Screening assessment resins and rosins group

Official title: Screening Assessment - Resins and Rosins Group

Environment and Climate Change Canada

Health Canada

July 2022

Cat. No.: En84-300/2022E-PDF

ISBN 978-0-660-43856-6

Synopsis

Pursuant to section 68 or 74 of the Canadian Environmental Protection Act, 1999 (CEPA), the Minister of the Environment and the Minister of Health have conducted a screening assessment of 12 substances collectively referred to as the Resins and Rosins GroupFootnote 1 Footnote 2 . The Chemical Abstracts Service Registry Numbers (CAS RN)Footnote 3 , their Domestic Substances List (DSL) names and their abbreviations or common names are listed in the table below.

| CAS RN | Domestic Substances List (DSL) name | Abbreviation or common name |

|---|---|---|

| 1740-19-8 | 1-Phenanthrenecarboxylic acid, 1,2,3,4,4a,9,10,10a-octahydro-1,4a-dimethyl-7-(1-methylethyl)-, [1R-(1α,4aβ,10aα)] | DHAA |

| 8002-26-4a | Tall oil | CTOb or DTOb |

| 8016-81-7a,c | Tall-oil pitch | TOP |

| 8046-19-3a,c | Storax (balsam) | Storax |

| 8050-09-7a,d | Rosin | Rosind |

| 8050-15-5a,c | Resin acids and Rosin acids, hydrogenated, Me esters | RHME |

| 8050-28-0a | Rosin, maleated | RMa |

| 8052-10-6a,d | Tall-oil rosin | Rosind |

| 9007-13-0a | Resin acids and Rosin acids, calcium salts | RCa |

| 61790-51-0a | Resin acids and Rosin acids, sodium salts | RNa |

| 68186-14-1a | Resin acids and Rosin acids, Me esters | RME |

| 73138-82-6a,d | Resin acids and Rosin acids | Rosind |

a This CAS RN is a UVCB (unknown or variable composition, complex reaction products, or biological materials).

b Crude tall oil (CTO) and distilled tall oil (DTO) are both covered under this DSL name and CAS RN although they may have different properties, compositions and uses.

c This substance was not identified under subsection 73(1) of CEPA, but was included in this screening assessment as it was considered a priority on the basis of other human health concerns.

d These substances may be used interchangeably by industry and are referred to under the same name (rosin).

Resins and Rosins Group substances may be imported or manufactured in Canada and are naturally present in the environment. Variability in composition of the Resins and Rosins Group substances may be due to source material variability and/or the production process conditions.

All of the substances in the Resins and Rosins Group have been included in a survey issued pursuant to section 71 of CEPA and subsequent voluntary surveys. All 12 substances were reported to be imported into Canada in quantities for each substance ranging from <100 kg to 1 000 000 kg, for the 2011 reporting year. CTO was incidentally co-produced in Canada at 10 000 000 kg to 100 000 000 kg for the 2011 reporting year. RCa and RNa were manufactured in Canada at 10 000 kg to 100 000 kg and 100 kg to 1 000 kg respectively, for the 2011 reporting year.

Commercial and industrial uses of the substances in this group include processing aids, electronics solder, concrete production, rubber compounding, steelmaking, and formulation of paints and coatings, as well as products available to consumers, such as adhesives, binding agents, cosmetics, natural health products and non-prescription drugs.

The major sources of emissions of substances in the Resins and Rosins Group to the environment in Canada are related to manufacturing and industrial uses. Potential releases of concern occur primarily to surface water.

Most components of CTO, DTO, rosin, RCa and RNa are moderately persistent in water and are expected to be moderately to highly persistent in sediments. Components of TOP, RHME and RMa are predicted to have a moderate to high persistence in water and a high persistence in sediments.

Most substances in the Resins and Rosins Group have components with a low to moderate bioconcentration potential. The bioconcentration factors of components of RHME show a moderate to high bioconcentration potential. Certain CTO, DTO and TOP representative chemicals are predicted to have a high bioaccumulation potential based on modelled bioaccumulation factor results.

CTO, DTO, TOP, rosin, RCa, RNa and RMa all consist of components that could have non-specific (i.e., narcotic) or compound-specific effects to organisms in the environment at low concentrations of exposure. RHME consists of only narcotic components with effects at low concentrations. Exposure scenarios were developed for the manufacturing and industrial use of the Resins and Rosins Group substances. Risk quotient analyses were conducted to compare estimated aquatic concentrations with adverse effect concentrations, assuming a concentration addition of the components of the UVCBs in aquatic organisms for different exposure scenarios. Scenarios for the manufacturing of CTO indicate that there is a risk to aquatic organisms; however, no risk was identified for the other scenarios for the Resins and Rosins Group substances at levels of exposure based on reported quantities.

The ecological risks of four substances in the Resins and Rosins Group (DHAA, storax, RME, and rosin CAS RN 73138-82-6) were characterized using the ecological risk classification of organic substances (ERC), which is a risk-based approach that employs multiple metrics for both hazard and exposure, with weighted consideration of multiple lines of evidence for determining risk classification. The ERC identified DHAA, storax, RME, and rosin CAS RN 73138-82-6 as having low potential to cause ecological harm.

Considering all available lines of evidence presented in this screening assessment, there is risk of harm to the environment from tall oil (CAS RN 8002-26-4), specifically due to CTO. It is concluded that tall oil meets the criteria under paragraph 64(a) of CEPA as it is entering or may enter the environment in a quantity or concentration or under conditions that have or may have an immediate or long-term harmful effect on the environment or its biological diversity. However, it is concluded that tall oil does not meet the criteria under paragraph 64(b) of CEPA as it is not entering the environment in a quantity or concentration or under conditions that constitute or may constitute a danger to the environment on which life depends. It is also concluded that the other 11 Resins and Rosins Group substances do not meet the criteria under paragraphs 64(a) or (b) of CEPA as they are not entering the environment in a quantity or concentration or under conditions that have or may have an immediate or long-term harmful effect on the environment or its biological diversity or that constitute or may constitute a danger to the environment on which life depends.

RMa and rosin (CAS RN 8052-10-6) were previously evaluated using the approach applied in the Rapid Screening of Substances with Limited General Population Exposure , which determined that the substances required further assessment. The potential for exposure of the general population to RMa and rosin (CAS RN 8052-10-6) was considered in this assessment to be negligible, indicating a low probability of risk to human health. Therefore, RMa and rosin (CAS RN 8052-10-6) are considered to be of low concern for human health at current levels of exposure.

TOP was evaluated using the Threshold of Toxicological Concern (TTC)-based Approach for Certain Substances, which is based on the potential hazard of similar chemical structures, as well as chemical-specific genotoxicity data, when available. The estimate of exposure generated for TOP was lower than the TTC value, indicating a low probability of risk to human health. Therefore, TOP is considered to be of low concern for human health at current levels of exposure.

Substances in the Resins and Rosins Group have not been identified as carcinogenic. Limited toxicological effects have been reported in repeated-dose studies with resins and rosins substances with effects such as decreased body weights. Some histopathological changes were noted in target organs.

Exposure to the Resins and Rosins Group substances is expected to be predominantly via the dermal route and can occur from use of rosin as a gripping agent by athletes and violinists, as a non-medicinal ingredient in sunscreens, and in cosmetic products, such as moisturizers and cleansers. There is the potential for oral ingestion from uses such as non-medicinal ingredient in dental varnishes, as well as from dental sealants and lipsticks. On the basis of a comparison of estimates of exposure to substances in the Resins and Rosins Group and levels associated with effects observed in laboratory studies, margins of exposure are considered adequate to address uncertainities in the health effects and exposure datasets.

Considering all the information presented in this screening assessment, it is concluded that the 12 Resins and Rosins Group substances do not meet the criteria under paragraph 64(c) of CEPA as they are not entering the environment in a quantity or concentration or under conditions that constitute or may constitute a danger in Canada to human life or health.

It is therefore concluded that tall oil meets one or more of the criteria set out in section 64 of CEPA, specifically on the basis of risk presented by CTO and that the other 11 Resins and Rosins Group substances do not meet any of the criteria set out in section 64 of CEPA.

1. Introduction

Pursuant to section 68 or 74 of the Canadian Environmental Protection Act, 1999 (CEPA) (Canada 1999), the Minister of the Environment and the Minister of Health have conducted a screening assessment of 12 of 14 substances collectively referred to under the Chemicals Management Plan as the Resins and Rosins Group, to determine whether these 12 substances present or may present a risk to the environment or to human health. These 14 substances were identified as priorities for assessment as they met categorization criteria under subsection 73(1) of CEPA or were considered a priority on the basis of other human health concerns (ECCC, HC [modified 2017]).

Two substances (CAS RN 26266-77-3, 1-phenanthrenemethanol, dodecahydro-1,4a-dimethyl-7-(1-methylethyl)-, and CAS RN 91081-53-7, rosin, reaction products with formaldehyde) were both considered in the Ecological Risk Classification of Organic Substances (ERC) Science Approach Document (ECCC 2016a) and in either the Threshold of Toxicological Concern (TTC)-based Approach for Certain Substances Science Approach Document (Health Canada 2016) or via the approach applied in the Rapid Screening of Substances with Limited General Population Exposure (ECCC, HC 2018a), and both were identified as being of low concern to both human health and the environment. As such, they are not further addressed in this screening assessment. The conclusion for the substance bearing CAS RN 26266-77-3 is provided in the Substances Identified as Being of Low Concern based on the Ecological Risk Classification of Organic Substances and the Threshold of Toxicological Concern (TTC)-based Approach for Certain Substances Screening Assessment (ECCC, HC 2018b). The conclusion for the substance bearing CAS RN 91081-53-7 is provided in the Rapid Screening of Substances with Limited General Population Exposure Screening Assessment (ECCC, HC 2018a).The 12 substances addressed in this draft screening assessment will hereinafter be referred to as the Resins and Rosins Group.

Four of the 12 substances in the Resins and Rosins Group (DHAA, storax, RME, and rosin CAS RN 73138-82-6) were identified as having a low potential to cause ecological harm using the ERC approach (ECCC 2016a; Appendix A). A further three substances were identified as having a low potential to cause harm to human health: RMa and rosin (CAS RN 8052-10-6), as determined on the basis of the Rapid Screening of Substances with Limited General Population Exposure Screening Assessment (ECCC, HC 2018a), and tall-oil pitch (TOP), as determined on the basis of the Threshold of Toxicological Concern (TTC)-based Approach for Certain Substances Science Approach Document (Health Canada 2016). These results, in conjunction with any other relevant information that became available after the publication of these documents, are considered in support of the conclusions made under section 64 of CEPA in this screening assessment.

This screening assessment includes consideration of information on chemical properties, environmental fate, hazards, uses and exposures, including additional information submitted by stakeholders and collected by Environment and Climate Change Canada (ECCC) staff during site visits of Canadian kraft pulp mills. Relevant data and observations were identified up to March 2020. Empirical data from key studies as well as some results from models are used to reach conclusions. When available and relevant, information presented in assessments from other jurisdictions was considered.

This screening assessment was prepared by staff in the CEPA Risk Assessment Program at Environment and Climate Change Canada and Health Canada and incorporates input from other programs within these departments. The ecological and human health portions of this screening assessment have undergone external review and/or consultation. Comments on the technical portions relevant to the environment were received from Dr. Pamela M. Campbell at ToxEcology Environmental Consulting Ltd., Dr. Bjarne Holmbom at Separation Research Inc. and Dr. Vickie Tatum at the United States (U.S) National Council for Air and Stream Improvement (NCASI). Comments on the technical portions relevant to human health were coordinated and received from Tetratech. Additionally, the draft of this screening assessment (published June 22, 2019) was subject to a 60-day public comment period. While external comments were taken into consideration, the final content and outcome of the screening assessment remain the responsibility of Health Canada and ECCC.

This screening assessment focuses on information critical to determining whether substances meet the criteria as set out in section 64 of CEPA by examining scientific information and incorporating a weight-of-evidence approach and precaution.Footnote 4 This screening assessment presents the critical information and considerations on which the proposed conclusions are based.

2. Identity of substances

The CAS RN, Domestic Substances List (DSL) names and common names and/or abbreviations of the individual substances along with (if applicable) their representative chemical structures and percentage of the substance represented in the Resins and Rosins Group are presented in Tables 2-1 and 2-2.

|

CAS RN (abbreviation) |

DSL name (common name) |

Chemical structure and molecular formula | Molecular weight (g/mol) |

|---|---|---|---|

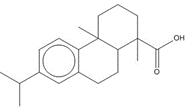

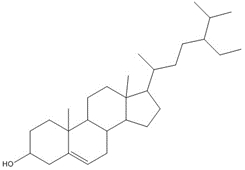

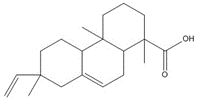

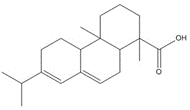

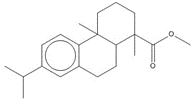

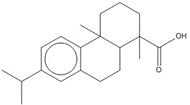

| 1740-19-8 (DHAA) |

1-Phenanthrenecarboxylic acid, 1,2,3,4,4a,9,10,10a-octahydro-1,4a-dimethyl-7-(1-methylethyl)-, [1R-(1α,4aβ,10aα)]- (Dehydroabietic acid) |

![Chemical structure of dehydroabietic acid (DHAA), with SMILES notation: C[C@@]1([C@]2([C@@](CCC1)(C)C3=C(CC2)C=C(C(C)C)C=C3)[H])C(O)=O](/content/dam/eccc/images/pded/resins-rosins/20190524Figure2.1.1.jpg) C20H28O2

C20H28O2

|

300.44 |

|

CAS RN (abbreviation) |

DSL name (common name) |

Representative chemical structure Molecular formula, molecular weight Chemical Name, %wt./wt. represented (in bold) |

|---|---|---|

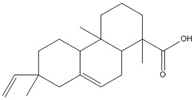

|

8002-26-4 (CTO and DTOa) |

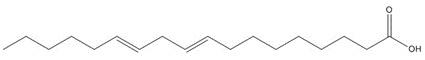

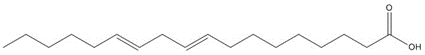

Tall oil |  C18H32O2, 280.45 g/mol

C18H32O2, 280.45 g/mollinoleic acidb, 41%/65a%  C20H30O2, 302.46 g/mol

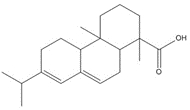

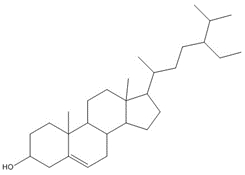

C20H30O2, 302.46 g/molabietic acidc, 20%/15a%  C29H50O, 414.72 g/mol

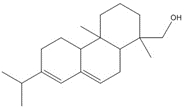

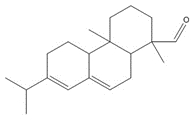

C29H50O, 414.72 g/molβ-sitosterold,e, 7%/0a%  C20H32O, 288.25 g/mol

C20H32O, 288.25 g/molabietinolf,e, 10%/2a%  C20H28O2, 300.44 g/mol

C20H28O2, 300.44 g/moldehydroabietic acid (DHAA)c, 5%/8a%  C20H30O2, 302.46 g/mol

C20H30O2, 302.46 g/molisopimaric acid (IPA)c, 5%/10a%  C20H30O, 286.46 g/mol

C20H30O, 286.46 g/molabietinalg,e, 2%/0a% [No Structure] polymeric and esters > 750 g/mol and/or log Kow >9, 10%/0% |

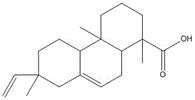

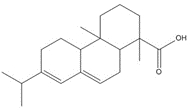

| 8016-81-7 (TOP) | Tall oil pitch |  C20H30O2, 302.46 g/mol

C20H30O2, 302.46 g/molabietic acidc, 15%  C29H50O, 414.72 g/mol

C29H50O, 414.72 g/molβ-sitosterolh,e, 15%  C18H32O2, 280.45 g/mol

C18H32O2, 280.45 g/mollinoleic acidb, 5% [No Structure] polymeric and esters > 750 g/mol and/or log Kow >9, 65% |

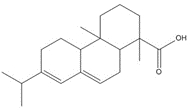

| 8050-09-7 / 8052-10-6 / 73138-82-6 |

Rosin / tall-oil rosin / resin acids and rosin acids (rosin) |

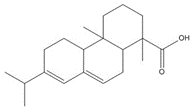

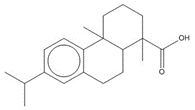

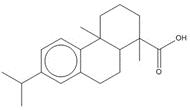

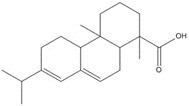

C20H30O2, 302.46 g/mol

C20H30O2, 302.46 g/molabietic acidh,c, 60%  C20H28O2, 300.44 g/mol

C20H28O2, 300.44 g/moldehydroabietic acid (DHAA)c, 15%  C20H30O2, 302.46 g/mol

C20H30O2, 302.46 g/molisopimaric acid (IPA)c, 25% |

| 9007-13-0 (RCa) | Resin acids and rosin acids, calcium salts |  C20H30O2, 302.46 g/mol

C20H30O2, 302.46 g/molabietic acidh,c, 58%  C20H28O2, 300.44 g/mol

C20H28O2, 300.44 g/moldehydroabietic acid (DHAA)c, 13%  C20H30O2, 302.46 g/mol

C20H30O2, 302.46 g/molisopimaric acid (IPA)c, 23% Ca2+, 40.08 g/mol calcium counter ion, 6% |

| 61790-51-0 (RNa) | Resin acids and rosin acids, sodium salts |  C20H30O2, 302.46 g/mol

C20H30O2, 302.46 g/molabietic acidh,c, 57%  C20H28O2, 300.44 g/mol

C20H28O2, 300.44 g/moldehydroabietic acid (DHAA)c, 13%  C20H30O2, 302.46 g/mol

C20H30O2, 302.46 g/molisopimaric acid (IPA)c, 23% Na1+, 22.99 g/mol sodium counter ion, 7% |

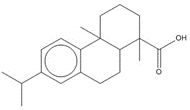

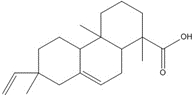

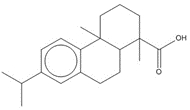

| 8050-15-5 (RHME) | Resin acids and rosin acids, hydrogenated, methyl esters |  C21H36O2, 320.27 g/mol

C21H36O2, 320.27 g/moltetrahydroabietic acid methyl ester (THAME)h,i, 75%  C21H30O2, 314.47 g/mol

C21H30O2, 314.47 g/moldehydroabietic acid methyl ester (DHAME)i, 20%  C20H28O2, 300.44 g/mol

C20H28O2, 300.44 g/moldehydroabietic acid (DHAA)c, 5% |

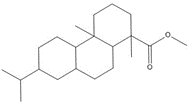

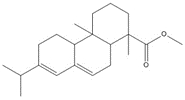

| 68186-14-1 (RME) | Resin acids and rosin acids, methyl esters |  C21H34O2, 318.50 g/mol

C21H34O2, 318.50 g/molabietic acid methyl esterh,i, 100% |

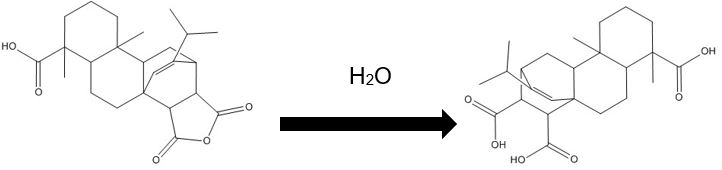

| 8050-28-0 (RMa) | Rosin, maleated |  parent hydrolysis product parent hydrolysis productC24H32O5, 400.52 g/mol maleopimaric acid (MPA)h15% → C24H34O6, 418.53 g/mol MPA hydrolysis product, 15%  C20H28O2, 300.44 g/mol

C20H28O2, 300.44 g/moldehydroabietic acid (DHAA)c, 25%  C20H30O2, 302.46 g/mol

C20H30O2, 302.46 g/molabietic acidc, 60% |

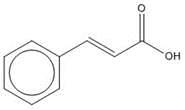

| 8046-19-3 |

Storax (balsam) |

C9H8O2, 148.16 g/mol

C9H8O2, 148.16 g/molcinnamic acidh, 100% |

Abbreviations: Kow, octanol–water partition coefficient; % wt./wt., weight percentage

a Distilled tall oil (DTO) has a distinct composition, compared to crude tall oil (CTO) and thus, the associated percentage representation of each representative chemical will differ accordingly. However, both CTO and DTO bear the CAS‑RN 8002-26-4.

Chemical Classes: b Fatty acid; c Resin acid; d Phytosterol; e;Estimated component as the neutrals fraction may not have been fully characterized and uncertainty exists f Alcohol; g Aldehyde; i Ester.

h Key representative chemical (used for initial tier profiling of this substance during categorization, 2006, and more recently in Ecological Risk Classification of Organic Substances (ECCC 2016b).

In the ecological assessment, representative chemicals are used to represent the UVCB (unknown or variable composition, complex reaction products, or biological materials) substances in the Resins and Rosins Group for the purposes of estimating the properties of the many components or of the whole substance. Whole substance-based empirical data (if available) is also considered together with this component-based information in a weight-of-evidence approach. However, in many instances, there are significant deficiencies in the whole substance testing of these UVCBs, such that relevant and reliable whole substance data are generally not available. The principal factors taken into account to select the representative chemicals (shown for each UVCB in Table 2-2) were bioavailability, persistence, and toxicity and/or reactivity. The availability of empirical data for each representative chemical was also considered in the selection process. In general, components with a higher bioavailability, persistence and toxicity and known presence in the environment were selected to represent the respective sub-classes. However, given the high degree of variability in the types and amounts of components present, there may be some uncertainty respecting the degree of the representation of the subclass.

The proportions allocated for each representative chemical in Table 2-2 are determined on the basis of information available from the published literature along with information obtained from industry. As a conservative approach, a higher proportion of those representative chemicals that are more hazardous were allocated. In most cases, more than one representative chemical is used to describe the composition of the substance rather than selecting a single “worst case” component, which could result in a less realistic assessment. Each representative structure represents a number of components within a fraction of the substance (not just the proportion known for that specific representative chemical), and a distinction must therefore be made between a representative chemical and a component of the substance for the purposes of this screening assessment.

Most of the Resins and Rosins Group substances are derivatives of CTO, which is a co-product of kraft pulping of coniferous wood formed by acidifying black liquor soap skimmings with sulfuric acid. CTO is a dark oily liquid with 26% to 42% resin acids (represented by abietic acid, isopimaric acid (IPA), and DHAA), 36% to 48% fatty acids (e.g., linoleic acid), and 10% to 38% neutral compounds (represented by β-sitosterol, abietinol and abietinal) (Huibers 2000). Variability in composition may be due to both the pulpwood variability (e.g., tree species used) and the process or operational conditions.

CTO may serve as a source material for several downstream products manufactured through extensive fractional distillation. This process is aimed at separating out desirable fatty and resin acid components while minimizing the proportion of neutral compounds. The first step in CTO distillation is the removal of the TOP fraction (see Figure 2-1). The composition of TOP can be highly variable, and since the commercial uses are limited, this fraction is often burned as fuel at the distillation plants. Recent data submitted to ECCC suggests that a large percentage (~65%) of TOP may be a polymeric material with molecular weights greater than 750 g/mol (Study Submission 2017a). Thus, the remaining and more bioavailable fraction of TOP includes 2% to 8% fatty acids represented by linoleic acid, 5% to 15% resin acids represented by abietic acid, along with ~15% phytosterols represented by β-sitosterol (Table 2-2) (Zinkel and Russell 1989; Study Submission 2017a). While esterified neutral compounds including polymeric and esterified phytosterols (e.g., sitosterol linoleate with a molecular weight of 677 g/mol) may also be present in CTO (10%), these are not considered significantly bioavailable due to their large molecular size, and thus, are not considered further as representative chemicals for the purpose of this screening assessment.

After the TOP has been removed, the depitched CTO is fed into a distillation column to produce a heads (i.e.,. low boiling point or volatile components), rosin and crude fatty acid fractions. Rosin (which in this screening assessment includes CAS RNs 8050-09-7, 8052-10-6 and 73138-82-6) has a higher boiling point than the fatty acid components and is taken from the bottom of the column. Rosin is largely (~90% w/w) made up of specific resin acids (also named rosin acids) along with smaller amounts of fatty acids (1% to 5%) and neutrals (1% to 7%), the latter of which are mainly diterpenoids (US EPA 2004; Holmbom 2011). Two other rosin production methods exist: extraction from live pine trees (gum rosin) and, to a lesser degree, extraction from wood stumps (wood rosin). Depending on the production method, the relative proportion of these resin acids may vary as shown in Table 2-3 (Zinkel and Russell 1989).

| Components (ID) | Tall oil rosinc | Gum rosinc | Wood rosinc |

|---|---|---|---|

| Abietic acida | 38 | 24 | 51 |

| Palustric acida | 8 | 21 | 8 |

| Isopimaric acidb | 11 | 17 | 16 |

| Dehydroabietic acida | 18 | 5 | 8 |

| Neoabietic acida | 3 | 19 | 5 |

| Pimaric acidb | 4 | 5 | 7 |

a Abietic-type.

b Pimaric-type.

c Percent proportion of total acids fraction.

Three types of rosin derivatives included in this screening assessment are also shown in Figure 2-1. The first includes sodium (Na) or calcium (Ca) salts of unmodified rosin (i.e., CAS RNs 9007-13-0 and 61790-51-0), made by treating rosin with the appropriate alkali earth or alkali metal (US EPA 2004). The second type, resin acid methyl esters, is produced through methylation (CAS RN 68186-14-1) or methylation preceded by hydrogenation (CAS RN 8050-15-5). Hydrogenated methyl esters of resin acids are produced by catalyzed hydrogenation to saturate one or more of the conjugated double bonds and create di- or tetra-hydro products (Zinkel and Russell 1989), a process that typically achieves a 75% hydrogenation level (Panda 2005). The hydrogenated product is then methylated. The processes typically have high (85% to 95%) yields of methylated resin acid or methylated hydrogenated resin acid derivatives (Study Submission 2016a, 2016b). The third type is maleated rosin (CAS RN 8050-28-0), which is produced when abietic-type resin acids (e.g., abietic, neoabietic, palustric and levopimaric acids) in rosin react with maleic anhydride under conditions that favour the Diels-Alder reaction and formation of maleopimaric acid (MPA). Yield of MPA varies depending on reaction conditions, relative proportions of reactants, and types of solvents and acids used. Gonis et al. (1973) reported 32% to 42% (weight basis) after refluxing rosin, maleic anhydride, and glacial acetic acid under nitrogen at elevated temperatures in a laboratory study. However, MPA content is much lower, i.e., 12%-16%, in certain commercial products (Study Submission 2017b).

Distilled tall oil (DTO) is produced as a product of CTO distillation (Zinkel and Russell 1989). DTO is obtained from the crude fatty acid fraction, which is distilled into a heads fraction, a purified tall oil fatty acids (TOFAs) fraction and a DTO fraction. DTO consists of 25% to 30% resin acids (represented by abietic acid, IPA, and DHAA), 60% to 70% fatty acids (represented by linoleic acid), and 2% to 6% neutrals (represented by abietinol. However, the neutrals fraction of DTO has not been characterized) (Holmbom et al. 2010). In 1994, CAS RN 8002-26-4 was added to the DSL with the DSL name “tall oil”. The substance, as nominated to the DSL. may refer to both CTO and DTO. Where possible distinction is made in the screening assessment between these two substances. However, given that this distinction was not made during the original DSL nomination and CTO and DTO share a common CAS RN, instances may remain where it is not possible to accurately distinguish between CTO and DTO.

Long description

CTO is distilled on distillation columns to produce, in decreasing boiling point, TOP, rosin, DTO, tall oil fatty acids and tall oil heads, the latter two of which are not being assessed. Rosin may be further chemically reacted to form: rosin, maleated; resin acids and rosin acids, hydrogenated, methyl esters; resin acids and rosin acids, methyl ester; resin acids and rosin acids, calcium salts; and resin acids and rosin acids, sodium salts.

This screening assessment also includes the essential oil storax produced from steam or water distillation of resins from the deciduous tree species sweetgum (Liquidambar spp.). This substance is a type of resin (thus, grouped together with rosin in this group). However, unlike rosin from North American coniferous wood species (e.g., CAS RNs 8050-09-7, 8052-10-6, and 73138-82-6), storax is comprised predominantly of esters of cinnamic acid and benzoic acid (Baser and Demirci 2011).

3. Physical and chemical properties

A summary of physical and chemical property data for the substances in the Resins and Rosins Group is presented in Tables 3-1 to 3-9. For the UVCBs, a range of empirical or modelled physical and chemical property values are provided for each UVCB substance based on either the whole substance or its representative chemicals. Most standard tests for physical-chemical properties were originally developed for application to discrete organic substances, although they have been applied to UVCBs. Thus, results of applying such tests to a whole UVCB substance are interpreted with caution. For example, while empirical whole substance data are available for certain UVCB substances on melting point, vapour pressure and water solubility, these data do not accurately reflect the properties of the individual components or the range present for all components within the UVCB substance. Component-based information is therefore used for modelling purposes, and empirical whole-substance data is included as an added line of evidence where possible. In several cases, a large range of values is shown, reflecting the large range in individual representative chemical physical-chemical properties.

When experimental data are limited or not available for a property, quantitative structure-activity relationship (QSAR) models are used to generate predicted values for the substance and/or analogues are used for read-across. Component specific physical-chemical information is provided in ECCC (2021b).

Where more than one valid modelled or empirical value is available for a given property for a specific component, the mean or geometric mean is taken as the key value for that parameter. The selected key values for the estimation of vapour pressure, water solubility and log Kow or log Dow (log Dow is used in place of log Kow when the component ionizes more than 50% within the range of pH 6-8) are adjusted using the least-squares adjustment procedure (Cole and Mackay 2000; Schenker et al. 2005) and represent internally consistent partitioning properties considering thermodynamic constraints.

| Property | Value | Key reference(s) |

|---|---|---|

| Physical state | Liquida,b (w) | ECHA c2007-2017 |

| Melting point (°C) |

-8.5–171a,b (c)

-3.15c/-20d (w) |

Liss et al. 1997 US EPA 2017 ECHA c2007-2017 |

| Vapour pressure (Pa) |

2.5 × 10−5c–0.19c,a (c) 4.6 x 10-5c–0.19c,b (c) |

MPBPWIN 2010 |

| Henry’s law constant (Pa·m3/mol) | 1.79 × 10−2–84a,b (c) | HENRYWIN 2008 |

| Water solubility (mg/L) |

7.62 × 10−7c–153a,b,c, (c) 73a / 8–42b (w) |

Meylan et al. 1996 Nyren and Back 1958 WATERNT 2010 WSKOWWIN 2010 ACD/Percepta c1997-2012 ECHA c2007-2017 |

| log Kow or log D (dimensionless) at pH 7 unless otherwise specified |

3.15–7.02a (c) 3.15–5.78b (c) 3.2–6.8a,b,d (w) |

ACD/Percepta c1997-2012 Meylan and Howard 1995 VCCLab 2005 ECHA c2007-2017 |

| log Koc (dimensionless) | 1.88——5.08a (c) 1.88–3.52b (c) | KOCWIN 2010 |

| pKa (dimensionless) | 4.8–15a,b (c) | ACD/Percepta c1997-2012 |

Abbreviations: Kow, octanol–water partition coefficient; Koc, organic carbon–water partition coefficient; pKa, acid dissociation constant; D, distribution coefficient.

a CTO (EC#931-433-1).

b DTO (EC#232-304-6).

c Sub-cooled corrected for solids at standard temperature.

d pH = 5-6.

| Property | Value | Key reference(s) |

|---|---|---|

| Physical state | Tacky thermoplastic | Zinkel and Russell 1989 |

|

Softening / Pour point (°C)

Melting point (°C) |

40 (w) 20.9 (w) -8.5–171 (c) |

Zinkel and Russell 1989 ECHA c2007-2017 US EPA 2017 |

| Vapour pressure (Pa) | 2.5 × 10-5a–0.19a (c) | MPBPWIN 2010 |

| Henry’s law constant (Pa·m3/mol) | 0.16–30 (c) |

US EPA 2017 HENRYWIN 2008 |

| Water solubility (mg/L) |

7.6 × 10-7a–153a (c)

<1–20 mg/L (w) |

Nyren and Back 1958 Meylan et al. 1996 WATERNT 2010 WSKOWWIN 2010 ACD/Percepta c1997-2012 ECHA c2007-2017 |

| log Kow or log D (dimensionless) at pH 7 unless otherwise specified |

3.34–8.26 (c)

2.8–4.4b (w) |

ACD/Percepta c1997-2012 Meylan and Howard 1995 VCCLab 2005 ECHA c2007-2017 |

| log Koc (dimensionless) | 2.00–5.08 (c) | KOCWIN 2010 |

| pKa (dimensionless) | 4.8–15 (c) | PhysProp c2013, ACD/Percepta c1997-2012 |

Abbreviations: Kow, octanol–water partition coefficient; Koc, organic carbon–water partition coefficient; N/A, not applicable; pKa, acid dissociation constant; D, distribution coefficient.

a Sub-cooled corrected for solids at standard temperature.

b pH = 7.5.

| Property | Range | Key reference(s) |

|---|---|---|

| Physical state | Solid (w) | ECHA c2007-2017 |

| Melting point (°C) |

160–171 (c)

67–93 (w) |

US EPA 2017 Liss et al. 1997 ECHA c2007-2017 |

| Vapour pressure (Pa) |

2.2×10-3b–0.19b(c) 6 (w) |

MPBPWIN 2010 ECHA c2007-2017 |

| Henry’s law constant (Pa·m3/mol) | 1.8×10-2–0.68 (c) | HENRYWIN 2008 |

| Water solubility (mg/L) |

18b–153b (c)

0.6–0.9 (w) |

Meylan et al. 1996 WATERNT 2010 WSKOWWIN 2010 ACD/Percepta c1997-2012 Liss et al. 1997 ECHA c2007-2017 |

| log Kow or log D (dimensionless) at pH 7 unless otherwise specified |

3.2–5.8 (c)

3.0–6.2c (w) 1.9–7.7d (w) |

ACD/Percepta c1997-2012 ECHA c2007-2017 |

| log Koc (dimensionless) | 1.9–2.3 (c) | KOCWIN 2010 |

| pKa (dimensionless) | 4.8–6.4 (c) |

ACD/Percepta c1997-2012 Nyren and Back 1958 |

Abbreviations: Kow, octanol–water partition coefficient; Koc, organic carbon–water partition coefficient; pKa, acid dissociation constant; D, distribution coefficient.

a Considered the principal CAS RN for rosin in this assessment.

b Sub-cooled corrected for solids at standard temperature.

c pH = 6-7.

d pH = 2.

| Property | Range | Key reference(s) |

|---|---|---|

| Physical state | Viscous liquid | ECHA c2007-2017 |

| Melting point (°C) |

113–171 (c)

-5.5 (w) |

Liss et al. 1997 US EPA 2017 MPBPWIN 2010 ECHA c2007-2017 |

| Vapour pressure (Pa) |

2.2 x 10-3a–7.8 x 10-3a (c)

2.6 × 10-2 (w) |

MPBPWIN 2010

ECHA c2007-2017 |

| Henry’s law constant (Pa·m3/mol) | 1.8 × 10-2–250 (c) | HENRYWIN 2008 |

| Water solubility (mg/L) |

0.2a–124a (c)

0.42–6 (w) |

Liss et al. 1997 WSKOWWIN 2010 WATERNT 2010 ACD/Percepta c1997-2012 ECHA c2007-2017 |

| log Kow or log D (dimensionless) at pH 7 unless otherwise specified |

4.8–6.6 (c)

6.4–7.6b; >6.5c (w) |

KOWWIN 2010 VCCLab 2005 ACD/Percepta c1997-2012 ECHA c2007-2017 |

| log Koc (dimensionless) | 1.9–4.5 (c) | KOCWIN 2010 |

| pKa (dimensionless) | 4.8–5.7 (DHAA only) |

Liss et al. 1997 ACD/Percepta c1997-2012 |

Abbreviations: Kow, octanol–water partition coefficient; Koc, organic carbon–water partition coefficient; pKa, acid dissociation constant; D, distribution coefficient.

a Sub-cooled corrected for solids at standard temperature.

b pH = 6.

c pH = 7.

| Property | Range | Key reference(s) |

|---|---|---|

| Physical state | Solid | |

| Melting point (°C) |

171–207 (c)

94–116 (w) |

Liss et al. 1997 US EPA 2017 MPBPWIN 2010 Zinkel and Russell 1989 |

| Vapour pressure (Pa) |

1.33 × 10-7a—0.19a (c) 4 (w) |

MPBPWIN 2010

ECHA c2007-2017 |

| Henry’s law constant (Pa·m3/mol) | 1 x 10-4--0.68 (c) |

HENRYWIN 2008 PhysProp c2013 |

| Water solubility (mg/L) |

25a–153 (c)

1.4 (w) |

Nyren and Back 1958;

Liss et al. 1997 WSKOWWIN 2010 WATERNT 2010 ACD/Percepta c1997-2012 ECHA c2007-2017 |

| log Kow or log D (dimensionless) at pH 7 unless otherwise specified |

3.1515–3.6 (c)

1.5b–7.6b (w) 2.2c–5.9c (w) |

ACD/Percepta c1997-2012

Study Submission 2016d ECHA c2007-2017 |

| log Koc (dimensionless) | 1.72 (c) | KOCWIN 2010 |

| pKa (dimensionless) | 4.8–6.4 |

Liss et al. 1997 ACD/Percepta c1997-2012 |

Abbreviations: Kow, octanol–water partition coefficient; Koc, organic carbon–water partition coefficient; pKa, acid dissociation constant; D, distribution coefficient.

a Sub-cooled corrected for solids at standard temperature.

b pH = 2.

c pH > 2.

| Property |

Range RCa / RNa |

Key reference(s) |

|---|---|---|

| Physical state | Solid (w) | ECHA c2007-2017 |

| Melting point (°C) |

160–171a (c)

>300b / >255 (w) |

US EPA 2017 Liss et al. 1997 ECHA c2007-2017 |

| Vapour pressure (Pa) | 2.2×10-3ac–0.19ac (c) | MPBPWIN 2010 |

| Henry’s law constant (Pa·m3/mol) | 1.8×10-2a–0.68a (c) | HENRYWIN 2008 |

| Water solubility (mg/L) |

18a–153a (c)

43 / miscibled (w) |

Meylan et al. 1996 WATERNET 2010 WSKOWWIN 2010 ACD/Percepta c1997-2012 Liss et al. 1997 ECHA c2007-2017 |

| log Kow or log D (dimensionless) at pH 7 unless otherwise specified |

3.2a–5.8a (c)

3.01e / 0.9–6.6f (w) |

ACD/Percepta c1997-2012

ECHA c2007-2017 |

| log Koc (dimensionless) | 1.9a–2.3a (c) | KOCWIN 2010 |

| pKa (dimensionless) | 4.8a–6.4a (c) |

ACD/Percepta c1997-2012 Nyren and Back 1958 |

Abbreviations: Kow, octanol–water partition coefficient; Koc, organic carbon–water partition coefficient; pKa, acid dissociation constant; D, distribution coefficient.

a Values are for organic components of rosin (CAS RNs 8050-09-7, 8052-10-6, 73138-82-6); does not account for properties of Na or Ca salts.

b Decomposes at > 115°C (ECHA c2007-2017).

c Sub-cooled corrected for solids at standard temperature.

d Concentration tested was 0.25 to 4 g/mL of water.

e pH = 6.8 - 7.3.

f pH = 7.

| Property | RME | Key reference |

|---|---|---|

| Physical state | Viscous liquid | ECHA c2007-2015 |

| Molecular Weight (g/mol) | ~318.5 | n/a |

| Boiling point (°C) | 360 – 430 (decomposition) | ECHA c2007-2015 |

| Vapour pressure (Pa) | 3.1 ×10-3 | ECHA c2007-2015 |

| Henry’s law constant (Pa·m3/mol) | 2.16 × 10-3 | HENRYWIN 2008 |

| Log Kaw (dimensionless) | -6.155 | HENRYWIN 2008 |

| Water solubility (mg/L) | <0.22 to <32.3 | ECHA c2007-2015 |

| log Kow | 2.44 to >6.5 2.13 | ECHA c2007-2015 |

| log Koc (dimensionless) | 1.334–1.731 | KOCWIN 2010 |

| log Koa (dimensionless) | 8.285 | KOAWIN v 1.10 |

Abbreviations: Kow, octanol–water partition coefficient; Koc, organic carbon–water partition coefficient; Kaw, air-water partition coefficient; Koa, octanol-air partition coefficient.

| Property | Storax (balsam) | Key reference(s) |

|---|---|---|

| Physical state | solid | ECHA c2007-2015 |

| Molecular Weight (g/mol) | ~212.3 | n/a |

| Boiling point (°C) | 300–343.9 | Pubchem |

| Vapour pressure (Pa) | 6.67 × 10-3 | ECHA c2007-2015 |

| Henry’s law constant (Pa·m3/mol) | 1.71 × 10-3 | HENRYWIN 2008 |

| Log Kaw (dimensionless) | -6.155 | HENRYWIN 2008 |

| Water solubility (mg/L) | 0.1 (at 18°C) | ECHA c2007-2015 |

| log Kow | 2.13 | ECHA c2007-2015 |

| log Koc (dimensionless) | 1.73 | KOCWIN 2010 |

| log Koa (dimensionless) | 8.28 | KOAWIN v 1.10 |

Abbreviations: Kow, octanol–water partition coefficient; Koc, organic carbon–water partition coefficient; Kaw, air-water partition coefficient; Koa, octanol-air partition coefficient.

| Property | DHAA | Key reference(s) |

|---|---|---|

| Physical state | solid | ECHA c2007-2015 |

| Molecular Weight (g/mol) | 300.4 | n/a |

| Boiling point (°C) | 326–425 | US EPA Chem Dashboard |

| Vapour pressure (Pa) | 7.37 × 10-6–6.13 × 10-5 | US EPA Chem Dashboard |

| Henry’s law constant (Pa·m3/mol) | 4.78 × 10-3 | HENRYWIN 2008 |

| Log Kaw (dimensionless) | -5.14 | HENRYWIN 2008 |

| Water solubility (mg/L) | 2.4 | WSKOWWIN 2008 |

| log Kow | 4.80 | KOAWIN 2008 |

| log Koc (dimensionless) | 2.81–4.34 | KOCWIN 2010 |

| log Koa (dimensionless) | 9.94 | AEROWIN v 1.10 |

Abbreviations: Kow, octanol–water partition coefficient; Koc, organic carbon–water partition coefficient; Kaw, air-water partition coefficient; Koa, octanol-air partition coefficient.

4. Sources and uses

All of the substances in the Resins and Rosins Group have been included in a survey issued pursuant to section 71 of CEPA (Canada 2012) and subsequent voluntary surveys (ECCC 2016c, 2016d; 2017). Table 4-1 presents a summary of information reported on the total manufacture and total import quantities for the Resins and Rosins Group.

| Abbreviation or Common name | Number of companies or facilities manufacturing | Total manufacturea (kg) | Number of companies or facilities importing | Total importsa (kg) |

|---|---|---|---|---|

| DHAA | 0 | NR | <4 | 100–1 000 |

| CTO | 4 | 10 000 000–100 000 000b | <4 | 10 000–100 000 |

| DTO | 0 | NR | 18 | 100 000–1 000 000 |

| TOP | 0 | NR | 4 | 100 000–1 000 000 |

| Storax | 0 | NR | <4 | <100 |

| Rosin (CAS RNs 8050-09-7, 8052-10-6, 73138-82-6c) | 0 | NR | 31 | 100 000–1 000 000 |

| RCa | <4 | 10 000–100 000 | 10 | 10 000–100 000 |

| RNa | <4 | 100–1 000 | 13 | 10 000–100 000 |

| RHME | 0 | NR | 6 | 10 000–100 000 |

| RME | 0 | NR | <4 | 100–1 000 |

| RMa | 0 | NR | 4 | 1 000–10 000 |

Abbreviations: NR, not reported above the 100 kg reporting threshold.

a Values reflect quantities reported in response to the surveys conducted under section 71 of CEPA (Environment Canada 2013). See surveys for specific inclusions and exclusions (Schedules 2 and 3). Values also reflect quantities reported from voluntary surveys (ECCC 2016c, 2016d and 2017).

b CTO manufacture is a result of incidental co-production.

c 4 companies reported importing 100-1 000 kg under this CAS RN only.

| Major usesa | CTO | DTO | TOP |

Rosin (CAS RNs 8050-09-7, 8052-10-6) |

|---|---|---|---|---|

| Lubricants and greases | N | Y | N | Y |

| Plastic and rubber | N | N | Y | Y |

| Agriculture | N | N | N | Y |

| Adhesives and sealants | N | Y | N | Y |

| Building or construction materials | N | Y | N | Y |

| Oil and natural gas extraction | N | Y | Y | N |

| Explosives | N | N | N | Y |

| Intermediate | Nb | Y | N | Y |

| Pigments | N | N | N | Y |

| Processing aids | N | Y | Y | Y |

| Plasticizer | N | Y | N | Y |

| Paints and coatings | N | Y | N | Y |

| Solvents | N | N | N | Y |

| Propellant | N | N | N | Y |

| Solder flux | N | N | N | Y |

| Water treatment | N | Y | N | N |

| Fabrics and textiles | N | Y | N | N |

| Pharmaceuticals | N | N | N | Y |

| Personal care | N | N | N | Y |

| Toys, playground and sporting equipment | N | N | N | Y |

| Food packaging | N | Y | N | N |

| Metal manufacturing | N | Y | N | N |

Abbreviations: N, this use was not reported for this substance; Y, this use was reported for this substance in 2011.

a Non-confidential uses reported in response to the surveys conducted under section 71 of CEPA (Environment Canada 2013). See surveys for specific inclusions and exclusions (Schedules 2 and 3). Also reflects uses quantities reported from voluntary surveys (ECCC 2016c, 2016d, 2017).

b CTO may be refined to produce other products including DTO, TOP and rosin which are also listed here (this activity is not known to occur currently in Canada).

| Major usesa | RCa | RNa | RHME | RMa |

|---|---|---|---|---|

| Lubricants and greases | N | N | Y | N |

| Plastics and rubber | Y | N | N | N |

| Adhesives and sealants | Y | Y | N | N |

| Building or construction materials | N | Y | N | Y |

| Pigments | Y | Y | N | N |

| Processing aids | N | N | Y | N |

| Plasticizers | N | Y | N | Y |

| Paints and coatings | Y | Y | N | Y |

| Odour agents | N | N | Y | N |

| Surface active agents | N | Y | N | N |

| Pest control | Y | N | N | N |

| Automotive care | N | N | Y | N |

| Laundry and dishwashing | N | N | Y | N |

| Cleaning and furnishing care | N | N | Y | N |

| Personal care | N | N | Y | N |

| Air care | N | N | Y | N |

| Apparel and footwear care | N | N | Y | N |

| Pet care | N | N | Y | N |

| Agricultural products | Y | N | N | N |

| Floor coverings | Y | N | N | N |

| Arts, crafts and hobby materials | Y | N | N | N |

Abbreviations: N, this use was not reported for this substance; Y, this use was reported for this substance in 2011.

a Non-confidential uses reported in response to the surveys conducted under section 71 of CEPA (Environment Canada 2013). See surveys for specific inclusions and exclusions (Schedules 2 and 3) Also reflects uses reported from voluntary surveys (ECCC 2016c, 2016d and 2017).

As described in section 2, CTO is a co-product of kraft pulping, which is an industrial activity in Canada. CTO produced as a co-product of kraft pulping is typically burned in a recovery boiler (Wising and Stuart 2006). In addition, the intermediate use of CTO is as a feedstock for refining into various downstream products including TOP, rosin and DTO. CTO refining is not known to occur currently in Canada, but downstream products of CTO are imported into Canada. CTO that is imported into Canada may have various industrial applications, including use as a raw material for oil and gas drilling applications (Georgia-Pacific 2018). In addition to the uses outlined in Table 4-1, TOP (CAS RN 8016-81-7) has been known to be used in corrosion inhibitors, coatings, as a rubber modifier, in cement and asphalt and minerals processing, as well as burned as a fuel (Zinkel and Russell 1989; Lesokhimik Trade House 2018). Products formulated with CTO or DTO that are available to consumers include cosmetics (up to 30%), adhesives and sealants (<10%), paints and coatings (5% to 30%), kitchen cleaners (1% to 10%) and degreasers (>5%) (COSING c2009-2017a; MSDS 2007, 2009, 2010, 2015a, 2015b, email from the Consumer and Hazardous Product Safety Directorate, Health Canada, to the Existing Substances Risk Assessment Bureau, Health Canada, dated June 26, 2017; unreferenced).

DTO, rosin (primarily CAS RNs 8050-09-7 and 8052-10) and its derivatives RCa, RNa, RHME and RMa have a diverse number of industrial and consumer/commercial uses, as specified in Tables 4-2 and 4-3. In addition, some commonly known applications for DTO include use in the manufacture of certain materials and use in agricultural products, drilling muds, cement additive, washing fluids, metal working fluids, oilfield chemicals, soaps, cleaners, and alkyd resins (Pine Chemicals Group 2018; UCY Energy 2018). Rosin salts, RCa and RNa, and rosin derivative RHME were also reported to be manufactured in Canada at over 100 kg in 2011, as shown in Table 4-1. RCa and RNa are also used in paints and coatings.

Other reported Canadian uses for substances in the Resins and Rosins Group are presented in Tables 4-4 and 4-5.

| Use | DHAA | DTO | Storax |

Rosin (CAS RNs 8050-09-7, 73138-82-6) |

|---|---|---|---|---|

| Food Flavouring Agenta | N | N | Y | N |

| Food packaging materialsa | N | N | N | Y |

| Incidental Additivesa | N | N | N | Yf |

| Internal Drug Product Database as medicinal or non-medicinal ingredients in pharmaceutical, disinfectant or veterinary drug products in Canadab | N | N | Y | Y |

| Natural Health Products Ingredients Databasec | N | Y | Y | Y |

| Licensed Natural Health Products Database as medicinal or non-medicinal ingredients in natural health products (NHPs) in Canadac | N | N | Y | Y |

| List of Prohibited and Restricted Cosmetic Ingredientsd | N | N | N | N |

| Notified to be present in cosmetics, based on notifications submitted under the Cosmetic Regulations to Health Canadad | N | Y | Y | Y |

| Formulant in pest control products registered in Canadae | N | Y | Y | Y |

Abbreviations: Y = this use was reported for this substance; N = this use was not reported for this substance.

a Personal communication, email from the Food Directorate, Health Canada, to the Existing Substances Risk Assessment Bureau, Health Canada, dated July 4, 2017; unreferenced. While not defined under the Food and Drugs Act (FDA), incidental additives may be regarded, for administrative purposes, as those substances which are used in food processing plants and which may potentially become adventitious residues in foods (e.g.,. cleaners, sanitizers).

b Personal communication, email from the Therapeutic Products Directorate, Health Canada, to the Existing Substances Risk Assessment Bureau, Health Canada, dated May 31, 2017; unreferenced.

c Personal communication, email from the Natural and Non-prescription Health Products Directorate, Health Canada, to the Existing Substances Risk Assessment Bureau, Health Canada, dated June 1, 2017; unreferenced.

d Personal communication, email fromthe Consumer and Hazardous Product Safety Directorate, Health Canada, to the Existing Substances Risk Assessment Bureau, Health Canada, dated June 26, 2017; unreferenced.

e Personal communication, email from the Pest Management Regulatory Consumer and Hazardous Product Safety Directorate, Health Canada, to the Existing Substances Risk Assessment Bureau, Health Canada, dated June 29, 2017; unreferenced.

f Rosin (CAS RN 8050-09-7) may be used as a component in incidental additives used in food processing establishments with no direct food contact, therefore exposure is not expected. Rosin (CAS RN 73138-82-6) was not identified to be used as a component in incidental additives.

| Use | RHME | RCa | RNa | RME |

|---|---|---|---|---|

| Food packaging materialsa | Y | Y | Y | N |

| Internal Drug Product Database as medicinal or non-medicinal ingredients in pharmaceutical, disinfectant or veterinary drug products in Canadab | Y | N | N | N |

| Natural Health Products Ingredients Databasec | Y | N | N | Y |

| Licensed Natural Health Products Database as medicinal or non-medicinal ingredients in NHPs in Canadac | Y | N | N | Y |

| List of Prohibited and Restricted Cosmetic Ingredientsd | N | N | N | N |

| Notified to be present in cosmetics, based on notifications submitted under the Cosmetic Regulations to Health Canadad | Y | N | N | N |

| Formulant in pest control products registered in Canadae | Y | Y | Y | Y |

Abbreviations: Y = this use was reported for this substance; N = this use was not reported for this substance.

a Personal communication, email from the Food Directorate, Health Canada, to the Existing Substances Risk Assessment Bureau, Health Canada, dated July 4, 2017; unreferenced.

b Personal communication, email from the Therapeutic Products Directorate, Health Canada, to the Existing Substances Risk Assessment Bureau, Health Canada, dated May 31, 2017; unreferenced.

c Personal communication, email from the Natural and Non-prescription Health Products Directorate, Health Canada, to the Existing Substances Risk Assessment Bureau, Health Canada, dated June 1, 2017; unreferenced.

d Personal communication, email fromthe Consumer and Hazardous Product Safety Directorate, Health Canada, to the Existing Substances Risk Assessment Bureau, Health Canada, dated June 26, 2017; unreferenced.

e Personal communication, email from the Pest Management Regulatory Consumer and Hazardous Product Safety Directorate, Health Canada, to the Existing Substances Risk Assessment Bureau, Health Canada, dated June 29, 2017; unreferenced.

5. Releases to the environment

According to an analysis of sources and use information along with relevant monitoring data (ECCC 2021a), the major sources of emissions for substances in the Resins and Rosins Group are related to industrial activities in Canada. Releases of concern occur primarily to surface water where certain components may transfer to sediments via partitioning from overlying water, along with releases to soils via wastewater treatment systemFootnote 5 biosolids amendment. However, soil amendment using biosolids from pulp and paper mills is not a common practice, and there are limited contributions to collective biosolids from a small number of facilities in other sectors, which suggests that soils are less important to the evaluation of environmental risk than the aquatic environment for the Resins and Rosins Group. Significant components found in CTO, DTO, TOP, rosin, RCa, RNa, RMa and RHME are also naturally occurring in terrestrial (e.g., plants and soil) and aquatic environments (e.g., lakes, streams) due to natural processes. Releases to air or transfers to air from other environmental media are not considered significant for Resins and Rosins Group substances based on the evaluation of the physical-chemical properties of the representative chemicals together with consideration of the major industrial uses and use volumes of these substances.

Despite recovery measures in place, CTO may be released to water from kraft pulping facilities in Canada, such as through spills. Releases of other substances in the Resins and Rosins Group to water may occur from RCa manufacturing and industrial uses of CTO, DTO, rosin, RNa, TOP and RMa.

6. Environmental fate and behaviour

The fate, persistence and bioaccumulation potential of the Resins and Rosins Group is characterized using empirical and/or modelled data for the suite of 12 representative chemicals (see Table 2-2) along with some available empirical whole substance biodegradation data where applicable. Given the natural occurrence of a number of the components of the UVCBs in this screening assessment it is important to note that fate, persistence, and bioaccumulation must be interpreted in the context of these components occurring naturally and being released via natural processes (e.g., from the decomposition of vegetation), resulting in near continuous background exposure in many aquatic and terrestrial environments.

6.1 Environmental distribution

Level III fugacity-based Equilibrium Criterion Model (New EQC 2011) results based on modelling of representative chemicals are presented in Table 6-1 for each of the substances. The detailed representative chemical-based media-partitioning information is available in a supporting document (ECCC 2021b). Once released to the environment, substances in the Resins and Rosins Group will tend to partition to water and soil (depending on the compartment in which they are released), with lesser amounts also partitioning to sediment from water and negligible amounts to air. No significant direct releases to air are expected for the substances in this group (see section 5). This, along with the relatively low log Kaw values for most representative chemicals in this group, suggest that exposure in this medium is not significant.

Given their pKa values of ≥4.8 (see Tables 3-1 to 3-6), it is expected that certain substances and representative chemicals in the Resins and Rosins Group, especially the resin acids, will ionize within an environmentally relevant pH range (6 to 9). Components containing carboxylic acid functional groups (pKa ≤6) will be present primarily in ionized form, while components containing alcohol functional groups (pKa >9) will be present primarily in the neutral form at an environmentally relevant pH range (6 to 9). Although the input parameters that account for this ionization (e.g., log D vs. log Kow) are used in the New EQC modelling, some of the potential interactions with solids (suspended solids or sediment) may not be predictable. Many solid particles, including sediment in the environment, may be negatively charged so the freely available fraction of a chemical to which organisms are exposed could be greater for anionic chemicals (charge repulsion), such as carboxylate ion groups, than for neutral chemicals. However, there are many empirical studies that show that resin acids (e.g., representative chemicals abietic acid, DHAA, IPA, etc.) may accumulate in sediments of waters receiving industrial (largely pulp and paper) effluent (Meriläinen et al. 2006; Leppänen et al. 2000; Leppänen and Oikari 2001) despite the relatively low percentages (≤1%) of these components predicted to partition to sediments (ECCC 2021b). Some uncertainty therefore exists despite EQC results and additional ionization considerations.

| CTO Substance released to: |

Air (%) | Water (%) | Soil (%) | Sediment (%) |

|---|---|---|---|---|

| Air (100%) | 1–80 | 2–15 | 17–96 | 0–2 |

| Water (100%) | 0 | 51–99 | 0–1 | 1–48 |

| Soil (100%) | 0 | 0–6 | 94–100 | 0 |

| DTO Substance released to: |

Air (%) | Water (%) | Soil (%) | Sediment (%) |

|---|---|---|---|---|

| Air (100%) | 3-48 | 4-15 | 37-92 | 0–2 |

| Water (100%) | 0 | 84–99 | 0 | 1–16 |

| Soil (100%) | 0 | 0–6 | 94–100 | 0 |

| TOP Substance released to: |

Air (%) | Water (%) | Soil (%) | Sediment (%) |

|---|---|---|---|---|

| Air (100%) | 1–48 | 2–15 | 37–96 | 0–1 |

| Water (100%) | 0 | 51–99 | 0–1 | 1–48 |

| Soil (100%) | 0 | 0–5 | 95–100 | 0 |

| Rosin (CAS RNs 8050-09-7 / 8052-10-6 / 73138-82-6) and RCa and RNa Substance released to: |

Air (%) | Water (%) | Soil (%) | Sediment (%) |

|---|---|---|---|---|

| Air (100%) | 3–48a | 9–15a | 37–87a | 0a |

| Water (100%) | 0a | 99a | 0a | 1a |

| Soil (100%) | 0a | 0–6a | 94–97a | 0a |

| RHME Substance released to: |

Air (%) | Water (%) | Soil (%) | Sediment (%) |

|---|---|---|---|---|

| Air (100%) | 3–35 | 1–9 | 59–87 | 0–4 |

| Water (100%) | 0–1 | 31–99 | 0–1 | 1–67 |

| Soil (100%) | 0 | 0–6 | 94–100 | 0 |

a Values do not account for dissociation of salts (RCa and RNa).

| RMa Substance released to: |

Air (%) | Water (%) | Soil (%) | Sediment (%) |

|---|---|---|---|---|

| Air (100%) | 0-48a | 9–28a | 37–87a | 0a |

| Water (100%) | 0a | 99–100a | 0a | 0–1a |

| Soil (100%) | 0a | 5–25a | 75–95a | 0a |

a Takes into account hydrolysis product of MPA.

Although no significant releases to soil are expected, most of the substances in the Resins and Rosins Group will stay in soil if released to this medium. However, some of the RMa components will also partition into water from soil.

6.2 Environmental persistence

Abiotic degradation

Given the importance of aqueous media, the hydrolysis rates for the substances that may have representative chemicals with hydrolysable groups, such as methyl esters (e.g., components of RHME) and succinic anhydride functional groups of MPA (e.g., component of RMa), are estimated using HYDROWIN 2010. Representative chemicals of THAME and DHAME are expected to show hydrolysis half-lives of >10 years based on estimation for cyclohexyl methyl ester available in HYDROWIN 2010. Hydrolysis rates for the succinic anhydride functional group associated with the MPA representative chemical of RMa are estimated to be 4.3 min. Considering such quick hydrolysis, it is assumed that the dicarboxylic acid hydrolysis products shown in Table 2-2 for MPA would be the main component associated with MPA in the environment.

Biodegradation

CTO and DTO have a complex composition, and some components are known to be easily biodegraded, such as linoleic acid (representing 41% and 65% of CTO and DTO, respectively), which has been shown to pass the criteria for ready biodegradation (70% empirical biodegradation in 28-days) in water via the modified MITI test I protocol (TG 301 C)(J-CHECK c2010-). No empirical biodegradation data exist for any other representative chemicals used in the assessment of the UVCB substances in the Resins and Rosins Group. However, aerobic biological wastewater treatment systems have been shown to reduce resin acid concentrations (notably for representative chemicals abietic acid, IPA and DHAA) from pulp and paper mill effluent (MacLeay and Associates Ltd. 1986; Liss et al. 1997; Sturthridge et al. 1991; Kostamo et al. 2004), although a considerable amount of this removal may be attributed to sorption to sludge. The performance of aerobic biological treatment systems in degrading resin acids is greatly influenced by the variation in effluent component composition, nutrient availability, and the status of the microbial community. Given the inhibiting properties of some resin acid components, biodegradation of resin acid mixtures can experience a lag period of variable duration (Hemingway and Greaves 1973). Pimaric-type resin acids such as isopimaric acid (IPA) are observed to be less readily removed than abietic-type resin acids such as abietic acid or dehydroabietic acid because of the presence of the vinyl group (Liss et al. 1997). While biodegradation occurs in the natural environment, these rates are often slow, and only a few bacteria are able to use resin acids as a sole carbon source (Liss et al. 1997). Lastly, it is important to note that a well-characterized stable resin acid metabolite, called retene, is known to be the major product of biodegradation from resin acids in an anaerobic environment (Tavendale et al. 1997; Leppänen et al. 2000), such as those found in certain benthic environments.

Dykstra et al. (2014) showed that biodegradation rates of phytosterols treated with a mixed culture developed from a pulp and paper wastewater treatment system are limited (i.e., <20% decrease in chemical oxygen demand or COD in 26 days) by their limited solubility (e.g., β-sitosterol water solubility estimated to be 7.6 x 10-7 mg/L). In addition, this study also suggests that when the solubility of phytosterols is enhanced, there may still be a significantly slower degradation period of about 7 days, followed by a period of more rapid degradation, suggesting that the induction of enzymes may be required for microorganisms to biodegrade this component.

Table 6-2 summarizes the key data regarding the biodegradation of substances in the Resins and Rosins Group based on the available whole substance empirical data and/or empirical or modelled representative chemical data in ranges. Detailed representative chemical-based modelled biodegradation information may be found in a supporting document (ECCC 2021b). Given the paucity of empirical biodegradation data for RCa, empirical biodegradation results for RNa, rosin calcium/zinc and rosin magnesium (CAS RNs 68334-35-0 and 68440-56-2), are used as read-across data to RCa. All of these analogues showed a similar water solubility to that of RCa (43 mg/L; see Table 3-6), as rosin calcium/zinc has a water solubility of 18 mg/L and rosin magnesium has a water solubility of 65 mg/L (ECHA c2007-2017).

| Abbreviation or Common name | Test conditions | Degradation endpoint or prediction (28 days) | t1/2 (days) | Reference |

|---|---|---|---|---|

| CTO | Empirical OECD 301 F of whole substance | 79%–83% | NA | ECHA c2007-2017 |

| CTO | Modelled OECD 301 B, C of components | 0%–97% | 6–960a | CATALOGIC 2016 |

| DTO | Empirical OECD 301 F, E and D of whole substance | 60%-73% | NA | ECHA c2007-2017 |

| DTO | Modelled OECD 301 B, C of components | 0%–97% | 6–960a | CATALOGIC 2016 |

| TOP | Empirical OECD 301 B, D of whole substance | 9%–36% | NA | ECHA c2007-2017 |

| TOP | Modelled OECD 301 B, C of components | 5%–97% | 6–233a | CATALOGIC 2016 |

| Rosin | Empirical OECD 301 B | 14%–64% | NA | ECHA c2007-2017 |

| Rosin | Modelled OECD 301 B, C of components | 0%–22% | 78–960a | CATALOGIC 2016 |

| RCa | Empirical OECD 301 B, D of whole substance | 71%–89%c | NA | ECHA c2007-2017 |

| RCa | Modelled OECD 301 B, C of componentsd | 0%–22% | 78–960a | CATALOGIC 2016 |

| RNa | Empirical OECD 301 D of whole substance | 71% | NA | ECHA c2007-2017 |

| RNa | Modelled OECD 301 B, C of componentsd | 0%–22% | 78–960a | CATALOGIC 2016 |

| RHME | Empirical OECD 301 B, D of whole substance | 18%–40% | NA | ECHA c2007-2017 |

| RHME | Modelled OECD 301 B, C of components | 0%–8% | 233–960a | CATALOGIC 2016 |

| RMab | Empirical OECD 301 B of whole substance | 0.34% | NA | ECHA c2007-2017 |

| RMab | Modelled OECD 301 B, C of components | 0%–19% | 233–960a | CATALOGIC 2016 |

Abbreviations: NA, not available.

a Greater than 182 days, suggesting a high environmental persistence is likely.

b Including hydrolysis products.

c Analogue information for Na, Ca/Zn and Mg salts.

d Components of rosin (does not take salt into account).

The results of standard biodegradation tests (e.g., OECD Test Guideline 301 and 302 series) are considered in a weight-of-evidence approach along with modelled or empirical results available for representative chemicals of each UVCB to determine the environmental persistence of each substance in this group. CTO and DTO have a range of highly biodegradable components (such as fatty acids which are represented by linoleic acid), while still containing some moderate to highly persistent components such as resin acids (e.g., DHAA, abietic acid), alcohols (e.g., abietinol) and aldehydes (e.g., abietinal). Empirical evidence suggests that CTO component phytosterols (e.g., β-sitosterol) may be poorly degraded because of a low solubility, despite estimated biodegradation half-lives of <182 days (see Table 6-2). The more recalcitrant components of CTO and DTO will largely reside in water and sediment.

TOP has shown a lower potential for biodegradation and contains a high proportion of highly persistent components, including resin acids (e.g., abietic acid) and phystosterols (e.g., β-sitosterol). The more recalcitrant components of TOP will largely reside in water and sediment.

Rosin has moderate persistence, and recalcitrant components of rosin will largely reside in water and sediment. Whole substance empirical information shows that calcium and sodium salts of rosin (RCa and RNa) have low to moderate persistence, likely due to higher solubility and thus enhanced bioavailability associated with the salt forms of rosin compared with the neutral form. Components with higher predicted persistence in water, such as resin acids, are also present in these substances. However, there is additional uncertainty about the persistence of components of RCa and RNa in water as water solubility, bioavailability and biodegradability may vary depending on the pH of the receiving environment for resin acids. Lastly, the more recalcitrant components of RCa and RNa are predicted to largely reside in water and sediment. Given the higher persistence of these substances, the long-range transport distance of abietic acid (the major representative chemical in rosin, RNa and RCa) in water was estimated using TaPL3 (TaPL3, 2003) as an extra line of evidence. TaPL3 uses a multi-media fugacity based model to evaluate a chemical’s potential for long-range transport (LRT) in a mobile medium (either air or water). The LRT value calculated for abietic acid in water was 4 500 km, suggesting an increased potential for the spatial distribution of exposure for rosin, RNa and RCa.

Components of CTO, DTO, TOP, rosin, RCa and RNa are known to partition to sediment from water. As mentioned in section 5, soil is expected to be less important as a medium for exposure for the Resins and Rosins Group. Given their persistence in water, as already discussed and using an extrapolation ratio of 1:1:4 for a water:soil:sediment biodegradation (Boethling et al. 1995), components of CTO, DTO, TOP, rosin, RCa and RNa are expected to be moderately to highly persistent in sediments (and soil).

The representative chemicals of RHME are predicted to have high persistence in both water (e.g., 0% to 8% degradation of components based on modelled data) and sediment based on modelled evidence. However, whole substance empirical data shows that a significant fraction (18% to 40%) of this substance is available for ready biodegradation in a 28-day test, suggesting that the modelling results may be over-predicting environmental persistence in this case.

RMa is very persistent in water based on empirical biodegradation data (28-day biodegradation of 0.34%). Modelling of RMa representative chemicals supports this given that all representative chemicals, including the hydrolysis productss of MPA, show biodegradation half-lives >182 days in water (ECCC 2021b).

Since no direct releases to air or transfers to air from other environmental media are expected for this group (see section 5), metrics for persistence in air have not been evaluated.

6.3 Potential for bioaccumulation

Experimental data on the bioconcentration of representative chemical resin acids (e.g., abietic acid, IPA and DHAA) in rainbow trout showed steady-state bioconcentration factors (BCFs) ranging from <25 to 130 L/kg (wet weight) at exposure concentrations of 0.7 to 3 µg/L at ~15°C and pH ~8 for 20 days (Niimi and Lee 1992). In addition, the metabolic half-lives (t1/2) of these acids are reported as less than 4 days. There is empirical evidence showing that resin acids are taken up in fish primarily via the gills into the blood stream, are converted to glucuronide conjugates in the liver, and are then excreted through the bile (Oikari et al. 1984; Oikari and Holmbom 1985). In addition, a decarboxylated resin acid degradation product called fichtelite (CAS RN 2221-95-6) was shown in a freshwater mussel study to have a BCF of at least an order of magnitude greater than that of the parent resin acids (Burggraaf et al. 1996). The results of this study suggest that metabolites of resin acids may increase the overall body burden and associated effect of narcosis of resin acid exposed organisms.

Table 6-3 summarizes the modelled component based data regarding the bioconcentration and bioaccumulation of the substances in the Resins and Rosins Group in aquatic organisms. Representative chemical specific modelled bioaccumulation information can be found in a supporting document (ECCC 2021b).

| Common name | log Dowa/Kow | Metabolic t1/2 (days)b | BCF/BAF (L/kg) | Reference |

|---|---|---|---|---|

| CTO | 3.2–7.00 | 2–111 | 3–3210 (BCF) | BCFBAF 2010 (regression-based estimate) |

| DTO | 3.2-5.8 | 2-10 | 3-1780 (BCF) | BCFBAF 2010 (regression-based estimate) |

| CTO | 3.2–7.00 | 2–111 | 13–1585 (BCF) | CATALOGIC 2016 |

| DTO | 3.2-5.8 | 2-10 | 447-1585 (BCF) | CATALOGIC 2016 |

| CTO | 3.2–7.00 | 2–111 | 125–1.6 x 106 (BAF) | BCFBAF 2010 (Arnot-Gobas upper trophic) |

| DTO | 3.2-5.8 | 2-10 | 125-6270 (BAF) | BCFBAF 2010 (Arnot-Gobas upper trophic) |

| TOP | 3.3–8.3 | 5–111 | 3–3210 (BCF) | BCFBAF 2010 (regression-based estimate) |

| TOP | 3.3–8.3 | 5–111 | 13–1318 (BCF) | CATALOGIC 2016 |

| TOP | 3.3–8.3 | 5–111 | 212–1.6 x 106 (BAF) | BCFBAF 2010 (Arnot-Gobas upper trophic) |

| Rosin, RCa and RNa | 3.2–5.8 | 2–6 | 3–132 (BCF) | BCFBAF 2010 (regression-based estimate) |

| Rosin, RCa and RNa | 3.2–5.8 | 2–6 | 447–1585 (BCF) | CATALOGIC 2016 |

| Rosin, RCa and RNa | 3.2–5.8 | 2–6 | 125–519 (BAF) | BCFBAF 2010 (Arnot-Gobas upper trophic) |

| RHME | 4.8–6.6 | 1–7 | 132–1.1 x 104 (BCF) | BCFBAF 2010 (regression-based estimate) |

| RHME | 4.8–6.6 | 1–7 | 447–5754 (BCF) | CATALOGIC 2016 |

| RHME | 4.8–6.6 | 1–7 | 125–1.1x104 (BAF) | BCFBAF 2010 (Arnot-Gobas upper trophic) |

| RMac | 1.7–3.6 | 2–12 | 3–132 (BCF) | BCFBAF 2010 (regression-based estimate) |

| RMac | 1.7–3.6 | 2–12 | 10–1318 (BCF) | CATALOGIC 2016 |

| RMac | 1.7–3.6 | 2–12 | 3–413 (BAF) | BCFBAF 2010 (Arnot-Gobas upper trophic) |

Abbreviations: Dow, octanol-water partitioning coefficient for ionized organic chemicals; Kow, octanol-water partitioning coefficient for neutral chemicals. Metabolic T1/2, metabolic half-lives; BCF, bioconcentration factor; BAF, Bioaccumulation Factor.

a log Dow is used for BCF/BAF estimate if greater than 50% of representative chemical is predicted to be ionized at pH 6-8.

b Estimated using BCFBAF 2010 normalized to 10 gram fish.

c Including hydrolysis products.

Generally, Table 6-3 shows that CTO, DTO, TOP, rosin, RCa, RNa and RMa have representative chemicals with low to moderate bioconcentration potential based on modelling of their representative chemicals. The BCFs of components of RHME show moderate to high bioconcentration potential, with THAME having the highest predicted BCF.

With respect to bioaccumulation, the THAME representative chemical, which represents 75% of the RHME substance, is predicted to have high bioaccumulation potential by all three models (see Table 6-3). Representative chemical-specific modelled bioaccumulation information can be found in a supporting document (ECCC 2021b). Given its high bioavailability, the uptake rate would likely be rapid for THAME, with a log Kow of 6.6 being quite close to optimal for bioavailability. However, in general, esters are known to be quite quickly hydrolyzed into their corresponding acids (THA in this case), which, in turn, are known to have a much lower bioaccumulation potential. The estimated metabolic half-life for THAME was approximately 7 days, corresponding to a metabolic rate of (Km) 0.1 / day. The metabolic rate of most classes of esters, including a number of benzenedicarboxylic esters among several other classes, are empirically known to be even faster than this prediction indicates (Arnot et al. 2008). However, resin acid esters, including those in RHME are known to be recalcitrant to abiotic hydrolysis under even strong alkaline conditions (Holmbom and Ekman 1978). Thus, some uncertainty exists in the overall bioaccumulation prediction for THAME due the uncertainty in metabolic rate (Km).

Certain CTO and DTO representative chemicals, including β-sitosterol (CTO only), abietinal and to some extent abietinol, are predicted to have a high bioaccumulation potential based on modelled BAF results. These components are predicted to have relatively slow biotransformation half-lives (111, 17 and 10 days, for β-sitosterol, abietinal and abietinol respectively). Given the large discrepancy in BCFs between the BCFBAF (2010) estimate and that by CATALOGIC (2016) for abietinal (1290 vs 17 L/kg) and β-sitosterol (3210 vs 13 L/kg), there is some uncertainty and possible overestimation in the bioconcentration and bioaccumulation estimates (e.g., 1.6 x 106 L/kg for β-sitosterol) using BCFBAF (2010). In this regard, it is important to note that mitigating factors such as metabolic rate and effect of molecular size (Deff = 10.3 nm for β-sitosterol) are taken into account in the BCF estimate from CATALOGIC (2016). Nevertheless, it is expected that the bioaccumulation potential for β-sitosterol may still be high. In addition, a recent study has shown that certain diterpene components (sclarene, abieta-7,13-diene, dehydroabietane, norabietatetraene, tetrahydroretene, simonellite and retene), some of which may be present in the neutrals fraction of CTO and possibly also in DTO (uncertainy exists in the characterization of the neutrals fraction in DTO), may show a high biota-sediment accumulation based on empirical field studies with intertidal clams (Yunker et al. 2011).

Representative chemical resin acids (e.g., abietic acid, IPA and DHAA) show a limited bioaccumulation potential based on both modelled BCF and BAF values and empirical BCF studies in mussels and fish at an environmentally relevant pH range (6 to 8). This includes the representative chemical resin acid esters THAME and DHAME once they are hydrolyzed within the organism. Lastly, the representative chemical linoleic acid shows a moderate bioaccumulation potential (BAF ~ 2500) and makes up a significant proportion of CTO and DTO (41% and 65%).

7. Potential to cause ecological harm

7.1 Ecological effects assessment

7.1.1 Mode/mechanism of action

The analysis of their representative chemicals shows that CTO, DTO, TOP, rosin, RCa, RNa and RMa all consist of components that could have non-specific (e.g., narcotic) or compound-specific effects (ECCC 2021b). Because of the significant presence of specifically acting components that would likely dominate the effects profile of the whole substance, CTO, DTO, TOP, rosin, RCa, RNa and RMa are considered specifically acting substances as a whole. The analysis of the representative chemicals of RHME shows that it consists of only narcotic components and is thus considered a narcotic substance (ECCC 2021b). Determination of mode of action (MoA) is based on predictions from the United States Environmental Protection Agency (US EPA)’s ASTER, TEST and the OASIS MoA profiler in OECD toolbox (ASTER 1999; TEST 2016; OECD QSAR Toolbox 2016). In addition, for the representative chemical β-sitosterol, a number of low dose sub-lethal effects related to reproduction and endocrine function have been documented, including atrophy of the albumen gland in a European snail at a no observed effect concentration (NOEC) of 0.0001 mg/L (Czech et al. 2001), reductions in plasma sex steroids,an increase in vitellogenin in rainbow trout at NOEC of <0.075 mg/L (Tremblay and Van Der Kraak 1999), and reduction in plasma male and female sex steroid levels with a NOEC of 0.01 mg/L (MacLatchy and Van Der Kraak 1995) among others. Despite not being directly tied to adverse outcomes in test organisms, these low-level effects support the prediction that β-sitosterol is a specifically acting component.

7.1.2 Effects on aquatic organisms