Screening Assessment for the Challenge

This page has been archived on the Web

Information identified as archived is provided for reference, research or recordkeeping purposes. It is not subject to the Government of Canada Web Standards and has not been altered or updated since it was archived. Please contact us to request a format other than those available.

Archived

2-Propenoic acid, ethyl ester

(Ethyl acrylate)

Chemical Abstracts Service Registry Number

140-88-5

Environment Canada

Health Canada

September 2011

Table of Contents

- Synopsis

- Introduction

- Substance Identity

- Physical and Chemical Properties

- Sources

- Uses

- Releases to the Environment

- Environmental Fate

- Persistence and Bioaccumulation Potential

- Potential for Bioaccumulation

- Potential to Cause Ecological Harm

- Potential to Cause Harm to Human Health

- Conclusion

- References

- Appendix 1: Upper-Bounding Estimates of Exposure to the General Population of Canada from Environmental Media (µg/kg-bw/d)

- Appendix 2: Upper-Bounding Estimates of Exposure to Ethyl Acrylate from Consumer Products

- Appendix 3: Summary of health effects information for ethyl acrylate

- Appendix 4: Robust Study Summary Aquatic Toxicity

Pursuant to section 74 of the Canadian Environmental Protection Act, 1999 (CEPA 1999), the Ministers of the Environment and of Health have conducted a screening assessment of 2-Propenoic acid, ethyl ester (ethyl acrylate), Chemical Abstracts Service Registry Number 140-88-5[1]. The substance ethyl acrylate was identified in the categorization of the Domestic Substances List as a high priority for action under the Challenge initiative under the Chemicals Management Plan. Ethyl acrylate was identified as a high priority as it was considered to pose the greatest potential for exposure of individuals in Canada and it is classified by other agencies on the basis of carcinogenicity. The substance did not meet the ecological categorization criteria for persistence, bioaccumulation potential or inherent toxicity to aquatic organisms.

According to information submitted under section 71 of CEPA 1999, ethyl acrylate was not manufactured by any company in Canada in the calendar year 2006 above the 100 kg reporting threshold. However between 1 000 000 and 10 000 000 kg of ethyl acrylate was reported to have been imported in 2006. The major use of ethyl acrylate is in the manufacture of polymers and copolymers. Releases of ethyl acrylate to the environment from these sources do occur. However, exposure of the general population of Canada to ethyl acrylate is not expected to occur at any appreciable level.

As ethyl acrylate was classified on the basis of carcinogenicity by international regulatory agencies, carcinogenicity was a key focus for this screening assessment. Induction of forestomach tumours were observed in rats and mice administered ethyl acrylate by oral gavage for 2 years. However, no induction of tumours was observed by other routes of administration including oral drinking water, inhalation and dermal. Collective evidence from genotoxicity studies suggests that ethyl acrylate is not likely to be mutagenic but may exert some clastogenic effects in vitro. While the mode of induction of tumours has not been fully elucidated, sustained forestomach hyperplasia has been suggested to be a precursor event. Therefore a threshold approach is used to characterize risk to human health.

Margins between upper-bounding estimates of exposure to ethyl acrylate from environmental media, food and the use of consumer products and levels associated with effects in experimental animals are considered to be adequate to address uncertainties in the health effects and exposure databases.

Based on the information presented in this screening assessment, it is concluded that ethyl acrylate is not entering the environment in a quantity or concentration or under conditions that constitute or may constitute a danger in Canada to human life or health.

Based on available empirical data and modelling results, ethyl acrylate is not expected to be persistent or to bioaccumulate in the environment. The substance therefore does not meet the persistence criteria or the bioaccumulation criteria as set out in the Persistence and Bioaccumulation Regulations. In addition, available empirical data suggest that the substance has a moderate to high potential to be toxic to aquatic organisms. However, based on a comparison of predicted no-effect concentrations with estimated reasonable worst-case environmental exposure concentrations, it is considered unlikely that ethyl acrylate is causing ecological harm in Canada.

Based on the information available, it is concluded that ethyl acrylate is not entering the environment in a quantity or concentration or under conditions that have or may have an immediate or long-term harmful effect on the environment or its biological diversity or that constitute or may constitute a danger to the environment on which life depends.

Based on the information available, it is concluded that ethyl acrylate does not meet any of the criteria set out in section 64 of CEPA 1999.

This substance will be considered for inclusion in theDomestic Substances List inventory update initiative. In addition and where relevant, research and monitoring will support verification of assumptions used during the screening assessment.

The Canadian Environmental Protection Act, 1999 (CEPA 1999) (Canada 1999) requires the Minister of the Environment and the Minister of Health to conduct screening assessments of substances that have met the categorization criteria set out in the Act to determine whether these substances present or may present a risk to the environment or to human health.

Based on the information obtained through the categorization process, the Ministers identified a number of substances as high priorities for action. These include substances that

- met all of the ecological categorization criteria, including persistence (P), bioaccumulation potential (B) and inherent toxicity to aquatic organisms (iT), and were believed to be in commerce in Canada; and/or

- met the categorization criteria for greatest potential for exposure (GPE) or presented an intermediate potential for exposure (IPE) and had been identified as posing a high hazard to human health based on classifications by other national or international agencies for carcinogenicity, genotoxicity, developmental toxicity or reproductive toxicity.

The Ministers therefore published a notice of intent in the Canada Gazette, Part I, on December 9, 2006 (Canada 2006), that challenged industry and other interested stakeholders to submit, within specified timelines, specific information that may be used to inform risk assessment, and to develop and benchmark best practices for the risk management and product stewardship of those substances identified as high priorities.

The substance 2-propenoic acid, ethyl ester (ethyl acrylate) was identified as a high priority for assessment of human health risk because it was considered to present the greatest potential for exposure and had been classified by other agencies on the basis of carcinogenicity. The Challenge for this substance was published in the Canada Gazette on September 26, 2009 (Canada 2009). A substance profile was released at the same time. The substance profile presented the technical information available prior to December 2005 that formed the basis for categorization of this substance. As a result of the Challenge, submissions of information pertaining to the substance were received.

Although ethyl acrylate was determined to be a high priority for assessment with respect to human health, it did not meet the categorization criteria for persistence or bioaccumulation in thePersistence and Bioaccumulation Regulations and it did not meet the criteria for toxicity to aquatic organisms.

Screening assessments focus on information critical to determining whether a substance meets the criteria for defining a substance as toxic as set out in section 64 of CEPA 1999. Screening assessments examine scientific information and develop conclusions by incorporating a weight-of-evidence approach and precaution[2].

This screening assessment includes consideration of information on chemical properties, hazards, uses and exposure, including the additional information submitted under the Challenge. Data relevant to the screening assessment of this substance were identified in original literature, review and assessment documents, stakeholder research reports and from recent literature searches, up to April 2010 for human and ecological sections of the document. Key studies were critically evaluated; modelling results may have been used to reach conclusions.

Evaluation of risk to human health involves consideration of data relevant to estimation of exposure (non-occupational) of the general population, as well as information on health hazards (based principally on the weight of evidence assessments of other agencies that were used for prioritization of the substance). Decisions for human health are based on the nature of the critical effect and/or margins between conservative effect levels and estimates of exposure, taking into account confidence in the completeness of the identified databases on both exposure and effects, within a screening context. The screening assessment does not represent an exhaustive or critical review of all available data. Rather, it presents a summary of the critical information upon which the concluded conclusion is based.

This screening assessment was prepared by staff in the Existing Substances Programs at Health Canada and Environment Canada and incorporates input from other programs within these departments.

The ecological and human health portions of this assessment have undergone external written peer review/consultation. Comments on the technical portions relevant to human health were received from scientific experts selected and directed by Toxicology Excellence for Risk Assessment (TERA), including Dr. Bernard Gadagbui (Toxicology Excellence for Risk Assessment [TERA]), Dr. Michael Jayjock (The LifeLine Group) and Dr. Chris Bevans (CJB Consulting). Although external comments were taken into consideration, the final content and outcome of the screening assessment remain the responsibility of Health Canada and Environment Canada.

Additionally, the draft of this screening assessment was subject to a 60-day public comment period. While external comments were taken into consideration, the final content and outcome of the screening assessment remain the responsibility of Health Canada and Environment Canada. Approaches used in the screening assessments under the Challenge have been reviewed by an independent Challenge Advisory Panel.

The critical information and considerations upon which the assessment is based are summarized below.

For the purposes of this document, this substance will be referred to as ethyl acrylate, the common chemical name for the substance.

Table 1. Substance identity for ethyl acrylate

| CAS Registry Number | 140-88-5 |

| DSL name | 2-propenoic acid, ethyl ester |

| National Chemical Inventories(NCI) names[1] | Ethyl acrylate (EINECS, ENCS) 2-Propenoic acid, ethyl ester (TSCA, AICS, SWISS, PICCS, ASIA-PAC, NZIoC) 2-Propenoic acid ethyl ester (ECL) Acrylic acid, ethyl ester (PICCS) Acrylate, ethyl (PICCS) |

| Other names | Ethyl 2-propenoate; Acrylic acid ethyl ester; Ethyl 2-propenoate; Ethyl acrylic ester; Ethyl propenoate; NSC 8263; UN 1917 |

| Chemical group (DSL Stream) | Discrete organics |

| Major chemical class or use | Esters |

| Major chemical sub-class | Acrylates |

| Chemical formula | C5H8O2 |

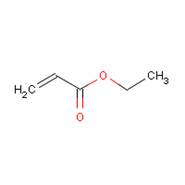

| Chemical structure |  |

| SMILES[2] | O=C(OCC)C=C |

| Molecular mass | 100.116 g/mol |

[2] Simplified Molecular Input Line Entry Specification

Table 2 contains experimental and modelled physical and chemical properties of ethyl acrylate that are relevant to its environmental fate.

The models based on quantitative structure-activity relationships (QSAR) were used to generate data for some of the physical and chemical properties of ethyl acrylate.

Table 2. Physical and chemical properties for ethyl acrylate

| Property | Type | Value[1] | Temperature (°C) |

Reference | |||||

|---|---|---|---|---|---|---|---|---|---|

| Melting point (ºC) |

Experimental | -72[2] | BASF AG 2000 | ||||||

| Modelled | -70.73 | MPBPWIN 2008 | |||||||

| Boiling point (ºC) |

Experimental | 100 | BASF AG 2000 | ||||||

| Experimental | 99.4[2] | O’Neil et al. 2001 | |||||||

| Modelled | 100.51 | MPBPWIN 2008 | |||||||

| Density (kg/m3) |

Experimental | 922 (0.922 g/cm3) |

20 | BASF AG 2000 | |||||

| Vapour pressure (Pa) |

Experimental | 3800 | 20 | BASF AG 2000 | |||||

| Experimental | 3900 (29.3 mmHg) |

20 | IPCS 2004 | ||||||

| 3800[2] (28.5 mm Hg) |

CEDRE 2006 | ||||||||

| 5147 (38.6 mm Hg) |

25 | Daubert and Danner 1989 | |||||||

| Modelled | 5120 (38.6 mm Hg) |

20 | MPBPWIN 2008 | ||||||

| Henry’s Law constant (Pa·m3/mol) |

Experimental | 25.3[2] | BASF AG 2000 | ||||||

| Calculated | 25.3 | 20 | ECETOC 1994 | ||||||

| Modelled | 6.37 (6.29x10-5 atm m3/mol) |

25 | HENRYWIN 2008 (Group) | ||||||

| 12.46 (1.23x10-4 atm m3/mol) |

25 | HENRYWIN 2008 (Bond) | |||||||

| Log Kow (Octanol-water partition coefficient) (dimensionless) |

Experimental | 1.18[2] | 25 | BASF AG 2000 | |||||

| Modelled | 1.22 | 25 | KOWWIN 2008 | ||||||

| Log Koc (Organic carbon-water partition coefficient) (dimensionless) |

Experimental | 1.34 | IUCLID 2000 | ||||||

| Modelled | 1.07 | PCKOCWIN 2008 | |||||||

| Log KOA (Organic –air partition coefficient) |

Modelled | 3.5 | KOAWIN 2008 | ||||||

| Water solubility (mg/L) |

Experimental | 15 000[2] | 25 | BASF AG 2000 | |||||

| 20 000 | Tyler and Smock 1993 | ||||||||

| 20 000 | 20 | O’Neil et al 2001 | |||||||

| 15 000 | Riddick et al 1986 | ||||||||

| Modelled | 17 630 (KOW method) |

25 | WSKOWWIN 2008 | ||||||

| pKa (Acid dissociation constant) (dimensionless) |

Modelled | Does not ionize in water | ACD/pKaDB 2005 | ||||||

[1] Values in parentheses represent the original ones as reported by the authors or as estimated by the models.

[2] Value used for modelling.

Ethyl acrylate occurs naturally in blackberries, raspberries, pineapples, yellow passion fruit and durian (NTP 1998; Burdock 1997).

Sources of human exposure to ethyl acrylate in Canada, in addition to those occurring naturally, may either be from point source releases such as those associated with industrial sites of processing, and non-point sources such as from food, food packaging release of residual ethyl acrylate, and commercial or industrial products within the Canadian marketplace, e.g., by off-gassing or migration.

Based on information collected through a survey conducted pursuant to section 71 of CEPA 1999, between 1 000 000 and 10 000 000 kg of ethyl acrylate were imported into Canada in 2006. The substance was not reported to be manufactured in Canada (Environment Canada 2010a).

Previously received information from the Domestic Substances List nomination (1984–1986) showed that the quantity reported to be manufactured, imported or in commerce in Canada during the calendar year 1986 was 12 100 000 kg (Environment Canada 1988). Outside of Canada, ethyl acrylate has been identified as a high production volume (HPV) chemical by the Organisation for Economic Co-operation and Development (OECD) (OECD 2005). The production volume of ethyl acrylate is estimated to be 50 000 to 100 000 tonnes per year in Europe and 250 000 to 500 000 tonnes per year in North America (OECD 2005).

Process for Industrial Production of Ethyl Acrylate: The majority of ethyl acrylate is prepared commercially by the catalyzed esterification of acrylic acid with ethanol (McLaughlin et al. 1993). Ethyl acrylate will polymerize readily under the influence of heat, light or peroxides (O’Neil 2006). To prevent premature polymerization, ethyl acrylate is usually inhibited with 10 to 20 ppm of monomethyl ether of hydroquinone (OECD 2005). Some dissolved oxygen should be present in the liquid for the inhibitor to be effective (OECD 2005). Pure ethyl acrylate monomer can be stored below 10oC without incurring polymerization (O’Neil 2006).

Ethyl acrylate is primarily used in closed systems during manufacture and transport. This is due to its volatility and flammability (McLaughlin et al. 1993). Ethyl acrylate has an unpleasant irritating odour and a low odour-detection threshold (0.0012 ppm) (Amoore 1983). Air concentrations of greater than 0.05 ppm would be intolerable to most individuals (McLaughlin et al. 1993).

In Canada, ethyl acrylate is used for synthesis of polymers and copolymers for use in formulations of industrial and consumer products. There are no direct consumer end-use products of ethyl acrylate itself; ethyl acrylate may be found in products as a residual from the polymerization process. Ethyl acrylate imparts flexibility to hard films (O’Neil 2006).

Ethyl acrylate emulsion (water-based) polymers are used in latex paints, coatings, caulks and construction products; in pigment binders and overvarnishes for gravure printing inks; in basecoats for treating natural leather; and in adhesives (McLaughlin et al. 1993). Emulsion polymers using ethyl acrylate are found in floor polishes, sealants, and in textile-treatment processes such as binding fibrefill and non-wovens, laminating, flocking, back coating and fabric finishing (McLaughlin et al. 1993). Solvent-based ethyl acrylate polymer products include lacquer, enamels, and viscosity-index improvers for oils (McLaughlin et al. 1993). Solid-grade polymers include acrylic plastic sheet goods and plastic impact modifiers (McLaughlin et al. 1993).

According to submissions made under section 71 of CEPA 1999 and from the Challenge questionnaire submissions, 1 000 000 - 10 000 000 kg of ethyl acrylate were used in Canada in 2006 (Environment Canada 2010a). Not all ethyl acrylate used remains within Canada, as some is exported from Canada in finished products (Environment Canada 2010b).

Ethyl acrylate is not listed as an approved food additive in the Canadian Food and Drug Regulations (Canada 1978). However it is possible that ethyl acrylate is used as a flavour in foods that are offered for sale in Canada. Food flavours are not regulated as a food additive. The Flavor and Extract Manufacturers Association (FEMA) of the United States reported that there is a decreasing trend in the amount of ethyl acrylate being used as a food flavour in the United States. They reported a total poundage used of 11 lbs (4.98 kg) in 1995 (Lucas et al. 1999) and 3 lbs (1.36 kg) in 2005 (Gavin et al. 2008).

Ethyl acrylate is also used in food packaging materials as a starting material monomer used in the manufacturing of acrylic polymers and copolymers (2010 emails from Food Directorate, Health Canada, to Risk Management Bureau, Health Canada; unreferenced). Ethyl acrylate is listed in the Natural Health Products Ingredients Database as an acceptable non-medicinal ingredient to be used as a flavour enhancer in natural health products (NHPID 2010). As ethyl acrylate is listed in the Licensed Natural Health Products Database, it is present in currently licensed natural health products (LNHPD 2010).

In Canada, ethyl acrylate is not listed in the Drug Products Database nor the Therapeutic Product Directorate's internal Non-Medicinal Ingredients Database as a medicinal or non-medicinal ingredient in pharmaceutical products or veterinary drugs (DPD 2010; 2010 e-mails from Therapeutic Products Directorate, Health Canada to Risk Management Bureau, Health Canada; unreferenced).

Based on information collected through a survey conducted pursuant to section 71 of CEPA 1999, 306 kg of ethyl acrylate was released to air and 1,954 kg was reported as transferred to off-site waste management facilities in Canada in 2006 (Environment Canada 2010a). No releases to water or land were reported (Environment Canada 2010a). According to releases reported under the National Pollutant Release Inventory (NPRI), 476 kg of ethyl acrylate was released to the environment in 2006 by point sources in Ontario and Quebec. A total of 72 kg was reported as released to ambient air and 3 kg reported as off-site disposal (NPRI 2008). The remaining 401 kg was not specified (air, water, land). The reported releases to NPRI went down to 133 kg to air and 8 kg to off-site disposal in 2008 (NPRI 2008). A total of 31 000 kg of ethyl acrylate was reported under TRI as released in the United States (TRI 2008).

Based on reported releases to the NPRI, the majority of ethyl acrylate releases to the environment occur to ambient air (Environment Canada 2008). It should be noted that there is a possibility of incomplete reporting to the NPRI including some industrial release to water. This assessment assumes some release of ethyl acrylate to surface water in estimating predicted environmental concentrations in water.

Table 3. NPRI Data for Ethyl Acrylate (Environment Canada 2008)

| Year | On-Site Releases (tonnes) | Disposa (tonnes) | ||||

|---|---|---|---|---|---|---|

| Air | Water | Land | Total | On-Site | Off-Site | |

| 2008 | 0.133 | 0.133 | 0.008 | |||

| 2007 | 0.555 | 0.555 | 0.006 | |||

| 2006 | 0.072 | 0.476[1] | 0.003 | |||

| 2005 | 0.059 | 0.115[2] | 0.024 | |||

| 2004 | 0.044 | 0.116[3] | ||||

| 2003 | 0.015 | 0.114[4] | ||||

| 2002 | 0.048 | 0.156[5] | 0.004 | |||

| 2001 | 1.5 | 1.7[6] | 9.2 | |||

| 2000 | 1.8 | 1.9[7] | 15 | |||

| 1999 | 0.322 | |||||

[2] 0.056 tonnes as total release but no indication of to which media

[3] 0.073 tonnes reported as total but no indication of to which media

[4] 0.099 tonnes reported as total but no indication of to which media

[5] 0.108 tonnes reported as total but no indication of to which media

[6] 0.21 tonnes reported as total but no indication of to which media

[7] 0.128 tonnes reported as total but no indication of to which media

Based on its physical and chemical properties (Table 2), the results of Level III fugacity modelling (Table 4) suggest that ethyl acrylate will predominantly reside in air, water or soil, depending on the compartment of release. The modelling program pKadB (ACD 2005) indicates that the substance does not ionize in water (there are no ionizable groups present).

Table 4. Results of the Level III fugacity modelling (EQC 2003)

| Substance released to: | Percentage of substance partitioning into each compartment | |||

|---|---|---|---|---|

| Air | Water | Soil | Sediment | |

| Air (100%) | 93.8 | 5.6 | 0.7 | 0.0 |

| Water (100%) | 1.8 | 97.9 | 0.0 | 0.2 |

| Soil (100%) | 3.2 | 11.4 | 85.3 | 0.0 |

If released to air, high amounts of the substance are expected to reside in air (see Table 4 above). Based on the high experimental vapour pressure of 3900 Pa and moderate to high Henry's Law constant of 25.3 Pa·m3/mol, ethyl acrylate is considered volatile. Therefore, if released solely to air, it will tend to remain in this compartment although a small amount of the substance will also be deposited to water (~6%, see Table 4).

If released into water, ethyl acrylate is expected to weakly adsorb to suspended solids and sediment based upon a low log Koc value of 1.34. Volatilization from water surfaces is expected to be an unimportant fate process based upon this compound's Henry's Law constant and due to the rapid degradation in water that limits transport to air. There is a possibility that polymerization of ethyl acrylate may be initiated via ultraviolet radiation in the river system, however, polymerization will only result in low molecular weight oligomers (<4 units in length) which are expected to biodegrade. Thus, if water is a receiving medium, ethyl acrylate is expected to mainly reside in water and to a very limited extent partition to air (see Table 4).

If released to soil, ethyl acrylate is not expected to have high adsorptivity to soil (i.e., expected to be mobile based upon its low log Koc). Volatilization from moist soil surfaces seems to be an unimportant fate process based upon its Henry's Law constant. This chemical may slightly volatilize from dry soil surfaces based upon its vapour pressure. Therefore, if released to soil, ethyl acrylate is expected to mostly remain in this environmental compartment, although some will likely be transported to surface water from run-off, diffuse to groundwater and volatilize to air.

Environmental Persistence

Table 5a presents the empirical biodegradation data that indicates that for ethyl acrylate, the half-life in air is likely to be shorter than two days and the half-life in water is likely to be shorter than 182 days (6 months) and that the substance is therefore likely to not persist in those environmental compartments.

Table 5a presents empirical biodegradation data (MITI 1992) that show 52% ultimate biodegradation of ethyl acrylate over 14 days in a ready biodegradation test. This test result suggests that the half-life in water would be about 13 days (assuming first order kinetics) – which is much shorter than 182 days (6 months) indicating that the substance is unlikely to persist in that environmental compartment. Staples et al. (2000) reported 57% degradation in 28 days using OECD methods (OECD 301D) (OECD 1992), indicating that ethyl acrylate is inherently biodegradable. The authors also tested the substance in the five day biochemical oxygen demand (BOD5) test, and found that ethyl acrylate degrades easily (77%). Ethyl acrylate was shown to be readily biodegradable (80-90% after 28 days) using the ISO (14593) method, identical to OECD 310 (OECD 2005; OECD 2003).

Table 5a. Empirical data for degradation of ethyl acrylate

| Medium | Fate Process | Degradation Value | Degradation Endpoint | Reference |

|---|---|---|---|---|

| Air | Ozone reaction | 2.01 | Half-life, days | Atkinson 1989 |

| Air | Atm. Oxidation | 0.67 | Half-life, days | Atkinson 1989 |

| Water | Hydrolysis | 1277.5 | Half-life, days (pH 7) |

Mabey and Mill 1978 |

| Water | Biodegradation | 52 | Biodegradation, % after 14 days (BOD) | MITI 1992 |

| Water | Biodegradation | 92.6 - 100 | Biodegradation, % after 14 days (analysis for parent compound) | MITI 1992 |

| Water | Biodegradation | 57 | Biodegradation, % after 28 days | Staples et al. 2000 |

| Water | Biodegradation | 80-90 | Biodegradation, % after 28 days | OECD 2005 |

Although experimental data on the degradation of ethyl acrylate are available, a QSAR-based weight-of-evidence approach (Environment Canada 2007) was also applied using the degradation models shown in Table 5b below. Given the ecological importance of the water compartment, the fact that most of the available models apply to water and the fact that ethyl acrylate is expected to be released to this compartment, biodegradation in water was primarily examined.

Table 5b summarizes the results of available QSAR models for degradation in water and air.

Table 5b. Modelled data for degradation of ethyl acrylate

| Fate Process | Model and model basis |

Model Result and Prediction | Extrapolated Half-life (days) |

|---|---|---|---|

| Air | |||

| Atmospheric oxidation | AOPWIN 2008[1] | t1/2 = 11.8 hours | ≤ 2 |

| Ozone reaction | AOPWIN 2008[1] | t1/2 = 6.5 days | ≥ 2 |

| Water | |||

| Hydrolysis | HYDROWIN 2008[1] | t1/2 = 9 years (pH7) t1/2 = 329 days (pH8) |

≥ 182 |

| Primary biodegradation | |||

| Biodegradation (aerobic) | BIOWIN 2008[1] Sub-model 4: Expert Survey (qualitative results) |

3.9[2] (biodegrades fast) |

≤ 182 |

| Ultimate biodegradation | |||

| Biodegradation (aerobic) | BIOWIN 2008[1] Sub-model 3: Expert Survey (qualitative results) |

3.1[2] (biodegrades fast) |

≤ 182 |

| Biodegradation (aerobic) | BIOWIN 2008[1] Sub-model 5: MITI linear probability |

0.8[3] (biodegrades fast) |

≤ 182 |

| Biodegradation (aerobic) | BIOWIN 2008[1] Sub-model 6: MITI non-linear probability |

0.9[3] (biodegrades fast) |

≤ 182 |

| Biodegradation (aerobic) | TOPKAT 2004 Probability |

1.0[3] (biodegrades very fast) |

≤ 182 |

| Biodegradation (aerobic) | CATABOL c2004-2008 |

% BOD = 52 (biodegrades fast) |

≤ 182 |

[2] Model does not provide an estimate for this type of structure.

[3] Output is a numerical score from 0 to 5.

[4] Output is a probability score.

In air, a predicted atmospheric oxidation half-life value of 11.8 hours (see Table 5b) demonstrates that this substance is likely to be rapidly oxidized. The substance is expected to react with other photo-oxidative species in the atmosphere such as O3 , but at a significantly slower rate. In addition, the atmospheric half-life as a result of indirect photolysis was estimated to be 6.5 hours (OECD 2005). Therefore, it is expected that reactions with hydroxyl radicals will be the most important fate process in the atmosphere for ethyl acrylate. With an empirically based half-life of 0.67 days (~16 hours; Table 5a) and an estimated half-life of 11.8 hours via reactions with hydroxyl radicals, ethyl acrylate is considered not persistent in air.

In water, a predicted hydrolysis half-life value of 9 years at pH 7 (see Table 5b) demonstrates that this chemical is likely to be slowly hydrolysed. However, other fate processes in water need to be considered to determine overall persistence in this medium.

The five ultimate biodegradation models suggest that biodegradation is fast and that the half-life in water would be significantly less than 182 days. The result of the BIOWIN Sub-model 4 (primary survey model) would suggest the substance has a primary half-life of much less than 182 days and the ultimate biodegradation sub-models of BIOWIN indicate that complete mineralization would occur within 182 days. Also, the predictions for CATABOL and TOPKAT are in the domains of both models. Thus, they are considered to be reliable and suggest a fast rate of biodegradation.

Using an extrapolation ratio of 1:1:4 for water: soil: sediment biodegradation half-life (Boethling et al. 1995), and an ultimate biodegradation half-life of < 90 days in water the ultimate biodegradation half-life in soil is also < 90 days and the half-life in sediments is ≤365 days. This indicates that ethyl acrylate is not expected to be persistent in soil and sediment.

Based on the empirical and modelled data (see Tables 5a and 5b) ethyl acrylate does not meet the persistence criteria in air, soil, water or sediment (half-life in air ≥ 2 days, half-lives in soil and water ≥ 182 days and half-life in sediment ≥ 365 days) as set out in the Persistence and Bioaccumulation Regulations (Canada 2000).

Experimental log Kow values for ethyl acrylate suggest that this chemical has low potential to bioaccumulate in biota (see Table 2). Although the log Kow focuses primarily on aquatic based criteria and does not evaluate the potential impacts in the terrestrial environment and organisms, terrestrial organisms will not be exposed to this chemical through the diet and there will be low biomagnification potential in terrestrial animals.

Table 6: Modelled data for bioaccumulation for ethyl acrylate

| Test Organism | Log Kow | Endpoint | Value Wet Weight (L/kg) |

Reference |

|---|---|---|---|---|

| Fish | 1.18 | BAF | 1.59 | Gobas BAF T2MTL (Arnot and Gobas 2003) |

| Fish | 1.18 | BCF | 1.59 | Gobas BCF T2LTL (Arnot and Gobas 2003) |

| Fish | 1.22 | BCF | 0.91 | OASIS Forecast 2005 |

| Fish | 1.18 | BCF | 2.79 | BCFWIN 2000 |

| Fish | 1.33 | BCF | 6.0 | Tyler and Smock 1993[1] |

The available evidence indicates that ethyl acrylate is expected to have a low bioaccumulation potential due to its low experimental log Kow value. Model-estimated BCF and BAF values are much less than 5000 (Table 6). A BAF and BCF of 1.593 L/kg resulted from using an estimated metabolic rate constant to correct bioaccumulation predictions (Arnot and Gobas 2003). Based on the available kinetic-based and other modelled values, ethyl acrylate does not meet the bioaccumulation criterion (BCF or BAF ≥ 5000) as set out in the Persistence and Bioaccumulation Regulations (Canada 2000).

As indicated earlier, ethyl acrylate does not meet the persistence or bioaccumulation criteria as set out in thePersistence and Bioaccumulation Regulations (Canada 2000).

Ecological Effects Assessment

A study on the chronic aquatic toxicity of ethyl acrylate to Daphnia magna resulted in a LOEC of 0.45 mg/L and an EC50 of 0.5 mg/L (Table 7a). These values are considered to be indicative of potential for moderate to high chronic toxicity to aquatic organisms. The authors concluded that the low measured test concentration results may have been as a result of a number of factors, including the volatility, adsorption to the glass aquaria, adsorption to particulate matter and biodegradability of ethyl acrylate.

Table 7a. Empirical data for aquatic toxicity

| Test Organism | Test Type | Endpoint | Value (mg/L) | Reference |

|---|---|---|---|---|

| Algae (Selenastrum capricornutum) | Acute (96 hours) |

EC50 | 5.5 | OECD 2005 |

| Daphnia magna | Acute (48 hours) |

EC50[1] | 7.9 | OECD 2005 |

| Daphnia magna | Chronic (21 days) | NOEC[2] | 0.19 | OECD 2005 |

| Daphnia magna | Chronic (21 days) | LOEC[3] | 0.45 | OECD 2005 |

| Daphnia magna | Chronic (21 days) | EC50 | 0.5 | OECD 2005 |

| Fish (Cyprinodon variegatus) | Acute (96 hours) |

LC50[4] | 2.0 | IUCLID 2000 |

| Fish (Pimephales promelas) | Acute (96 hours) |

LC50[4] | 2.5 | Geiger et al. 1990 |

| Fish (Oncorhynchus mykiss) | Acute (96 hours) |

LC50[4] | 4.6 | OECD 2005 |

[2] NOEC – No observed Effect Concentration.

[3] LOEC – Lowest Observed Effect Concentration.

[4] LC50 – The concentration of a substance that is estimated to be lethal to 50% of the test organisms.

Table 7b. Modelled data for aquatic toxicity.

| Test organism | Type of test |

Endpoint | Value (mg/L) |

Reference |

|---|---|---|---|---|

| Fish | Acute (96 hours) |

LC50[1] | 2.2 | ECOSAR 2008 |

| 2.06 | OASIS Forecast 2005 | |||

| 18.79 | AIES 2003-2005 | |||

| 8.0 | TOPKAT 2004 | |||

| Fish | Chronic (30 day) |

ChV | 0.16 | ECOSAR 2008 |

| Daphnia | Acute (96 hours) |

EC50[2] | 6.8 | ECOSAR 2008 |

| Acute | 36.4 | TOPKAT 2004 | ||

| Acute (48 hours) | <221.9 | OASIS 2004 | ||

| Algae | Acute (96 hours) |

EC50[2] | 1.07 | ECOSAR 2008 |

[2] LC50 – The concentration of a substance that is estimated to be lethal to 50% of the test organisms.

The experimental and modeled toxicity results are comparable and indicate that ethyl acrylate has a moderate to high potential to be harmful to aquatic organisms. Ethyl acrylate is a reactive chemical, however, the mode of action is not known.

No suitable ecological effects studies were found for ethyl acrylate in media other than in water.

Ecological Exposure Assessment

No data concerning concentrations of this substance in water in Canada have been identified; therefore, environmental concentrations are estimated from available information, including estimated substance quantities, release rates, and size of receiving water bodies.

A – Industrial Release

As ethyl acrylate is used industrially (see Uses section) and is expected to be released to water, a reasonable worst-case industrial release scenario is used to estimate the aquatic concentration of the substance with the help of Environment Canada's (2009a) Industrial Generic Exposure Tool – Aquatic (IGETA). A site-specific exposure analysis was conducted for the aquatic compartment at two separate industrial sites where ethyl acrylate is used (Environment Canada 2010c). These sites were identified based on responses to the CEPA Section 71 Survey (Environment Canada 2010a). Each user reported an annual consumption quantity of ethyl acrylate in the range of 10 000 to 200 000 kg. The selection of these sites is therefore expected to represent a realistic worst case release scenario across Canada based on a general assumption that the quantity released is proportional to the quantity consumed.

In this site-specific exposure analysis, each site includes one facility, one wastewater treatment plant and one receiving water body. The predicted environmental concentration (PEC) in the receiving water was estimated based on the concentration in the wastewater treatment effluent and applying a dilution factor of 10. The concentration in the wastewater treatment effluent was estimated based on a fraction of the substance assumed to be lost from the facility to a local municipal wastewater treatment plant, an assumed wastewater treatment plant removal rate and the effluent flow rate of the treatment plant. The loss fraction was conservatively estimated to be 5% resulting from the chemical container handling operations and the industrial processes relevant to the facilities under consideration. It should be noted that this value is expected to represent the upper bound of the losses to wastewater and the release from an actual facility is expected to be below this upper bound. The removal at the local wastewater treatment plant was conservatively assumed to be zero. The effluent flow of the local wastewater treatment plant is proportional to the population served and was in the range of 100 000 to greater than 1 000 000 m3 per day for the sites considered. An assumption for the frequency of release was also used in the estimation which is 250 days/year for the industrial users (small or medium sized facilities).

Based on the above assumptions, the PECs at the 2 separate industrial sites where ethyl acrylate is used, were estimated to be 0.0002 mg/L and 0.0305 mg/L, respectively. The PEC values obtained are considered to represent the level of exposure under a realistic worst case release scenario in the receiving water near the point of the discharge from wastewater treatment plants at industrial sites in Canada.

B – Consumer Release

As ethyl acrylate is found in consumer products and can be released to water, Mega Flush, Environment Canada’s spreadsheet tool was employed to estimate the substance concentration in multiple water bodies receiving sewage treatment plant effluents to which consumer products containing the substance may have been released (Environment Canada 2009b). The spreadsheet tool provides these estimates for approximately 1000 release sites across Canada based on realistic assumptions. Although ethyl acrylate is found in consumer products, the amount of the substance that is released to sewers is estimated to be very small (1%) as the substance is transformed at the industrial stage.

The realistic assumptions include:

- loss to sewer at 100%;

- sewage treatment plant removal rate estimated at 0.0 % in case of no treatment;

- 3.1 % for primary only treatment and 68 % for primary-secondary combined treatment;

- number of annual release days at 365 days/year; and

- receiving water dilution factor in the range of 1 to 10.

The predicted environmental concentration (PEC) of ethyl acrylate in the receiving water bodies was estimated to be 0.0065 mg/L. The estimate is based on a range of 10 000 to 100 000 kg/year for the quantity of the substance used by consumers. The equation and inputs used to calculate the PEC are described in Environment Canada (2010d).

Characterization of Ecological Risk

The approach taken in this ecological screening assessment was to examine various supporting information and develop conclusions based on a weight-of-evidence approach and using precaution as required under CEPA 1999. Lines of evidence considered include results from conservative risk quotient calculations, as well as information on persistence, bioaccumulation, toxicity, sources and fate of the substance.

Ethyl acrylate is not expected to be persistent in air, water, soil and sediment; it is also expected to have a low bioaccumulation potential. Although there are high importation volumes of ethyl acrylate into Canada, once released into the environment, it will be found mainly in water, although based on the substance’s volatility and emission pattern, there will be release to the atmosphere. It has also been demonstrated to have moderate to high potential for toxicity to aquatic organisms.

A risk quotient analysis, integrating conservative estimates of exposure with toxicity information, was performed for the aquatic medium to determine whether there is potential for ecological harm in Canada. The two separate site-specific industrial scenarios (considering the actual receiving water bodies) presented above yielded predicted environmental concentrations (PECs) of 0.0002 mg/L and 0.0305 mg/L (Environment Canada 2010c). By dividing the chronic toxicity value (LOEC) of 0.45mg/L (the most sensitive valid experimental value) for Daphnia magna, by an assessment factor of 10 (to account for interspecies and intraspecies variability in sensitivity) a predicted no effect concentration (PNEC) of 0.045 mg/L is derived. Conservative risk quotients (PEC/PNEC) for the two industrial scenarios are thus determined to be 0.0047 and 0.68. Therefore harm to aquatic organisms is unlikely.

When the PEC of 0.0065 mg/L for ethyl acrylate predicted for the consumer release scenario is divided by the PNEC of 0.045 mg/L, the resulting conservative risk quotient (PEC/PNEC) = 0.14. As with the industrial release scenario, harm to aquatic organisms from consumer use is unlikely.

This information suggests that ethyl acrylate is unlikely to cause ecological harm in Canada.

Uncertainties in Evaluation of Ecological Risk

There is uncertainty present from the use of QSAR predictions but due to the small relatively simple structure of this chemical, the majority of the modelled results are judged to be reliable and within the domain of the models and therefore the uncertainty is deemed to be lower overall.

There is uncertainty in the results of the aquatic effects to ethyl acrylate as the substance is expected to degrade rapidly in water, however polymerization is also possible. Only valid aquatic effects measured data were considered.

Although there is some uncertainty in the estimation of environmental exposure levels, as no Canadian monitoring data were identified, two conservative release scenarios were used to fill the data gap.

Exposure Assessment

Environmental Media and Food

The upper-bounding estimate of intake of ethyl acrylate from ambient air, indoor air, soil, drinking water, and food and beverages in Canada is 0.00581 mg/kg-bw per day (Appendix 1). Although the principal source of environmental exposure is identified as indoor air; this is considered highly conservative as ethyl acrylate was not detected in any of 757 homes monitored in a Canadian study and the limit of detection (10 µg/m3 ) was assumed in deriving indoor air concentrations. (Otson et al. 1994). Indoor air concentrations of 0.04-2.1 mg/m3 ; ethyl acrylate were reported in a US office building (no location or sample information reported, BUA 1992).

Ethyl acrylate was reported as naturally occurring in fresh pineapple (IARC 1986), raspberries, blackberries, yellow passion fruit, and durian (NTP 1998; Burdock 1997). The Joint FAO/WHO Expert Committee on Food Additives (JECFA) reports an estimated daily intake of ethyl acrylate from food flavouring based on annual production volumes of ethyl acrylate used as a flavouring agent (JECFA 2006). The intake was estimated to be 1.1 x 10-5and 2.6 x 10-5 mg/kg bw/day in the United States and Europe, respectively (JECFA 2006). Based on the information available, foods are not the primary contributors to overall exposure to ethyl acrylate (Appendix 1).

Although ethyl acrylate-based materials are used in food packaging applications, residual ethyl acrylate in food packaging materials is low and migration into food is negligible (2010 emails from Food Directorate, Health Canada, to Risk Management Bureau, Health Canada; unreferenced). The potential daily intake resulting from residual ethyl acrylate in food packaging applications is insignificant compared to exposures from its natural occurrence in some fruits and its use as a food flavour.

Ethyl acrylate may also be present as a residual in packaging for pharmaceutical products. This is not considered to be a significant source of exposure to the general population.

The ambient air concentration is based on an air monitoring study conducted in Houston and Boston, US, with 22 samples collected at each location between August 1990 and August 1991 (Kelly et al. 1993). Ethyl acrylate was not detected in any samples, so the reported limit of detection of 0.2 ppb (0.82 µg/m3) for the concentration of ethyl acrylate in ambient air was used as a conservative input for modelling. No Canadian data were available. Ethyl acrylate was also detected in ambient air (0.6-1.8 ng/m3) in 3 of 15 samples at 1 of 5 locations collected in Japan in 2001 (NITE 2010).

Ethyl acrylate was also qualitatively detected in the ambient air at a US landfill (no location or sample information reported) (BUA 1992) and in the exhaust air of production plants in the US (12 500 and 25 000 mg/m3), New Zealand (11-622 mg/m3) and Japan (qualitatively) (BUA 1992), however these point sources would not represent general population exposure.

Ethyl acrylate was not detected in any of the more than 250 groundwater samples taken from or around five industrial plants which produce ethyl acrylate, therefore the drinking water concentration used for modelling exposure was based on the reported limit of detection of between 1 and 10 ppb (McLaughlin et al. 1993). Since no soil monitoring studies were identified, a Canadian-specific environmental exposure model was used to predict conservative concentrations in soil based on the amount of the substance released in Canada (ChemCAN 2003).

Other reported monitoring studies of ethyl acrylate in water and sediment include: Ethyl acrylate non-detects in 51 surface water and bottom sediment samples collected from 17 locations in Japan in 1980 (the limit of detection was 0.3-50 µg/L, NITE 2010). In 100 samples of soil, wastewater and surface water analysed, only two sediment samples showed detectable levels of ethyl acrylate at 2.1 and 2.2 mg/kg (no limit of detection was reported, McLaughlin et al. 1993). Ethyl acrylate was not detected at a wastewater treatment plant in Germany (the limit of detection was 0.02 mg/L; BUA 1992). Ethyl acrylate was detected, but not quantified, in one of 17 ground water samples collected in the USA (location not reported, BUA 1992).

Consumer Products

Based on information received under the s. 71 survey, consumer exposure modeling was performed using RIVM’s ConsExpo v.4.1 software (ConsExpo 2006) of the Netherlands for consumer product and personal care product scenarios (Table 3, Appendix 2).

Ethyl acrylate may be found as a residual in consumer products. For modelling purposes, 100% uptake by the inhalation and dermal routes was used for ConsExpo v.4.1. Due to the types of products where ethyl acrylate is used, the oral route of exposure was not relevant. These conservative uptakes would result in slightly higher modelled exposures compared to those that may be occurring.

In addition to use of ConsExpo (ConsExpo 2006), the US EPA’s Wall Paint Exposure Model (WPEM) software (US EPA 2001) was used to model consumer exposure during household painting. The WPEM results were consistently lower; therefore, the ConsExpo model outputs were considered to provide a more conservative estimate of exposure.

Acrylic polymers that could contain ethyl acrylate are typically found in more expensive indoor paints, since the addition of an acrylic polymer to paint provides increased durability and scrub resistance, as well as in semi-gloss paints that are used to paint interior wood trim (Frederick 1998). In a small market basket study (Frederick 1998), 30 samples of a variety of consumer paints were analysed for ethyl acrylate. They reported between 1.26 and 4.49 ppm (mean 1.28 ppm) ethyl acrylate in flat latex wall paint, and between 1.61 and 13.02 ppm (mean 4.06 ppm) in indoor trim paint (Frederick 1998).

In a laboratory study, two samples of paints with residual concentrations of ethyl acrylate (940 ppm and 2000 ppm w/w) were prepared and used to paint a test room (McLaughlin et al. 1993). There was no ventilation in the test room. Maximum concentrations of ethyl acrylate reported in the air in the room were 2.5 ppm and 8.0 ppm from the 940 and 2000 ppm paint samples, respectively (McLaughlin et al. 1993). The report also indicated that when the painting scenarios were repeated with proper ventilation, no ethyl acrylate was detected (limit of detection 0.2 ppm) (McLaughlin et al. 1993).

Ethyl acrylate may be present as a residual in a variety of do-it-yourself products. An estimate of exposure to individuals using caulk is provided in Table 3. A concentration of <0.1% was assumed based on a reference to paintable joint sealant on the Household Products Database (Household Products Database 2009).

Ethyl acrylate can be used in the manufacture of non-woven personal wipes and other non-woven materials for medical and hospital applications at an estimated maximum ethyl acrylate concentration of 28 ppm[3],[4] (Environment Canada 2010b).

Other products that may contain residual ethyl acrylate were identified: Roofing products and other industrial binding and coating applications containing a maximum estimated concentration of 29 ppm[4] (Environment Canada 2010b). Ethyl Acrylate may also be present in wood glue at a maximum concentration of 40 ppm[3](Environment Canada 2010b). Since these products are used infrequently, they are not considered a significant source of exposure to the general population and exposure estimates were not derived.

Cosmetics that previously contained acrylic polymers that may have included ethyl acrylate have been re-formulated and ethyl acrylate is no longer used. These products are no longer available on the Canadian market (2010 emails from Consumer Product Safety Bureau, Health Canada, to Existing Substances Division, Health Canada; unreferenced).

In the literature, ethyl acrylate has been described as an additive to adhesives (McLaughlin et al. 1993), such as in self-adhesive bandages. The amount of residual ethyl acrylate in self-adhesive bandages is considered to be very low. Since self-adhesive bandages are used infrequently, it is not considered a significant source of exposure to the general population and exposure estimates were not, accordingly, derived.

Ethyl acrylate is used in various parts of automotive vehicles including: the exterior paint, sealants, and in the plastic components. Based on information received under the s71 survey, the estimated total concentration of ethyl acrylate in a finished vehicle is less than 0.031 kg/vehicle (Environment Canada 2010a). These components are not in the passenger area of the vehicle and are therefore not considered a significant source of exposure to the general population.

Ethyl acrylate may be present as a residual in additional products[4] (Environment Canada 2010b) used in industrial settings only, and are therefore not considered a source of exposure to the general population.

Table 3. ConsExpo v.4.1 models (See Appendix 2)

| Modelled consumer product at specified level | Dermal acute exposure (mg/kg) |

Dermal chronic exposure (mg/kg/day) | Inhalation mean event concentration (mg/m3) |

|---|---|---|---|

| Paint – flat latex (4.5 ppm) |

2.54 x 10-4 | 1.39 x 10-6 | 0.225 |

| Paint – semi-gloss trim (13.2 ppm) | 3.6 x 10-4 | 1.99 x 10-6 | 0.108 |

| Caulk (<0.1%) | 2.12 x 10-3 | 1.74 x 10-5 | 0.427 |

| Personal wipes - infants (28 ppm) |

7.47 x 10-5 | 3.73 x 10-4 | - |

| Personal wipes - adults (28 ppm) |

7.9 x 10-6 | 7.89 x 10-6 | - |

Health Effects Assessment

A summary of the available health effects information for ethyl acrylate is provided in Appendix 3.

The International Agency for Research on Cancer (IARC) has classified ethyl acrylate as a Group 2B carcinogen (possibly carcinogenic to humans) because of sufficient evidence for carcinogenicity in experimental animals and no adequate epidemiological data relevant to the carcinogenicity in humans was available (IARC 1986, 1999). US EPA has classified ethyl acrylate as a possible human carcinogen (Group B2) (US EPA 2005, 2009). Ethyl acrylate was first listed in the National Toxicology Program (NTP) Fifth Annual Report on Carcinogens as “reasonably anticipated to be a carcinogen” but later delisted from the NTP Ninth Annual Report on Carcinogens after reassessment indicating no carcinogenic potential (NTP 1989, 2000).

In experimental animal toxicity studies, increased incidences of forestomach tumours were observed in rats and mice orally administered ethyl acrylate by gavage. Fischer 344 rats and B6C3F1 mice treated with ethyl acrylate by oral gavage at 0, 100 or 200 mg/kg-bw per day, 5 days/week for 103 weeks had a significantly increased incidence of forestomach tumours (NTP 1986a). Forestomach tumours (squamous cell papillomas and squamous cell carcinomas) were observed at 100 and 200 mg/kg-bw per day in both sexes in both species. In a follow-up study, male Fischer 344 rats were orally administered ethyl acrylate by gavage at 0 or 200 mg/kg-bw per day, 5 days/week for 6 or 12 months followed by recovery periods of up to 15 months (Ghanayem et al. 1993, 1994). No neoplastic effects were observed in animals treated 200 mg/kg-bw per day ethyl acrylate for 6 months with 0, 2 or 15 months of recovery and animals sacrificed immediately after 12 months. Development of forestomach tumours was observed during 2-9 month recovery periods in animals treated with ethyl acrylate for 12 months.

In contrast to the gavage studies, no neoplastic effects were observed in experimental animals administered ethyl acrylate by other routes. In a drinking water study, Wistar rats were administered ethyl acrylate at 0, 6-7, 60-70 or 2000 ppm (approximately 0, 0.84-0.98, 9.4-9.8 and 280 mg/kg-bw respectively) for 2 years (Borzelleca et al. 1964). Histopathological findings showed no treatment-related lesions. Borzelleca et al. (1964) also conducted a chronic toxicity study in dogs. Beagle dogs were orally administered ethyl acrylate in gelatin capsules at 0, 10, 100 or 1000 ppm (approximately 0, 0.3, 3 and 30 mg/kg-bw per day respectively) for 2 years and no neoplastic effects were observed.

In inhalation carcinogenicity studies, no treatment-related neoplastic lesions were observed in Fischer 344 rats and B6C3F1 mice exposed to ethyl acrylate at 0, 25 or 75 ppm (approximately 0, 100 and 310 mg/m3 respectively), 6 hour per day, 5 day per week for 27 months (Miller et al. 1985). In another study conducted by Miller et al. (1985), Fischer 344 rats and B6C3F1 mice were exposed to ethyl acrylate at 0 or 5 ppm (approximately 20 mg/m3) for 24 months and no neoplastic effects were observed.

In a dermal carcinogenicity study, male C3H/HeJ mice were administered 800 mg/kg-bw per day of ethyl acrylate, 3 times per week for life (DePass et al. 1984). No epidermal tumours were observed.

In epidemiological studies, results from workplace cohort studies were inconsistent. Ethyl acrylate exposures were not well quantified and workers were exposed to other chemicals as well. In a cohort study in 1933-1945, workers in an acrylic sheet manufacturing facility at Bristol, Pennsylvania, were exposed to ethyl acrylate, methyl methacrylate, lead, ethylene dichloride, methylene chloride and acrylonitrile. Excess mortality from colon cancer and rectal cancer were observed in exposed workers 20 years after the equivalent of 3 years of employment (Walker et al. 1991). However, two other similar cohort studies described by Walker et al. (1991) reported no excess mortality from any cause.

Limited mutagenic potential was observed in in vitromutation assays. A number of Ames tests in different strains ofSalmonella typhimurium were conducted in the presence and/or in the absence of metabolic activation and the results were negative (Rohm and Haas 1977, 1981; Ishidate et al. 1981; Haworth et al. 1983; Waegemaekers and Bensink 1984; NTP 1986a; Brusick 1977; Zeiger et al. 1992; ECETOC 1994; Emmert et al. 2006). Result from a umu test conducted using Salmonella typhimurium was negative (Yasunaga et al. 2004) whereas induction of mitotic recombination in Saccharomyces cerevisiae was positive (Zimmermann and Mohr 1992). In mammalian cells, induction of gene mutations was observed in mouse lymphoma L5178Y TK+/- cells (Myhr 1980; McGregor et al. 1988; Moore et al. 1988; Dearfield et al. 1991) but not in HGPRT assays in Chinese hamster ovary (CHO) cells (Moore et al. 1989). In terms of clastogenic effects, chromosome aberration assays were mostly positive in mouse lymphoma cells, CHO cells, mouse splenocytes and Chinese hamster lung (CHL) cells (NTP 1986b; Moore et al. 1988; Ishidate et al. 1981; Loveday et al. 1990; Kligerman et al. 1991). Mixed results were available for sister chromatid exchange assays in CHO cells and in mouse splenocytes (NTP 1986b; Loveday et al. 1990; Kligerman et al. 1991).

In in vivo assays, genotoxicity results were mostly negative. No induction of chromosome aberrations was observed in mice administered ethyl acrylate intraperitoneally (Kligerman et al. 1991). Micronucleus induction assays conducted in different strains of mice administered ethyl acrylate intraperitoneally, orally or dermally were mostly negative (Przybojewska et al. 1984; Basler and van der Hude 1987; Ashby et al. 1989; Kligerman et al. 1991; Hara et al. 1994; Morita et al. 1997; Tice et al. 1997). Sister chromatid exchange assays conducted in mice administered ethyl acrylate intraperitoneally were negative (Kligerman et al. 1991). In germ cells, results from sex-linked recessive lethal assays conducted in Drosophilia melanogaster by feeding or by injection were negative (Valencia et al. 1985).

The Organisation for Economic Co-operation and Development (OECD) Screening Information Dataset Initial Assessment Meeting (SIAM) in 2004 concluded that ethyl acrylate posed “no mutagenic hazard” concerns (OECD 2004).

The proposed mode of induction of rat forestomach tumours by ethyl acrylate has not been fully elucidated. In rodents, forestomach is a non-glandular food storage organ that connects to the oesophagus and is lined by keratinized, stratified squamous epithelium; whereas, the glandular stomach, which empties into the duodenum, is lined by a specialized glandular epithelium. In contrast, in humans, the entire stomach is glandular; however, comparable squamous epithelial tissues are present in the oral cavity and the upper two-thirds of the oesophagus. Unlike rodents, neither location, plays a role in food storage. IARC (2003) published a report that discussed the predictive value of rodent forestomach tumours in evaluating carcinogenic risks to humans of several chemicals including ethyl acrylate. Although IARC (2003) did not propose a mode of action for ethyl acrylate induced forestomach tumour, the working group suggested that a certain time of sustained hyperplasia is required for effective tumourigenesis (Boorman and Sills 2003). Oral gavage studies in rodents indicted that ethyl acrylate induced forestomach hyperplasia is sustained as long as ethyl acrylate is administered. Full recovery of forestomach hyperplasia was observed in animals treated for 6 months, but persistence of forestomach hyperplasia was observed in rats treated for 12 months (Ghanayem et al. 1993, 1994). In addition, development of forestomach tumours was not observed immediately, but observed during recovery periods in rats treated for 12 months.

Williams and Iatropoulos (2009) proposed that the induction of forestomach tumours by ethyl acrylate is route-specific. The authors proposed that a long transit time ranging from half a day to 2 or 3 days and the less acidic pH in the forestomach allows for the presence of proliferating bacteria, and that the progression from local tissue irritation, inflammation and hyperkeratosis to sustained hyperplasia are major precursor events leading toward ethyl acrylate induced forestomach neoplasia. Hyperplasia or cell proliferation has long been recognized as an important factor in carcinogenesis. It has been suggested that sustained cell proliferation, rather than just cell proliferation is required for carcinogenesis (Preston-Martin et al. 1990; Melnick et al 1993; Huff 1995). Proctor et al. (2007) further suggested that forestomach tumours associated with chronic irritation of the forestomach epithelium, particularly those induced by repeated oral gavage dosing might result in a tissue dose that is not representative of human exposure.

No classifications for reproductive or developmental toxicity were available from national and international regulatory agencies. The lowest-observed-effect level (LOEL) identified for oral developmental toxicity was 25 mg/kg-bw per day based on delayed ossification when rats were administered ethyl acrylate by gavage at 0, 25, 50, 100, 200 or 400 mg/kg-bw per day on gestation days 7-16 (Pietrowicz et al. 1980). At all doses, a reduction in maternal body weight gain was also observed. For the inhalation route, the LOEC was 200 ppm (800 mg/m3) based on a significant decrease in fetal body weight in Sprague-Dawley rats exposed to ethyl acrylate at 0, 25, 50, 100 or 200 ppm (approximately 0, 100, 200, 400 and 800 mg/m3respectively), 6 hours per day on gestation days 6-20 (Saillenfait et al. 1999). A significant decrease in maternal body weight gain and absolute weight gain were also observed at 200 ppm. In a limited case study, a mother who was exposed to polymers containing ethyl acrylate reported to have a child diagnosed with congenital anomalies; however, further details of the study were not available (Sherman 1985). No reproductive toxicity studies and no dermal developmental toxicity studies were identified.

In rodents, oral repeated dosing of ethyl acrylate generally affects the forestomach. The lowest LOAEL identified was 20 mg/kg-bw per day based on an increase in stomach weight and a dose-related increase in epithelial hyperplasia and hyperkeratosis of the forestomach in male Fischer 344 rats administered ethyl acrylate orally by gavage in several studies conducted from 14 days to 13 weeks (Rohm and Haas 1986b, 1987; Frederick et al. 1990). In a similar study conducted by Frederick et al. (1990), a LOAEL of 1000 ppm (99 mg/kg-bw per day) was identified based on minimal irritation and diffuse epithelial hyperplasia of the forestomach when male Fischer 344 rats were administered ethyl acrylate in drinking water at 0, 200, 1000, 2000 or 4000 ppm (corresponding to 0, 23, 99, 197 and 369 mg/kg-bw per day respectively), 5 days/week for 14 days. However, in a 2-year study in rats administered ethyl acrylate by drinking water, no histopathological changes were observed (Borzelleca et al. 1964).

Rodent inhalation toxicity studies generally resulted in nasal effects. The lowest LOAEC for acute exposure was 25 ppm (100 mg/m3) based on reversible olfactory epithelium lesions in male rats exposed nose-only to ethyl acrylate for 3 hours (Frederick et al. 2002). It should be noted that rodents have substantive differences in nasal anatomy and nasal air flow compared to human (Frederick et al. 1998, 2002). Computational inhalation model simulations suggested that human olfactory epithelium is expected to have at least two- to threefold lower tissue concentrations of inhaled organic acid vapour such as ethyl acrylate than that of rodents (Frederick et al. 1998, 2002). A higher LOAEC for acute exposure was 75 ppm (310 mg/m3) based on olfactory epithelium lesions (focal degeneration, necrosis, exfoliation and mild inflammation) in monkeys exposed to ethyl acrylate for 3 hours (Rohm and Haas 1994; Harkema et al. 1997). The US EPA used both the Frederick et al. (2002) rat study and the Rohm and Haas (1994), Harkema et al. (1997) monkey study as points of departure for derivation of the interim Acute Exposure Guideline Level-1 (AEGL-1) and Acute Exposure Guideline Level-2 (AEGL-2) respectively (US EPA 2007). The critical LOAEC for short term exposure was 300 ppm (1200 mg/m3) based on inflammation, degeneration, focal necrosis and squamous metaplasia of the nasal turbinates in rats and mice exposed to ethyl acrylate for 30 days (Miller et al. 1979). The critical LOAEC for long term inhalation exposure was 25 ppm (100 mg/m3) based on non-neoplastic lesions of the olfactory mucosa which included degeneration, inflammation and hyperplasia in rats and mice exposed to ethyl acrylate from 6 to 27 months (Jersey et al. 1978; Dow Chemical 1979a; Miller et al. 1985).

For the dermal route, the lowest LOAEL identified was 800 mg/kg-bw per day based on dermatitis, dermal fibrosis, epidermal necrosis and hyperkeratosis in male C3H/HeJ mice administered approximately 800 mg/kg-bw per day ethyl acrylate, 3 times per week for life (DePass et al. 1984).

In humans, a workplace cohort study suggested a correlation of ethyl acrylate exposure to central nervous system disturbance. However, this study is of limited utility in characterizing health effects associated with ethyl acrylate exposure as individuals were also concurrently exposed to significant levels of other chemicals (n-butyl acrylate and acrylonitrile) (Kuzelova et al. 1981).

Ethyl acrylate is a strong skin irritant and eye irritant in experimental animals (Haskell Laboratories 1945; Pozzani et al. 1949; Treon et al 1949; Oettel and Zeller 1958; Celanese Chem Co. 1972; BASF AG 1978; Lomonova and Klimova 1979; Poole 1980; Potokar et al. 1985; Rohm and Haas 1986a, c, d, 1991; Union Carbide Corp 1989; BAMM 1994; BASF 2005). In a human case study, accidental exposure to ethyl acrylate resulted in severe eye irritation (Dow Chemical 1964). In addition, there is some evidence suggesting that ethyl acrylate is a sensitizer and exposure to ethyl acrylate may result in cross-sensitization with other acrylates in animals (Van der Walle et al. 1982). However, results from ear swelling tests and local lymph node assays were negative (Kimber 1992; NTP 1994; Hayes and Meade 1999). In humans, sensitization was observed in volunteers (Epstein 1974) and in patients who had suspected allergic contact dermatitis (Foulger and Fleming 1945; Jordan 1975; Fregert 1978; Bjorkner and Dahlquist 1979; Malten et al. 1984; Conde-Salazar et al. 1988; Kanerva et al. 1988; 1989, 1992, 1995; Stenman and Bergman 1989; Skoglund and Egelrud 1991; Koppula et al. 1995; Marks et al. 1995; Rustemeyer and Frosch 1996; Tucker and Beck 1999; Lazarov 2007; Aalto-Korte et al. 2007). Some of these dermatitis patients had a history of exposure to acrylates or had developed occupational dermatitis in response to dental materials, acrylic sealants or artificial nails.

Toxicokinetic studies in experimental animals show that ethyl acrylate is absorbed and metabolized rapidly following oral and inhalation exposure (Stott and McKenna 1984; Ghanayem et al. 1987). The two major routes of metabolism are hydrolysis of the ester linkage and conjugation with glutathione (GSH). Hydrolysis of ethyl acrylate is catalyzed by the carboxylesterases, resulting in the production of ethanol and acrylic acid (Miller et al. 1981; Frederick et al. 1994a). Ethanol is further metabolized under catabolic process and acrylic acid goes through the propionate degradative pathway of cellular metabolism, resulting in the formation of carbon dioxide in both cases. Conjugation with GSH can occur either spontaneously by a Michael addition or can be mediated by GSH transferase (Ghanayem et al. 1987; Potter and Tran 1992). Inhalation of ethyl acrylate in rats resulted in nonprotein sulfhydryl (NPSH) depletion most pronounced in liver followed by blood, brain and lungs (Vodicka et al. 1990). In oral gavage toxicity studies in rodents, significant reduction of NPSH in the forestomach and the glandular stomach was observed suggesting that conjugation at the site of contact might be an important detoxification process (De Bethizy et al. 1987). Following GSH conjugation, ethyl acrylate is rapidly eliminated by urinary excretion (De Bethizy et al. 1987). Although theoretically possible, no evidence was available for the generation of epoxidation products in ethyl acrylate metabolism (Delbressine et al. 1982; De Bethizy et al. 1987). A physiologically based pharmacokinetic and pharmacodynamic model of rats was developed and described the absorption, distribution and metabolism of orally dosed ethyl acrylate (Frederick and Chang-Mateu 1990; Frederick et al. 1992). Similar biologically based interspecies dosimetry models for inhalation of ethyl acrylate were also developed (Frederick et al. 1994b, 2002; Sweeney et al. 2004).

The confidence in the toxicity database for ethyl acrylate is considered to be moderate to high. Data were identified for carcinogenicity, genotoxicity, developmental toxicity, acute and repeated–dose toxicity in experimental animals. However, reproductive toxicity studies were not identified and conclusive epidemiology studies were not available.

Characterization of Risk to Human Health

Based on the classifications by other national and international regulatory agencies, a critical effect for characterization of risk to human health for ethyl acrylate is carcinogenicity. Forestomach tumours were induced in both sexes in rats and mice when ethyl acrylate was administered orally by gavage for 2 years. However, no induction of tumours was observed when ethyl acrylate was administered by other routes including orally in drinking water, inhalation and dermal. The collective evidence from genotoxicity studies indicates that ethyl acrylate is not likely to be mutagenic but may exhibit some clastogenicity in in vitro assays. The OECD Screening Information Data Set Initial Assessment Meeting 18 (meeting concluded that ethyl acrylate posed “no mutagenic hazard” concerns (OECD 2004). Although the mode of induction of rodent specific forestomach tumours is not fully elucidated, it is proposed that chronic ethyl acrylate bolus gavage dosing into the forestomach (an organ not found in humans), induces sustained irritation and hyperplasia as a precursor for the development of tumors (OECD 2004, NTP 2000, Williams and Iatropoulos (2009)).

Accordingly, a threshold approach is used to characterize risk to human health.

In terms of non-cancer effects, no reproductive toxicity studies were identified. Developmental effects were accompanied by maternal toxicity suggesting a secondary effect. The margins of exposure are based on conservative upper-bounding estimates of general population exposure and the critical LOAELs and LOAEC for non-cancer effects. The critical LOAEL for the oral route is 20 mg/kg-bw per day based on an increase in stomach weight and forestomach hyperplasia and hyperkeratosis in rats treated from 14 days to 13 weeks by gavage (Rohm and Haas 1986b, 1987; Frederick et al. 1990). A higher LOAEL of 99 mg/kg-bw per day with similar health effects via drinking water was identified; however, the more conservative LOAEL from gavage studies was used to derive margins of exposure.

The critical LOAECs for acute inhalation exposure were 25 ppm (100 mg/m3) and 75 ppm (310 mg/m3) based on olfactory epithelium lesions in rats (Frederick et al. 2002) and in monkeys (Rohm and Haas 1994; Harkema et al. 1997), respectively, exposed to ethyl acrylate for 3 hours. Based on substantive differences in nasal anatomy and nasal air flow, human olfactory epithelium is expected to have at least two- to threefold lower tissues concentration than that of rodents (Frederick et al. 1998, 2002). The US EPA adopted these studies for derivation of AEGL-1 and AEGL-2 levels (US EPA 2007). The critical LOAEC for short term inhalation exposure is based on inflammation, degeneration, focal necrosis and squamous metaplasia of the nasal turbinates observed in rats and mice exposed to ethyl acrylate at 300 ppm (1200 mg/m3) for 30 days (Miller et al. 1979). The critical LOAEC for long term inhalation is 25 ppm (100 mg/m3) based on olfactory mucosa lesions in rats and mice exposed for 6 to 27 months. The critical LOAEL for the dermal route is 800 mg/kg-bw per day based on induction of dermatitis in a chronic mouse study.

The principal routes of exposure to ethyl acrylate to the general population in Canada is expected to be from short term inhalation of indoor air and from the use of consumer products (such as paint and other do-it-yourself products). Spontaneous polymerization, photodegradation and volatilization properties of ethyl acrylate (OECD 2004) are expected to minimize long term inhalation exposure for the general population.

Comparison of the critical effect dose level for repeated dosing via the oral route (20 mg/kg-bw per day) and the upper-bounding estimate of total daily intake from environmental media and food by the general population in Canada (0.00199 - 0.00581 mg/kg-bw per day) results in margins of exposure of 3500 - 10 000.

Based on consumer product scenario modelling, the air concentration of ethyl acrylate resulting from using do-it-yourself caulking is 0.427 mg/m3. Comparison of this upper-bounding acute estimate with the range of critical effect concentrations for acute inhalation of 100-310 mg/m3results in margins of exposure of 230-700. The dermal exposure of ethyl acrylate resulting from use of personal wipes (infants) was 3.73 x 10-4 mg/kg-bw per day. Comparison of this exposure level with the critical effect level for the dermal route from a chronic mouse study (800 mg/kg-bw per day) results in a margin of exposure of 2.14 x106. This is a conservative margin of exposure because exposure from use of personal wipes is compared to the critical effect level from a chronic dermal study.

This margin of exposure is considered adequate for both skin sensitization and skin irritation.

It is also noteworthy that 14 of 24 human volunteers dermally exposed to ethyl acrylate (4% ethyl acrylate in petrolatum) in a maximization test for 48 hours showed no sensitization and no skin irritation (Epstein 1974 cited in Opdyke 1975).

The margins of exposure are considered adequate to address uncertainties in the health effects and exposure databases.

Uncertainties in Evaluation of Risk to Human Health

The determination of margins of exposure within the scope of this screening assessment does not take into account possible differences between humans and experimental animals in terms of sensitivity to effects induced by ethyl acrylate. The rodent forestomach tumours are not considered relevant to human health risk assessment as humans lack a forestomach, although histologically similar organs are present. In addition, the tissue dose in rodent forestomach via gavage administration is not representative of the nature of human exposures. Developmental toxicity is accompanied by maternal toxicity suggesting a secondary effect. No information for reproductive toxicity was available. The purity of ethyl acrylate is generally >99% and some studies indicated that the ethyl acrylate used contained a polymerization inhibitor such as monomethyl ether of t-butylhydroquinone or 4-methoxyphenol. The presence of a polymerization inhibitor, though the quantity is minimal, might confound the experimental results. Spontaneous polymerization, photodegradation and volatilization of ethyl acrylate might also affect the actual dosage in the experimental studies.

Inhalation was identified as the primary exposure route for the general population for both environmental media and consumer products, as one could expect from ethyl acrylate’s vapour pressure and volatile nature. Canadian environmental data available for indoor air showed no quantifiable levels; however, the LOD of the analytical method was used for derivation of the upper-bounding estimates of exposure. There is a moderate degree of confidence in upper-bounding estimates of exposure from use of consumer products, because there is ome uncertainty around the concentrations of residual ethyl acrylate remaining in consumer products in the marketplace. However, ethyl acrylate polymerizes when exposed to light and is therefore not expected to be available as a monomer.

On the basis of the adequacy of the margins between upper-bounding estimates of exposure to ethyl acrylate and critical effect levels, it is concluded that ethyl acrylate is not entering the environment in a quantity or concentration or under conditions that constitute or may constitute a danger in Canada to human life or health.

Based on the information presented in this screening assessment, it is concluded that ethyl acrylate is not entering the environment in a quantity or concentration or under conditions that have or may have an immediate or long-term harmful effect on the environment or its biological diversity or that constitute or may constitute a danger to the environment on which life depends. Additionally, ethyl acrylate does not meet the criteria for persistence and bioaccumulation potential as set out in the Persistence and Bioaccumulation Regulations (Canada 2000).

It is therefore concluded that ethyl acrylate does not meet any of the criteria under section 64 of CEPA 1999.

This substance will be considered for inclusion in the Domestic Substances List inventory update initiative. In addition and where relevant, research and monitoring will support verification of assumptions used during the screening assessment.

Aalto-Korte K, Alanko K, Kuuliala O, Jolanki R. 2007. Methacrylate and acrylate allergy in dental personnel. Contact Derm 57(5):324-330.

ACD/pKaDB [Prediction Module]. 2005. Version 9.04. Toronto (ON): Advanced Chemistry Development. [cited 2010 May 18]. ACD/Labs. [restricted access]