Determination of tobacco specific nitrosamines in whole tobacco by GC-TEA: T-309A

1 Scope of application

1.1

This method is suitable for the quantitative determination of 4 tobacco specific N-nitrosamines (TSNA) in whole tobacco:

N-nitrosonornicotine (NNN), 4-(methylnitrosamino)-1-(3-pyridyl)-1-butanone (NNK), N-nitrosoanatabine (NAT) and N-nitrosoanabasine (NAB) by combined Gas Chromatography-Thermal Energy Analysis (GC-TEA).

2 Normative references

2.1

Health Canada Official Method T-402. Preparation of Sample for Testing of Cigarettes, Tobacco Sticks, Cigarette Tobacco, Cigars, Little Cigars, Kreteks, Bidis, Leaf, Pipe and Smokeless Tobacco, 2016.

2.2

Health Canada Official Method T-115. Determination of Tar, Water, Nicotine and Carbon Monoxide in Mainstream Tobacco Smoke, 2016.

2.3

International Organization for Standardization, ISO 8243 Cigarettes - Sampling. 2013.

2.4

International Organization for Standardization, ISO 15592-1 Fine-Cut tobacco and smoking articles made from it - Methods of sampling, conditioning and analysis - Part 1: Sampling. 2001.

2.5

AOAC INTERNATIONAL, AOAC Official Method 966.02 Moisture in Tobacco, Gravimetric Method. Official Methods of Analysis of AOAC INTERNATIONAL, 20th Ed., 2016.

3 Definitions

3.1

Refer to T-301 for definitions of terms used in this document.

4 Method summary

4.1

The TSNAs are extracted using an aqueous buffer, containing ascorbic acid, which prevents artifact formation. The TSNAs are enriched by extraction with dichloromethane, followed by column chromatography. The fraction containing TSNA is then quantitatively analyzed by combined gas chromatography-thermal energy analysis (GC-TEA). N-nitrosoguvacoline (NG) is used as an internal standard.

Warning: The testing and evaluation of certain products against this test method may require the use of materials and/or equipment that are potentially hazardous and this document does not purport to address all the safety aspects associated with its use. Anyone using this test method has the responsibility to consult with the appropriate authorities and to establish health and safety practices in conjunction with all existing applicable regulatory requirements prior to its use.

Warning: All 4 TSNAs are carcinogenic in several species of laboratory animals. Extreme care should be taken in handling these compounds. The exhaust of the TEA detector should be vented properly in order to reduce exposure to possible excess ozone (03).

5 Apparatus and equipment

5.1

Equipment needed to prepare tobacco for testing as specified in T-402.

5.2

Flask with ground glass joint, 250 mL.

5.3

Volumetric flasks, 5-100 mL.

5.4

Aluminum foil.

5.5

Wrist-action shaker.

5.6

Glass Pasteur pipettes.

5.7

Zymark TurboVap II Concentrator equipped with 200 mL tubes with graduated 1 mL stem or equivalent.

5.8

Thermal energy analyzer, Elutia 800 series or equivalent, interfaced to GC.

5.9

Gas chromatograph, equipped with temperature programmable injector and electronic flow control (or equivalent).

5.10

GC column, 30 m × 0.32 mm × 3.0 µm DB-1 fused silica capillary column or equivalent.

5.11

Varian Chem-Elut CE20100 adsorbent tube or equivalent.

5.12

Non-ultraviolet lighting.

5.13

Amber flasks.

6 Reagents and supplies

6.1

All reagents shall be at least analytical reagent grade.

Note: Wherever possible, reagents are identified by their Chemical Abstract Service [CAS] registry numbers in square brackets.

6.2

Acetone - [67-64-1] Distilled-In-Glass (DIG).

6.3

L-Ascorbic acid - [50-81-7].

6.4

Citric Acid (Anhydrous) - [77-92-9].

6.5

Dichloromethane (DCM) - [75-09-2] DIG.

6.6

Methanol - [67-56-1] DIG.

6.7

Sodium Phosphate Dibasic - [7558-79-4].

6.8

Sodium Sulphate, anhydrous - [7757-82-6].

6.9

Water, Type I (as outlined in ASTM D1193, Table 1: Processes for Reagent Water Production, Note A).

6.10

N-Nitrosoguvacoline (NG), ≥ %98.7 - [55557-02-3]

6.11

N-Nitrosonornicotine (NNN), ≥ %98 – [64162-58-9]

6.12

N-Nitrosoanatabine (NAT), ≥ %96 - [71267-22-6]

6.13

N-Nitrosoanabasine (NAB), ≥ %96.1 - [1133-64-8]

6.14

4-(N-Methyl-N-nitrosoamino)-1-butanone (NNK), ≥ %98 - [55557-02-3]

7 Preparation of glassware

7.1

Clean and dry glassware in a manner to ensure that contamination from residues on glassware does not occur.

8 Preparation of solutions

8.1

Citrate-Phosphate Buffer containing L-Ascorbic Acid

8.1.1

Prepare a 1 L aqueous solution containing :

8.1.1.1

55 mM citric acid (0.055 × 192.12 = 10.6 g/L)

8.1.1.2

90 mM sodium phosphate dibasic (0.090 × 141.96 = 12.8 g/L)

8.1.1.3

20 mM L-ascorbic acid (0.02 × 176.13 = 3.5 g/L)

Note: The pH of the solution must be between 4.3 and 4.5.

9 Preparation of standards

9.1

N-nitrosoguvacoline (NG) Internal Standard (ISTD)

9.1.1

Prepare a solution at 5000 ng/mL in dichloromethane.

9.1.2

Store in an amber flask and protect from light.

9.2

TSNA Mixed Standard Solution

9.2.1

Prepare a mixed standard dilution stock solution of NNN, NAT, NAB and NNK in dichloromethane at the following range of concentrations:

- NNK at 3000 ng/mL.

- NNN and NAT at 1500 ng/mL.

- NAB at 500 ng/mL.

Note: Concentrated solutions are stable for approximately 6 months if stored at -20 °C.

9.3

Calibration Standards

9.3.1

Build a calibration ranging from approximately 20 ng/mL (for NAB) to 2000 ng/mL (for NNK) containing NG as an internal standard at 500 ng/mL in each of the standards.

Note: Individual calibration stocks are stable for 2 months if stored at minus 20 °C.

Note: Additional standards may have to be prepared to cover the range of anticipated responses for test samples.

10 Sampling

10.1

The sampling of cigarettes for the purpose of testing shall be in accord with ISO 8243.

10.2

The sampling of kreteks, little cigars, bidis, tobacco sticks for the purpose of testing shall be in accord with ISO 8243, but modified such that the term "cigarette" is substituted with "kreteks", "little cigars", "bidis" or "tobacco sticks", whereby the term "carton" is equivalent to 200 units.

10.3

The sampling of cigars for the purpose of testing shall be in accord ISO 8243, but modified such that the term "cigarette" is substituted with "cigar", whereby 200 units of cigarette is equivalent to 200 grams of cigar.

10.4

The sampling of cigarette tobacco for the purpose of testing shall be in accord with ISO 15592-1.

10.5

The sampling of leaf tobacco, pipe tobacco or smokeless tobacco shall be in accord with ISO 15592-1 but modified such that the term "fine-cut" is substituted with "leaf tobacco", "pipe tobacco" or "smokeless tobacco".

11 Tobacco product preparation

11.1

Preparation of Test Sample

11.1.1

Remove product from its packaging to make a composite sample.

11.1.2

The preparation of tobacco products for the purpose of testing shall be as specified in T-402.

12 Sample preparation

12.1

Extraction of Tobacco and Tobacco Products

12.1.1

Use only non-UV lighting in the room(s) in which this analysis is conducted.

12.1.2

Weigh 1 g of the whole tobacco into a 250 mL flask.

12.1.3

Add 50 mL of citrate-phosphate buffer containing L-ascorbic acid.

12.1.4

Add 500 µL of NG (ISTD) solution.

12.1.5

Place on a wrist-action shaker for 60 minutes to totally saturate and extract the tobacco.

12.2

Sample Clean-up

12.2.1

Place a 200 mL TurboVap tube beneath the Chem-Elut tube.

Note: Tube or cartridge size and amount of packing material may be varied depending on manufacture and type of solid phase extraction unit used.

Note: The elution pattern from the solid phase extraction cartridge(s) must be diluted depending on the manufacturer, cartridge size and amount of packing material, such that recoveries are acceptable.

12.2.2

Pour the entire extract from the flask into the Chem-Elut tube.

12.2.3

Rinse the flask with 2 × 5 mL additions of the citrate-phosphate buffer and add to the Chem-Elut tube.

12.2.4

Wait 5 minutes to allow the packing to absorb the aqueous solution.

12.2.5

Rinse the flask with 150 mL of dichloromethane and add to the Chem-Elut tube.

12.2.6

Repeat 12.2.5 with an additional 150 mL of dichloromethane once the first 150 mL has passed through the column and is dripping at a rate of less than 1 drop/second.

12.2.7

Continue to collect the extract until 250 mL has been collected.

Note: This will require the collection of the TSNA fraction into a second tube, which will be combined with the first tube after some evaporation.

12.2.8

Place the sample into the Turbo evaporator set at 38 °C and 10 psi nitrogen.

12.2.9

Concentrate the samples to 3.5 mL (approximately 45 minutes).

12.2.10

Transfer the concentrate to a 5 mL volumetric flask and make to volume with DCM using DCM washings of the TurboVap tube.

12.2.11

Transfer the sample to an amber autosampler vial with Teflon-lined septum for GC analysis.

13 Sample analysis

13.1

GC-TEA Operating Conditions

- Carrier Flow Rate (He):

- 2.8 mL/minute using electronic flow control (velocity = 60 cm/second)

- Injector Temperature:

- Programmable 35 to 220 °C

- Oven Temperature:

- Programmed 50 to 170 to 212 °C

- TEA Interface Temp.:

- 275 °C

- TEA Furnace Temp.:

- 500-525 °C (dependent on analyzer sensitivity)

- Analysis Run Time:

- 35 minutes

- Injection Volume:

- 1.5 µL

Note: Adjustment to the operating conditions may be required, depending on instrument and column conditions as well as resolution of the analyte peak.

13.2

GC-TEA Calibration

13.2.1

Inject 1.5 µL of each standard solution and determine peak areas for the 4 components and NG (ISTD).

13.3

TSNA Determination

13.3.1

Inject 1.5 µL of the sample concentrate (12.2.11) and determine areas of the peaks having retention times corresponding to NNN, NAT, NAB and NNK.

14 Calculations

14.1

Obtain the content, M (ng/g), of a given TSNA from the formula:

- M (ng/g) = CVs/N

- where:

- C = analytical concentration determined by ISTD calibration of given TSNA.

- Vs = final volume of concentrate.

- N = the weight (in g) of tobacco extracted.

14.2

In order to convert the result to ng/g on a 'dry matter basis,' correct for moisture by using the following formula:

M (ng/g) dry matter = M (ng/g) as is / (1 - (% Moisture/100))

where the % moisture is determined from the same sample 'as received' by AOAC Official Method 966.02.

15 Quality control

15.1

For a typical chromatogram, see appendix 1.

15.2

Typical Control Parameters

Note: If the control measurements are outside the tolerance limits of the expected values, appropriate investigation and action must be taken.

Note: Laboratory Control Sample should be conducted within each set, while the other quality control checks may be performed as an initial validation and used as investigative tools to assess unexpected results, and are not necessary to be conducted with every test.

15.2.1

Laboratory Reagent Blank (LRB)

To detect potential contamination during the sample preparation and analysis processes, include a laboratory reagent blank (LRB). The LRB consists of all reagents and materials used in performing the analysis on test samples and is analyzed as a test sample.

15.2.2

Laboratory Fortified Blank (LFB)

To detect potential loss of analyte during the sample preparation and analysis processes, include a laboratory fortified blank (LFB). The LFB consists of all reagents and materials used in performing the analysis on test samples plus fortification with a known concentration of at least one of the analytes of interest. The level of fortification should reflect the range of typical results for that sample. The LFB is then analyzed as a test sample.

15.2.3

Laboratory Fortified Matrix (LFM)

To detect potential matrix interferences, include a laboratory fortified matrix (LFM). During the sample preparation and/or analysis processes, divide a test sample and fortify an aliquot with at least one of the analytes of interest in known concentration. The level of fortification should reflect the range of typical results for that sample. The LFM is then analyzed as a test sample.

15.2.4

Laboratory Control Sample

To assess the overall performance of an analysis, a control sample is analyzed. The results of the control sample should be compared, using appropriate statistical techniques, to 'expected values' generated by the laboratory or, if none exist, to values found in literature. This provides information to the laboratory, on test accuracy and precision.

15.2.5

Standard as Sample

To assess the stability of the analytical system, a standard is analyzed as a sample. The results of this standard should be compared, using appropriate statistical techniques, to expected concentrations.

15.3

Recoveries and Levels of Contamination

15.3.1

A typical LRB should be less than the LOD.

15.3.2

Typical LFB and LFM recoveries fall in the range 85-115% recovery.

15.4

Limit of Detection (LOD) and Limit of Quantification (LOQ)

15.4.1

The LOD can be determined as 3 times the standard deviation of results obtained by analyzing the lowest standard level a minimum of 10 times over several days. See Section 15.4.3 for typical values.

15.4.2

The LOQ can be determined as 10 times the standard deviation of results obtained by analyzing the lowest standard level a minimum of 10 times over several days.

15.4.3

Typical LOD and LOQ values as received are:

| N/A | LOD (ng/g) |

LOQ (ng/g) |

|---|---|---|

| NNN | 54 | 180 |

| NAT | 64 | 213 |

| NAB | 31 | 103 |

| NNK | 82 | 272 |

16 References

16.1

Adams, J. D.; Brunnemann, K. D. and Hoffmann, D. 1983. Chemical studies on tobacco smoke. LXXV. Rapid method for the analysis of tobacco-specific N-nitrosamines by gas-liquid chromatography with a thermal energy analyzer. J. Chromatogr. 256: 347-351.

16.2

Hecht, S. S.; Adams, J. D. and Hoffmann, D. 1983. Tobacco-specific nitrosamines in tobacco and tobacco smoke. In: Preussmann, et al. eds., Environmental Carcinogens- Selected Methods of Analysis, Vol. 6, N-Nitroso Compounds (IARC Scientific Publications No. 45), Lyon, International Agency for Research on Cancer, 93-101.

16.3

Hoffmann, D. et al. 1979. Assessment of tobacco-specific N-nitrosamines in tobacco products. Cancer Res. 39: 2505-2509.

16.4

Risner, C. H. and Wendelboe, F. N. 1994. Quantification of tobacco specific nitrosamines in tobacco. Tob. Sci. 38: 1-6.

16.5

Spiegelhalder, B.; Kubacki, S. J. and Fischer, S. 1989. A method for the determination of tobacco-specific nitrosamines (TSNA), nitrate and nitrite in tobacco leaves and processed tobacco. Beitrage zur Tabakforschung International 14: 135-143.

16.6

United States. Protocol to Measure the Quantity of Nicotine Contained in Smokeless Tobacco Products Manufactured, Imported, or Packaged in the United States. Federal Registrar. 62: 85. 1997.

16.7

ASTM International, ASTM Standard D1193-06(2011). Standard Specifications for Reagent Water.

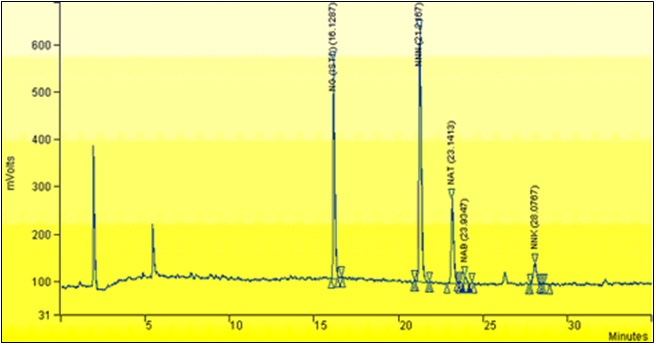

Appendix 1: A typical chromatogram

A sample chromatogram of the extract of whole tobacco for 1R4F.

Appendix 1: A typical chromatogram: Text description

The following figure is a sample chromatogram of extract of whole tobacco for 1R4F. The voltage in mVolts is plotted against time in minutes. The detected peaks include

N-nitrosoguvacoline (NG-internal standard) at 16.1287 min, N-Nitrosoguvacoline (NNN) at 21.2167 min, N-nitrosoanatabine (NAT) at 23.1413 min, N-nitrosoanabasine (NAB) at 23.9347 min and 4-(N-nitrosomethylamino)- 1 -butanone (NNK) at 28.0767 min.