Screening Assessment for the Challenge

This page has been archived on the Web

Information identified as archived is provided for reference, research or recordkeeping purposes. It is not subject to the Government of Canada Web Standards and has not been altered or updated since it was archived. Please contact us to request a format other than those available.

Archived

Siloxanes and Silicones, di-Me, hydrogen-terminated

Chemical Abstracts Service Registry Number

70900-21-9

Environment Canada

Health Canada

September 2011

Table of Contents

- Synopsis

- Introduction

- Substance Identity

- Physical and Chemical Properties

- Sources

- Uses

- Releases to the Environment

- Environmental Fate

- Persistence and Bioaccumulation Potential

- Potential for Bioaccumulation

- Potential to Cause Ecological Harm

- Potential to Cause Harm to Human Health

- Conclusion

- References

- Appendix I: Relationship between viscosity, degree of polymerisation and molecular weight (Wacker 1992 and Fendinger et al. 1997)

- Appendix II: PBT Model Inputs Summary Table

- Appendix III: Estimated concentrations of MHDnMH in environmental media using ChemCAN version 6.00 (ChemCAN 2003)

- Appendix IV: Estimates of dermal exposure to MHDnMH from use of disposable bras, skin whitening cream, eye makeup and lipstick

Pursuant to section 74 of the Canadian Environmental Protection Act, 1999 (CEPA 1999), the Ministers of the Environment and of Health have conducted a screening assessment on siloxanes and silicones, di-Me, hydrogen-terminated (MHDnMH), Chemical Abstracts Service Registry Number[1] 70900-21-9. This substance was identified as a high priority for screening assessment and included in the Challenge initiative under the Chemicals Management Plan because, based on model predictions, it was found to meet the ecological categorization criteria for persistence, bioaccumulation potential and inherent toxicity to non-human organisms and is believed to be in commerce in Canada.

The substance, MHDnMH, was not considered to be a high priority for assessment of potential risks to human health, based upon application of the simple exposure and hazard tools developed for categorization of substances on the Domestic Substances List (DSL).

MHDnMH was originally classified as an organic UVCB (Unknown or Variable Composition, Complex Reaction Products or Biological Material) during the DSL Categorization. Based on new information received, the substance is considered to be an organic siloxane polymer.

MHDnMH is not naturally produced in the environment. In 2006, between 10 000 and 100 000 kg of the substance were manufactured in Canada, and less than 100 kg were imported into the country.

Based on reported use, MHDnMH is manufactured as an intermediate polymer, and then exported in bulk form out of the country for producing plastics. During the industrial process, a small amount of the polymer is released to wastewater, and to a lesser extent air and land; however, the total environmental release is not significant.

Based on the available information, it is determined that the form of MHDnMH in commerce in Canada meets the Reduced Regulatory Requirement polymer criteria as specified in the New Substances Notification Regulations (Chemicals and Polymers).Given that polymers are often complex mixtures and the molecular weight of a polymer varies as a function of the number of repeating units, two forms of the polymer of different molecular weights were considered in this assessment. This was done in order to address concerns relating to both number-average (e.g., MHDnMH where n = 34) and low (e.g., MHDnMH where n = 5) molecular weight forms of the polymer.

Information for an analogous polymer, polydimethylsiloxanes (PDMS), has been used for assessing MHDnMH. Based on the read-across data of the analogue, the substance is expected to be persistent in the environment. Based on the information for the analogue on the potential for bioaccumulation, and taking into account its relatively large molecular size, the substance is not likely to be bioavailable and is expected to have a low potential to accumulate in the lipid tissues of organisms. The substance therefore meets the persistence criteria but does not meet the bioaccumulation criteria as set out in the Persistence and Bioaccumulation Regulations. In addition, new modelled toxicity data for the substance and experimental data for an analogous polymer indicate that MHDnMH has a low potential to cause harm to organisms in water, soil, and sediment.

For this screening assessment, a conservative exposure scenario was developed in which an industrial operation discharges MHDnMH into the aquatic environment. The predicted environmental concentration in water was well below the predicted no-effect concentration calculated for the aquatic organisms. Therefore, based on the information presented in this screening assessment, it is expected that MHDnMH is not entering the environment in a quantity or concentration or under conditions that have or may have an immediate or long-term harmful effect on the environment or its biological diversity or that constitute or may constitute a danger to the environment on which life depends.

Empirical health effects data were not identified for MHDnMH. Based on health effects data for PDMS, and on the weight-of-evidence based risk assessments for PDMS conducted by international agencies, it is considered that MHDnMH demonstrates low hazard potential.

Based on the estimated concentrations of MHDnMH in environmental media (air, drinking water and soil), exposure of the general population is expected to be negligible. General population exposure can occur through use of consumer products containing MHDnMH. Margins between conservative upper-bounding estimates of exposure for MHDnMH and effect levels from health effects studies with the analogue (PDMS) are considered adequate to address uncertainties in the health effects and exposure databases. It is therefore concluded that MHDnMH is not entering the environment in a quantity or concentration or under conditions that constitute or may constitute a danger in Canada to human life or health.

Based on the information available, it is concluded that the Reduced Regulatory Requirement form of MHDnMH does not meet any of the criteria set out in section 64 of CEPA 1999.

Given the complexity associated with the polymer formulation and the potentially hazardous properties associated with low molecular weight polymers, there is concern that new activities for MHDnMH which have not been identified or assessed under CEPA 1999 could lead to the substances meeting the criteria as set out in section 64 of the Act. Therefore, it is recommended that the DSL be amended to indicate that MHDnMH meets the Reduced Regulatory Requirement (RRR) Polymer criteria. Should other forms of MHDnMH, not meeting the Reduced Regulatory Requirement polymer criteria, be introduced on the Canadian market, those forms would be subject to the requirements of the New Substances Notification Regulations.

The Canadian Environmental Protection Act, 1999 (CEPA 1999) (Canada 1999) requires the Minister of the Environment and the Minister of Health to conduct screening assessments of substances that have met the categorization criteria set out in the Act to determine whether these substances present or may present a risk to the environment or to human health.

Based on the information obtained through the categorization process, the Ministers identified a number of substances as high priorities for action. These include substances that

- met all of the ecological categorization criteria, including persistence (P), bioaccumulation potential (B) and inherent toxicity to aquatic organisms (iT), and were believed to be in commerce in Canada; and/or

- met the categorization criteria for greatest potential for exposure (GPE) or presented an intermediate potential for exposure (IPE) and had been identified as posing a high hazard to human health based on classifications by other national or international agencies for carcinogenicity, genotoxicity, developmental toxicity or reproductive toxicity.

The Ministers therefore published a notice of intent in theCanada Gazette, Part I, on December 9, 2006 (Canada 2006), that challenged industry and other interested stakeholders to submit, within specified timelines, specific information that may be used to inform risk assessment, and to develop and benchmark best practices for the risk management and product stewardship of those substances identified as high priorities.

The substance, siloxanes and silicones, di-Me, hydrogen-terminated (MHDnMH), was initially identified as a high priority for assessment of ecological risk during the DSL Categorization as it was found to be persistent, bioaccumulative and inherently toxic to aquatic organisms and is believed to be in commerce in Canada. The Challenge for this substance was published in the Canada Gazette on September 26, 2009 (Canada 2009). A substance profile was released at the same time. The substance profile presented the technical information available prior to December 2005 that formed the basis for categorization of this substance. As a result of the Challenge, submissions of information pertaining to the properties and uses of the substance were received.

Although MHDnMH was determined to be a high priority for assessment with respect to the environment, it did not meet the criteria for GPE or IPE and high hazard to human health based on classifications by other national or international agencies for carcinogenicity, genotoxicity, developmental toxicity or reproductive toxicity.

Screening assessments focus on information critical to determining whether a substance meets the criteria set out in section 64 of CEPA 1999. Screening assessments examine scientific information and develop conclusions by incorporating a weight-of-evidence approach and precaution[2].

This screening assessment includes consideration of information on chemical properties, hazards, uses and exposure, including the additional information submitted under the Challenge. Data relevant to the screening assessment of this substance were identified in original literature, review and assessment documents, stakeholder research reports and from recent literature searches, up to May 2010 for the human health sections and December 2010 for ecological sections of the document. Key studies were critically evaluated; modelling results may have been used to reach conclusions.

When available and relevant, information presented in hazard assessments from other jurisdictions was considered. The screening assessment does not represent an exhaustive or critical review of all available data. Rather, it presents the most critical studies and lines of evidence pertinent to the conclusion.

This screening assessment was prepared by staff in the Existing Substances Programs at Health Canada and Environment Canada and incorporates input from other programs within these departments. The ecological portion of this assessment has undergone external written peer review/consultation. Additionally, the draft of this screening assessment was subject to a 60-day public comment period. While external comments were taken into consideration, the final content and outcome of the screening assessment remain the responsibility of Health Canada and Environment Canada. Approaches used in the screening assessments under the Challenge have been reviewed by an independent Challenge Advisory Panel.

The critical information and considerations upon which the assessment is based are summarized below.

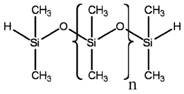

For the purposes of this document, the substance, siloxanes and silicones, di-Me, hydrogen-terminated, will be referred to as MHDnMH, derived from the chemical structure. MH refers to the silicon atom in end groups, having one shared bond to oxygen, two shared bonds to methyl substituents and one shared bond to hydrogen. D symbolizes the silicon atoms in the backbone, having two shared bonds to oxygen and two shared bonds to methyl substituents, while n is the number of D in the polymer molecule.

MHDnMH was originally classified as an organic UVCB in the DSL Categorization. Based on new information received, MHDnMH can be characterized by 1) the monomer unit of dimethyl-siloxy and 2) hydrogen and dimethyl groups attached to the silicon atom functioning as the polymer terminating groups (Environment Canada 2010a).

According to results from gel permeation chromatography (GPC), MHDnMH has been reported to have a number-average molecular weight (Mn) of approximately 2 700 g/mol (Environment Canada 2010a), equivalent to an average of 34 monomer units of dimethyl-siloxy (n=34, based on the molecular weight of the monomer unit of dimethyl-siloxy as 74.15 g/mol). Any single molecule of MHDnMH contains more than three monomer units. Differences in molecular weights (MW) are primarily attributable to differences in the number of units. Therefore, MHDnMH meets the definition of a polymer (OECD 1994), as summarized below:

- molecules characterized by the sequence of one or more types of monomer units;

- greater than 50% by weight of molecules having three of more monomer units that are covalently bound to one or more other monomer units or reactants;

- less than 50% by weight of molecules of the same molecular weight; and

- molecules distributed over a range of molecular weights whose differences in molecular weights are primarily attributable to differences in the number of monomer units.

There have been considerably smaller oligomers (the lowest molecular weight of ~500 g/mol) detected in the polymer product but at a very low concentration. Furthermore, looking at the global market, there are other products manufactured and sold under the same CAS RN (70900-21-9), including the polymer with an average molecular weight around 500 g/mol (Gelest 2010). A molecular weight of ~500 g/mol corresponds to a polymer with five monomer units of dimethyl-siloxy (n=5). Given the above, both MHD34MH and MHD5MH are considered in the assessment, to represent both the number-average molecular weight and low molecular weight polymers.

The assessment considers critical data on key parameters for assessing persistence, bioaccumulation, and ecotoxicity for both the number-average molecular weight and the low molecular weight polymers. In some cases when experimental data are not available for MHDnMH, experimental data for analogous chemicals and Quantitative Structure-Activity Relationship (QSAR) models will be used to fill the data gaps.

The identity of MHDnMH is summarized in Table 1 below.

Table 1. Substance identity for MHDnMH

| Chemical Abstracts Service Registry Number (CAS RN) | 70900-21-9 |

| DSL name | Siloxanes and silicones, di-Me, hydrogen-terminated |

| National Chemical Inventories(NCI) names[1] | Siloxanes and Silicones, di-Me, hydrogen-terminated (TSCA, REACH, ENCS, ECL, PICCS, ASIA-PAC, NZIoC) Siloxanes and silicones, dimethyl hydrogen terminated (AICS) SILOXANE, DI-ME, HYDROGEN TERMINATED (PICCS) |

| Other names | Di-Me, dimethylsilyl-terminated siloxanes FH 0023 Hydrogen-terminated di-Me silicones Hydrogen-terminated di-Me siloxanes MCR-H 07 MHD6MH Polysiloxanes, di-Me, hydrogen-terminated PS 542 SE 1886A SE 1887A Silicones, di-Me, dimethylsilyl-terminated Siloxanes and Silicones, di-Me, (dimethylsilyl)-terminated XF 40A6100 Dimethylsiloxanes et silicones, termines par un atome d'hydrogene |

| Chemical group (DSL Stream) | Polymer |

| Major chemical class or use | Organosilicon |

| Major chemical sub-class | Siloxane |

| Chemical formula | C(4+2n)H(14+6n)O(1+n)Si(2+n) |

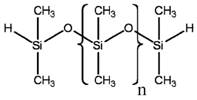

| Representative chemical structure used to run the estimation model[2] |  |

| SMILES[3] | MHDnMH (n=34) or MHD34MH: not available MHDnMH (n=5) or MHD5MH: Si(C)(C)OSi(C)(C)OSi(C)(C)OSi(C)(C)OSi(C)(C)OSi(C)(C)OSi(C)(C) |

| Molecular mass | MHD34MH: 2655.45 g/mol MHD5MH: 505.10 g/mol |

[2] This substance is an organic polymer; i.e., it is not a discrete chemical and thus can be characterized by a representative structure. For this assessment, two representative structures were used, one with n=34 and one with n=5.

[3] Simplified Molecular Input Line Entry System

It is noted that the polymer may contain a small fraction of impurities, i.e., residual monomers or by-products which have much lower molecular weights. The quantities and the types of impurities vary, based on a number of factors, including different manufacturing processes and operations, reaction conditions, and use of catalysts and promoters. Based on a data submission received (Environment Canada 2010a),

octamethylcyclotetrasiloxane (D4, CAS RN 556-67-2), decamethylcyclopentasiloxane (D5, CAS RN 541-02-6), dodecamethylcyclohexasiloxane (D6, CAS RN 540-97-6), and 1,3-dihydrotetramethyldisiloxane (CAS RN 3277-26-7) have been reported as residual monomers or byproducts in the polymer products under the same CAS RN 70900-21-9, however the concentrations of these residual monomers and byproducts vary in the polymers manufactured by different companies. D4, D5 and D6 were previously assessed under the Challenge; and according to the GPC results, 1,3-dihydrotetramethyldisiloxane was not detected in MHDnMH in commerce in Canada. Therefore risk associated with impurities in the polymer will not be addressed in this assessment on MHDnMH.

Unlike any discrete substance which has a defined molecular weight, the molecular weight of a polymer varies as a function of the number of repeating units, which can range from three to many thousands. Therefore, a polymer is usually characterized by the average number of repeating units it contains or its number-average molecular weight.

As mentioned in the previous section of Substance Identity, MHD34MH represents the polymer which is manufactured in Canada; while MHD5MH refers to the polymer product produced internationally that has a molecular weight of 505.10 g/mol. There is a difference in assessment approaches for these two polymer products based on the molecular weights.

For the purpose of the assessment, the number of repeating units (n) may be referred to in a certain case if information is only applicable to either one of the above two forms. If there is no indication of the number of repeating units, the assessment applies to the polymer MHDnMH (n=5) in general.

There are no experimental physical and chemical properties for MHDnMH, thus information on analogous substance, polymethylsixolanes (PDMS), is considered in the assessment.

An analogue is a chemical that is structurally similar to the substance under assessment and is therefore expected to have similar physical and chemical properties, similar fate in the environment, and/or similar toxicity. Where there are experimental data for a given property of an analogue substance, they can be used to characterize the substance under assessment, though differences in structure which may affect bioavailability should be noted.

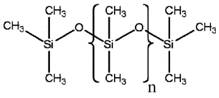

PDMS is another siloxane polymer, having the same repeating unit of di-methyl groups attached to the silicon of the –Si-O-Si- backbone. The difference between MHDnMH and PDMS lies in the terminating units. While there is a hydrogen atom and two methyl groups at both end units in MHDnMH, PDMS has three methyl groups (see Table 2a below). The chemical formula of PDMS can be referred to as MDnM. Such differences are not anticipated to significantly affect the substances’ physical and chemical properties between MHDnMH and PDMS (when numbers of repeating units are similar). Given the similarities of these chemicals, the experimental data for PDMS were used to evaluate environmental fate, potential for persistence and bioaccumulation, and ecological toxicity for both forms of MHDnMH (n=5 and n=34) with no need for qualitative adjustment.

Table 2a. Chemical structures of PDMS and MHDnMH

| Chemical | PDMS | MHDnMH |

|---|---|---|

| Representative Structure |  |

|

MHD5MH

For the low molecular weight form of MHDnMH (n=5), several linear methyl siloxanes (MDnM) have been used as analogues (see Table 2b below). These linear methyl siloxanes (n=3) are low molecular weight PDMS.

Table 2b. Linear methyl siloxanes used as analogues of MHD5MH

| Chemical Name and CAS RN | Formula | Molecular Weight (g/mol) |

|---|---|---|

| Dodecamethylpentasiloxane (141-63-9) | MD3M | 384.84 |

| Tetradecamethylhexasiloxane (107-52-8) | MD4M | 459.00 |

| Hexadecamethylheptasiloxane (541-01-5) | MD5M | 533.15 |

| Siloxanes and silicones, di-Me, hydrogen-terminated (70900-21-9) | MHD5MH | 505.10 |

- M refers to the silicon atoms in end groups, having one shared bond to oxygen and three shared bonds to methyl substituents.

- MH refers to the silicon atoms in end groups, having one shared bond to oxygen, two shared bonds to methyl substituents and one shared bond to hydrogen.

- D symbolizes the silicon atoms in the backbone, having two shared bonds to oxygen and two shared bonds to methyl substituents.

Selected experimental physical and chemical property information for MDnM was read-across to MHD5MH with some adjustments for structural differences (i.e., the number of repeating units). QSAR models were also used to fill data gaps where there was no experimental information for certain physical and chemical properties (see Appendix II). These models (except WSKOWWIN 2008) are mainly based on fragment addition methods, i.e., they rely on the structure of a chemical. It is noted that most models do not have siloxanes in their training sets, and therefore MHD5MH is technically outside the domain of the models. However, given that low molecular weight material such as MHD5MH remains in a neutral form under environmental conditions, estimations based on its fragments and molecular weight are expected to provide approximate values.

The modelled physical and chemical properties for MHD5MH are summarized in Table 2c below. Experimental data for the analogous linear methyl siloxanes (see Table 2b) are also presented in the table. For enhancing the reliability of model predictions, an experimental value adjustment (EVA) method was applied using sub-models in EPISUITE to derive an estimate from an experimental measure, with consideration of the structural differences between the analogue and MHD5MH.

Table 2c. Estimated physical and chemical properties for MHD5MH (MW=505.10 g/mol)

| Property | Value[1] | Temperature (°C) |

Reference |

|---|---|---|---|

| Melting point (ºC) |

12.02 | MPBPWIN 2008 | |

| -59 (for MD4M) | Gelest 2008a[5] | ||

| Boiling point (ºC) |

317.45 | MPBPWIN 2008 | |

| 245 (for MD4M) | Gelest 2008a | ||

| Density (kg/m3) |

890 (for MD4M) | Gelest 2008a | |

| Viscosity[2] (centistoke, cs) |

2.6 (for MD4M) | Gelest 2008a | |

| Vapour pressure (Pa) |

0.10 (7.69 × 10-4 mmHg) |

25 | MPBPWIN 2008 |

| <1 mm Hg (for MD4M) | 25 | Gelest 2008a | |

| Henry’s Law constant (Pa·m3/mol) |

2.0 × 107 (2.0 × 102atm·m3/mole) | HENRYWIN 2008 | |

| Log Kow (Octanol-water partition coefficient) (dimensionless) |

6. 6 | KOWWIN 2008 | |

| 6.7 (EVA extrapolation from MD4M and MD5M)[3] |

KOWWIN2008 | ||

| 6.0 (for MD3M) 6.6 (for MD4M) 7.2 (for MD5M) 7.7 (for MD6M) |

Bruggeman et al. 1984 | ||

| Log Koc (Organic carbon-water partition coefficient) (dimensionless) |

5.7 | PCKOCWIN 2008 | |

| Water solubility (mg/L) |

2.2 × 10-6 – 2.7 × 10-6 (based on log Kow = 6.7 – 6.6) |

25 | WSKOWWIN 2008 |

| 5.7 × 10-9 – 2.2 × 10-6 (EVA extrapolation from MD4M and MD5M)[3] |

WATERNT 2008 | ||

| 3.4 × 10-2 (for MDM) 7.0 × 10-5 (for MD3M) 1.3 × 10-5 (estimated for MD4M) 5.4 × 10-7 (estimated for MD5M) |

25 | Varaprath et al. 1996 WSKOWWIN 2008 |

|

| Cross-sectional diameter (nm)[4] | 1.46 – 2.18 | CPOPs 2008 |

[2] The viscosity of a polymer is used to characterize the molecular size and molecular weight of polymers. The unit for kinematic viscosity of a polymer is centistoke (cs).

[3] An experimental value adjustment (EVA) method was applied using EPISUITE to derive an estimate from an experimental measure, with consideration of the structural differences

[4] Values represent the range of possible maximum molecular diameters (i.e., Dmax values) estimated by CPOPs

[5] Information cited from Gelest 2008a is for a product of MD4M (>95%), with fraction of MD3M and higher linear siloxanes (<5%)

According to the experimental data on log Kow and water solubility for MD3-6M (see Table 2c), the low molecular weight linear methyl siloxanes are extremely hydrophobic. They possess low water solubilities (at the level of 10-4 mg/L or lower) and high octanol-water partition coefficients (log Kow=6 or higher).

Having a hydride in the terminating unit, MHD5MH is expected to demonstrate similar water solubility and octanol-water partition coefficient to those parameters of the analogous PDMS with the similar molecular weight. The modelled predictions of log Kow for MHD5MH are 6.7 with the experimental value adjustment and 6.6 without, close to the octanol-water partition coefficients for MD4M (log Kow = 6.6) and MD5M (log Kow = 7.2). The estimated water solubilities for MHD5MH (derived based on the log Kow values) are 2.2 × 10-6 – 2.7 × 10-6 mg/L, between the water solubilities of MD4M (1.3 × 10-5 mg/L) and MD5M (5.4 × 10-7 mg/L).

Based on the model predictions, MHD5MH is not expected to be particularly volatile and not soluble in water. The estimated vapour pressure is moderate (0.10 Pa) and the water solubility is very low (~2.5 × 10-6 mg/L), which consequently make the Henry’s Law constant very high, estimated as 2.0 × 107 Pa·m3/mol.

MHD34MH

The polymer in commerce in Canada (MHD34MH) has a number-average molecular weight of ~2 700 g/mol. There is no component in the polymer having a molecular weight less than 500 g/mol and less than 5% of the components have molecular weights less than 1000 g/mol. There are no cationic or reactive functional groups in either the terminating unit or the repeating unit in the polymer, thus the functional group equivalent weight[3] (FGEW) for MHD34MH is more than 1000 g/mol. Given this, the polymer meets Reduced Regulatory Requirement polymer criteria as specified the New Substances Notification Regulations (Chemicals and Polymers).

Having a number-average molecular weight of ~ 2 700 g/mol, which is higher than the limit acceptable for the QSAR models, MHD34MH is outside the domains of applicability and there are no QSAR models that can be used for assessing the substance. Consequently, read-across data from PDMS were considered when characterizing the physical and chemical properties for MHD34MH.

In a toxicity test, a hydroxyl terminated PDMS (approximately equivalent to n=45 and MW=3 500 g/mol, derived from the viscosity of PDMS as 55 cs) was reported with a maximum water solubility of 0.26 mg/L and an equilibrium concentration of 0.04 to 0.05 mg/L (Gettings and Lane 1982). Given that the hydroxyl in the terminating unit would make the polymer somewhat more soluble, the water solubility MHD34MH is expected to be inferior to 0.26 mg/L.

For large molecular weight polymers, there is a relationship between viscosity and the average molecular weight (see Appendix I). Viscosity is a measure of how much a fluid resists flow when a force is applied to it. It is also a measure for ability to flow. The larger the polymer molecule is (higher number of the monomer units and average molecular weight), the more “thickness” the polymer will display (indicating a higher viscosity value) (see Appendix I). In many studies on PDMS which have been referred in the assessment, viscosity has been reported and used to characterize the molecular weight of a polymer.

High molecular weight siloxane polymers (including PDMS) are not volatile and not expected to partition into air and degrade (Graiver et al. 2003). For a polymer with an average molecular weight >1 000 g/mol, the vapour pressure is expected to be less than 1.33 × 10-6 Pa (10-8 mm Hg) and the Henry’s Law constant less than 1.01 × 10-3Pa•m3/mol (10-8 atm•m3/mol) (USEPA 2008). Given the large molecular weight of MHD34MH (2655.45 g/mol), the n=34 form of the polymer is expected to possess a low vapour pressure and low Henry’s Law constant.

Siloxane polymers are relatively free-flowing liquids, even at high molecular weight (viscosity up to 500 000 cs, which is equivalent to an average molecular weight around 100 000 g/mol) (Fendinger et al. 1997). This may be attributed to the high degree of flexibility of the siloxane backbone and to the resulting low inter-molecular attractive forces. The polymer is characterized by a low melting point and a high boiling point, and remains as a liquid at standard environmental temperatures (Fendinger et al. 1997; Graiver et al. 2003).

Based on the data for PDMS, MHD34MH is anticipated to be insoluble in water, while the octanol-water partition coefficient (Kow) is anticipated to be high. The polymer contains no functional groups which could undergo hydrolysis in water. If released to water, the polymer may form a thin layer on the surface of the water, due to a specific gravity slightly less than water (approximately 960 kg/m3) (Fendinger et al. 1997; Environment Canada 2010a; ECETOC 1994).

Given the above information, the n=5 form of MHDnMH is expected to have a moderate vapour pressure; however the n=34 form of the polymer is anticipated to be much less volatile with the increase of the chain length.

The polymer (both n=5 and n=34 forms) is expected to be insoluble in water, with a specific gravity slightly less than water, and remains in the liquid state at environmental temperatures.

MHDnMH is not reported to be naturally produced in the environment.

Recent information was collected through industry surveys conducted for the 2005 and 2006 calendar years by means ofCanada Gazette notices issued pursuant to section 71 of CEPA 1999 (Canada 2006). These notices required submission of data on the Canadian manufacture and import of MHDnMH. In the notice for 2006, data were also required on the use quantity of the substance.

In 2005, fewer than 4 companies identified themselves as manufacturing 100-1000 kg or importing 1 001 to 100 000 kg of MHDnMH in Canada. There were also fewer than 4 companies reporting a stakeholder interest in this substance.

In 2006, fewer than 4 companies identified themselves as manufacturing between 10 000 to 100 000 kg of MHDnMH in Canada and fewer than 4 companies identified themselves as importing less than 100 kg of the substance into the country. There were also fewer than 4 companies reporting a stakeholder interest in this substance.

The quantity reported to the Domestic Substances List (DSL) as being manufactured, imported or in commerce in Canada during the 1986 calendar year was between 100 – 1000 kg.

According to information from the United States Environmental Protection Agency (USEPA), the import/production of MHDnMH was in the range of 4 500 to 225 000 kg (originally reported as 10 000 to 500 000 lb) in 1994; no import or production data were reported in 1998 and 2002 (USEPA 2005).

MHDnMH was also used in Nordic Countries in the range of 6 000 to 60 000 kg from 1999 to 2008 in Sweden, and in the range of 400 to 13 000 kg from 2000 to 2008 in Denmark (SPIN 2006).

Information on uses for the 2005 and 2006 calendar years was also obtained as part of the response to the CEPA 1999 section 71 notices (Canada 2006 and 2009).

In 2005, MHDnMH was imported mainly for basic chemical manufacturing.

In 2006, the polymer was manufactured as a chemical intermediate for use in further plastic synthesis outside Canada. The substance was also imported in 2006 in a silicone elastomer mixture that contains between 1% and 59% of MHDnMH. It is used as a curing agent for silicone rubber, adhesive or protective coating resins (Environment Canada 2010a).

MHDnMH was notified as an ingredient in four types of cosmetic products in Canada: in bra adhesive (30-100% by weight); skin whitening cream (0.1-0.3% by weight); lipstick (< 0.1 % by weight); and eye makeup (< 0.1 % by weight) (CNS 2010). However, MHDnMH does not appear on the Cosmetic Ingredient Hotlist, Health Canada’s administrative list of ingredients that are intended to be prohibited or restricted for use in cosmetics in Canada (Health Canada 2009). MHDnMH is not currently used in any pest control products registered for use in Canada as either an active ingredient or a formulant (PMRA 2007). MHDnMH is not listed as an approved food additive under Division 16 of the Food and Drug Regulations (Canada 1978). MHDnMH was not identified in food packaging applications or in incidental additives (April 2010 email from Food Directorate, Health Canada, to Risk Management Bureau, Health Canada; unreferenced). MHDnMH is not listed in the Drug Product Database (DPD), the Therapeutic Products Directorate's internal Non-Medicinal Ingredient Database, the Natural Health Products Ingredients Database or the Licensed Natural Health Products Database as a medicinal or a non-medicinal ingredient present in final pharmaceutical products, natural health products or veterinary drugs (DPD 2010; NHPID 2010; LNHPD 2010; April 2010 email from Therapeutic Products Directorate, Health Canada to Risk Management Bureau, Health Canada; unreferenced).

The following DSL use codes have been identified for MHDnMH:

04- Adhesive / binder / sealant / filler

25- Humectant/dewatering aid/dehumidifier/dehydrating agent

89- Printing and Publishing

Other uses of MHDnMH have not been identified.

A method has been developed by Environment Canada to estimate a substance’s losses during different stages of its life cycle, including its fate after being incorporated into a finished product or article (Environment Canada 2008). This method consists of a life cycle analysis and a spreadsheet tool (Mass Flow Tool or MFT) that integrates information on the manufacturing, importation and use data available for the substance. Starting with an identified mass of the substance, each life cycle stage is subsequently evaluated until all of the mass is accounted for. Relevant factors are considered, uncertainties recognized and assumptions may be made during each stage, depending on information available. The estimated losses represent a complete mass balance over the life cycle of the substance and include releases to wastewater and other receiving compartments (land, air), chemical transformation, transfer to recycling activities and transfer to waste disposal sites (landfill, incineration). However, unless specific information on the rate or potential for release of the substance from landfills and incinerators is available, the method does not quantitatively account for releases to the environment from disposal. Ultimately, the estimated losses provide a first tier in the exposure analysis of a substance and help to estimate environmental releases and focus exposure characterization in the assessment.

In general, releases of a substance to the environment depend upon various losses from its manufacture, industrial use, and/or consumer/commercial use. These losses can be grouped into seven types: (1) discharge to wastewater; (2) emission to air; (3) loss to land; (4) chemical transformation; (5) disposal to landfill; (6) loss to incineration; and (7) disposal through recycling (i.e., recycling is deemed a loss and not considered further). They are estimated using regulatory survey data, industry data and data published by different organizations. The discharge to wastewater refers to raw wastewater prior to any treatment, whether it is on-site industrial wastewater treatment or off-site wastewater treatment. In a similar manner, the loss via chemical transformation refers to changes in a substance's identity that may occur within the manufacture, industrial use, and consumer/commercial use stages, but excludes those during waste management operations such as incineration and wastewater treatment. The loss to land includes unintentional transfer or leakage to soil or paved/unpaved surfaces during the substance’s use and service life (e.g., from the use of agricultural machinery or automobiles). The loss to land, however, does not include transfers subsequent to a substance’s use and service life (e.g., land application of biosolids and atmospheric deposition).

The losses estimated for MHDnMH over its lifecycle (based on conservative assumptions) are presented in Table 3 (Environment Canada 2010b). The estimated losses are calculated based on the identified uses in 2006.

Table 3. Estimated Losses of MHDnMH during Its Lifecycle

| Type of Loss | Proportion (%) | Pertinent Lifecycle Stages |

|---|---|---|

| Wastewater | 1.0 | Manufacture and industrial use |

| Air emission | <0.1 | Manufacture and industrial use |

| Land | 0.3 | Manufacture and industrial use |

| Chemical transformation | - | - |

| Landfill | 1.0 | Manufacture and industrial use |

| Incineration | - | - |

| Recycling | - | - |

| Export | 97.7 | Manufacture and industrial use |

According to the section 71 survey, the majority of the polymer was exported out of the country as a chemical intermediate in bulk to manufacture plastics (Environment Canada 2010a).

Although there is the possibility that other consumer/commercial products containing MHDnMH may be imported into Canada in addition to those reported as a result of industry surveys conducted pursuant to Section 71 of CEPA 1999, no information is available on the quantity of such imports. However, the actual mass of the substance lost from each of the life cycle stages may be higher than the estimates provided above, if such information was available for consideration.

Environmental fate of MHD5MH and MHD34MH may be inferred from their physical and chemical properties as indicated previously.

MHD5MH

Based on estimated physical and chemical properties (Table 2c), MHD5MH is characterized by very low water solubility (~2.5 × 10-6 mg/L), moderate vapour pressure (0.1 Pa), high log Koc value (5.7), and very high Henry’s Law Constant (2.0 × 107

Pa·m3/mol). Thus, partitioning to each of the air, soil, sediment and water compartments is potentially significant, depending on the compartment of release and the rates of partitioning relative to other fate processes such as advection and degradation.

The Level III fugacity model has been used to predict the environmental partitioning of the low molecular weight polymer, with consideration of the half-lives in air (estimated as 122.64 hours, equivalent to 5.11 days), water (4386 hours, equivalent to 182 days), soil (670 hours, equivalent to 4 weeks), and sediments (8760 hours, equivalent to 365 days). Half-lives used for Level III fugacity modelling are estimated later in this report (see Environmental Persistence section).

Table 4. Results of the Level III fugacity modelling for MHD5MH (EQC 2003)

| Substance released to: | Percentage of substance partitioning into each compartment | |||

|---|---|---|---|---|

| Air | Water | Soil | Sediment | |

| Air (100%) | 97.6 | 0.1 | 0.2 | 2.1 |

| Water (100%) | 0.1 | 3.4 | <0.1 | 96.4 |

| Soil (100%) | 55.1 | <0.1 | 43.6 | 1.2 |

If released to air, a high amount of the substance is expected to reside in this environmental compartment. Based on the moderate vapour pressure (modelled as 0.10 Pa) and very high Henry’s Law constant (calculated as 2.0 × 107Pa•m3/mole), the polymer is semi-volatile. Therefore, if released solely to air, MHD5MH will tend to reside in this compartment, with little partitioning to other environmental media.

If released into water, MHD5MH is expected to strongly adsorb to suspended solids and sediment based upon its high estimated log Koc value of ~6. Volatilization from water surfaces is expected to be an unimportant fate process. Thus, if water is a receiving medium, MHD5MH is expected to mainly partition to sediment with a small amount residing in water.

If released to soil, MHD5MH is expected to have moderate adsorptivity to soil (i.e., expected to be relatively immobile based upon its estimated log Koc). Volatilization from soil surfaces seems to be a significant fate process based upon the expectation that this compound’s Henry's Law constant is very high. This chemical may volatilize from soil surfaces based upon its vapour pressure (estimated at 0.1 Pa). Therefore, if released to soil, it is expected that less than half of the total quantity of MHD5MH will remain in the soil.

MHD34MH

Due to the high molecular weight, MHD34MH is not suitable for use with any model to predict its environmental fate. Based on the read-across of physical and chemical properties of PDMS, MHD34MH remains in a liquid state at environmental temperatures and is expected to be non-volatile and insoluble in water.

If released to air, a negligible amount of the substance is expected to reside in this environmental compartment, based on the assumptions that MHD34MH has a low vapour pressure, and the polymer is non-volatile. Therefore, if released solely to air, the polymer will tend to be deposited to soil and sediment.

If released into water, MHD34MH in emulsions is expected to strongly adsorb to suspended solids and sediment. In a study by Gettings and Lane (1982), a hydroxyl-endblocked PDMS (the physical and chemical properties equivalent to PDMS 55 cs) was adsorbed from water phase to suspended particulates and settled in the sediment without further remobilisation over a 6 week period. If mixed with sediment prior to the test, the polymer remained immobile during the test period. Eales and Taylor (1983) also studied the movement of PDMS (50cs) in sea sediment. The polymer was concluded to be bound firmly to marine sediment and unlikely to be remobilised by seawater. Volatilization from water surfaces is expected to be an unimportant fate process. Thus, if water is a receiving medium, MHD34MH is expected to mainly partition to sediment.

If released to soil, MHD34MH is expected to behave similarly to PDMS and demonstrate high adsorptivity to soil (i.e., expected to be relatively immobile based upon its large molecular size and assumption of high log Koc). In a study on the distribution in soil (Battelle 1992), there was no movement of a14C-PDMS (200 cs) after it was released into this environmental compartment, and it was not shown to partition into the aqueous or atmospheric phases. Therefore, if released to soil, MHD34MH is expected to mainly reside in this environmental compartment.

Environmental Persistence

No experimental degradation data for MHDnMH have been identified.

MHD5MH

QSAR models have been applied to the low molecular weight polymer MHD5MH to assess the potential for degradation. Such predictions are considered acceptable for use in this situation, as the molecular weight of MHD5MH is in the domain of all the models.

Table 5 summarizes the results of available QSAR models for the degradation of MHD5MH in water and air.

Table 5. Modelled data for degradation of MHD5MH

| Fate Process | Model and model basis | Model Result and Prediction | Extrapolated Half-life (days OR hours ) |

|---|---|---|---|

| Air | |||

| Atmospheric oxidation | AOPWIN 2008[1] | t 1/2 = 5.11 days | ≥ 2 |

| Water | |||

| Hydrolysis | HYDROWIN 2008[1] | n/a[2] | n/a |

| Primary biodegradation | |||

| Biodegradation (aerobic) | BIOWIN 2008[1] Sub-model 4: Expert Survey (qualitative results) |

3.11[3] “biodegrades fast” |

< 182 |

| Ultimate biodegradation | |||

| Biodegradation (aerobic) | BIOWIN 2008[1] Sub-model 3: Expert Survey (qualitative results) |

2.08[3] “does not biodegrade fast” |

≥ 182 |

| Biodegradation (aerobic) | BIOWIN 2008[1] Sub-model 5: MITI linear probability |

-0.78[4] “does not biodegrade fast” |

≥ 182 |

| Biodegradation (aerobic) | BIOWIN 2008[1] Sub-model 6: MITI non-linear probability |

0.00[4] “does not biodegrade fast” |

≥ 182 |

| Biodegradation (aerobic) | CATABOL c2004–2008 % BOD (biological oxygen demand) |

1.68 “biodegrades very slowly” |

≥ 182 |

[2] Model does not provide an estimate for this type of structure.

[3] Output is a numerical score from 0 to 5.

[4] Output is a probability score.

In air, a predicted atmospheric oxidation half-life of 5.11 days (see Table 5) indicates that MHD5MH is not likely to be rapidly oxidized. Reaction with ozone is not anticipated to be significant either. Therefore, MHD5MH is considered to be persistent in air. Depending on the media of release, and because of the substance’s anticipated moderate volatility and very high Henry’s Law constant, it is expected to be found in air in a significant portion, compared to its distribution to the other environmental media.

In water, MHD5MH is not expected to undergo significant hydrolysis in this environmental compartment. Although the BIOWIN (2008) aerobic biodegradation model (BIOWIN submodel 4) suggests fast primary degradation for the polymer, the four ultimate biodegradation models (BIOWIN submodels 3, 5, 6 and CATABOL) suggest that the substance does not biodegrade rapidly in water. When these results are considered, there is model consensus that the ultimate biodegradation half-life for MHD5MH in water is > 182 days.

MHD34MH

Due to its large molecular weight (2655.45 g/mol), the n=34 form of this polymer is considered to be out of the domain of QSAR models for predicting degradation in the aquatic environment. For the purpose of this assessment, experimental data for PDMS (presented below) are used to evaluate the potential for persistence of MHD34MH in the environment.

Air and Water

PDMS is not volatile and not expected to partition into the atmospheric compartment, and is thus not considered available for further degradation in this compartment (Graiver et al. 2003; ETETOC 1994). There is also no evidence indicating that PDMS would degrade fast in the aquatic environment. From the studies of wastewater treatment, PDMS was found not to degrade or decompose in the wastewater treatment process but end up in the solid sludge (Graiver et al. 2003). Having a hydrogen-dimethyl terminating group, MHD34MH is slightly more reactive than PDMS, but no significant reaction is expected in environmental conditions. Based on this information for PDMS, MHD34MH is thus not expected to degrade rapidly in air or water.

Soil

For degradation in soil, there have been a number of studies reporting the depolymerisation and rapid clay-catalyzed hydrolysis of PDMS such that the polymer is broken down to low molecule weight oligomers.

Buch and Ingebrigtson (1979) reported a half-life of approximately 30 days of PDMS (1 000 cs, equivalent to a molecular weight of ~15 000 g/mol) at a 6 000 mg/kg concentration in a dry Iowa topsoil. Such reaction was inhibited even with only 1% moisture content. In the same study, they also reported an extensive loss of the polymer (50 cs) due to degradation over the 53-day duration of the test.

There are several studies on the environmental behaviour of PDMS in soil (summarized in Graiver et al. 2003). Results from these studies indicate that PDMS quickly depolymerises by soil hydrolysis, thereby breaking the siloxane bonds and producing lower molecular weight oligomeric PDMS. Such soil-catalyzed hydrolytic degradation is random, not specific to certain bonds, and does not necessarily start from the chain end. Furthermore, the hydrolysis catalyzed by clay minerals in soil does not occur in any of the other media (air, water or sediment) to a significant degree.

Lehmann et al. (1994a) and Carpenter et al. (1995) also studied degradation under more realistic soil conditions, by analyzing the degradation product extracted with either 0.01 M CaCl2or tetrahydrofuran. The results indicate that the degradation of PDMS (204 cs) took place in the soil, which was gradually air drying from 12% to 3% moisture faster than the degradation of the substance maintained at constant moisture (12-13% moisture) in incubation chambers.

In another experiment, Lehmann et al. (1995) further studied 7 soils with widely differing properties. PDMS (350 cs) was spiked into moist soil and allowed to gradually dry for 2 weeks. PDMS degraded extensively after 14 days to lower molecular weight materials. Although degradation took place when the soil was still moist, the degradation rates were greatest in the most weathered soil. However, there is no correlation observed between PDMS degradation rate and the soil properties measured (pH, % organic matter, and % clay).

The rate of depolymerization by hydrolytic degradation in soil is fast but dependent on several factors such as the moisture level and the temperature. Lehmann et al. (1995) reported that the overall degradation rates were slower in moist soil than in the soil which was allowed to gradually dry for two weeks, indicating that continuous moisture could be an important factor, but moisture content is inversely related to the degradation rate (Lehmann et al. 1998b). In addition, the study results also demonstrated that warm temperatures favour the degradation rate during a yearly weather cycle.

In another study (Xu 1998), no PDMS was detected after 30 days of incubation in goethite and even faster degradation was observed when the polymer was incubated in Al-montmorillonite. For the impact of water content, the study reported a faster depolymerisation rate at the relative humidity (RH) of 32% compared to a RH of 100%. Considering the field data from different types of soil in the study, the PDMS depolymerization half-life is expected to be no longer than 3 weeks.

Based on results from two experimental studies, PDMS is anticipated to undergo clay-catalyzed hydrolysis rapidly in soil with a half-life of a few weeks. Given this evidence for PDMS, MHD34MH is anticipated to hydrolyze rapidly in soil with a half-life of a few weeks, which is much less than 182 days; therefore the polymer is considered to be not persistent in this environmental medium.

Dimethylsilanediol (DMSD) is the major product from soil-catalyzed hydrolysis of PDMS (Stevens 1998; Craig 2003). Following the polymer decomposition phase of the experiment, radio-labelled 14C was used to detect the source of CO2, which was eventually coming from the biodegradation of the 14C-PDMS degradation products. DMSD biodegradation was illustrated by Sabourin et al. (1996), who reported that biodegradation of DMSD began with the oxidation of a methyl group producing methylsilanetriol. Methylsilanetriol then further degrades to CO2 and silica.

Volatilization may also account for DMSD loss from the soil and compete with losses that result from biodegradation. After its release in the air, the methyl groups of DMSD will undergo reaction with OH radicals that are generated in the presence of sunlight (Atkinson 1991). Neither ozone nor the NO3 radicals were found by these authors to react with methylsiloxanes, but the reaction with OH radicals yielded atmospheric lifetimes of 10-30 days for several oligomeric methylsiloxanes. In another similar study (Sommerlade et al. 1993), lifetimes of 2-9 days in air were found for various oligomeric methylsiloxanes and trimethylsilanol, and the identification of several reaction products showed that methyl groups were being replaced with hydroxy groups.

Based on the experimental evidence from PDMS and the structural similarity between the analogue and the polymer, MHD34MH is expected to degrade rapidly in soil and does not persist in this environmental medium.

Sediment

In sediment, degradation of PDMS has also been observed; however, the rate is apparently much slower than in soil, as the half-life is more than a year (Environment Canada 2010a).

An experiment (Christensen 1994) has examined the potential for PDMS degradation in freshwater sediment. A concentration of 500 ppm of 14C-labelled PDMS (350 cs) was added into sediment/water columns. Water soluble materials and the off-gas were monitored as the evidence of degradation. After 56 days, no evidence of 14CO2 or water soluble14C was observed, indicating no degradation in sediment occurred during the test period.

In other longer incubation studies, degradation of PDMS in sediment was, however, evident (Fendinger et al. 1997). Following a year of incubation under aerobic conditions, 5-10% of the PDMS (350 cs) was hydrolyzed to DMSD and approximately 0.25% of the total14C had been oxidized to carbon dioxide (Carpenter et al. 1995). The rate and extent of DMSD formation and carbon dioxide production from sediment agree closely with the rates observed by Lehmann et al. (1994a, 1994b) in moist soil (3% DMSD and 0.13% carbon dioxide formed in 6 months). Given its high adsorption and immobility in sediment in combination with the water content of the substrate, it is anticipated that PDSM degrades very slowly in sediment and the half-life of the polymer in this environmental medium is expected to be longer than 365 days. The prediction can be extrapolated to the polymer under assessment such that MHD34MH is not expected to degrade rapidly in sediment either, and the half-life in this environmental medium is expected to be more than 365 days.

Based on the modelled data for the low molecular weight polymer (MHD5MH) (see Table 5) and experimental studies on the analogue polymer (PDMS) as read-across for the high molecular weight polymer (MHD34MH), MHDnMH is expected to degrade rapidly in soil (half-life in soil = 182 days). However the substance meets the persistence criteria in air, water and sediment (half-life in air = 2 days, half-life in water = 182 days, and half-life in sediment = 365 days) as set out in the Persistence and Bioaccumulation Regulations (Canada 2000), and therefore is concluded to be persistent in the environment.

There are no experimental data on the potential for bioaccumulation of MHDnMH.

Experimental data for the analogous linear methyl siloxane have been used to predict the bioaccumulation potential for MHD5MH. Additionally, QSAR models have also been applied for estimating a bioaccumulation factor (BAF) and bioconcentration factor (BCF) for this low molecular weight compound.

For the large molecular weight polymer, MHD34MH, experimental data for PDMS have been used to assess potential for bioaccumulation.

MHD5MH

Modelled data for bioaccumulation for MHD5MH are summarized in Table 6 below.

Table 6a. Modelled data for bioaccumulation for MHD5MH

| Test organism | Endpoint | Value wet weight (L/kg) | Reference |

|---|---|---|---|

| Fish | BCF | 1.04 × 104 | BCFBAF 2008 (mid trophic level) |

| Fish | BCF | 7.41 × 104 | Arnot and Gobas 2003 (mid trophic level) |

| Fish | BCF | 3.24 × 104 | BBM with Mitigating Factors 2008 |

| Fish | BAF | 5.48 × 106 | BCFBAF 2008 (mid trophic level) |

| Fish | BAF | 3.39 × 106 | Arnot and Gobas 2003 (mid trophic level) |

According to the model predictions (based on the modelled log Kow= 6.60), MHD5MH may have a high BAF and BCF in fish. However, experimental results indicate different bioaccumulation potentials of the low molecular weight linear methyl siloxanes.

Annelin and Frye (1989) reported no intake of the linear PDMS oligomers, having molecular weights greater than 384 g/mol (MD3M, which is the smallest form of PDMS), by fish after an exposure period of greater than 5 weeks. The experimental results indicated that none of the MD3M, MD4M, or MD7M (MW=607 g/mol) was bioconcentrated in rainbow trout after 35 to 77 days exposure.

In another study on absorption and retention of PDMS in fish (Bruggeman et al. 1984), a number of linear methyl siloxanes were present in food at the average daily intake of 1 × 10-3mg/g of fish for 6-8 weeks. At the end of feeding period, MD3M and MD4M were found below detection limits (approximately 3 × 10-4 mg /g) in all fish samples, while MD5M and other longer linear methyl siloxanes did not exceed 2 × 10-3 mg/g. Comparing to the average daily intake (1 × 10-3 mg/g), these results indicated that absorption and retention and accumulation of MD3-6M via food is not significant. It therefore can be expected that MHD5MH (with a similar linear structure and a molecular weight higher than MD3M and MD4M) possesses a similar bioaccumulation potential and is also not likely to bioaccumulate in fish.

Investigations by Dimitrov et al. (2002), Dimitrov et al. (2005) and the Baseline Bioaccumulation Model (BBM 2008) suggests that the probability of a molecule crossing cell membranes as a result of passive diffusion declines significantly with increasing maximum cross-sectional diameter (Dmax). The probability of passive diffusion lowers appreciably when cross-sectional diameter is > ~1.5 nm and more significantly for molecules having a cross-sectional diameter of >1.7 nm. Sakuratani et al. (2008) have also investigated the effect of cross-sectional diameter on passive diffusion from a test set of about 1200 new and existing chemicals. They also observed that substances not having a very high bioconcentration potential often have a Dmax>2.0 nm and an effective diameter (Deff) >1.1 nm.

According to the estimation of physical and chemical properties for MHD5MH, the substance has a cross-sectional diameter in the range 1.46 to 2.18 nm. Based on the observation mentioned above (Sakuratani et al. 2008), the n=5 form of the polymer is associated with a potential for reduced uptake rate from water and reduced in vivo bioavailability of MHD5MH.

Based on the experimental data for analogous linear methyl siloxanes, with consideration of the molecular size, MHD5MH is not expected to bioaccumulate in aquatic organisms.

MHD34MH

Compared to the low molecular weight form of MHDnMH (n=5), MHD34MH would have a correspondingly much larger molecular size. Such character would limit the partitioning behaviour (i.e., crossing biological membranes), and therefore make the polymer even less bioavailable and less likely to bioaccumulate in aquatic organisms. Data from studies on PDMS are used to characterize the bioaccumulation potential for MHDnMH (see data summarized in Table 6b below).

Table 6b. Empirical data for bioaccumulation and bioconcentration of PDMS

| Polymer Character (Molecular Weight, Viscosity or Emulsion) |

Test Organism | Experimental Concentration (mg/L) and/or Exposure Source | Endpoint of BAF/BCF (L/kg) and/or BMF[1](dimensionless) | Reference |

|---|---|---|---|---|

| 300 cs 15% emulsion | Bluegill sunfish (Lepomis macrochirus) |

1.5 | BCF = 0.16 – 0.5 (after 2 weeks) |

Hobbs et al. 1975 |

| MD15-17M | Guppies (Poecilia reticulate) |

Saturation | BCF < 10 | Opperhuizen et al. 1987 |

| Approximately 32 mg/kg in dry food | BAF < 0.01 | |||

| Commercial PDMS MW (g/mol): 1200 6000 25000 56000 |

Carp sp. | Saturation solutions measured concentrations 1.330 0.486 0.135 0.060 |

BCF = 2.9 BCF = 7.1 BCF = 386 BCF = 1250 |

Watanabe et al. 1984a |

| 50 cs 35% emulsion |

Level 1: Phytoplankton (Tetraselmis sp.) Level 2: Mollusc (Mytilus edulis) |

70 Direct exposure from water Exposure from water and food |

BCF = 2.08 BMF = 0.12 |

Aubert et al. 1985 Guillemaut et al. 1987 |

| Level 1: Plankton (Tatreselmis sp.Artemia salina) Level 2: Fish (Carassius auratus) |

70 Direct exposure from water Exposure from water and food |

BCF = 1.9 BMF = 0.05 |

||

| Level 1: Annelid (Nereis diversicolor) Level 2: Fish (Scorpaena porcus) |

70 Direct exposure from water Exposure from water and food |

BCF = 0.036 BMF = 1.4 |

||

| Level 1: Annelid (Nereis diversicolor) Level 2: crab (Carcinus maenas) |

70 Direct exposure from water Exposure from water and food |

BCF = 0.036 BMF = 1.09 |

||

| 50 cs | Bullhead catfish (Ictalurus melas) |

Exposure from food | < detection level | Annelin 1979 |

Generally, PDMS with a variety of molecular weights (MW=1200 g/mol and above) demonstrates low bioaccumulation and bioconcentration in aquatic organisms and terrestrial species.

Opperhuizen et al. (1987) conducted a bioaccumulation study on guppies (Poecilla reticulate) using PDMS (5 cs, MD15-17M). After 12 weeks of exposure, siloxane polymers were not detected in the whole fish.

In another study, bluegill sunfish (Lepomis macrochirus) were exposed to a PDMS (molecular weight > 5 000 g/mol) for 30 days (Hobbs et al. 1975). There was no relationship found between the polymer tissue levels and duration or level of exposure. It was observed, however, that the polymer was adsorbed to surfaces of the fish, and not taken up into the cells.

In addition, there were studies of PDMS uptake by other species in other environmental media. In a 28-day study by Garvey et al. (1996), earthworms (Eisenia foetida) were exposed to 100 and 1 000 mg/kg PDMS in an artificial soil matrix. At termination of the exposure phase, the earthworms from each replicate were transferred to exposure media that contained no PDMS for the 14-day depuration phase of the study. Samples were collected through the 28-day exposure phase; however there was no statistical difference in the tissue residue concentrations between any the two groups. Furthermore, PDMS ingested by the earthworms and present in the gut was rapidly depurated during a following 14-day period.

Kukkonen and Landrum (1995) examined aquatic worms living in the sediments and concluded that there was no bioaccumulation of PDMS observed in these worms.

Results from studies on other benthic and terrestrial organisms (Putt 1994; Putt and Mihaich 1996) also indicated very limited bioaccumulation potential for PDMS.

There is one study that reports a contradictory finding, in which the higher molecular weight PDMS materials bioaccumulated more than lower molecular weight compounds – based on tests using silver carp (Watanabe et al. 1984a). The fact that the relationship between bioaccumulation and the molecular weight is the reverse of what would be expected is probably the result of surface contamination, and no evidence was available to indicate whether whole fish or fillet were analysed. Thus, these results are of uncertain quality.

Biomagnification or food-chain transfer of a PDMS (50 cs) emulsion in the marine environment has been studied (Aubert et al. 1985; Guillemaut et al. 1987). Organisms in the first level of the food chain were exposed to emulsified PDMS (50 cs) at a concentration of 70 mg/L in water. PDMS was either not bioconcentrated in water or the BCF was <2 in the first level of the food chain. The bioaccumulation between the two trophic levels was low, ranging between 0.05 and 1.4, indicating that the biomagnification of PDMS between two trophic levels is not significant in the aquatic food chain tested.

Based on the above information on PDMS, it is expect that MHD34MH is not bioavailable in either the aquatic or soil dwelling organisms. The polymer does not bioaccumulate in those organisms either.

Given the assessment on the bioaccumulation potentials for both the low and number-average molecular weight polymers, it is concluded that MHDnMH does not meet the bioaccumulation criteria (BAF or BCF = 5000) as set out in the Persistence and Bioaccumulation Regulations (Canada 2000).

Ecological Effects Assessment

A - In the Aquatic Compartment

There were no experimental toxicity data found for MHDnMH.

MHD5MH

For MHD5MH, QSAR models have been used to estimate the aquatic toxicity and the modelled data are summarized in Table 7a below.

Table 7a. Modelled data for aquatic toxicity of MHD5MH

| Test organism | Type of test | Endpoint | Value (mg/L) |

Model |

|---|---|---|---|---|

| Fish | Acute (96 hours) | LC50[1] | 0.035[*] | ECOSAR 2008 |

| Acute (14 days) | 0.038[*], [!] | |||

| Fish (sea water) | Acute (96 hours) | LC50 | 0.035[*] | |

| Daphnid | Acute (48 hours) | LC50 | 0.039[*] | |

| Green Algae | Acute (96 hours) | EC50[2] | 0.137[*] | |

| Mysid Shrimp | Acute (96 hours) | LC50 | 0.001[*] | |

| Fish | Chronic (30 days) | ChV[3] | 0.005[*] | |

| Daphnid | Chronic | ChV | 0.009[*] | |

| Green Algae | Chronic | ChV | 0.112[*] | |

| Mysid Shrimp | Chronic | ChV | 0.00003[*] | |

| Fish (sea water) | Chronic | ChV | 0.072[*] | |

| Earthworm | Chronic (14 days) | LC50 | 293.13[*] | |

| Fathead Minnow | Acute (96 hours) | LC50 | 146[*] | AIEPS 2003-2007 |

| Daphnia magna | Acute (48 hours) | LC50 | 13.19[*] | |

| Pseudokirchneriella subcapitata | Acute (72 hours) | EC50 | 14.09[*] | |

| Daphnia magna | Acute (48 hours) | EC50 | 0.18[*] | OASIS Forecast 2005 |

| Pimephales promelas | Acute (96 hours) | EC50 | 0.43[*] |

[2] EC50- The concentration of a substance that is estimated to cause some effect on 50% of the test organisms.

[3] ChV – Chronic toxicity value

[*] The exposure concentration is at least 10 times higher than the estimated water solubility, indicating that no effects at saturation are predicted for the subject chemical.

[!] Critical toxicity value (CTV). It is further used to derive the predicted no effect concentration (PNEC).

The model estimates of aquatic toxicity for MHD5MH have been summarized in Table 7a. It is noted that the modelled values of all endpoints are far higher than the modelled water solubility of MHD5MH (2.7 × 10-6 mg/L). These results therefore suggest that, at the maximum soluble level, MHD5MH does not have any observable effect on aquatic organisms in short term exposures. Nonetheless for the purposes of a conservative toxicity assessment for MHD5MH, a modelled 14-day LC50 = 0.038 mg/L on fish has been used as the critical toxicity value (CTV) to characterize the risk of MHD5MH on aquatic organisms.

MHD34MH

There are no QSAR models applicable for modelling the ecotoxicity for the polymer with a large molecular weight. Information on PDMS has thus been used to assess the toxicity of MHD34MH.

There are a number of toxicity studies reporting effects of PDMS on aquatic organisms and their results are summarized in Table 7b. As mentioned earlier in this report (see Potential for Bioaccumulation section), PDMS is not taken up by aquatic organisms (Annelin and Frye 1989; Bruggeman et al. 1984); therefore, effects are not expected. Because PDMS is extremely hydrophobic and tends to adsorb strongly to solid particles, the polymer in emulsion form has been used in many studies to maintain constant and nominal exposure concentrations. These concentrations are higher than the water solubility of PDMS.

In general, PDMS has demonstrated low toxicity to fish (see Table 7b). A chronic no observed effect concentration (NOEC) of 91 mg/L of PDMS (50 cs emulsion) to the sheepshead minnow was reported by Hill et al. (1984). In another study, Hill et al. (1980) reported an LC50 at the exposure level of 350 mg/L of PDMS (50 cs emulsion) to plaice. The toxic effects of PDMS emulsions at high concentrations were shown to have been caused by the emulsifier used in the formulation (Hobbs et al. 1975; Aubert et al. 1985).

PDMS has also shown low toxicity to aquatic invertebrates (see Table 7b). An LC50 of 1980 mg/L of PDMS (50 cs emulsion) has been reported from a study on the mussel Mytilus sp. (Hill et al. 1984). However the adverse effects are somewhat difficult to interpret. PDMS fluids are insoluble in water and have a specific gravity less than 1000 kg/m3. Therefore the polymer forms a surface film in which the aquatic invertebrate tends to be caught. Such entrapment may occur and therefore interfere with the assessment of the chemical toxicity of the polymer.

Toxicity to aquatic microorganisms has also been studied and PDMS has been found not to be very hazardous to such organisms (see Table 7b).

Since the exposure concentrations of PDMS are well above the maximum solubility expected for the polymer in the available aquatic toxicity studies, the polymer likely poses low hazard to aquatic organisms under environmental conditions.

The Critical Toxicity Value (CTV) is selected from a study by Hill et al. (1977) conducted with PDMS (50 cs, 35% emulsion), since it has a molecular weight closest to the average molecular weight of MHD34MH. For the purpose of characterizing the risk of MHD34MH on aquatic organisms, the NOEC of 91 mg/L reported in this study has been used as the CTV to derive the predicted no effect concentration (PNEC).

Table 7b. Toxicity data of PDMS on aquatic organisms

| Polymer Character -- (viscosity and/or emulsion) |

Test Organism | Type of Test | Endpoint | Value (mg/L) | Reference |

|---|---|---|---|---|---|

| Fish | |||||

| Not specified | Fish | Acute | LC50[1] | >1000 | Annelin and Humble 1978; Hobbs et al. 1975 |

| Not specified | Minnows (Phoxinus phoxinus) |

Semi-chronic | LT40[2] | 3000 (8 days) | Cabridenc 1978 |

| 100, 350, 12500 cs | Pomatoschistus minutus Gasterosteus aculeatus |

Acute (96 hours) |

LC0[3] | At saturation | Maggi and Alzieu 1977 |

| 50 cs 20% emulsion |

Plaice (Pleuronetes platessa) |

Acute (96 hours) |

EC[4] | 88 | Firmin 1984 |

| 50 cs 35% emulsion |

Scorpion fish Scorpaena porcus Carassius auratus |

Acute | LT50[5] | 1000 (12 hrs) 2000 (50 hrs) 10 000 (hrs) 700 (50 hours) 3500 (24 hours) |

Aubert et al. 1985 |

| 50 cs | Plaice (Pleuronectes platessa) |

Acute (96 hours) |

LC50 | 350 > 10 000 at the surface of the water (5 mg/L in water) |

Hill et al. 1980 Hill 1980 |

| 50 cs 35% emulsion |

Sheepshead minnow (Cyprinodon variegatus) |

Chronic (33 days) |

NOEC[6] EC |

91[!] 235 (minor effects observed) |

Hill et al. 1984 |

| 350 cs | Rainbow trout Oncorhynchus mykiss) almo gairdneri) |

Sub-chronic spiked food (28 days) | NOEL[7] | 10 000 mg/kg bw/day | Mann et al. 1977 |

| 350 cs 30% emulsion |

Bluegill sunfish (Lepomis macrochirus) Rainbow trout (Salmo gairdneri) |

Acute (96 hours) |

LC50 Hypoactivity |

> 10 000 At both 1000 and 10000 |

Hobbs et al. 1975 |

| Aquatic invertebrate and molluscs | |||||

| 10 – 60000 cs 66% emulsion |

Daphnia | Acute | NOEC | >200 | Annelin et al. 1994 |

| 350 cs emulsion |

Daphnia magna | Acute (48 hrs) |

LC50 | 1000 | Spacie 1972 |

| 100, 350, and 12,500 cs | European oyster (Ostrea edulis) Mussel sp. (Mytilus edulis) Periwinkle (Littorina littorea) |

Acute (96 hours) |

LC0 | Saturation in sea water | Maggi and Alzieu 1977 |

| 50 cs 35% emulsion |

Mussel (Mytilus edulis) Crab (Artemia salina Carcinus maenas) |

Acute Semi-chronic (10 days) Semi-chronic |

LT50 LT50 LC0 LC50 Mortality |

3500 (96 hrs) 10000 (80 hrs) (emulsifier only) 700 7000 (9 days) 3500 (10 days) |

Aubert et al. 1985 |

| 50 cs 20% emulsion |

Mytilus sp. | Acute (96 hours) |

LC50 | 1980 | Hill et al. 1984 |

| 50 cs | Mytilus sp. | Acute (96 hours) |

LC50 | 1020 | Hill et al. 1984 |

| 100 cs 100 cs 30% emulsion 350 cs 30% emulsion |

Daphnia magna Daphnia magna Cockles (Prothaca spaminea) Mummichog (Fundulus heteroclitus) Shore crabs (Pachygrapsus crassipes) Brown shrimp (Penaeus oxtecus) |

Acute (48 hrs) Acute (48 hrs) Acute (96 hrs) |

LC50 LC50 LC50 |

44.5 (polymer formed a layer on the surface) 73.4 >1000 |

Hobbs et al. 1975 |

| Aquatic microorganisms (bacteria, fungi, and phytoplankton) | |||||

| 55 cs hydroxyl-endblock | Aerobic and anaerobic bacteria, algae, and protozoa | Chronic (24 weeks) |

NOEC | > 0.26 | Gettings and Lane 1982 |

| 100, 350, and 12,500 cs | Marine algae (diatoms and flagellates) |

Semi-chronic (9 days) |

NOEC | Saturation in sea water | Maggi and Alzieu 1977 |

| 50 cs 35% emulsion |

Marine phytoplankton Tetraselmis sp.) |

Not specified | LOEC[8] | 350 | Maggi and Alzieu 1977 |

[2] LT40 – The concentration of a substance that is used in time-until-death to determine 40% lethality of the test organisms in hours.

[3] LC0- The concentration of a substance that is estimated to have no lethal effect on the test organisms.

[4] EC - The concentration of a substance that is estimated to demonstrate toxic effect on the test. organisms, however the percentage of affected test organisms can not be determined in the study.

[5] LT50 – The concentration of a substance that is used in time-until-death to determine 50% lethality of the test organisms in hours.

[6] NOEC – The No Observed Effect Concentration is the highest concentration in a toxicity test not causing a statistically significant effect in comparison to the controls.

[7] NOEL – The No Observed Effect Level is the highest level of exposure in a toxicity test not causing a statistically significant effect in comparison to the controls.

[8] LOEC – The Lowest Observed Effect Concentration is the lowest concentration in a toxicity test causing a statistically significant effect in comparison to the controls.

[!] CTV – Critical Toxicity Value. It is further used to derive the predicted no effect concentration (PNEC).

Based on the model predictions, MHD5MH is not expected to demonstrate observable effects on aquatic organisms at its maximum water solubility level. For MHD34MH, considering the structural similarity to PDMS, it is also not anticipated to have any significant effects on aquatic organisms also within the range of its water solubility. Therefore, it is concluded that MHDnMH has low toxicity to aquatic organisms.

B - In Other Environmental Compartments

The primary route of exposure in an aquatic environment would be through contact with the polymer absorbed to sediments, due to its low water solubility; and therefore, the potential effects of the polymer on sediment-dwelling organisms is also considered in this screening assessment. Furthermore, since biosolids from treated wastewater system sludge is often used to augment agricultural soils and reclaim land, this pathway of exposure to the polymer to terrestrial organisms is also considered.

Since there are no experimental sediment or soil toxicity data for MHDnMH, information on PDMS is used to assess the toxicity of MHDnMH (see Table 7c below). In summary, PDMS demonstrates low toxicity to sediment and soil-dwelling organisms.

Table 7c. Toxicity data for PDMS on sediment and soil organisms

| Polymer Character (viscosity and/or emulsion) |

Test Organism | Test Medium and Type |

Endpoint | Concentration Value | Reference |

|---|---|---|---|---|---|

| Sediment organisms | |||||

| 350 cs | Marine amphipod (Ampelisca abdita) | Sediment Semi-chronic (10 days) |

LC0[1] | >2300 | Putt and Mihaich 1996 |

| 350 cs | Freshwater amphipod (Hyallela azteca) | Sediment Chronic (28 days) |

EC0[2] | >2200 | Putt and Mihaich 1996 |

| PDMS (viscosity/ emulsion characteristics not noted) | Polychaete worm (Nereis diversicolor) | Sediment Chronic (28 days) |

EC0 | 1000 | Craig et al. 1984 |

| 50 cs | Annelids | Sediment Acute (96 hours) Chronic (28 days) |

EC0 | >10 000 | Craig and Caunter 1990 |

| 50 cs 35 % emulsion (sea water) |

Polychaete worm (Nereis diversicolor) | Sediment Semi-chronic (9 days) |

LC0 EC0 | > 350 > 700 | Aubert et al. 1985 |

| 350 cs | Benthic invertebrates (H. azteca and C. tentans) |

Sediment Semi-chronic (10 days) Life-cycle (28 days for H. azteca and 50-65 days forC. tentans) |

LC0 EC0 | > 1000 | Henry et al. 2001 |

| Soil organisms | |||||

| 350 cs fluid |

Earthworm (Eisenia foetida) | Soil Chronic (21 days) |

EC0 | 1100 | Garvey et al. 1996 |

| 350 cs fluid |

Springtail (Folsomia candida) | Soil Chronic (21 days) |

NOEC[3] | 250 | Garvey et al. 1996 |

| Plant | |||||

| 10 cs 10% emulsion |

Conifer plantation | Soil Acute (right after the treatment) Chronic (1 year) |

NOEL[4] | 30 ml/m3 | Belt et al. 1977 |

| Birds | |||||

| 100 cs | Mallard duck (Anas platyrhynchos) Bobwhite quail (Colinus virginatus) |

Semi-chronic (5 days) |

LC0 | >5000 | Hobbs et al. 1975 |

| 100 cs | White Leghorn chickens | Chronic (24 weeks) |

EC0 | >5000 | Hobbs et al. 1975 |

[2] EC0- The concentration of a substance that is estimated to observed adverse effect on the test organisms.

[3] NOEC – The No Observed Effect Concentration is the highest concentration in a toxicity test not causing a statistically significant effect in comparison to the controls.

[4] NOEL – The No Observed Effect level is the highest level of exposure in a toxicity test not causing a statistically significant effect in comparison to the controls.

The effect of PDMS (5 to 1 000 cs) was also evaluated on adultAcheta domesticus (cricket) by direct application of the polymer (5 × 10-3 mg) to the ventral thorax (Levier 1988). The time of loss of righting reflex (the ability of a cricket to flip back over when placed on its back) increased with the viscosity of the PDMS and the mortality at 48 hours decreased 2 fold when the viscosity of PDMS increased 200 fold. A similar effect of PDMS (10 cs) was observed in another study (Nielson et al. 1975).

Based on study results for PDMS, it is expected that MHDnMH does not have a significant potential for toxicity to either soil or sediment-dwelling organisms.

Ecological Exposure Assessment

A – Industrial Release

No data concerning concentrations of MHDnMH in the environmental media in Canada have been identified. Environmental concentrations are therefore estimated based on the exposure analysis for the polymer with consideration of the quantities of MHD34MH manufactured in Canada, as well as MHD5MH contained in the polymer.