Determination of nicotine-related alkaloids in whole tobacco by GC-TSD: T-301

1 Scope of application

1.1

This method is used to determine the amount of nicotine, nornicotine, anabasine, myosmine, and anatabine (alkaloids) in whole tobacco. The method is designed to quantify nicotine directly against a nicotine calibration that is also used to determine the amounts of each of the other alkaloids assuming a similar response factor.

1.2

Nornicotine, anabasine, myosmine and anatabine (if desired) may also be quantified against calibrations generated from commercially available standards. Anatabine must be quantified using the response factor generated by the anabasine standard if pure anatabine is not available.

1.3

Total alkaloids are determined as the sum of nicotine, nornicotine, anabasine, myosmine, and anatabine.

2 Normative references

2.1

Health Canada Official Method T-115. Determination of Tar, Water, Nicotine and Carbon Monoxide in Mainstream Tobacco Smoke, 2016.

2.2

International Organization for Standardization, ISO 8243 Cigarettes - Sampling. 2013.

2.3

International Organization for Standardization, ISO 15592-1 Fine-Cut tobacco and smoking articles made from it - Methods of sampling, conditioning and analysis - Part 1: Sampling. 2001.

2.4

Health Canada Official Method T-402. Preparation of Sample for Testing of Cigarettes, Tobacco Sticks, Cigarette Tobacco, Cigars, Little Cigars, Kreteks, Bidis, Leaf, Pipe and Smokeless Tobacco, 2016.

2.5

AOAC INTERNATIONAL, AOAC Official Method 966.02 Loss on Drying (Moisture) in Tobacco. Official Methods of Analysis of AOAC INTERNATIONAL, 20th Ed. 2016.

3 Definitions

3.1

Whole tobacco is used to represent the unburned tobacco present in a given tobacco product.

4 Method summary

4.1

This method is a gas chromatographic (GC) method using a fused silica capillary column and a thermionic specific detector (TSD). Freeze-dried and ground tobacco is extracted with methanolic KOH solution (containing 4,4-dipyridyl dihydrochloride as the internal standard) in an ultrasonic bath. The mixture is then centrifuged at low speed to separate the solid tobacco from the solution. The supernatant is transferred to an autosampler vial where it is analyzed by GC.

4.2

The alkaloids are analyzed on a CAM fused silica capillary column which has a polyethylene glycol (PEG) stationary phase that has been specifically base deactivated for volatile amine analysis. Quantification is achieved using an internal standard calibration by comparing the TSD response of the analytes in the samples against a multi-point calibration of nicotine in the standards.

Warning: The testing and evaluation of certain products against this test method may require the use of materials and/or equipment that are potentially hazardous and this document does not purport to address all the safety aspects associated with its use. Anyone using this test method has the responsibility to consult with the appropriate authorities and to establish health and safety practices in conjunction with all existing applicable regulatory requirements prior to its use.

5 Apparatus and equipment

5.1

Freeze dryer, Lyophilizer or equivalent.

5.2

Culture tubes, disposable borosilicate, 10 mm x 125 mm.

Note: Thin walled culture tubes provide a better extract as the walls absorb less ultrasonic energy.

5.3

Analytical balance measuring to at least 4 decimal places.

5.4

Volumetric flasks, 10 mL, 1000 mL, 2000 mL.

5.5

Glass Pasteur transfer pipettes.

5.6

Micropipettes or gas-tight syringes.

5.7

Dispenser, 1-5 mL and bottle.

5.8

Parafilm®.

5.9

Scintillation vial with aluminum lined cap, 20 mL.

5.10

Bench grinder with #40 screen.

5.11

Cotton swabs.

5.12

Gas chromatograph equipped with TSD or equivalent.

5.13

Autosampler or equivalent.

5.14

Autosampler vials with screw caps and Teflon-lined septa.

5.15

CAM fused silica capillary column, 30 m × 0.25 mm × 0.25 µm or equivalent.

5.16

Ultrasonic bath.

5.17

Centrifuge.

5.18

Vortex mixer.

6 Reagents and supplies

6.1

All reagents shall be at least analytical reagent grade.

Note: Wherever possible, reagents are identified by their Chemical Abstract Service [CAS] registry numbers in square brackets.

6.2

4,4-Dipyridyl dihydrochloride - [27926-72-3] used as an internal standard (ISTD).

6.3

Methanol - [67-56-1] Distilled-in-Glass (DIG).

6.4

(-)-Nicotine6 Reagents and supplies Footnote * - [54-11-5].

6.5

Potassium hydroxide - [1310-58-3].

6.6

Water, Type I (as outlined in ASTM D1193, Table 1: Processes for Reagent Water Production, Note A).

6.7

If quantification of minor alkaloids is specifically requested:

- (±)-Anabasine - (Neonicotine)6 Reagents and supplies Footnote * - [13078-04-1].

- (±)-Nornicotine - (2-[3-pyridyl]-pyrrolidine)6 Reagents and supplies Footnote * - [5746-86-1].

- Myosmine - (3-[1-Pyrrolin-2-yl] pyridine)6 Reagents and supplies Footnote * - [532-12-7].

- (R,S)-Anatabine6 Reagents and supplies Footnote * - [2743-90-0].

6 Reagents and supplies footnotes

- 6 Reagents and supplies Footnote *

-

Note: All neat compounds must be of known purity and be as close to 100% pure as is possible.

7 Preparation of glassware

7.1

Clean and dry glassware in a manner to ensure that contamination from residues on glassware does not occur.

8 Preparation of solutions

8.1

Extraction Solution - (0.25 mg/mL 4,4-dipyridyl dihydrochloride in Methanolic-KOH)

8.1.1

Weigh 5.6 g (± 0.05 g) of potassium hydroxide (KOH) into a 2000 mL volumetric flask and make to volume with methanol (MeOH).

Note: Sonication is necessary to dissolve the pellets.

8.1.2

Label as '0.05 N KOH in MeOH' with the preparation date.

8.1.3

Weigh 0.25 g ± 0.005 g of 4,4-dipyridyl dihydrochloride into a 1000 mL volumetric flask and make to volume with the 0.05N KOH in MeOH solution.

8.1.4

Mix well and transfer the contents to a 1250 mL dispenser bottle and label as 'Alkaloids Extraction Solution' with the date of preparation.

Note: When a new batch of extraction solution is prepared, a new series of working standards must be prepared to ensure a consistent level of internal standard in both the samples and in the standards.

9 Preparation of standards

9.1

Nicotine Primary Stock (Concentration: approximately 5 mg/mL)

9.1.1

Weigh 0.05 g (± 0.005 g) of nicotine into a 10 mL volumetric flask and make to volume with extraction solution.

Note: Nicotine is very hygroscopic and weighing should be done carefully and quickly to prevent the absorption of moisture from affecting the weight.

Note: Primary stocks of the minor alkaloids (if necessary) are to be made up similarly. Although their levels are considerably lower than that of nicotine, it is not recommended to weigh less of the standard, but to make a secondary stock for the preparation of working standards.

9.2

Working Standards

9.2.1

Make all standards into volumetric flasks using the dilutions described in the following table:

| Nicotine Standard No. |

Volume of Primary Std (µL) |

Volume (mL) |

Nicotine [µg/mL] |

Nicotine: ISTD ratio |

|---|---|---|---|---|

| 1 | 2000 | 10 | 1000 | 4 |

| 2 | 1000 | 10 | 500 | 2 |

| 3 | 500 | 10 | 250 | 1 |

| 4 | 250 | 10 | 125 | 0.5 |

| 5 | 100 | 10 | 50 | 0.2 |

9.2.2

Make volumetric flasks to volume with the extraction solution containing the internal standard.

Note: Analytical concentrations may vary depending on the concentration of primary stock and must be calculated in order to prepare an accurate calibration.

Note: In order to define a tighter calibration range for determining the concentration of the minor alkaloids, a standard of 1/10 that of the lowest standard of nicotine can be prepared. A separate response factor (or calibration curve) using the 3 lowest standards can be determined for calculating the minor alkaloids.

Note: Additional standards may have to be prepared to cover the range of anticipated responses for test samples.

10 Sampling

10.1

The sampling of cigarettes for the purpose of testing shall be in accord with ISO 8243.

10.2

The sampling of kreteks, little cigars, bidis, tobacco sticks for the purpose of testing shall be in accord with ISO 8243, but modified such that the term "cigarette" is substituted with "kreteks", "little cigars", "bidis" or "tobacco sticks", whereby the term "carton" is equivalent to 200 units.

10.3

The sampling of cigars for the purpose of testing shall be in accord ISO 8243, but modified such that the term "cigarette" is substituted with "cigar", whereby 200 units of cigarette is equivalent to 200 grams of cigar.

10.4

The sampling of cigarette tobacco for the purpose of testing shall be in accord with ISO 15592-1.

10.5

The sampling of leaf tobacco, pipe tobacco or smokeless tobacco shall be in accord with ISO 15592-1 but modified such that the term "fine-cut" is substituted with "leaf tobacco", "pipe tobacco" or "smokeless tobacco".

11 Tobacco product preparation

11.1

The preparation of tobacco products for the purpose of testing shall be as specified in T-402.

12 Sample preparation

12.1

Lyophilizing the Tobacco Samples

12.1.1

Accurately weigh and record the weight (only for the control tobacco) of an appropriately labelled, dry 20 mL scintillation vial with an aluminum-lined cap.

12.1.2

Transfer the tobacco, approximately 2 g, to a 20 mL scintillation vial with an aluminum-lined cap.

12.1.3

Accurately weigh and record the total weight (only for the control tobacco) of the capped scintillation vial with tobacco.

12.1.4

Accurately weigh and record the total weight (only for the control tobacco) of the capped scintillation vial with tobacco after freeze-drying (lyophilizing) and calculate the percent moisture content.

Note: The control tobacco moisture content is only determined to monitor the performance of the lyophilizer.

12.2

Grinding of samples

12.2.1

Grind the tobacco using the #40 (40 sections per square inch) screen of the bench-top grinder.

12.2.2

After grinding, wipe off the remaining tobacco particles into the sample using a cotton swab, then vacuum the grinder to remove any tobacco dust.

12.2.3

Disassemble the components of the grinder and clean with methanol.

12.2.4

Reassemble the grinder and use the vacuum again in order to volatilize any residual methanol from the grinder.

12.2.5

Repeat the cleaning process between samples.

12.3

Extraction of samples

12.3.1

Weigh 25 mg (± 5 mg) of ground tobacco into a 10 mm × 125 mm disposable borosilicate culture tube.

12.3.2

Add 1 mL of the extraction solution to the sample.

12.3.3

Seal the culture tube with four layers of Parafilm®and place into a metal rack suitable for placement into an ultrasonic bath.

12.3.4

Remove the samples from bath after one hour to vortex. Swirl the tube to get all of the tobacco into the solvent then return to the sonicator.

12.3.5

Sonicate the samples in the ultrasonic bath for 3 hours.

Note: The sonication process will generate heat, and the bath should be monitored to not exceed 40 °C. For best results, change the bathwater every hour using cool water.

Note: The sonication process must be closely monitored. The pieces of tobacco should be visibly vibrating and the solution should be homogeneous in colour at the end of the sonication.

12.3.6

After sonication is finished, the samples may be shaken on a wrist-action shaker for 30 minutes.

12.3.7

After the wrist-action shaking is complete, centrifuge the tubes for five minutes at low speed to separate the tobacco from the solvent.

12.3.8

Transfer the supernatant to an autosampler vial to be analyzed on the GC.

13 Sample analysis

13.1

Gas chromatograph conditions

- Injector:

- Split

- Column:

- CAM, 30 m × 0.25 mm × 0.25 µm

- Detector:

- Thermionic Specific (TSD)

- Carrier:

- Helium at 15.0 psi, linear velocity approximately 30 cm/s

Note: Set detector gas flows as per manufacturer's specifications for H2, X-Dry air, and N2 as make-up gas.

13.1.1

Temperature Program

- Injector:

- 220 °C

- Detector:

- 300 °C

- Start Temp.:

- 110 °C, hold for one minute

- Rate:

- 5 °C/min to 225 °C, hold for two minutes

- Total Run Time:

- 26.00 minutes

13.1.2

Autosampler conditions

Injection volume: 1.0 µL

Note: Adjustment to the operating conditions may be required, depending on instrument and column conditions as well as resolution of the analyte peak.

Note: The first standard should be injected a minimum of 3 times initially to re-condition the column.

Note: Before starting, install a new pre-silianized insert to minimize reactivity in the injector. Replace the insert after approximately 40 'true' samples due to the build up of impurities. Nornicotine is particularly sensitive to degradation.

14 Calculations

14.1

Generate an internal standard calibration curve from the area response of the standard solutions. These calibration factors are used to calculate the concentration of each analyte in each sample. By entering the correct multiplier (overall volume the original sample is diluted to in mL - one) and divisor (the original sample weight in g to fourth decimal place) the concentration of each of the alkaloids is automatically calculated in µg/g.

Analytical Result (on a 'dry matter' basis)

Analyte [µg/g] = (AreaAnalyte Sample / AreaISTD Sample) × RFµg/mL × (MultipliermL / Divisorg)

where the Response Factor (RF) is defined from the calibration.

14.2

All results are expressed on a 'dry matter' basis. These may be expressed on an 'as received' basis using the appropriate moisture result.

Conversion to an 'as received' basis

Analyte [µg/g]as received = Analyte [µg/g]dry matter × {1– (% Moisture / 100)}

where the percent moisture is determined by AOAC Official Method 966.02.

15 Quality control

15.1

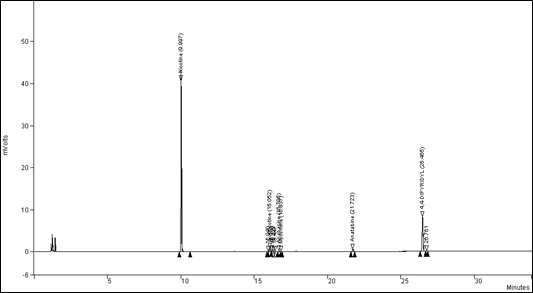

For typical chromatograms, see appendix 1, figure 1 and figure 2.

15.2

Typical Control Parameters

Note: If the control measurements are outside the tolerance limits of the expected values, appropriate investigation and action must be taken.

15.2.1

Laboratory Reagent Blank (LRB)

To detect potential contamination during the sample preparation and analysis processes, include a laboratory reagent blank (LRB). The LRB consists of all reagents and materials used in performing the analysis on test samples and is analyzed as a test sample.

15.2.2

Laboratory Fortified Blank (LFB)

To detect potential loss of analyte during the sample preparation and analysis processes, include a laboratory fortified blank (LFB). The LFB consists of all reagents and materials used in performing the analysis on test samples plus fortification with a known concentration of at least one of the analytes of interest. The level of fortification should reflect the range of typical results for that sample. The LFB is then analyzed as a test sample.

15.2.3

Laboratory Fortified Matrix (LFM)

To detect potential matrix interferences, include a laboratory fortified matrix (LFM). During the sample preparation and/or analysis processes, divide a test sample and fortify an aliquot with at least one of the analytes of interest in known concentration. The level of fortification should reflect the range of typical results for that sample. The LFM is then analyzed as a test sample.

15.2.4

Laboratory Control Sample

To assess the overall performance of an analysis, a control sample is analyzed. The results of the control sample should be compared, using appropriate statistical techniques, to 'expected values' generated by the laboratory or, if none exist, to values found in literature. This provides information to the laboratory, on test accuracy and precision.

15.2.5

Standard as Sample

To assess the stability of the analytical system, a standard is analyzed as a sample. The results of this standard should be compared, using appropriate statistical techniques, to expected concentrations.

15.3

Recoveries and Levels of Contamination

15.3.1

Typical LRB values (based on average ± standard deviation) are:

| N/A | LRB (µg/g) |

|---|---|

| Anabasine | 0.3 ± 1.1 |

| Anatabine | 1.0 ± 2.6 |

| Myosmine | 4.6 ± 5.3 |

| Nornicotine | 15 ± 14 |

| Nicotine | 108 ± 167 |

15.3.2

Typical LFB and LFM recoveries fall in the range 70-120% recovery.

15.4

Limit of Detection (LOD) and Limit of Quantification (LOQ)

15.4.1

The LOD can be determined as 3 times the standard deviation of results obtained by analyzing the lowest standard level a minimum of 10 times over several days.

15.4.2

The LOQ can be determined as 10 times the standard deviation of results obtained by analyzing the lowest standard level a minimum of 10 times over several days.

15.4.3

Typical values for alkaloids:

| N/A | LOD (μg/g) |

LOQ (μg/g) |

|---|---|---|

| Nicotine | 75 | 250 |

| Minor Alkaloids | 15 | 50 |

15.5

Stability of Reagents and Samples

15.5.1

The CAM column has a polyethylene glycol stationary phase that has been base-deactivated for volatile amine analysis. However, tailing may affect quantification of the minor alkaloids because of their smaller quantity and therefore, smaller signal-to-noise ratio. These tailing effects are caused by 2 sources other than reactivity of the compounds:

- solvent effect

- reactivity in the injector

15.5.2

Methanol is generally a poor solvent choice for injecting onto the GC because it causes an enormous amount of tailing. This effect can be minimized by using a large split ratio, a high linear velocity, a thick stationary phase, and de-activated glass injection liners.

15.5.3

Reactivity in the injector is minimized by using de-activated glass inserts. It is necessary that the injection liner be changed between each set of samples (approximately 40 'true' samples) since the injected solution is quite dirty and creates active sites on the liner after repeated injections of sample.

15.5.4

There is no indication of a problem with the stability of either samples or standards if kept at 4 °C.

16 References

16.1

Severson, R. F. et al. 1981. Rapid method for the analysis of tobacco nicotine alkaloids. J. Chromatog. 211: 111-121.

16.2

ASTM International, ASTM Standard D1193-06(2011). Standard Specifications for Reagent Water.

16.3

Appendix 1:

Figure 1: Typical Chromatogram of Minor Alkaloids: Text description

Figure 1: This figure displays an example chromatogram for Canadian Industry Monitor 7 cigarette showing the nicotine concentration relative to that of the minor alkaloids.

Typical chromatogram for Canadian Industry Monitor 7 cigarette.

Typical retention times are:

- Nicotine:

- 9.997 min

- Nornicotine:

- 16.052 min

- Anabasine:

- 16.705 min

- Myosmine:

- 16.837 min

- Anatabine:

- 21.723 min

- 4,4-Dipyridyl dihydrochloride (ISTD):

- 26.465 min

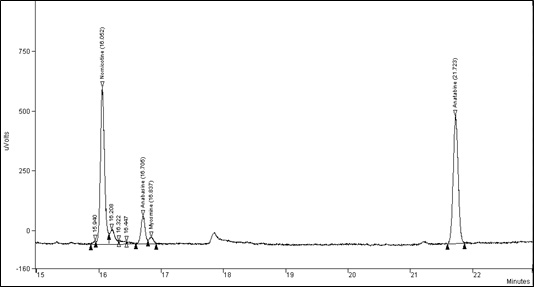

Figure 2: Typical Chromatogram of Minor Alkaloids: Text description

Figure 2: This figure displays an expanded view of the minor alkaloid components of figure 1.