The homebuilding sector is evolving - but how homes are wired hasn’t changed in over 100 years. This is what electricians do for a new home today:

- mount electrical boxes

- drill holes through the wooden wall studs

- pull wire between the boxes and power panel

- turn them on after inspection

This traditional method consumes many materials and is labour intensive.

On the other hand, today’s wireless smart homes use almost no materials and cost less to all involved. Edmonton’s Levven Electronics, is improving new home construction with this sustainable technology. Levven offers wireless controls that save time, materials and cost during construction, while providing the luxuries of a smart home to the average homeowner.

Wire-free controls:

- are good for the environment

- save energy

- use fewer materials (less pollution to make them and less waste at end-of-life)

The Smart Sustainable Resilient Infrastructure Association (SSRIA) reports that 18% of greenhouse gas emissions in Canada come from generating the power required to run our buildings. As much as two-thirds of emissions in Alberta’s largest cities come from buildings.

Innovation is key to reducing emissions and boosting energy efficiency. James Keirstead, President of Levven Electronics, says, “We focus on products that enable home builders to offer unique and meaningful technology to all consumers. Homeowners have more control over energy usage and additional levels of convenience throughout the home. These solutions contribute to reducing the environmental impact of building and operating homes.”

Levven makes its products locally, with lean manufacturing principles, says Keirstead.

“We seek opportunities to meet sustainable development objectives to make home automation available to the average homeowner.”

Levven received $660,000 in Business Scale-up and Productivity (BSP) funding from PrairiesCan. This investment allowed it to scale up its business and marketing and add to its engineering team. Levven also added new manufacturing equipment, allowing improved quality in the products it designs for homeowners and businesses.

Edmonton company's smart technology saves time, materials and money when building new homes (length: 2:01)

Transcript: Edmonton company's smart technology saves time, materials and money when building new homes

[music]

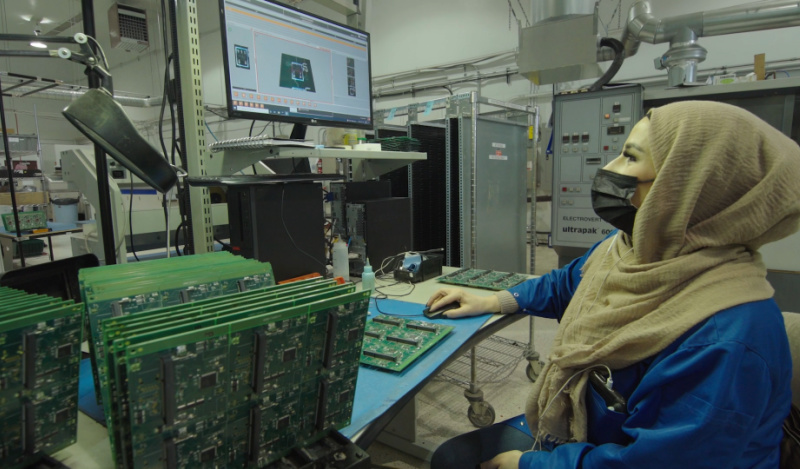

Video opens to hand turning on light switch. Then shows employees working on electronic devices and computers.

JAMES KEIRSTEAD, President, Levven Electronics (voiceover): At Levven Electronics, we're in the business of making homes more affordable to build, purchase and operate with smart controls.

Video transitions to James Keirstead speaking to camera.

Some of the best benefits of wireless technology is that it reduces tons of material that are going into homes that is really unnecessary.

Video transitions to installation of wiring in home construction.

We eliminate wire, we eliminate boxes, we eliminate marrettes and staples.

Video transitions to James Kierstead meeting with staff.

(voiceover) It also increases efficiency and capacity. And, it helps make things more programmable in the future, so your homes can be updated.

Video transitions to staff working on electronics and computers showing the operational side of Levven.

(voiceover) Another wonderful benefit about wireless technologies like this, is that it reduces greenhouse gas emissions.

(voiceover) Both in the production and development of it and then the operational side by having all this programmability which can improve the operational efficiency of homes. It's really going to have an impact.

The support of PrairiesCan has really helped us expand. There's a few things that we were able to do with this funding. The first is, we were able to buy some new equipment. We bought new pace machines and a new optical inspection machine. Those devices will help us improve our throughput and increase the quality of our product.

Video transitions to James Kierstead meeting with staff.

But the other side, the money was used to also help us add people to our engineering team and our front of house team, so that we could continue to focus on our export expansion.

Video transitions to manufacturing and packaging staff preparing equipment for delivery.

(voiceover) Number one thing I'm most proud of is that we're changing an industry. And that kind of change is really hard but it's also incredibly fulfilling.

Text on screen: PrairiesCan committed $660,000 in interest free, repayable funding to Levven to scale up and expand its electronics manufacturing facility.

Text on screen: Additional footage provided by Levven Electronics.

PrairiesCan website: www.prairiescan.gc.ca

PrairiesCan Twitter: @PrairiesCanEN

Prairies Economic Development Canada Wordmark appears on screen.

Animated Canada Wordmark appears on screen.