEPA) (Canada 1999) provides the authority for the Minister of the Environment and the Minister of Health (the Ministers) to conduct assessments to determine if substances are toxic to the environment and/or harmful to human health as set out in section 64 of CEPAFootnote 1, Footnote 2 and if so, to manage the associated risks.

The six substances, listed in Annex A, are included in the Flame Retardants Group of the third phase of the Chemicals Management Plan (Canada, 2016).

2. Issue

Health Canada and Environment and Climate Change Canada conducted a joint scientific assessment relevant to the evaluation of Flame Retardants in Canada. A notice summarizing the scientific considerations of the draft screening assessment for these substances was published in the Canada Gazette, Part I, on November 6, 2021 (Canada 2021). For further information, refer to the draft screening assessment for the Flame Retardants Group.

2.1 Draft screening assessment conclusion

On the basis of the information available, the draft screening assessment proposes that substances in the aryl OP subgroup (TPHP, BPDP, BDMEPPP, IDDP, and IPPP) are toxic under section 64(a) of CEPA as they are entering or may enter the environment in a quantity or concentration or under conditions that have or may have an immediate or long-term harmful effect on the environment or its biological diversity. IPPP is also proposed toxic under section 64(c) as it is entering the environment in a quantity or concentration or under conditions that constitute or may constitute a danger in Canada to human life or health (ECCC, HC 2021).

Within the alkyl OP subgroup, TEP is proposed toxic under section 64(c) of CEPA.

The draft screening assessment also proposes that TPHP and TEP meet the criteria for persistence but do not meet the criteria for bioaccumulation. BPDP and IDDP do not meet the persistence criteria or the bioaccumulation criteria, and BDMEPPP and IPPP do not meet the persistence criteria but do meet the bioaccumulation criteria, as defined in the Persistence and Bioaccumulation Regulations made under CEPA (Canada 1999).

TBOEP and TDBDPB do not meet section 64 of CEPA, but have been identified for follow-up action due to potential for concern should environmental exposure levels increase.

| Sub group | Substance | Proposed Conclusion | Persistence (P) or Bioaccumulation (B) | Proposed follow-up action |

|---|---|---|---|---|

| Aryl Organo phosphate | TPHP (triphenyl phosphate) | Meets s. 64 (a) criteria | P | Regulatory action (see section 3.3) |

| Aryl Organo phosphate | BPDP (tert-butylphenyl diphenyl phosphate) | Meets s. 64 (a) criteria | - | Regulatory action (see section 3.3) |

| Aryl Organo phosphate | BDMEPPP (bis(tert-butylphenyl)phenyl phosphate) | Meets s. 64 (a) criteria | B | Regulatory action (see section 3.3) |

| Aryl Organo phosphate | IDDP (isodecyl diphenyl phosphate) | Meets s. 64 (a) criteria | - | Regulatory action (see section 3.3) |

| Aryl Organo phosphate | IPPP (isopropylated triphenyl phosphate) | Meets s. 64 (a) and (c) criteria | B | Regulatory and/or non-regulatory action (see section 3.3) |

| Alkyl Organo phosphate | TEP (triethylphosphate; Triethyl Phosphate) | Meets s. 64 (c) criteria | P | Regulatory and/or non-regulatory action (see section 3.3) |

| Alkyl Organo phosphate | TBOEP (tris(2-butoxyethyl) phosphate) | Does not meet s. 64 criteria | - | Identified for follow-up action due to potential for concern should environmental exposure levels increase |

| Alkyl Organo phosphate | TEHP (tris(2-ethylhexyl) phosphate) | Does not meet s. 64 criteria | - | No further action |

| Alkyl Organo phosphate | BEHP (bis (2-ethylhexyl phosphate; bis (2- ethylhexyl) hydrogen phosphate) | Does not meet s. 64 criteria | - | No further action |

| Individual | TDBDPB (tetradecabromo- 1,2- diphenoxybenzene; perbromo- 1,4 diphenoxybenzene) | Does not meet s. 64 criteria | - | Identified for follow-up action due to potential for concern should environmental exposure levels increase |

The environmental risks of concern, identified in the draft screening assessment for TPHP, BPDP, BDMEPPP, IDDP, and IPPP are based on the potential release of flame retardants from industrial processing activities and consumer product emissions, via wastewater to surface water, and via application of biosolids to land. Aryl OP subgroup substances are considered to have high toxicity to aquatic organisms with acute and chronic effects at low concentrations. TPHP/BPDP/BDMEPPP mixture and IPPP UVCB data also indicate moderate to high toxicity in soil and sediment. Additionally, recent studies suggest that the substances in the aryl OP subgroup may induce neurobehavioral effects as well as endocrine related effects in biota. As such, this document will focus on these activities/applications/risks and exposure sources of concern (refer to section 5).

The exposure sources of concern for human health, identified in the draft screening assessment, are dermal exposures to IPPP and TEP from certain products made with polyurethane foam (PUF), a type of polymeric foam. Specifically, the potential concerns are for infants and children who have prolonged skin contact with certain manufactured products made from PUF that contain IPPP, as well as for people of all ages who have prolonged skin contact with certain manufactured products made from PUF that contain TEP. These products may include upholstered furniture, mattresses, mattress toppers, and other foam–containing mattresses or furniture products with which prolonged skin contact may be expected. A potential concern for infants and children who have prolonged skin contact with infant or child restraint seats that contain TEP was also identified. As such, this document will focus on these exposure sources of concern (refer to section 5).

2.2 Proposed recommendation under CEPA

On the basis of the findings of the draft screening assessment conducted under CEPA, the Ministers propose to recommend that TPHP, BPDP, BDMEPPP, IDDP, IPPP, and TEP be added to the List of Toxic Substances in Schedule 1 of the ActFootnote 3.

The Ministers will take into consideration comments made by stakeholders during the 60-day public comment period on the draft screening assessment for the Flame Retardants Group and the associated Risk Management Scope document.

If the Ministers finalize the recommendation to add TPHP, BPDP, BDMEPPP, IDDP, IPPP, and TEP to Schedule 1, risk management instruments will be proposed and finalized within a set period of (refer to section 8 for publication timelines applicable to this group of substances).

3. Proposed risk management

3.1 Proposed environmental and human health objectives

Environmental and human health objectives are quantitative or qualitative statements of what should be achieved to address environmental and human health concerns.

For the substances in the aryl OP subgroup, the proposed objective is focused on addressing the risks/exposure sources of ecological concern outlined in section 5 of this document. As such, the proposed objective for the aryl OP subgroup is to reduce the concentration of aryl OP subgroup substances in the aquatic environment and sediment to levels below the predicted no-effect concentration (PNEC) of 0.37µg/L and 0.37 mg/kg dw respectively.

The proposed human health objectives are to reduce exposure of infants and children to IPPP to levels that are protective of human health; and to reduce exposure of people of all ages (including infants and children) to TEP to levels that are protective of human health.

3.2 Proposed risk management objectives

Risk management objectives set quantitative or qualitative targets to be achieved by the implementation of risk management regulations, instruments and/or tools for a given substance or substances. The risk management objectives set in sections 3.2.1 and 3.2.2 will be refined based on consultation with stakeholders, the proposed risk management, consideration of further information received, the outcome of the final screening assessment, and socio-economic and technical considerations (such as may be outlined in section 6 of this document). Revised environmental and risk management objectives will be presented in the Risk Management Approach document that will be published concurrently with the final Screening Assessment Report (fSAR) for the Flame Retardants (including TPHP, BPDP, BDMEPPP, IDDP, IPPP, and TEP), or in subsequent risk management documents (e.g., consultation document on proposed instrument).

3.2.1 Environmental risk management objectives

The proposed environmental risk management objective for the aryl OP subgroup is to achieve the lowest level of releases that is technically and economically feasible, taking into consideration socio-economic factors.

3.2.2 Human health risk management objectives

The proposed human health risk management objective for IPPP and TEP is to help reduce dermal exposure of infants and children to IPPP from foam-containing mattresses or furniture, and infants and children to TEP from infant or child restraint seats, and to help reduce dermal exposure of people of all ages, including infants and children, to TEP from foam-containing mattresses or furniture.

3.3 Proposed risk management options under consideration

To achieve the proposed environmental risk management objectives and to work towards achieving the proposed environmental objectives, the risk management option under consideration for the aryl OP subgroup is:

- Regulatory measures to minimize the release of the substances from industrial processing activities and from products available to consumers via wastewater to the Canadian environment.

To achieve the proposed human health risk management objective and to work towards achieving the proposed human health objective, the risk management options under consideration are:

- Regulatory or non-regulatory actions to help reduce dermal exposure of infants and children to IPPP, and people of all ages, including infants and children, to TEP in certain products made with polymeric foams such as polyurethane foam. These products include:

- IPPP: Upholstered furniture, mattresses, mattress toppers, and other foam-containing products with which prolonged skin contact may be expected.

- TEP: Infant or child restraint seats made with polymeric foam, and upholstered furniture, mattresses, mattress toppers, and other foam-containing products with which prolonged skin contact may be expected.

Note that the proposed risk management options described in this document are preliminary and subject to change. Following the publication of this document, additional information obtained from the public comment period and from other sources will be considered, along with the information presented in this document, in the instrument selection and development processFootnote 4. The risk management options outlined in this document may also evolve through consideration of assessments and risk management options or actions published for other CMP substances to ensure effective, coordinated, and consistent risk management decision-making.

3.4 Performance measurement and evaluation

Performance measurement evaluates the ongoing effectiveness and relevance of the actions taken to manage risks from toxic substancesFootnote 5. The aim is to determine whether human health and/or environmental objectives have been met and whether there is a need to revisit the risk management approach for that substance, so that risks are managed effectively over time. To achieve this, the Government of Canada will review the effectiveness of the risk management actions for the Flame Retardants Group.

The Government of Canada plans to measure the effectiveness of the risk management actions by collecting and analyzing data to evaluate progress towards meeting the risk management objective.

In addition, the Government of Canada plans to collect and analyze data, such as monitoring data obtained from the Monitoring and Surveillance Program on the presence of the aryl OP subgroup in the aquatic environment and sediment in order to establish a baseline environmental presence, and again over time to measure progress towards meeting the environmental objectives.

The results of performance measurement and evaluation will be used to inform whether further risk management action is warranted and will be made available to Canadians along with recommendations for further action, if applicable.

3.5 Risk management information gaps

Interested stakeholders are invited to provide further information, as outlined below, to inform risk management decision-making regarding the Flame Retardants Group:

- Quantity and current use of aryl OP subgroup substances (TPHP, BPDP, BDMEPPP, IDDP, and IPPP) by Canadian importers/exporters in different products (e.g., adhesives and sealants, paints and coatings, lubricants and greases, and plastic and rubber formulation) including:

- Location of each industrial facility, and their annual quantity of import/export/production/usage for each aryl OP subgroup substances or their annual quantity and concentration for each aryl OP subgroup substances-containing products for 2017 and 2018;

- A description of the specific uses of these substances for these applications;

- Industrial use information, specifically on the use of aryl OP subgroup substances in the plastic (i.e., compounding and conversion) and rubber formulation, and in the formulation of lubricants and greases;

- Releases of aryl OP subgroup substances to the Canadian environment, including from landfill leachate;

- Annual quantity and concentration of aryl OP subgroup substances-containing products sold to downstream users, along with their sector(s) of activity;

- Industrial uses of aryl OP subgroup substances-containing products, other than the activities listed above;

- Characterization of aryl OP subgroup substances in final wastewater effluents released from facilities; and

- Best management practices and technologies in place to reduce the risk of aryl OP subgroup substances released to the environment from industrial facilities.

- The use of IPPP and TEP in textiles, including textile backings in furniture.

- The use of IPPP and TEP in polymeric foams other than polyurethane foams, which may be used in products such as furniture, mattresses, and other foam-based products to which prolonged skin contact may be expected.

- Changes to Flame Retardants Group (TPHP, BPDP, BDMEPPP, IDDP, IPPP and TEP) use patterns and economic impacts, including:

- Anticipated economic impacts if the import/export and/or use of the flame retardants in question are prohibited or restricted in Canada;

- Ongoing or anticipated changes in use of the above flame retardants, whether in response to:

- Market forces;

- Shifts to alternative substances (please provide commercial name), alternative systems and approaches;

- Changes in performance-based flammability requirements and/or standards; and/or

- Other reasons (please provide information on these reasons).

- Chemical and non-chemical alternatives to TPHP, BPDP, BDMEPPP, IDDP, IPPP, and TEP

Details on chemical alternatives and/or technologies to the above flame retardants and their feasibility, as applicable to Canadian importers for use in adhesives and sealants, paints and coatings, lubricants and greases, plastic and rubber formulation, food packaging materials, cosmetics, pest control products, polymeric foams and others (please specify).

Data collection initiatives (such as section 71 surveys or informal data gathering) may be undertaken to collect additional information on the six substances to inform risk management decision making.

Should stakeholders have further information to help address these gaps, they should provide it ideally on or before January 5, 2022 to inform the risk management decision-making process, within the timelines (and to the contact) identified in section 8 of this document.

4. Background

4.1 General information on flame retardants

The five substances (TPHP, BPDP, BDMEPPP, IDDP, and IPPP) of the aryl OP subgroup are part of the organophosphate substances addressed in the Flame Retardants Group draft screening assessment. They are organophosphate esters containing two to three aryl groups (i.e., diaryl or triaryl, respectively). The aryl groups can have varying degrees of alkyl substitution. BPDP and BDMEPPP are both structural analogs of TPHP containing tert-butyl groups. IPPP is a UVCB (Unknown or Variable composition, Complex reaction products, or Biological materials) of potentially over 50 isomers of isopropylated triphenyl phosphates in which TPHP is a main component (5 – 50%) (US EPA 2010; EA 2009; Sjögren et al. 2009). The assessment approach used for IPPP was to consider two representative component structures; TPHP which represents the more water soluble components, and tris(3-isopropylphenyl) phosphate (T3IPPP) which represents the less water soluble/more hydrophobic components. IDDP varies slightly in structure in that it is the only alkyldiaryl phosphate ester assessed in the aryl OP subgroup. Many of the substances in the aryl OP subgroup have been identified in commercially available flame retardant mixtures (McGee et al. 2013; Phillips et al. 2017).

TEP is part of the alkyl OP subgroup addressed in the screening assessment. Substances in the alkyl OP subgroup contain three alkyl substituents, with alkyl chain length and branching varying throughout the subgroup. TEP is a phosphate ester that contains three ethyl groups.

The five aryl OP substances addressed in the screening assessment and the alkyl OP, TEP, are synthetically produced and do not occur naturally in the environment.

4.2 Current uses and identified sectors

OP flame retardants are a widely used class of flame retardants for which global consumption reached approximately 290 000 000 kg in 2011 (Du et al. 2015). Use information in Canada for substances in the aryl OP subgroup was obtained in part through surveys pursuant to a CEPA section 71 notice (Environment Canada 2009, 2012). An additional survey with key industry stakeholders was also conducted in 2016 (ECCC 2016a) to further refine quantity and use estimates for aryl OPs.

According to information submitted in response to surveys under section 71 of CEPA (Environment Canada 2009, 2013), the quantities of TPHP, IDDP, and IPPP imported into Canada were each reported to be in the range of 100 000 – 1 000 000 kg. BPDP and BDMEPPP were each reported to be imported into Canada in the range of 10 000 – 100 000 kg. TPHP, IDDP, and IPPP were identified as High Production Volume Chemicals (HPV) by the OECD (ECHA c2007-2018a; ECHA c2007-2018b; ECHA c2007-2018c).

Results from industry surveys indicate that none of the aryl OPs were manufactured in Canada; however, 30 companies reported importing substances in the aryl OP subgroup into Canada in each of the 2008, 2011, 2015 reporting years (Environment Canada 2009, 2013; ECCC 2016b).

In Canada, aryl OPs are used as additive flame retardants and/or plasticizers in a number of applications involving hydraulic fluids, lubricants, plastics, synthetic rubber, textiles, foam, paints and coatings, adhesives and sealants, and building materials. As plasticizers, aryl OPs are used to impart low temperature flexibility in polyvinylchloride (PVC), PUF, and thermoplastic materials (Marklund 2005). IPPP like TPHP has been identified as a component in commercially available flame retardant blends such as Firemaster 550 (FM 550), Reofos 35 and Reofos 65 (Chemtura 2018a, b), and Phosflex 41 (ICL-IP 2018) (McGee et al. 2013; Phillips et al. 2017). Other applications of aryl OPs include the potential use of TPHP and IDDP in food packaging applications, and as pest control formulants, and TPHP in cosmetics.

According to information submitted in response to surveys under section 71 of CEPA (Environment Canada 2013), the quantities of TEP imported into Canada were in the range of 100 000 – 1 000 000 kg. There was no reported domestic manufacture of TEP within the same reporting year.

Like the substances in the aryl OP subgroup, TEP is primarily used as an additive flame retardant and/or plasticizer. In Canada, TEP may also be used as a component in certain food packaging materials. TEP can be used as a formulant in pest control products, and has been identified in adhesives and sealants, paints and coatings, and building materials.

5. Exposure sources and identified risks

5.1 Environmental exposure sources and identified risks

Aryl OPs are synthetically produced substances. Anthropogenic releases to the environment may occur during the manufacture and processing, including transportation and storage, and industrial use. Releases to the environment from industrial activities are expected from point sources such as processing facilities and wastewater treatment systems (WWTS) where subsequent release is expected to occur primarily to water and sediment compartments. Releases to soil could also occur through the application of WWTS biosolids to agricultural lands.

Releases to the environment may also result from consumer or commercial use of products that contain OP flame retardants. Based on their applications as additive flame retardants and plasticizers in consumer and industrial products, OP flame retardants are also expected to enter the environment through disperse releases from the use and disposal of products available to consumers, for instance, leaching from PVC and PUF products or hydraulic fluid bleeding. Of the substances within the aryl OP subgroup, TPHP was the only substance in monitoring and surveillance studies to be present in remote areas. Environmental concentrations of TPHP have been detected in the air in the remote Canadian Arctic supporting that TPHP can be considered persistent in air. It is still unknown whether TPHP is reaching remote areas due to particle bound long-range transport or due to local sources such as hydraulic fluids in ships and aircraft.

The substances in the aryl OP subgroup are generally not expected to be highly persistent in water, soil or sediment; however, relatively slow ultimate degradation has been identified for BDMEPPP and IPPP. Metabolism rates are generally slower with increased alkyl substitution and hydrophobicity. BDMEPPP and IPPP, which have the greatest degree of alkyl substitution, demonstrated a relatively slow ultimate degradation.

Aryl OPs are considered to have high toxicity to aquatic organisms with acute and chronic effects observed at < 1 mg/L. Sediment and soil toxicity data are limited for the individual substances; however, TPHP/BPDP/BDMEPPP mixture and IPPP UVCB tests provide evidence for moderate to high toxicity in those media as well.

Studies suggest that substances in the aryl OP subgroup may have a potential for neurotoxic effects based on structurally similar OP substances shown to affect brain development (Shi et al. 2018; Jarema et al. 2015; Noyes et al. 2015). Additionally, endocrine-disrupting properties, with evidence of disruptions to the reproductive system, and thyroid systems in fish have been highlighted in recent studies (Liu et al., 2013; Zhang et al. 2014; Kim et al. 2015).

5.2 Human health exposures and identified risks

Exposure of the general population to IPPP is primarily from certain products available to consumers made with flexible foam, although environmental media and food may also contribute to exposure. Since it is a UVCB comprised of various isomers, identifying IPPP can be difficult. A study by the Commission for Environmental Cooperation (CEC) on flame retardants in foam-containing furniture from Canada, the US and Mexico detected the TPHP component of IPPP in foam-containing furniture (CEC 2015a). The isopropylated component of the IPPP UVCB was not detected. However, other studies have identified the commercial flame retardant mixture Firemaster 550 in products made with soft PUF, including upholstered furniture and mattresses (Stapleton et al. 2009; 2012). Given that IPPP is a component of the Firemaster 550 commercial blend (Weil and Levchick 2004; Phillips et al. 2017), it is expected that IPPP is present in these product types (ECCC, HC 2021).

The critical effect associated with exposure to IPPP is adverse effects on the adrenal glands and liver. Reproductive effects were also observed after exposure to IPPP. Exposure to IPPP from environmental media and food was evaluated in the draft screening assessment, based on the presence of different IPPP isomers, and was not identified as a concern to human health.

Direct exposures to IPPP from the use of products were evaluated. Product scenarios that resulted in the highest levels of potential exposure were presented in the draft screening assessment. Oral exposure through mouthing of foam in children’s products such as toys was not found to be a concern. However, dermal exposure to IPPP from prolonged skin contact with foam-containing furniture or mattresses was identified as a concern for infants and children (ECCC, HC 2021). No other sources of exposure to IPPP were identified as a concern.

Exposure to TEP from environmental media and food was estimated in the draft screening assessment, but was not identified as a concern. Exposure of the general population to TEP is predominantly from certain products available to consumers. TEP was found in 10 of 15 popular infant and child restraint seats tested in the US. It was found in the rigid foam component of the restraint seat, the fabric component, and in one case, the Velcro component (Miller and Gearhart 2016).

The critical effect for exposure to TEP is adverse effects on the liver. Direct exposures to TEP from the use of products were evaluated. Product scenarios that resulted in the highest levels of potential exposure were presented in the draft screening assessment. Dermal exposure to oven cleaner containing TEP was not identified as a concern, nor was inhalation of spray foam sealant. Oral exposure through mouthing of foam in children’s products such as toys was not found to be a concern. However, dermal exposure to TEP from prolonged skin contact with infant or child restraint seats was identified as a concern for infants and children. In addition, dermal exposure to TEP from prolonged skin contact with foam-containing mattresses or furniture was identified as a concern for all age groups, including infants and children. No other sources of exposure to TEP were identified as a concern.

6. Risk management considerations

6.1 Alternatives and alternate technologies

Flame retardant substances are generally used to meet performance-based flammability requirements and/or standards. These requirements do not specify that chemical flame retardants need to be used; rather, they may require a product or components thereof to pass a laboratory test such as a cigarette smolder or open flame ignition test. Performance-based flammability requirements exist internationally for various types of products, including electronics, building materials, mattresses and upholstered furniture, among others (UL 2014; ASTM 2014; Canada 2016a; California 2013; US CPSC 2006). They can be regulatory, and may exist at different levels of government (Canada 2016b; California 2013). Voluntary standards for flammability are also developed by independent standard development organizations (ASTM 2014; ISO 2014; UFAC 2014; UL 2014; ULC 2017). Using chemical flame retardants in their products is one means through which companies can help ensure that their products meet performance-based flammability requirements. However, technologies other than chemical flame retardants that allow products to meet performance-based flammability requirements also exist. Products may be made of materials with a low flammability or materials that require lower quantities of flame retardants to meet standards. For example, concentrations of flame retardants tend to be higher in lower density foams, which tend to ignite more easily than higher density foams (CEC 2015b). Materials such as foams may also be covered with a protective barrier made of a material that does not burn easily (US EPA 2005).

Where chemical flame retardants are concerned, a number of factors come into play in determining whether one flame retardant is a good alternative to another. Different flame retardants are appropriate for application to different materials and for different end uses. Their physical and chemical properties affect their ability to meet performance-based flammability requirements as well as the uses in which they can be effective. Flame retardant properties such as pH, viscosity, the ability to mix evenly and stability in exothermic reactions can impact the quality of end products such as foams (CEC 2015b; Danish EPA 2016a). The potential for effects on health and the environment are key considerations in the selection of alternatives. The United States Environmental Protection Agency updated its ‘Design for the Environment’ report comparing the health and environmental properties of a variety of flame retardants for use in flexible PUF in 2015 (US EPA 2015). The Danish Environmental Protection Agency (Danish EPA 2016b) also recently published a report on some flame retardants which may be used in flexible PUF. Finally, cost is also a factor companies consider in decisions regarding alternative flame retardants.

6.2 Socio-economic and technical considerations

Changes to performance-based flammability requirements are affecting the need for chemical flame retardants, particularly flame retardants used in flexible PUF. Companies producing foam may manufacture their foam so that it can pass the most stringent flammability standards for any product in which it is used, even if many of the end products containing the foam are not subject to those stringent flammability standards.

Within North America, California standard Technical Bulletin (TB) 117 previously required that upholstered furniture in the California marketplace pass an open flame test, creating a market for certain flame retardants in flexible PUF (Stapleton et al. 2011; Stapleton et al. 2012). The revised standard, California TB 117-2013 (California 2013), which came into effect on January 1, 2015, no longer requires an open flame test, but still requires a cigarette smoulder test. It also allows for the use of barrier materials in upholstered furniture to allow the furniture to pass the flammability tests.

Two federal flammability standards exist for mattresses in the US: The Standard for the Flammability of Mattresses and Mattress Pads, 16 CFR 1632 (eCFR, 2017); and the Standard for the Flammability (Open Flame) of Mattress Sets; 16 CFR 1633 (US CPSC, 2006). The standard 16 CFR 1633 was recently reviewed and there were concerns about the possible need for flame retardants to meet either the open flame test or the cigarette smoulder test of standard 16 CFR 1632. The standard 16 CFR 1633 only addresses enclosed resilient material; as such, it does not include uncovered foam mattress toppers or pads (US CPSC, 2006). The Standard 16 CFR 1632 excludes convoluted foam pads which are not totally encased in ticking.

The UK has consulted on proposed changes to its Furniture and Furnishings (Fire) (Safety) Regulations 1988, which could reduce the use of flame retardants and better reflect modern furniture manufacturing processes, while maintaining safety (UK Department for Business, Energy and Industrial Strategy, 2016).

Canada has regulations under the Canada Consumer Product Safety Act (CCPSA) that set out performance-based flammability requirements for mattresses and textile products that are manufactured, imported, sold or advertised in Canada (Canada 2016b, 2016c). As with other performance-based standards, the applicable regulations under the CCPSA do not prescribe how the requirements are to be met. Various options are available to manufacturers, including the use of materials that are less flammable, or that are inherently flame resistant (such as wool), fire barrier systems, or flame retardant chemicals. It is not expected that Canada’s federal flammability requirements for mattresses drive the flame retardant market. Canada does not have a federal flammability standard for upholstered furniture other than mattresses. Uncovered foam mattress pads are not considered mattresses, but may be subject to the Textile Flammability Regulations (Canada 2016c), as they may be considered ‘bedding’ under those regulations.

Infant and child restraint seats are also subject to flammability requirements. In Canada, infant and child restraint seats are regulated under both the CCPSA and the Motor Vehicle Safety Act (Canada 1993). The Motor Vehicle Restraint Systems and Booster Seats Safety Regulations require that infant restraint systems, child restraint systems and booster seats conform to a specific flammability standard, namely Technical Standards Document (TSD) 302 – Flammability of Interior MaterialsFootnote 6 (Transport Canada 2007; Canada 2010). In the US, the Federal Motor Vehicle Safety Standards require that materials used in child restraint systems conform to Federal Motor Vehicle Safety Standard (FMVSS) No. 302: Flammability of Interior Materials (US eCFR 2018c; US eCFR 2018d).

7. Overview of existing risk management

7.1 Related Canadian risk management context

TPHP and IPPP are included in the Pest Management Regulatory Agency (PMRA) Pesticide Formulants List and currently registered in Canada. TEP is on the PMRA Pesticide Formulants List based on historical registration (ECCC, HC 2021; Health Canada 2010). The registration of pest control products is regulated under the Pest Control Products Act in Canada (Canada 2017). The safety of chemicals used in incidental additives and food packaging materials is subject to the provisions of section 4(1)(a) of the Food and Drugs Act (Canada 2018b) and Division 23 of the Food and Drug Regulations.

Note that protective measures pertaining to flame retardants are being proposed under the Canada Consumer Products Safety Act, specifically, a prohibition or restriction of all flame retardants for use in tents under the Tents Regulations, and for use in play tents and other toys under the Toys Regulations (Health Canada, 2019).

7.2 Pertinent international risk management context

7.2.1 United States

Aryl OP subgroup substances are listed on the EPA TSCA chemicals list as active chemicals and have a TP Regulatory Flag, which indicates that the substance is the subject of a proposed Section 4 Test Rule which requires importers and manufacturers to conduct testing on substances (US EPA TSCA 2013). TPHP and IPPP are listed on TSCA Work Plan Chemicals (US EPA TSCA 2014) for chemical assessment.

EPA is proposing a rule to address certain persistent, bioaccumulative, and toxic chemicals (including IPPP) identified pursuant to section 6(h) of the Toxic Substances Control Act (TSCA), which requires EPA to take expedited regulatory action without a risk evaluation for chemicals meeting certain criteria. The proposal would prohibit processing and distribution in commerce of the chemical substance, and products containing the chemical substance with some exceptions (processing and distribution in commerce for use in aviation hydraulic fluid; processing and distribution in commerce for use in lubricants and greases; and processing and distribution in commerce for use in new and replacement parts for automobiles and other motor vehicles, and the distribution in commerce of the parts to which IPPP has been added). In addition, the rule would prohibit releases to water from the non-prohibited processing, distribution in commerce, and commercial use activities. Persons manufacturing, processing, and distributing IPPP, and products containing IPPP in commerce would be required to notify their customers of these restrictions (US EPA 2019)Footnote 7.

IPPP is listed in the EPA design for the environment report to help manufacturers of flexible foam products make informed decisions when considering chemical alternatives (US EPA 2015).

State level action for IDDP, BPDP, and BDMEPPP includes the prohibition of chemical flame retardants in residential upholstered furniture. The act establishes the prohibition on the sale and distribution of new upholstered furniture containing more than 0.1% of a flame retardant chemical or containing more than 0.1% of a mixture containing flame retardant chemicals (Maine 2017).

California State Legislature recently passed legislation that prohibits the sale of specific household products (new covered upholstered furniture, children’s products, mattresses) containing flame retardants above a concentration of 1000 ppm. It also prohibits the repair of upholstered products with foam-containing flame retardants with replacement components containing flame retardants above 1000 ppm. This prohibition will come into effect January 1, 2020 (California 2018).

TEP is permitted as an indirect food additive in the US, in adhesives that may be safely used as components of articles intended for use in packaging, transporting, or holding food in accordance with specific prescribed conditions (US eCFR 2018a).

TEP is approved as a pesticide for food and non-food use (US EPA 2018b). It is listed as a pesticide chemical residue in food that is exempted from the requirement of a tolerance when used in accordance with good agricultural practice as inert (or occasionally active) ingredients in pesticide formulations applied to growing crops only (US eCFR 2018b).

7.2.2 European Union

TPHP is listed on the EU REACH site, which notes that it is on the Public Activities Coordination Tool (PACT) indicating that an analysis or hazard assessment is under development, or has been completed since the implementation of the SVHC (substance of very high concern) Roadmap commenced in February 2013.

TPHP is the subject of the Community Rolling Action Plan (CoRAP) substance evaluation, sponsored by the UK. The assessment was delayed due to a request for additional testing related to the substance being a potential endocrine disruptor to aquatic organisms. A Hazard Assessment and Risk Management Options Analysis (RMOA) sponsored by France is currently under development as well (ECHA 2017).

TPHP, IDDP, BPDP, BDEMEPPP, and IPPP are subject to the Classification, Labelling, and Packaging (CLP) legislation that requires manufacturers, importers, or downstream users of substances or mixtures to classify, label and package their hazardous chemicals appropriately.

Two CAS RN numbers associated with the UVCB IPPP (26967-76-0 and 72668-27-0) are both listed on the European Chemicals Agency (ECHA) Annex III inventory as they are suspected to be bioaccumulative, hazardous to the aquatic environment, persistent in the environment and toxic for reproduction. BPDP and BDMEPPP are also included in the Annex III inventory, as there is indication that both substances could be hazardous to the aquatic environment, hazardous to the environment, and toxic for reproduction (ECHA 2007-2018).

8. Next steps

8.1 Public comment period

Industry and other interested stakeholders are invited to submit comments on the content of this Risk Management Scope or other information that would help to inform decision-making (such as outlined in section 3.2 and 3.3). Please submit additional information and comments prior to January 5, 2022.

The Risk Management Approach document, which will outline and seek input on the proposed risk management instrument(s), will be published at the same time as the final screening assessment. At that time, there will be further opportunity for consultation.

Comments and information submissions on the Risk Management Scope should be submitted to the address provided below:

Environment and Climate Change Canada

Gatineau, Quebec K1A 0H3

Telephone: 1-800-567-1999 (in Canada) or 819-938-3232

Fax: 819-938-5212

Email: substances@ec.gc.ca

Companies who have a business interest in substance within the Flame Retardants Group are encouraged to identify themselves as stakeholders. The stakeholders will be informed of future decisions regarding Flame Retardants and may be contacted for further information.

8.2 Timing of actions

Electronic consultation on the draft screening assessment and Risk Management Scope: November 6, 2021 to January 5, 2022. This should include the submission of public comments, additional studies and/or information on TPHP, BPDP, BDMEPPP, IDDP, IPPP, and TEP.

Publication of responses to public comments on the draft screening assessment and Risk Management Scope: concurrent to the publication of the final screening assessment and, if required, the Risk Management Approach document.

These are planned timelines, and are subject to change. Please consult the schedule of risk management activities and consultations for updated information on timelines.

9. References

[ASTM] ASTM International. 2014. Fire Standards and Flammability Standards.

[California] California Department of Consumer Affairs, 2013. Technical Bulletin 117-2013: Requirements, Test Procedure and Apparatus for Testing the Smolder Resistance of Materials Used in Upholstered Furniture [PDF].

Canada. 1999. Canadian Environmental Protection Act, 1999. S.C., 1999, c. 33. Retrieved October 13, 2017, from Canada Gazette. Part III. vol. 22, no. 3 [PDF].

Canada. 2000. Canadian Environmental Protection Act, 1999: Persistence and Bioaccumulation Regulations, P.C. 2000-348, 23 March 2000, SOR/2000-107 [PDF]. Retrieved October 13, 2017.

Canada. 2011. Canadian Environmental Protection Act, 1999: Announcement of planned actions to assess and manage, where appropriate, the risks posed by certain substances to the health of Canadians and the environment. Canada Gazette, Part I, vol. 145, no. 41 – October 8, 2011, p. 3125-3129.

Canada. 2016. Canadian Environmental Protection Act, 1999: Announcement of planned actions to assess and manage, where warranted, the risks posed by certain substances to the health of Canadians and the environment. Retrieved October 13, 2017, from Canada Gazette, Part I, vol. 150, no. 25. June 18, 2016, p. 1989-1994.

Canada. 1978. Food and Drug Regulations.

Canada. 1980. Hazardous Products (Mattresses) Regulations. Canada Consumer Product Safety Act. SOR 80/810, Registered 1980-10-23.

Canada 1993. Motor Vehicle Safety Act (S.C. 1993, c. 16). [Accessed 2018 Nov 5].

Canada 2010. Motor Vehicle Restraint Systems and Booster Seats Safety Regulations (SOR/2010-90) (Motor Vehicle Safety Act). [Accessed 2018 Nov 5].

Canada 2016a. Announcement of planned actions to assess and manage, where warranted, the risks posed by certain substances to the health of Canadians and the environment. Canada Gazette Part I, Vol 150, No. 25.

Canada. 2016b. Mattresses Regulations (Canada Consumer Product Safety Act). SOR/2016-183.

Canada. 2016c. Textile Flammability Regulations (Canada Consumer Product Safety Act). SOR/2016-194.

[CEC] Commission for Environmental Cooperation. 2015a. Enhancing Trilateral Understanding of Flame Retardants and Their Use in Manufactured Items: Analysis of Select Flame Retardants in Office and Household Furniture [PDF].

[CEC] Commission for Environmental Cooperation. 2015b. Enhancing Trilateral Understanding of Flame Retardants and Their Use in Manufactured Items: Supply Chain Analysis of Select Flame Retardants Contained in Manufactured Items Used in Indoor Environments [PDF].

Chemtura 2018. Safety Data Sheet: Reofos ® 35. [Accessed 2018 Nov 6].

Chemtura 2018. Safety Data Sheet: Reofos ® 65. [Accessed 2018 Nov 6].

Danish EPA. 2016a. Chlorinated phosphorous-based flame retardants in children’s articles containing foam [PDF]. Background for content and possibilities for prevention in the EU. Environmental project No. 1855.

Danish EPA. 2016b. Environmental and health screening profiles of phosphorous flame retardants: A LOUS follow-up project [PDF].

Du Z, Wang G, Gao S, Wang Z. 2015. Aryl organophosphate flame retardants induced cardiotoxicity during zebrafish embryogenesis: By disturbing expression of the transcriptional regulators. Aquatic Toxicology 161 (2015) 25–32.

[EA] Environmental Agency. 2009. Environmental risk evaluation report: triphenyl phosphate (CAS no. 115-86-6). [PDF]. Almondsbury, Bristol, Environment Agency: 93. [Accessed 2018 April 10].

[EC] Environment Canada. 2009. DSL Inventory Update data collected under the Canadian Environmental Protection Act, 1999, section 71: Notice with respect to certain inanimate substances (chemicals) on the Domestic Substances List. Data prepared by: Environment Canada, Health Canada; Existing Substances Program.

[EC] Environment Canada. 2012. DSL Inventory Update data collected under the Canadian Environmental Protection Act, 1999, section 71: Notice with respect to certain substances on the Domestic Substances List. Data prepared by: Environment Canada, Health Canada; Existing Substances Program.

[ECCC] Environment and Climate Change Canada. 2016a. Supporting documentation: data used to create substance-specific hazard and exposure profiles and assign risk classifications. Gatineau (QC): ECCC. Information in support of the science approach document: ecological risk classification of organic substances. Available from: substances@ec.gc.ca.

[ECCC] Environment and Climate Change Canada. 2016b. DSL Inventory Update data collected under the Canadian Environmental Protection Act, 1999, section 71: Notice with respect to certain substances on the Domestic Substances List. Data prepared by: Environment Canada, Health Canada; Existing Substances Program.

[ECCC, HC]. Environment and Climate Change Canada, Health Canada. 2021. Draft Screening Assessment for the Flame Retardants Group.

[ECHA] European Chemicals Agency. c2017-2019. Community rolling action plan update covering years 2017, 2018 and 20197 [PDF]. [Accessed 2019 Jun 17].

[ECHA] European Chemicals Agency. c2007-2018a. Registered substances database; search results for CAS RN 115-86-6. Helsinki (FI): ECHA. [Accessed 2018 April 4].

[ECHA] European Chemicals Agency. c2007-2018b. Registered substances database; search results for CAS RN 68937-41-7. Helsinki (FI): ECHA. [Accessed 2018 April 9].

[ECHA] European Chemicals Agency. c2007-2018c. Registered substances database; search results for CAS RN 29761-21-5. Helsinki (FI): ECHA. [Accessed 2018 April 9].

[ECHA] European Chemicals Agency. 2017. Substance evaluation – CoRAP. [Accessed 2019 Aug 16].

Health Canada. 2010. PMRA List of Formulants [PDF]. [Accessed 2018 Nov 5].

Health Canada. 2019. Notice to interested parties – Proposal to amend the Tents Regulations, including consequential amendments to the Toys Regulations [Accessed 2020 January 12].

ICL-IP 2018. Phosflex TM 41L. [Accessed 2018 Nov 6].

[ISO] International Organization for Standardization. 2014. Standards Catalogue.

Jarema KA, Hunter DL, Shaffer RM, Behl M, Padilla S. 2015. Acute and developmental behavioral effects of flame retardants and related chemicals in zebrafish. Neurotoxicology and Teratology 52 (2015) 194–209.

Kim S, Jung J, Lee I, Jung D, Youn H, Choi K. 2015. Thyroid disruption by triphenyl phosphate, an organophosphate flame retardant, in zebrafish (Danio rerio) embryos/larvae, and in GH3 and FRTL-5 cell lines. Aquatic Toxicology 160 (2015) 188–196.

Liu X, Ji K, Jo A, Moon H-B, Choi K. 2013a. Effects of TDCPP or TPP on gene transcriptions and hormones of HPG axis, and their consequences on reproduction in adult zebrafish (Danio rerio). Aquatic Toxicology. 134–135: 104–111.

[Maine] 2017. Maine Legislature. An Act to Protect Firefighters by Establishing a Prohibition on the Sale and Distribution of New Upholstered Furniture Containing Certain Flame-retardant Chemicals. [Accessed 2019 Jun 14].

Marklund A. 2005. Levels and Sources of Organophosphorus Flame Retardants and Plasticizers in Indoor and Outdoor Environments [PDF]. Umea (SE): Umea University. [Accessed 2016 Mar 23].

McGee SP, Konstantinov A, Stapleton HM, Volz DC. 2013. Aryl phosphate esters within a major pentabde replacement product induce cardiotoxicity in developing zebrafish embryos: potential role of the aryl hydrocarbon receptor. Toxicol Sci. 133(1):144-156.

Miller GZ, Gearhart J. 2016. Traveling with toxics: Flame retardants & other chemicals in children’s car seats [PDF]. Michigan (US): HealthyStuff ,EcologyCenter. [accessed 2018 Mar 29].

Noyes P, Haggard D, Gonnerman G, Tanguay R. 2015. Advanced Morphological — Behavioral Test Platform Reveals Neurodevelopmental Defects in Embryonic Zebrafish Exposed to Comprehensive Suite of Halogenated and Organophosphate Flame Retardants. Toxicological Sciences, 145:177–195.

Phillips AL, Hammel SC, Konstantinov A, Stapleton HM. 2017.Characterization of individual isopropylated and tert-butylated triarylphosphate (ITP and TBPP) isomers in several commercial flame retardant mixtures and house dust standard reference material SRM 2585. Environ Sci Technol. 51:13443-13449.

Shi Q, Wang M, Shi F, Yang L, Guo Y, Feng C, Liu J, Z B. 2018. Developmental neurotoxicity of triphenyl phosphate in zebrafish larvae. Aquatic Toxicology 203: 80–87.

Sjögren B, Anders Iregren A and Jill Järnberg J. 2009. Phosphate triesters with flame retardant properties. The Nordic Expert Group for Criteria Documentation of Health Risks from Chemicals. University of Gothenburg.

Stapleton, H.M., Klosterhaus, S., Eagle, S. et al., 2009. Detection of organophosphate flame retardants in furniture foam and US house dust. Environmental Science and Technology 43(19): 7490–7495.

Stapleton, H.M., Klosterhaus, S., Keller, A. et al. 2011. Identification of flame retardants in polyurethane foam collected from baby products. Environmental Science and Technology 45: 5323-5331.

Stapleton, H.M., Sharma, S., Getzinger, G., et al. 2012. Novel and high volume use flame retardants in US couches reflective of the 2005 PentaBDE phase out. Environmental Science and Technology 24(24): 13432-13439.

Transport Canada 2007. Technical Standards Document No. 302, Revision 0R. Flammability of Interior Materials [PDF]. [Accessed 2018 Nov 5].

UK Department for Business, Energy and Industrial Strategy. 2016. Consultation on updating the Furniture and Furnishings (Fire) (Safety) Regulations.

[UL] Underwriters Laboratories. 2014. UL 94, the Standards for Safety of Plastic Materials for Parts in Devices and Appliances.

[US CPSC] US Consumer Product Safety Commission. 2006. CPSC Staff Preliminary risk assessment of flame retardant chemicals in upholstered furniture foam [PDF]. Bethesda, MD: US Consumer Product Safety Commission. [accessed 2018 Mar 29].

US eCFR 2018a. Title 21: Food and Drugs; Part 175 – Indirect Food Additives: Adhesives and Components of Coatings; Subpart B: Substances for Use Only as Components of Adhesives; §175.106 Adhesives. [Accessed 2018 Nov 5].

US eCFR. 2018b. US CFR Title 40: Protection of the Environment, Part 180: Tolerances and Exemptions for Pesticide Chemical Residues in Food, Part D: Exemptions from Tolerances, Section 180.920. [Accessed 2018 Nov 5].

US eCFR 2018c. US CFR Title 49: Transportation; Subtitle B: Other Regulations Relating to Transport; Chapter V: National Highway Traffic Safety Administration, Department of Transportion; Part 571: Federal Motor Vehicle Safety Standards; Subpart B: Federal Motor Vehicle Safety Standards; § 571.213 Standard No. 213; Child restraint systems. [Accessed 2018 Nov 5].

US eCFR 2018d. US CFR Title 49: Transportation; Subtitle B: Other Regulations Relating to Transport; Chapter V: National Highway Traffic Safety Administration, Department of Transportion; Part 571: Federal Motor Vehicle Safety Standards; Subpart B: Federal Motor Vehicle Safety Standards; § 571.302 Standard No. 302: Flammability of Interior Materials. [Accessed 2018 Nov 5].

[US EPA] United States Environmental Protection Agency. 2005. Furniture Flame Retardancy Partnership: Environmental Profiles of Chemical Flame-Retardant Alternatives for Low-Density Polyurethane Foam [PDF].

[US EPA] United States Environmental Protection Agency. 2015. Flame retardants used in flexible polyurethane foam: an alternatives assessment update [PDF].

[US EPA] United States Environmental Protection Agency. 2010. Screening-level hazard characterization of Isopropylated Triphenyl Phosphate (3:1) (CASRN 68937-41-7).

US EPA] United States Environmental Protection Agency. 2013. Assessing and Managing Chemicals under TSCA. Industry Testing Requirements under TSCA Section 4. [Accessed 2019Jul 31].

[US EPA] United States Environmental Protection Agency. 2018a. Assessing and Managing Chemicals under TSCA: Persistent, Bioaccumulative, and Toxic (PBT) Chemicals under TSCA Section 6(h). [Accessed 2018 Jun 14] .

US EPA] Environmental Protection Agency 2018b. Inert Finder: Tri-ethyl phosphate. [Accessed 2018 Nov 5].

[US EPA] United States Environmental Protection Agency. 2019. Regulation of Persistent, Bioaccumulative, and Toxic Chemicals Under TSCA Section 6(h). [Accessed 2019 Jul 31].

[US EPA] United States Environmental Protection Agency. 2019. Assessing and Managing Chemicals under TSCA: Pre-publication version of Proposed Rule on Regulation of Persistent, Bioaccumulative, and Toxic Chemicals Under TSCA Section 6(h). [Accessed 2019 Jul 10].

[US EPA] United States Environmental Protection Agency. 2014. TSCA Work Plan for Chemical Assessments: 2014 Update [PDF]. [Accessed 2019 Jun 18].

Van der Veen I, de Boer J. 2012. Phosphorus flame retardants: properties, production, environmental occurrence, toxicity and analysis. Chemosphere 88: 1119-1153.

Wei G, Li D, Zhuo M, Liao Y, Xie Z, Guo T, Li J, Zhang S, Liang Z. 2015. Organophosphorus flame retardants and plasticizers: Sources, occurrence, toxicity and human exposure. Environ Pol. 196: 29-46.

Weil ED, Levchik S. 2003. Current practice and recent commercial developments in flame retardancy of polyamides. J Fire Sci. 22:251-264.

Zhang Q, Lu M, Dong X, Wang C, Zhang Cm Kiu Wm Zhao M. 2014. Potential Estrogenic Effects of Phosphorus-Containing Flame Retardants. Environ. Sci. Technol. 48: 6995−7001.

Annex A. Substance identities

| CAS RN | DSL Name (English) | Common Name/ Simplified Name | Acronym | Chemical Structure | Molecular Weight (g/mol) | Chemical Formula |

|---|---|---|---|---|---|---|

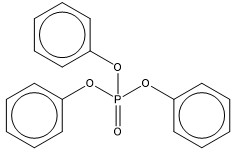

| 115-86-6 | Phosphoric acid, triphenyl ester | Triphenyl phosphate | TPHP |  |

326.29 | C18H15O4P |

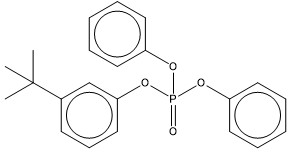

| 56803-37-3 | Phosphoric acid, (1,1-dimethylethyl)phenyl diphenyl ester | Tert-Butylphenyl diphenyl phosphate | BPDP |  |

382.40 | C22H23O4P |

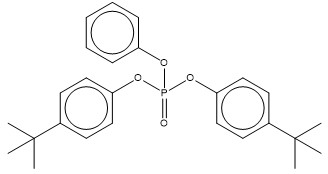

| 65652-41-7 | Phosphoric acid, bis[(1,1-dimethylethyl)phenyl] phenyl ester | Bis(tert-butylphenyl) phenyl phosphate | BDMEPPP |  |

438.5 | C26H31O4P |

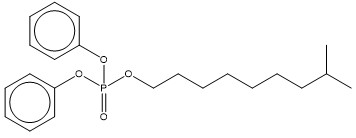

| 29761-21-5 | Phosphoric acid, isodecyl diphenyl ester | Isodecyl diphenyl phosphate | IDDP |  |

390.46 | C22H31O4P |

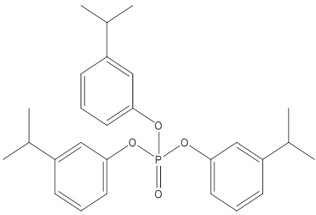

| 68937-41-7 | Phenol, isopropylated, phosphate (3:1) | Isopropylphenyl phosphate | IPPP |  |

452.53 | C27H33O4P |

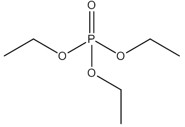

| 78-40-0 | Phosphoric acid, triethyl ester | Triethylphosphate | TEP |  |

182.15 | C6H15O4P |

IPPP is a UVCB that is a mixture of potentially over 50 isomers of isopropylated triphenyl phosphates (US EPA 2010). For the assessment, IPPP is characterized by two representative structures, TPHP (also shown as a discrete substance in this table) used to represent water soluble and less hydrophobic components and tris(3-isopropylphenyl) phosphate (T3IPPP) which represents the hydrophobic components of IPPP. For IPPP, this table shows the structure, molecular weight and chemical formula for T3IPPP.