Canadian Integrated Program for Antimicrobial Resistance Surveillance (CIPARS) 2018: Design and Methods

Download the PDF version, 1814 KB

To promote and protect the health of Canadians through leadership, partnership, innovation and action in public health, Public Health Agency of Canada.

Working towards the preservation of effective antimicrobials for humans and animals, Canadian Integrated Program for Antimicrobial Resistance Surveillance.

Également disponible en français sous le titre :

Programme intégré canadien de surveillance de la résistance aux antimicrobiens (PICRA) 2018 : Design et méthodes

To obtain additional information, please contact:

Dolly Kambo

Executive assistant

Public Health Agency of Canada

370 Speedvale Avenue West, Guelph, ON N1H 7M7

Telephone: 519-826-2174

Fax: 519-826-2255

E-mail: phac.cipars-picra.aspc@canada.ca

This publication can be made available in alternative formats upon request.

©Her Majesty the Queen in Right of Canada, as represented by the Minister of Health, 2020

Publication date: December 2020

This publication may be reproduced for personal or internal use only without permission provided the source is fully acknowledged.

Cat.: HP2-4/2018E-3-1-PDF

ISBN: 978-0-660-36797-2

Pub.: 200319

Suggested Citation:

Government of Canada. Canadian Integrated Program for Antimicrobial Resistance Surveillance (CIPARS) 2018: Design and Methods. Public Health Agency of Canada, Guelph, Ontario, 2020.

Table of Contents

- What's new for CIPARS in 2018

- Design and Methods

- Antimicrobial use

- Antimicrobial resistance

- Human surveillance

- Retail meat surveillance

- Abattoir surveillance

- Farm surveillance

- Surveillance of animal clinical isolates

- Feed and feed ingredients

- Bacterial isolation methods

- Serotyping and phage typing methods

- Antimicrobial susceptibility testing methods

- Antimicrobial susceptibility breakpoints

- Data analysis

- Antimicrobial classification

- Appendix

What's new for CIPARS in 2018

Antimicrobial use

- Data collected under legislation by Health Canada from veterinary pharmaceutical manufacturers, importers, and compounders for 2018 is currently being analyzed. Results will be released as a separate report in spring of 2020.

- In 2018, grower-finisher pig quantitative antimicrobial use metrics were reported for the first time for antimicrobial use in water and injectables.

- As of 2018, the antimicrobial use metric nDDDvet/PCU was no longer be reported.

Antimicrobial resistance

- There was no placement broiler chicken sampling conducted in 2018.

- For farm surveillance, sampling in turkeys was initiated in Alberta.

- Only a partial year of retail sampling was conducted in Ontario and the Prairies, and no sampling occurred in the Atlantic region; therefore no temporal retail data from these regions are presented in 2018.

In addition to the changes described above, we launched 2 sentinel farm surveillance activities in feedlot and dairy cattle with our stakeholders.

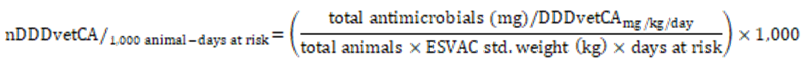

Design and Methods

Antimicrobial use

Human antimicrobial use monitoring activities within the Public Health Agency of Canada (PHAC) are presented in the Canadian Antimicrobial Resistance Surveillance System (CARSS), Update 2018Footnote 1. Select aspects of IQVIA data (formerly QuintilesIMS) are included in the integrated findings of this report (per communication with CARSS).

Quantities of antimicrobials distributed for sale for use in animals

As an estimate of antimicrobials used in animals, data on active ingredients distributed for sale were aggregated and provided to the Public Health Agency of Canada by the Canadian Animal Health Institute (CAHI). CAHI is the trade association representing the companies that manufacture and distribute drugs for administration to food (including fish), sporting, and companion animals in Canada. The association estimates that its members' sales represent approximately 95% of all sales of licensed animal pharmaceutical products in CanadaFootnote 2. CAHI coordinates electronic collection of data from its members. Data collection and analysis are performed by a third party, Impact Vet. The CAHI data include information from 17 companies that manufacture antimicrobials products for use in animals in Canada, and 4 major wholesalers/distributors. The CAHI data on the distribution of antimicrobials for use in animals provide a context to interpret other data on antimicrobial use in animals generated through surveillance or research on farm. They also provide a means to estimate gross temporal changes in antimicrobials used in animals.

The level in the distribution chain that kilograms of active ingredients are reported to CIPARS is at the feed manufacturer/veterinary clinic. Antimicrobial use was assigned to either production animal (inclusive of horses) or companion animal by the manufacturers according to label claim, and in the situation where mixed species was indicated on the label, the manufacturer assigned (estimated) the species as either companion animal or production animal.

These data do not represent actual antimicrobial use in a given year; rather, they reflect the volume of antimicrobials distributed by manufacturers and wholesalers. Distribution values should approximate amounts used, particularly when data from more than one year are included. However, when data from only one year are included, distribution values may vary from amounts actually used because of the time lag between distribution and actual use, as well as stockpiling of antimicrobials at various points in the distribution system. The sales data also do not account for drug wastage due to drug expiry.

The data do not include antimicrobials imported for personal use (own use importation or OUI) under the personal-use provision of the federal Food and Drugs Act and its Regulations, nor do they include imported active pharmaceutical ingredients (API), which are drugs imported in non-dosage form and compounded by a licensed pharmacist or veterinarian. The latest information from an Ipsos/Impact Vet study prepared for CAHI is that the lost opportunity value due to OUI and API was estimated to be 13% of total animal health product sales (personal communication Jean Szkotnicki). The CAHI data do not include prescriptions filled by pharmacists using human labelled drugs for antimicrobials used in companion animals. Hence, the CAHI data underestimate the true volume of antimicrobials used in animals in Canada. Also, the CAHI data do not capture what happens to the drugs after purchase; hence these data cannot provide information the actual antimicrobial use practices, such as dose, duration, reason for use, detailed species-specific information, or extra-label use.

The CAHI data include medicines sold directly to pharmacists that have a focus on dispensing for production medicine. It does not include antimicrobial agents moved from veterinarians to pharmacies and then subsequently dispensed by pharmacies. The latter distribution is captured with the veterinary clinic-level data.

CAHI provides the information in categories, with some antimicrobials not independently reported. This is based on a "3 company accounting rule" established by CAHI to comply with the European Union and the United States' anti-competition regulations. CAHI added in some cases a "90% rule" to be sure not to infringe the regulations in the United States. These accounting rules can result in changes to the categorization of specific antimicrobials over time. For 2018, the antimicrobials are categorized as per Table 1.

| Antimicrobial class | Ingredient |

|---|---|

| Aminoglycosides | Amikacin, apramycin, dihydrostreptomycin, framycetin sulfate, gentamicin, neomycin, spectinomycin, streptomycin |

| β-Lactams/penicillins | Amoxicillin, ampicillin, clavulanic acid, cloxicillin, penicillin |

| Cephalosporins | Cefadroxil, cefalexin, cefapirin, cefazolin, cefovecin, cefoxitin, cefpodoxime, ceftiofur |

| Fluoroquinolones | Ciprofloxacin, danofloxacin, enrofloxacin, marbofloxacin, orbifloxacin, pradofloxacin |

| Chemical coccidiostats and arsenicals | Amprolium, clopidol, decoquinate, diclazuril, halofuginone, narasin, pyrimethamine, robenidine, toltrazuril |

| Ionophore coccidiostats | Lasalocid, maduramicin, monensin, salinomycin |

| Lincosamides | Clindamycin, lincomycin, pirlimycin |

| Macrolides | Erythromycin, gamithromycin, tildipirosin, tilmicosin, tulathromycin, tylosin |

| Other antimicrobials | Avilamycin, bacitracin, bambermycin, chloramphenicol, chlorhexidine gluconate, florfenicol, fusidic acid, novobiocin, polymixin B, tiamulin, virginiamycin |

| Tetracyclines | Chlortetracycline, doxycycline, minocycline, oxytetracycline, tetracycline |

| Trimethoprim and sulfonamides | Sulfadiazine, sulfadoxine, sulfamerazine, sulfamethazine, sulfamethoxazole, sulfaquinoxaline, sulfathiazole, trimethoprim |

Temporal figures and data tables for significance testing

As the CAHI data represent census information, there is no testing of statistical differences between years (i.e., the CAHI data are not data derived from samples). Any difference in findings between years should reflect a true difference in the quantities of antimicrobials distributed for sale by the member companies.

Population correction unit

Changes in the overall quantity of antimicrobials distributed over time may reflect several things, including: true change in use practices, a change in the numbers or types of animals in the population (requiring antimicrobials), changes in disease prevalence necessitating antimicrobial use, and changes in the types of antimicrobials administered. As one way to adjust the sales data for the changing animal populations over time, a denominator accounting for the number of animals and their standardized weights (animal biomass) was applied. This denominator was based on the methodology currently in use by the European Surveillance of Veterinary Antimicrobial Consumption (ESVAC)Footnote 3.

ESVAC adjusts the sales data by a population correction unit (PCU) in which a PCU is a proxy for the animal biomass that is at risk of being treated with antimicrobials. It is a technical measurement only; where 1 PCU = 1 kg of different categories of livestock and slaughtered animals. ESVAC methodology was applied to the greatest extent possible, however population information collected by Statistics Canada and Agriculture and Agri-Food Canada is different in structure somewhat from the data accessed by ESVAC (Eurostat and TRACES), hence direct comparisons of PCU's or mg/PCU with ESVAC participating country data should only be made with due caution.

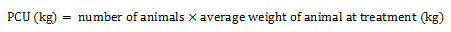

The PCU is calculated by multiplying the numbers of livestock and slaughtered animals in each species/production state by the theoretical (standardized) weight at the most likely time of treatmentFootnote 4,Footnote 5.

Equation 1 Formula for PCU calculation

Equation 1a. Formula for PCU calculation

Equation 1a - Text Description

The PCU (in kilogram) is calculated by multiplying the numbers of animals by the average weight of animal at treatment (in kilogram).

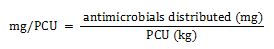

Equation 1b. Formula for PCU calculation

Equation 1b - Text Description

The milligrams per population correction unit (PCU) is calculated by dividing the amount of antimicrobials distributed for use (in milligram) by the PCU value (in kilogram).

National denominator data regarding the number of livestock and slaughtered animals were obtained from Statistics Canada, Agriculture and Agri-Food Canada, Fisheries and Oceans Canada, the Canadian Animal Health Institute, and Equestrian Canada (formerly known as Equine Canada) websites. Note, that some websites periodically update their historic data; hence the data are considered as accurate as possible on the date accessed.

In the fall of 2013, CIPARS met with animal commodity group volunteers, the pharmaceutical industry, and some provincial agriculture government representatives to discuss Canadian average weights at treatment. Using available CIPARS data and input from these participants (committee expert opinion), we jointly developed Canadian average weights at treatment. The rationale is that for some animal species or production stages, Canadian animals might be heavier or lighter than their European equivalents.

In 2017, based on consultation with an industry expert, CIPARS changed the weight of Canadian exported pigs (for feeding) for the PCUCANADA. CIPARS additionally applied the 1 kg weight for poultry imported and exported for the PCUESVAC, but used the reported Canadian weight categories for the PCUCANADA. In 2019, CIPARS, based on discussions with beef antimicrobial use researchers in Canada and the United States, updated the weights of beef cows and dairy cows. For beef cows, the new weight was based on the average mature beef cow 5 years and older according to the American National Animal Health Monitoring System (NAHMS) Beef 2007-08 Report, Part IV: Reference of Beef Cow-calf Management Practices in the United States, 2007-08. For dairy cows, the new weight was based on a 1400 lb mature cow as per the American Bovine Alliance on Management and Nutrition (BAMN) Publication Heifer Growth and Economics: Target Growth. This also resulted in a change to the average weight of cows slaughtered (it became the average weight of beef cows and dairy cows).

Detailed inclusion and exclusion criteria for the PCU denominator

As per ESVAC, exported animals were added to the PCU, whereas imported animals were subtracted, based on the ESVAC assumption that animals are treated in their country of origin. However, it was noted that in the Canadian context, this would vary depending upon the production stage that is crossing the border.

For the purposes of calculating the PCU, production animal species with the largest populations were included, using the same production classes as ESVAC (for the most part - dependent on the availability of the data), with the notable exception that we additionally included beef cows (not included by ESVAC).

Species currently excluded from our PCU calculations include game animals (e.g., moose), "pocket" companion animals (e.g., hamsters, guinea pigs, pet birds), reptiles, and amphibians.

For some production stages, import and export data for poultry are included in a different structure before and after 2009, based on the data available from Statistics Canada. The import and export of poultry for select weight categories were added, which is not included in the ESVAC methodology.

Provincial stratification of the numerator and denominator

There may be subsequent distribution of antimicrobials across provincial borders after being distributed to the veterinary clinics (in particular the movement of medicated feed; for example, anecdotal information was that New Brunswick has a negligible feed-mill industry, they generally purchase their medicated feed from Québec), hence caution should be applied when interpreting the quantities of antimicrobials distributed for sale within each province. Provincial/regional calculations of PCU are pending further discussion.

Overall discussion of strengths and limitations

The CAHI data provides a rough measure of antimicrobials distributed for sale for all animal species, including those not covered by CIPARS farm-level surveillance (with appropriate caveats regarding OUI/API). The PCU metric currently does not take into account the lifespan of the animal, which may affect the interpretation of the quantities of antimicrobials administered to animals. Also, use of a static standard weight may not reflect an industry shift in production affecting the average weights of animals treated, related to weather, trade, or other reasons. Measures of antimicrobial use as reported by broad categories and by a PCU denominator do not account for the amount of the drug needed to achieve therapeutic success. This could affect interpretation of trends. For example, a decrease in the mg/PCU could potentially reflect a switch to using a drug that has smaller daily dose, as opposed to reflecting a decrease in the actual exposure of animals to antimicrobials. The CAHI data should be interpreted as one measure describing antimicrobials used in animals, strong caution should be applied with making inferences to any use practice for a particular animal species.

There have been several advances in detail of these data over the past recent years. Since 2011, the data have been stratified by province, since 2012 stratified by companion animal/production animal, and since 2013 stratified by route of administration.

Quantities of antimicrobials distributed for sale for use on crops

Health Canada's Pest Management Regulatory Agency (PMRA) collects annual Canadian sales data from all pesticide manufacturers. Sales information on antimicrobials registered as pesticides on food crops was kindly provided by PMRA to CIPARS. These data represent antimicrobials administered for the following reasons: fireblight on pome fruits (apples, pears, quince), caneberries and Saskatoon berries; blossom blast and bacterial canker on cherries; stem canker and bacterial spot on greenhouse and field fruiting vegetables (peppers, tomatoes, and eggplant); and walnut blight of walnuts. To protect confidential business information, the data are only presented in combination with data from humans and animals.

Quantities of antimicrobials used in marine and freshwater finfish aquaculture

Fisheries and Oceans Canada (DFO) requires aquaculture industry operators to report on their use of drugs, including antimicrobials, (as authorized under the Food and Drugs Act) and pesticides (as registered under the Pest Control Products Act) under the authority of the Aquaculture Activities Regulations authorized under the Fisheries Act. In an annual report, aquaculture operators are required to report the quantity of drugs and pesticides used throughout the year at each location (i.e., farm site). From these data, the number of prescriptions and frequency of treatment periods are calculated, in addition to measures taken to avoid the need for such use. These data cover all marine and freshwater finfish aquaculture facilities in Canada. Further information on the use of antimicrobials and other products by the aquaculture industry in Canada can be found on DFO's Aquaculture Public Reporting websiteFootnote 6.

Farm surveillance

Farm questionnaire

Broiler chickens

In the broiler chicken Farm Surveillance component of CIPARS, sentinel farm data were collected through questionnaires administered by the poultry veterinarian (or designated practice staff) to the producer (or designated farm staff). The questionnaires collected information related to the hatchery and to the broiler farm. Veterinarians asked the producers for the chick delivery receipts, which contain information required to fill the hatchery-level portion of the questionnaire. Data collected included breeder flock information together with source origin (e.g., province of origin or imported); the age range of the breeder flock whether the hatchery purchased the chicks as hatching eggs or chicks; the antimicrobials used, routes of administration, and the dose. Additionally, the primary reason for antimicrobial use, such as treatment, prevention, high-risk flock source, or producer request was captured. Also collected were secondary reasons for use, such as avian pathogenic E. coli, Enterococcus cecorum, Salmonella spp., Staphylococcus spp., early clostridial infections and other diseases. Information on vaccines administered in ovo or at the time of hatch were recorded. The veterinarians or designated staff confirmed the information by calling the hatcheries.

The broiler farm portion of the questionnaire was completed by using feed delivery receipts, farm records, prescriptions and/or by asking the producer. Farm demographic information such as quota period, age and estimated weight of birds at the time of visit, farm/barn/floor capacity, as well as biosecurity and animal health information (i.e., vaccines administered at the farm level) were also obtained.

Producers or designated farm personnel were asked about antimicrobial use (AMU) via feed and water. Data were collected on each diet fed to the flock. Information collected on each ration included whether the feed contained antimicrobials (medicated feed) or did not contain antimicrobials (non-medicated feed), the total days fed and age of the flock at the start and end of each ration. Additional information was collected for diets containing antimicrobials including active ingredient(s), their concentration(s) in the feed, and the primary reason(s) for that AMU (growth promotion, disease prevention, or treatment). Secondary AMU reasons were captured if the primary use was for disease prevention or treatment; the list for secondary reasons included the most commonly diagnosed conditions in broilers: yolk sacculitis, septicemia, musculoskeletal diseases, respiratory diseases, necrotic enteritis, coccidiosis, and other diseases (e.g., any non-bacterial etiology such as viral and metabolic).

Data collected on exposure to antimicrobials though water included active ingredient(s) in the drug(s) used, dosage (g or mL/L of drinking water), start and end age of each water medication, the proportion of the flock exposed, and the reason(s) for use. The primary and secondary reasons for prevention and treatment for AMU in water were similar to those described for feed AMU. The producers were also asked if a prescription was provided by a veterinarian and whether the water medication was an over-the-counter purchase.

Based on the required components of the National Avian On-Farm Biosecurity StandardFootnote 7, relevant questions were asked pertaining to the level of biosecurity. Questions on access management, animal health management and operational management were included. Data on flock health status (i.e., diagnosis of the most common bacterial and viral diseases) and vaccine administration from the time of chick placement onwards were also collected.

Grower-finisher pigs

In the grower-finisher's Farm Surveillance component of CIPARS, sentinel farm data were collected through questionnaires administered by the herd veterinarian (or designated staff) to the producer (or designated farm staff). The questionnaires included sections requesting information on AMU, herd demographics and animal health.

Questions pertaining to the number of pigs in the population of interest differed by management system: continuous-flow or all-in-all-out. All-in-all-out management is a production system whereby animals are moved into and out of facilities in distinct groups. By preventing the commingling of groups, the intention is to reduce the spread of diseases. Facilities are normally cleaned and disinfected thoroughly between groups of animals. This type of management is generally all-in-all-out by room or by barn. In continuous-flow operations, animals are continually being added to and removed from the production system.

The AMU questionnaire was designed to collect data for groups of pigs in the grower-finisher production phase. No data on individual pigs were collected. Six pens representative of this population were selected for the collection of fecal specimens for bacterial culture and antimicrobial susceptibility testing. Thus, in herds with all-in-all-out management, the population of interest included all pigs that entered and exited the barn in the same group as the sampled pigs. The population of interest in herds with continuous-flow management was the pigs that entered the grower-finisher unit with the sampled pigs.

Herd owners/managers were asked about AMU via feed, water, and injections. Information collected on each type of feed administered during the grow-finish period included whether the feed contained antimicrobials (medicated feed) or did not contain antimicrobials (non-medicated feed), the average number of weeks each ration was fed and the associated start and end pig weights. Additional information was collected for diets (rations) containing antimicrobials: active antimicrobial ingredient(s), their concentration(s) in the feed, and the primary reason(s) for that AMU (either growth promotion, disease prevention, or treatment). If disease prevention or treatment was selected under the primary reason for AMU, respondents could choose any one of the following secondary reasons for use in feed: respiratory disease, enteric disease, lameness or other diseases. The proportion of pigs fed each diet was also captured.

Data collected on exposure to antimicrobials through water or injection included active ingredient(s) of the drug(s) used, the total grams per treatment course (water) or the dose injected in mg/kg of body weight (parenteral), the number of days the antimicrobial was given, the range in age at start of treatment, the range in weight at the start of treatment, the reason(s) for use, and the proportion of pigs exposed. The primary reasons for AMU in water included disease prevention and disease treatment with associated secondary reasons for use being respiratory disease, enteric disease, lameness or other diseases. Only disease treatment reasons were collected for AMU administered by injection.

No AMU data were collected for any production phase prior to the grower-finisher phase. Any data regarding AMU in pigs weighing less than 15 kg (33 lb) were excluded because this weight was considered below the industry standard for grower-finisher pigs.

Turkeys

In the turkey Farm Surveillance component of CIPARS, sentinel farm data were collected through questionnaires administered by the poultry veterinarian (or designated practice staff) to the producer (or designated farm staff). Data were collected on the intended market of the birds sampled. The potential markets were; broilers at 5.5 kg average weight and 64 to 71 days of age, light hens at 7.2 kg average weight and 76 to 83 days of age, heavy hens at 9.4 kg average weight and 99 to 106 days of age, light toms at 12.2 kg average weight and 97 to 104 days of age and heavy toms at 15.1 kg average weight and 109 to 116 days of age.

Hatchery drug use was obtained via the poult delivery receipts or by calling the hatcheries (if from domestic source). Data collected included breeder flock information together with source origin (e.g., province of origin or imported); the age range of breeder flock; whether the hatchery purchased the poults as hatching eggs or poults; the antimicrobials used, route of administration, and the dose. Additionally, the primary reason for antimicrobial use such as treatment, prevention, high risk breeder flock source, or producer request was obtained. The targeted bacteria or disease was also recorded; E. coli, Salmonella spp., Staphylococcus spp., or other.

Farm antimicrobial drug use was completed by using feed delivery receipts, farm records, prescriptions and/or by asking the producer. Farm demographic information, age and estimated weight of birds at the time of visit, farm/barn/floor capacity, as well as biosecurity and animal health information (i.e., vaccines administered at the farm level) were also obtained.

Producers or designated farm personnel were asked about AMU via feed and water. Data were collected on each diet fed to the flock. Information collected on each ration included whether the feed contained antimicrobials (medicated feed) or did not contain antimicrobials (non-medicated feed), the total days fed and age of the flock at the start and end of each ration. Additional information was collected for diets containing antimicrobials: active ingredient(s), their concentration(s) in the feed, and the primary reason(s) for that AMU (growth promotion, disease prevention, or treatment). Secondary AMU reasons were captured if the primary use was for disease prevention or treatment; the list for secondary reasons included the most commonly diagnosed conditions in turkeys: yolk sacculitis, septicemia, musculoskeletal diseases, respiratory diseases, enteric diseases, coccidiosis, and other diseases (e.g., any non-bacterial etiology such as viral and metabolic).

Data collected on exposure to antimicrobials though water included active ingredient(s) in the drug(s) used, dose (g or mL/L of drinking water), start and end age of each water medication, the proportion of the flock exposed, and the reason(s) for use. The primary and secondary reasons for prevention and treatment for AMU in water were similar to those described for feed AMU. The producers were also asked if a prescription was provided by a veterinarian and whether the water medication was an over-the-counter purchase.

Based on the required components of the National Avian On-Farm Biosecurity StandardFootnote 8, relevant questions were asked pertaining to the level of biosecurity. Questions on access management, animal health management and operational management were included. Data on flock health status (i.e., diagnosis of the most common bacterial and viral diseases) and vaccine administration from the time of poult placement onwards were also collected.

Data analysisFootnote 9

Data were entered into a PostGreSQL Database and descriptive statistics were obtained with commercially available softwareFootnote 10.

Broiler chickens

Antimicrobial exposures from the hatching stage to the end of growth or pre-harvest sampling stage (greater than or equal to 30 days) were summarized for each flock. An exposure was defined as any reported use of an active ingredient by a given route of administration. Data were reported as exposure to an active ingredient by a given route of administration, as well as by exposure to an active ingredient by any administration route. These exposures were summarized by antimicrobial active ingredient for frequency tables and summed up by class in the quantitative metrics/indicators.

Feed consumption

Estimates of feed intake were based on simple regression and integral calculus. Feed consumption estimates from most recently available performance standards (Ross and Cobb strains) and the performance objectives developed by nutrition companiesFootnote 11,Footnote 12,Footnote 13,Footnote 14,Footnote 15 were loaded into Microsoft™ Excel. From these data, the cumulative feed consumption was calculated using the average of feeding standards for the 2 most common broiler strains and the standards developed by feeding companies (i.e., non-strain specific) for as-hatched broilers (i.e., males and females combined). A plot of feed consumption in grams per bird per day was created.

From the broiler chicken questionnaire the start and end age of the birds was available for each ration. Since the end day of one ration was the start day of the next an algorithm was used to prevent overlapping days for each subsequent ration. Regression parameters were calculated within Microsoft™ Excel by using the plotted feed intake curve. A minimum R-square value of more than 0.99 was required to be considered a good fit of the regression line. To obtain the best fitting regression line, the broiler chicken feeding curve was divided into 3 segments. Segment 1, or the first regression line, the estimates were utilized to calculate feed consumption if the age of the birds when they started or finished the ration was less or equal to 21 days (i.e., equivalent to brooding and early grow-out period) (Table 2). The second regression line estimates (segment 2) were used if the age of the birds when they started or finished the ration was greater than or equal to 35 days of age (i.e., equivalent to finisher phase or extended grow-out period in roasters) (Table 2). All other age ranges had feed consumption based on the third regression line depicted (i.e., grow-out period) (Table 2).

Feed consumption calculations were then based on the regression coefficients that were calculated and presented in Table 2. For each ration the appropriate regression coefficients (based on start and end age of the birds) and the number of days the ration was fed (as entered in the survey) were substituted into the area under the curve formulas provided (Table 2). For each ration, 2 integrals were calculated. The lower integral set "t" as the ration start age and the upper integral set "t" as the ration end age. The difference between the upper and lower integral yielded the estimate of feed intake in g/bird for that ration. Feed consumption was converted from grams to tonnes and multiplied by the number of birds at risk (i.e., total birds minus half of the mortalities) to provide an estimate of total tonnes fed for each ration. The number of birds reported were the total birds delivered in the poultry unit of concern (barn or floor) including the 2% allowance provided by the hatchery. This value was then utilized to calculate the grams of antimicrobial consumed per ration and incorporated into the quantitative analysis.

| Segment of feed curve | Bird age in days | Calculated regression coefficients | R2 | Formula for area under the curve and feed consumption calculation | |||

| β0 | β1 | β2 | β3 | ||||

| 1 | ≤ 21 | 14.096 | 1.2095 | 0.228 | -0.003 | 0.99 | β0t+ β1t2/2+ β2t3/3+ β3t4/4 |

| 2 | ≥ 35 | -13.06 | 4.8777 | 0.085 | -0.0017 | 0.99 | β0t+ β1t2/2+ β2t3/3+ β3t4/4 |

| 3 | All other ages | -27.935 | 8.827 | -0.069 | -5.00E-05 | 0.99 | β0t+ β1t2/2+ β2t3/3+ β3t4/4 |

Water consumption

Estimates of water consumption were based on simple regression and integral calculus. Water consumption estimates were uploaded into Microsoft™ Excel. Estimates were based on daily water consumption chartFootnote 16 and a plot of intake in L/bird/day was created.

From the broiler chicken questionnaire, the start and end age of the birds was available for each water treatment. An algorithm was used to prevent any possible overlapping of age in days for consecutive water treatments with different antimicrobials in the same flock. Regression parameters were calculated within Microsoft™ Excel by using the plotted water intake curve. A minimum R-square value of greater than 0.99 was required to be considered a good fit of the regression line. To obtain the best fitting regression values, the water consumption curve was divided into 3 segments. If the age of the birds when they started and ended the water treatment was less than or equal to 21 days of age, the water consumption was based on the regression line for segment 1 of the curve (Table 3). If the age of the birds when they started or ended the water treatment was less than or equal to 38 days of age, the water consumption was based on the regression line for segment 2 of the curve (Table 3). All other age ranges had water consumption calculated from the regression line for segment 3 of the curve. From the regression coefficients, the water consumption could then be calculated using integral calculus and the area under the curve formula as described above under broiler chicken feed consumption (Table 3).

| Segment of feed curve | Bird age in days | Calculated regression coefficients | R2 | Formula for area under the curve and feed consumption calculation | |||

| β0 | β1 | β2 | β3 | ||||

| 1 | ≤ 21 | 0.0322 | 8.00E-05 | 0.0005 | -7.00E-06 | 0.99 | β0t+ β1t2/2+ β2t3/3+ β3t4/4 |

| 2 | ≥ 38 | 0.0335 | -0.0003 | 0.0005 | -7.00E-06 | 0.99 | β0t+ β1t2/2+ β2t3/3+ β3t4/4 |

| 3 | All other ages | -0.4475 | 0.0417 | -0.0007 | 4.00E-06 | 0.99 | β0t+ β1t2/2+ β2t3/3+ β3t4/4 |

Quantity of antimicrobials used in broiler chickens

Based on the species-specific calculations above, the milligrams of active ingredient were obtained for each route of administration, reported by route and aggregate of all routes. For Equation 2 to Equation 4, total animals pertains to the starting flock or herd population minus half of the reported mortalities.

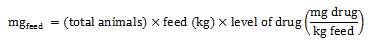

Equation 2. Estimation of total milligrams in feed (broiler chickens, pigs, and turkeys)

Equation 2 - Text Description

The total milligrams in feed is calculated by multiplying the total number of animals by the quantity of feed consumed (in kilogram), and the level of drug (milligram of active ingredient divided by the kilogram of feed).

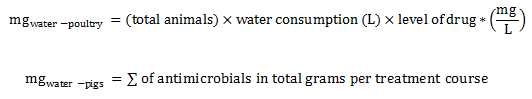

Equation 3. Estimation of total milligrams in water (broiler chickens, pigs, and turkeys)

Level of drug* = Inclusion rate indicated in the label x concentration of the drug.

Equation 3 - Text Description

The total milligrams in water for poultry is calculated by multiplying the total number of animals by the quantity of water consumed (in liter) and the level of drug (in milligram of active ingredient by liter).

or

The total milligrams in water for pigs is calculated by summing the total grams of antimicrobials per treatment course.

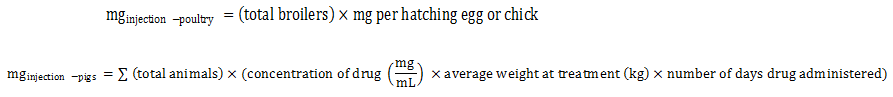

Equation 4. Estimation of total milligrams via in ovo or subcutaneous injections (broiler chickens, pigs, and turkeys)

Total animals pertain to the starting herd population minus half of the reported mortality rate at the time of sampling multiplied by the proportion of pigs exposed.

Equation 4 - Text Description

The total milligrams by injection for poultry is calculated by multiplying the total number of broilers by the quantity of milligrams injected by hatching egg or chick.

or

The total milligrams by injection for pigs is calculated by summing the results of the multiplication of the total number of animals by the result of the multiplication of the concentration of drug (in milligram by milliter) by the average weight at treatment (in kilogram) and the number of days of drug administration.

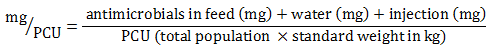

Based on the quantity of feed or water consumed, plus quantity administered via injection from the above calculations, the following antimicrobial use metrics or indicators were reported:

Milligrams active ingredient/population correction unit (mg/PCU): Total milligrams (combined injections, feed, and water) for each antimicrobial/class and overall, adjusted for animal population (1 grow-out cycle) and weight.

- Step 1 population correction unit (PCU) or biomass. (Equation 5): The PCU was calculated by multiplying the total number of animals reported in the questionnaire (equivalent to 1 grow-out cycle; population minus half the mortalities) by the theoretical (standardized) weight at the most likely time of treatment (ESVAC standard weight of 1 kg for broiler, 6.5 kg for turkeys, and 65 kg for swine was used).

- Step 2 mg/PCU (Equation 6): Estimation of mg/PCU for each antimicrobial active ingredient, subsequently aggregated by class, and overall to generate year-specific estimate per species.

Equation 5. Formula for PCU calculation

Equation 5 - Text Description

The PCU (in kilogram) is calculated by multiplying the numbers of animals by the average weight at treatment (in kilogram).

Equation 6. Formula for mg/PCU calculation

Equation 6 - Text Description

The milligram per population correction unit (PCU) is calculated by dividing the sum of the amount of antimicrobials administered in feed, water and by injection (in milligram) by the PCU value (total population multiplied by the standard weight in kilogram).

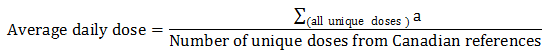

Canadian Defined Daily Doses using Canadian doses (DDDvetCA): The Canadian average labelled daily doses for each antimicrobial were assigned following similar methodology to ESVAC's DDDvet assignment with some exceptionsFootnote 17.

- Step 1 Average daily dose (Equation 7): The average daily dose was determined as follows: each antimicrobial was assigned a DDDvetCA by obtaining all approved doses for chickens, pigs, and turkeys (prevention and treatment purposes) from 2 Canadian referencesFootnote 18,Footnote 19 or from expert opinion, where no labelled product existed (extra-label drug use, ELDU)Footnote 20. The sum of all the doses was then divided by the total number of unique doses.

- Step 2 DDDvetCA (Equation 8): Because the labelled dose (inclusion rates) varied by pharmaceutical form (e.g., g/tonne for products administered via feed, g/L water for products administered via the drinking water, mg/chick or hatching eggs for injectable products), values were standardized in mgdrug/kganimal/day based on the ESVAC approach. As in the ESVAC methodologyFootnote 21, for combination products, DDDvetCA for each antimicrobial component was determined. In broiler chickens and turkeys, this applies to the combination drugs lincomycin-spectinomycin and trimethoprim-sulfadiazine. The values for the poultry and pigs are summarized in Table A. 1 and Table A. 2. Please note that metric development is an iterative process and that the database is continuously updated, thus these values may change (e.g., new products available, change in product labels or approved claims, refinement of the metric).

Equation 7. Average daily dose calculation

- Equation 7 note a

-

All unique doses indicated for treatment and prevention were used to calculate the average daily dose of an antimicrobial; an antimicrobial may have more than one unique dose by product format and/or indication.

Equation 7 - Text Description

The average daily dose is calculated by summing all unique doses divided by the number of unique doses from Canadian references.

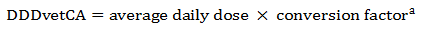

Equation 8. Standardization of average daily dose to obtain DDDvetCA with units in mg of drug per kilogram of body weight (animal) per day

- Equation 8 note a

-

A conversion factor is used to standardize the DDDvetCA unit in mgdrug/kganimal/day as in the ESVAC approach; please refer to Table A. 3 and Table A. 4 for broiler chicken/turkey and grower-finisher pig-specific conversion factors, respectively.

Equation 8 - Text Description

The DDDvetCA is calculated by multiplying the average daily dose by the conversion factor.

The nDDDvetCA (Equation 9): For each antimicrobial active ingredient and aggregate of all the antimicrobial active ingredients (yearly total) are adjusted by various species-specific technical units of measurement (e.g., population, weight, days at risk) as described in Equation 9 and Equation 10. Similar to mg/PCU, these indicators are also used for between antimicrobial class and inter-species comparisons over time.

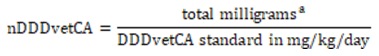

Equation 9. Calculating the number of daily doses in animals using Canadian standards (nDDDvetCA)

- Equation 9 note a

-

This is the numerator, combining milligrams consumed via feed, water and injections.

Equation 9 - Text Description

The nDDDvetCA is calculated by dividing the total milligrams by the DDDvetCA standard in milligrams per kilograms per day.

Number of Canadian Defined Daily Doses (nDDDvetCA)/1,000 animal-days at risk (Equation 10): Also known as treatment incidence and there are many variations of this equationFootnote 22,Footnote 23,Footnote 24,Footnote 25. This indicator was calculated by dividing the nDDDvetCA (Equation 9) values to the denominator value (flock or herd population minus half of the mortalities multiplied by the ESVAC standard weight and the mean number of days each for one production cycle for the monitored flocks or herds). The days at risk is year-specific (e.g., 2017: 34 days for broiler chickens, 114 days for grower-finisher pigs, and 90 days for turkeys). The final step multiplied the values by a 1,000. Please note that Equation 10 differed slightly from the 2016 CIPARS Annual Report; the calculation below was modified to reflect the sequential steps leading to the final antimicrobial use indicator and in line with the methodology described in the literature.

Equation 10. Formula for the number of DDDvetCA/1,000 animal-days at risk

Std. = standard.

Equation 10 - Text Description

The nDDDvetCA per thousand animal-days at risk is calculated by dividing the total antimicrobials (in milligrams) per DDDvetCA (in milligram per by milligrams per kilograms per day) by the value obtained by the multiplication of the total number of animals by the ESVAC standard weight (in kilograms) and the number of days at risk. The result of that division is then multiplied by 1,000.

Grower-finisher pigs

Antimicrobial exposures were summarized for each herd. An exposure was defined as any reported use of an active ingredient by a given route of administration in 2018. Data were reported as exposure to an active ingredient by a given route of administration, as well as by exposure to an active ingredient by any administration route. These exposures were summarized by antimicrobial class. It is important to note that antimicrobial exposures through feed tend to involve larger groups of pigs and longer durations of use than antimicrobial exposures via water. Injectable antimicrobials are generally administered on an individual basis to a limited number of pigsFootnote 26.

Feed consumption

Quantitative AMU data (dose and duration) were collected for antimicrobials administered through feed, water, and by injection. The amount of an antimicrobial consumed through feed was estimated from the concentration of the antimicrobial in a given ration multiplied by the cumulative tonnes consumed over the duration of exposure. Estimates of feed intake were based on simple regression equations and integral calculus. Plots of feed consumption per day were created within Microsoft™ Excel, using National Research Council (NRC) tables (Nutrient Requirements of Swine: Eleventh Revised Edition, National Academy of Sciences, 2012) for grower-finisher pigs. Three plots were created to reflect poor (15% less protein deposition per kg feed consumed than the standard pig), medium (standard pig described by NRC), and high (15% more protein deposition than the standard pig) performance. The lightest starting weight recorded for all rations listed on a questionnaire was selected and the corresponding day on the feed consumption table was identified. The number of days the ration was fed was then added to the start day to obtain an end day for that ration. For each successive ration, the number of days the ration was fed was added to the proceeding ration end day. When the reported feeding end day went beyond the NRC table, data were extrapolated up to maximum of 50 additional days.

Regression parameters for each level of pig performance were calculated within Microsoft™ Excel by using the feed intake curve (Table 4). A minimum R-square value higher than 0.99 was required to be considered a good fit of the regression line. From the regression coefficients the feed consumption could then be calculated using integral calculus and the area under the curve formula provided in Table 4 similar to that described above under broiler feed consumption. However, for swine, 3 regression lines (poor, medium and high performance) were created per ration. Two integrals were calculated using the formula in Table 4. For the lower integral "t" is the start age of the pigs on the ration and for the upper integral "t" is the end age of the pigs on the ration. The difference between the upper and lower integral yielded the estimate of feed intake in kilograms per pig for that ration. For each grower-finisher pig herd an average daily gain (ADG) was calculated based on data provided in the questionnaire; starting and ending weights as well as the number of days pigs were in the grower-finisher stage of production. Farms were categorized as having poor, medium, or high performance by using cut off points which were generated by partitioning the questionnaire ADG data into thirds. High performance herds were defined as herds with an ADG more than 0.8734, medium performance herds had an ADG between 0.8734 to 0.8045, and poor performance herds had ADG less than 0.8045. Based on this categorization, the appropriate regression line and integral were applied to calculate feed consumption. Feed consumption was converted from kilograms to tonnes and multiplied by the number of pigs at risk to provide an estimate of total tonnes fed for each ration. This value was then utilized to calculate the grams of antimicrobial consumed per ration and incorporated in quantitative analyses.

| Pig performance | Calculated regression coefficients | R2 | Formula for area under the curve and feed consumption calculation | ||

|---|---|---|---|---|---|

| β0 | β1 | β2 | |||

| Poor | 0.901 | 0.0243 | -7.00E-05 | 0.99 | β0t+ β1t2/2+ β2t3/3 |

| Medium | 0.8974 | 0.0267 | -9.00E-05 | 0.99 | β0t+ β1t2/2+ β2t3/3 |

| High | 0.8945 | 0.0291 | -0.0001 | 0.99 | β0t+ β1t2/2+ β2t3/3 |

Water consumption

From the grower-finisher pig questionnaire, the total grams of the active ingredient delivered for each water treatment course was available. By obtaining total grams delivered per treatment course there was no need to calculate out the water consumption for the proportion and size of pigs exposed. For each herd, total AMU through water was obtained by summing the grams of either active ingredient, antimicrobial class or any antimicrobial used as required for analysis.

Injection

From the grower-finisher questionnaire, for AMU by injection, the product concentration in mg/mL, the mg/kg body weight dose delivered, the number of days treated, the average weight of the pigs at the time of treatment and the proportion of pigs exposed was available. From these parameters the total mg of antimicrobial can be calculated for the farm. For each herd, total AMU via injection was obtained by summing the milligrams of either active ingredient, antimicrobial class or any antimicrobial used as required for analysis.

Quantity of antimicrobials used in grower-finisher pigs

Please refer to the "Quantity of antimicrobials used in broiler chickens" section (see above) for the quantity of antimicrobial use in grower-finisher pigs calculations.

Turkeys

Antimicrobial exposures from the hatching stage to the end of growth or pre-harvest sampling stage (approximately 1 week prior to slaughter) were summarized for each flock. An exposure was defined as any reported use of an active ingredient by a given route of administration. Data were reported as exposure to an active ingredient by a given route of administration, as well as by exposure to an active ingredient by any administration route. These exposures were summarized by antimicrobial class.

Feed consumption

Estimates of feed intake were based on simple regression and integral calculus. Feed consumption estimates from most recently available references including performance standards for Aviagen (Nicolas)Footnote 27 and Hybrid turkeysFootnote 28 were loaded into Microsoft™ Excel. From these data, the cumulative feed consumption was calculated using the average of feeding standards for the 2 most common turkey strains and the standards developed by feeding companies (i.e., non-strain specific) for as-hatched poults. Regression calculations were completed for broiler turkeys, turkey hens and tom turkeys.

Feed consumption was calculated on a per ration bases using the same methodology as described above for broiler chicken feed consumption. Separate regression coefficients were calculated for broiler turkeys, hens and toms and were applied appropriately based on the selection of the target market from the survey at the time of data entry. Regression line coefficients and area under the curve formulas are provided in Table 5.

| Bird type | Calculated regression coefficients | R2 | Formula for area under the curve and feed consumption calculation | |||

|---|---|---|---|---|---|---|

| β0 | β1 | β2 | β3 | |||

| Broiler turkeys | -0.1085 | 0.1782 | 0.008 | -0.0003 | 0.99 | β0t+ β1t2/2+ β2t3/3+ β3t4/4 |

| Toms | -0.0545 | 0.1398 | 0.016 | -0.0005 | 0.99 | β0t+ β1t2/2+ β2t3/3+ β3t4/4 |

| Hens | -0.1424 | 0.2016 | 0.002 | -0.0002 | 0.99 | β0t+ β1t2/2+ β2t3/3+ β3t4/4 |

Water consumption

Estimates of water consumption were based on simple regression and integral calculus. Water consumption estimates were uploaded into Microsoft™ Excel from most recently available referenceFootnote 29 and a daily water consumption chart and a plot of intake in litres/bird/day was created.

Water consumption was calculated on a per treatment course basis using the same methodology as described above for broiler chicken water consumption. Separate regression lines were calculated for birds less than or equal to 13 weeks of age and for those greater than 13 weeks of age to achieve the best fitting curve. Regression line coefficients and area under the curve formulas are provided in Table 6.

| Segment of water curve | Bird age in weeks | Calculated regression coefficients | R2 | Formula for area under the curve and water consumption calculation | ||

| β0 | β1 | β2 | ||||

|---|---|---|---|---|---|---|

| 1 | ≤ 13 | -0.0131 | 0.0487 | 0.0019 | 0.99 | β0t+ β1t2/2+ β2t3/3 |

| 2 | > 13 | 0.8922 | 0.0018 | 0.0002 | 0.99 | β0t+ β1t2/2+ β2t3/3 |

Quantity of antimicrobials used in turkeys

Please refer to the "Quantity of antimicrobials used in broiler chickens" section (see above) for the quantity of antimicrobial use in turkey calculations.

Antimicrobial resistance

Human surveillance

Objective(s)

The objective of the Surveillance of Human Clinical Isolates component of CIPARS is to provide a representative and methodologically unified approach to monitor temporal variation in the prevalence of antimicrobial resistance in Salmonella isolated from humans.

Surveillance design

Hospital-based and private clinical laboratories culture human Salmonella isolates in Canada. Although reporting is mandatory through laboratory notification of reportable diseases to the National Notifiable Disease Reporting System, forwarding of Salmonella isolates to provincial reference laboratories is voluntary and passive. A high proportion (84% in 2001)Footnote 30 of Salmonella isolates are forwarded to Provincial Public Health Laboratories (PPHLs), but this proportion may vary among laboratories. The Yukon, Northwest Territories, and Nunavut, which do not have a PPHL counterpart, forwarded their isolates to one of the PPHLs.

Prior to 2002, PPHLs forwarded Salmonella isolates to the Enteric Diseases Program, National Microbiology Laboratory (NML)@Winnipeg, Public Health Agency of Canada (PHAC), Winnipeg, Manitoba for confirmation and subtype characterization. A letter of agreement by which provinces agreed to forward all or a subset of their Salmonella isolates to NML@Winnipeg for CIPARS was signed in 2002 by the PPHLs and PHAC. This agreement officially launched the surveillance program.

To ensure a statistically valid sampling plan, all human Salmonella isolates (outbreak-associated and non-outbreak-associated) received passively by PPHLs in Saskatchewan, Manitoba, New Brunswick, Nova Scotia, Prince Edward Island, and Newfoundland and Labrador were forwarded to the NML. The PPHLs in more heavily populated provinces (British Columbia, Alberta, Ontario, and Québec) forwarded only the isolates received from the 1st to the 15th of each month. However, all human S. Newport and S. Typhi isolates were forwarded to the NML because of concerns of multidrug resistance and clinical importance, respectively.

The PPHLs were also asked to provide a defined set of data for each forwarded isolate, including serovar name, date collected, site of isolation, patient age, sex, and province of residence.

Retail meat surveillance

Objective(s)

The objectives of CIPARS Retail Meat Surveillance component are to provide data on the prevalence of antimicrobial resistance and to monitor temporal variations in selected bacteria found in raw meat at the province/region level.

Surveillance design

Retail Meat Surveillance provides a measure of human exposure to antimicrobial-resistant bacteria via the consumption of undercooked meat. Retail food represents a logical sampling point for surveillance of antimicrobial resistance because it is the endpoint of food animal production. Through meat sample collection and testing, the retail surveillance component provides a measure of human exposure to antimicrobial resistant bacteria through the consumption of meat products available for purchase by Canadian consumers. As resources allow, the scope of the surveillance framework can be modified as necessary (e.g., to evaluate different food commodities, bacteria, or geographic regions) and functions as a research platform for investigation of specific questions regarding antimicrobial resistance in the agri-food sector.

The unit of concern in Retail Meat Surveillance in 2018 was the bacterial isolate cultured from one of the commodities of interest. In this situation, the commodities were raw meat products commonly consumed by Canadians. These raw meat products consisted of chicken (legs or wings [skin on]), turkey (ground), pork (chops), and beef (ground). These products also reflect the 3 animal species sampled in the Abattoir Surveillance component as well as turkey beginning in 2012.

For ground beef, a systematic collection of extra-lean, lean, medium, and regular ground beef was performed to ensure representation of the heterogeneity of ground beef with respect to its origins (e.g., domestic vs. imported beef or raised beef cattle vs. culled dairy cattle). The meat cuts "legs or wings with skin on", "ground turkey", "pork chops", and "ground beef" were chosen on the basis of suspected high prevalence of the targeted bacterial species within and the low purchase prices of these commoditiesFootnote 31 and for comparability to other international retail surveillance programs.

Bacteria of interest in chicken were Campylobacter, Salmonella, and generic E. coli and in ground turkey Salmonella and generic E. coli. Recovery of Campylobacter from ground turkey was stopped mid-2016 due to low prevalence; no further testing is planned at this time. In pork, both Salmonella and E. coli were cultured, but only isolates of E. coli underwent antimicrobial susceptibility testing for routine surveillance and annual reporting. Salmonella was isolated from pork mainly to provide recovery estimates from this commodity for other Public Health Agency of Canada programs. Because the prevalence of Salmonella in pork is low, antimicrobial susceptibility results are not presented on an annual basis but are pooled and presented over a multi-year period in the interest of precision. Recovery of Campylobacter from pork was not attempted because of the low prevalence observed in the initial stages of Retail Meat Surveillance. In beef, only E. coli was cultured and then tested for antimicrobial susceptibility given the low prevalence of Campylobacter and Salmonella in this commodity at the retail level, as determined during the early phase of the program.

Sampling methods

Generally, the sampling protocol was designed to evaluate antimicrobial resistance in certain bacterial species that contaminate retail meat and to which Canadian consumers may subsequently be exposed. In 2018, it primarily involved continuous weekly submission of samples of retail meat from randomly selected geographic areas (i.e., census divisions defined by Statistics Canada), weighted by population, in each participating province.

In 2018, retail meat samples were collected routinely in British Columbia, and Québec. Only a partial year of sampling was conducted in the Prairies (a region including the provinces of Saskatchewan, Alberta, and ManitobaFootnote 32) and Ontario and thus no temporal data are presented in 2018. Unlike previous years (2013 and 2014), no data were presented in recent years (2015 to 2018) for the Atlantic region (a region including the provinces of New Brunswick, Nova Scotia, Prince Edward Island, and Newfoundland and LabradorFootnote 33) as retail sampling activities in this region were suspended due to budgetary constraints.

Data from Statistics Canada were used to define strata. This was done by using cumulative population quartiles (or tertiles from a list of census divisions in a province, sorted by population in ascending order. Generally, between 15 and 18 census divisions per province/region were then chosen by means of stratified random selection and weighted by population within each stratum. The number of sampling days allocated to each stratum was also weighted by population and is summarized as follows:

British Columbia

- Stratum 1: 10 divisions selected, with 1 sampling day per division per year

- Stratum 2: 4 divisions selected, with 3 sampling days per division per year

- Stratum 3: 1 division selected, with 20 sampling days per year

Prairies (Alberta only for 2018)

- Stratum 1: 9 divisions selected, with 2 sampling days per division per year

- Stratum 2: 5 divisions selected, with 3 sampling days per division per year

- Stratum 3: 2 divisions selected, with 5 sampling days per division per year

- Stratum 4: 1 division selected, with 7 sampling days per year

Ontario (partial year only for 2018) and Québec

- Stratum 1: 10 divisions selected, with 2 sampling days per division per year

- Stratum 2: 4 divisions selected, with 5 sampling days per division per year

- Stratum 3: 2 divisions selected, with 10 sampling days per division per year

- Stratum 4: 1 division selected, with 20 sampling days per year

Generally, field workers in Québec conducted sampling on a weekly basis, and those in British Columbia conducted sampling every other week. Sampling was less frequent in British Columbia and the Prairie region because of funding constraints, limited laboratory capacity, and a desire to avoid over-sampling at particular stores. In 2018, sampling activities in the Prairie region and Ontario much less frequent than originally planned resulting in only a limited and partial year's worth of data. Samples were collected on Mondays or Tuesdays for submission to the laboratory by Wednesday. Samples submitted from outside Québec were sent to the same laboratory via 24-hour courier.

In each province in most cases, 2 census divisions were sampled each sampling week. In each census division, 4 stores were selected prior to the sampling day, based on store type. Generally, 3 chain stores and 1 independent market or butcher shop were selected. An exception to this protocol was made in densely populated urban census divisions (e.g., Toronto or Montréal), where 2 chain stores and 2 independent markets or butcher shops were sampled to reflect the presumed shopping behaviours of that subpopulation. Generally speaking, from each store type, we aimed to collect 1 sample of each commodity of interest was for a total of 15 meat samples (4 chicken, 4 turkey, 4 pork, and 3 beef samples) per division per sampling dayFootnote 34. When possible, a given store was sampled only once per sampling year. In some cases due to reduced availability of certain meats and store closures etc., the desired sample yield was not achieved.

Prevalence estimates were used to determine the numbers of samples to be collected, which were based on an expected yield of 100 isolates per commodity per province per year, plus 20% to account for lost or damaged samples. Because sampling was less frequent in 2018 in British Columbia and the Prairie region than in Québec, the target of 100 isolates per year may not have always been met in those provinces/regions.

Notebook computers containing a custom electronic submission form were used to capture the following store and sample data:

- Type of store

- Number of cash registers (surrogate measure of store volume)

- "Sell-by" or packaging date

- "May contain previously frozen meat" label: yes or no

- Final processing in store: yes, no, or unknown

- Air chilled: yes, no, or unknown (applied to chicken samples only)

- Organic: yes, no, or unknown

- Antimicrobial free: yes, no, or unknown

- Price per kilogram

Individual samples were packaged in sealed zipper-type bags and placed in 16 L thermal coolers for transport. The ambient environmental temperature was used to determine the number of ice packs placed in each cooler (i.e., 1 ice pack for temperatures below 20°C and 2 ice packs for temperatures 20°C or higher). In 1 or 2 coolers per sampling day, instruments for recording temperature dataFootnote 35 were used to monitor temperatures to which samples were exposed.

Abattoir surveillance

Objective(s)

The objectives of the CIPARS Abattoir Surveillance component are to provide nationally representative, annual antimicrobial resistance data for bacteria isolated from animals entering the food chain, and to monitor temporal variations in the prevalence of antimicrobial resistance in these bacteria.

Surveillance design

Abattoir Surveillance only includes animals that originated from premises within Canada. Established in September 2002, this component initially targeted generic Escherichia coli and Salmonella within the food animal commodities associated with the highest per capita meat consumption: beef cattle, broiler chickens, and pigs. In 2003, the component was refined to discontinue Salmonella isolation from beef cattle because of the low prevalence of Salmonella in that population. Campylobacter surveillance was initiated in beef cattle in late 2005 in order to include a pathogen in beef cattle surveillance and to provide data on fluoroquinolone resistance, following the approval of a fluoroquinolone for use in cattle. Campylobacter surveillance was also initiated in chickens in 2010 and pigs in 2012.

In the Abattoir Surveillance component, the unit of concern (i.e., the subject of interest) was the bacterial isolate. The bacteria of interest were isolated from the caecal contents (not carcasses) of slaughtered food animals to avoid misinterpretation related to cross-contamination and to better reflect antimicrobial resistance in bacteria that originated on the farm.

Over 90% of all food-producing animals in Canada are slaughtered in federally inspected abattoirs annuallyFootnote 36. The program is based on the voluntary participation of federally inspected slaughter plants from across Canada. The sampling method was designed with the goal that, across Canada, 150 isolates of Salmonella and generic E. coli and 100 isolates of Campylobacter would be recovered from each of the 3 animal species over a 12 month period. These numbers represented a balance between acceptable statistical precision and affordabilityFootnote 37. The actual number of samples collected was determined for each food animal species on the basis of the expected caecal prevalence of the bacteria in that animal species. For example, if the goal was 150 isolates and the expected bacterial prevalence was 10%, then 1,500 samples would need to be collected and submitted for bacterial isolation.

The sampling design was based on a 2-stage sampling plan, with each commodity handled separately. The first stage consisted of random selection of federally inspected slaughterhouses. The probability of an abattoir being selected was proportional to its annual slaughter volume. The second stage involved systematic selection of animals on the slaughter line. The annual number of caecal samples collected at each abattoir was proportional to its slaughter volume.

Sampling methods

To minimize shipping costs and allow each abattoir to maintain efficiency, the annual total number of samples to be collected in each abattoir was divided by 5, resulting in the number of collection periods. For each collection period, 5 to 7 caecal samples were collected within 5 days, at the convenience of the slaughterhouse staff, provided the 5 animals and associated samples originated from different groups. Sampling from different groups of animals was important to maximize diversity and avoid bias attributable to overrepresentation of particular producers. Collection periods were uniformly distributed throughout the year to avoid any bias that may have resulted from seasonal variation in bacterial prevalence and antimicrobial susceptibility test results.

Forty-five federally inspected slaughter plants (4 beef cattle plants, 27 poultry plants, and 13 swine plants) from across Canada participated in the 2018 CIPARS Abattoir Surveillance component. These plants represented over 95% of the cattle, 70% of the chickens, and 80% of the pigs slaughtered at federally inspected abattoirs in Canada in 2018. Samples were obtained according to a predetermined protocol, with modifications to accommodate various production-line configurations in the different plants. Protocols were designed to avoid conflict with carcass inspection methods, plant-specific Food Safety Enhancement Programs, and Health and Safety requirements. They were also designed to avoid situations of potential cross-contamination. All samples were collected by industry personnel under the oversight of the Veterinarian-in-Charge of the Canadian Food Inspection Agency.

Farm surveillance

Objective(s)

The objectives of the CIPARS Farm Surveillance component are to provide data on antimicrobial use and resistance, to monitor temporal and spatial trends in the prevalence of antimicrobial resistance, to investigate associations between antimicrobial use and resistance in feedlot cattle, broiler chickens, grower-finisher pigs, and turkeys, and to provide data for human health risk assessments.

Surveillance design

The Farm Surveillance component was the third active surveillance component implemented by CIPARS. Taken together, with the Abattoir Surveillance and Retail Meat Surveillance components, these data validate the information collected at key points along the farm-to-fork food production chain. This initiative is built on a sentinel farm framework. Questionnaires are used to collect data on farm demographics, animal health and antimicrobial use. Composite fecal samples are collected and submitted to laboratories for bacterial isolation and antimicrobial susceptibility testing. The bacteria of interest in broiler chickens, feedlot cattle, grower-finisher pigs and turkey were Campylobacter, Salmonella, and generic E. coli.

Feedlot cattle

The CIPARS Farm Surveillance feedlot cattle component was initiated in 2016. Sampling is currently only being done in the Alberta FoodNet Canada site, however, expansion into a nation program is the long term objective. Feedlot cattle are sampled at close to market weight. This stage of production was selected because of their proximity to the consumer.

Broiler chickens

The CIPARS Farm Surveillance broiler chicken component was initiated in April 2013 in the 4 major poultry-producing provinces in Canada (British Columbia, Alberta, Ontario, and Québec). In 2014, due to external funding from Saskatchewan Agriculture, Saskatchewan also started to participate in the program. The Broiler Farm Surveillance component samples flocks at least 1 week before shipment for slaughter (i.e., pre-harvest stage). This stage of production was selected because it is most proximal to the consumer of all the farm production stages.

Grower-finisher pigs

The CIPARS Farm-Swine Surveillance framework was developed after extensive industry consultations and was implemented in 2006 in the 5 major pork-producing provinces in Canada (Alberta, Saskatchewan, Manitoba, Ontario, and Québec). Swine veterinarians recruited sentinel swine herds to the surveillance program. To ensure regional and national representativeness, herds were selected according to inclusion/exclusion criteria specified in the surveillance framework. Each herd was visited by the herd veterinarian, or designated technical staff, once per year to collect fecal samples for antimicrobial susceptibility testing. The Farm Surveillancecomponent concentrates on grower-finisher pigs. Pigs in this stage of production were chosen because of their proximity to the consumer.

Turkeys

The CIPARS Farm Surveillance turkey component was initiated in 2016 in the 3 major poultry-producing provinces in Canada (British Columbia, Ontario, and Québec). In 2018, the sampling was expanded to include the province of Alberta (Prairies). The turkey Farm Surveillance component samples flocks at least 1 week before shipment for slaughter (i.e., pre-harvest stage). This stage of production was selected because it is most proximal to the consumer of all the farm production stages.

Sampling methods

Feedlot cattle

Feedlot veterinarians, with feedlots in the FoodNet Canada (FNC) Alberta Sentinel site, were purposively selected from the list of veterinarians practicing feedlot medicine. Enrolled veterinarians then recruited sentinel herds to participate in this voluntary surveillance program. Enrolled feedlots were to be representative of the veterinary practice profile. The number of sentinel herds targeted for sampling is 30; which is the required number for the FNC sentinel site. To preserve the anonymity of participating producers, herd veterinarians collected the samples and data and submit coded information to the Public Health Agency of Canada.

Feedlots were visited once per year for sample and data collection. Pooled fecal samples were collected from 6 pens of cattle that were close to market weight (ideally greater than 120 days on feed and greater than 500 kg). Veterinarians were asked to distribute their sampling visits across the year to account for seasonal variations in pathogen prevalence and diseases that may drive AMU on farms.

A 1 page survey sheet was included with each sampling kit in order to collect information for both FNC and CIPARS. Data requested for each pen of cattle sampled included minimum and maximum days on feed, minimum and maximum weight of cattle in the pen, the average pen capacity, the feedlot capacity, and current inventory. Other information requested, for FNC purposes, related to water source, and water treatments.

Broiler chickens

Poultry veterinarians recruited sentinel flocks to participate in this voluntary national surveillance program. The number of sentinel flocks allocated to each of the 4 participating province/regions (British Columbia, Prairies [Alberta and Saskatchewan], Ontario and Québec) was proportional to the national total of quota-holding producers, except in the FoodNet Canada sentinel sites, where a minimum of 30 flocks were sampled. In Saskatchewan, the Saskatchewan Ministry of Agriculture provided full financial support for 14 flocks.

To preserve the anonymity of participating producers, poultry veterinarians collected the samples and data and submitted coded information to Public Health Agency of Canada (PHAC). The Canadian Hatchery Federation (CHF) and the Canadian Poultry and Egg Processors Council ensured confidentiality by holding the key to hatcheries; only the coded information was known to PHAC.

Poultry veterinary practices were purposively selected from each province. Each veterinarian recruited a predetermined number of sentinel farm sites proportional to their practice profile and availability by use of specific inclusion and exclusion criteria. To be included, farms were required to be a Safe, Safer, Safest™ compliant quota-holding broiler operations (i.e., broilers are the major commodity reared on-site but producers may also have other animal species and/or commodities). Antibiotic-free, raised without antibiotics or organic production systems were selected proportional to the veterinarian's practice profile. Veterinarians also ensured that selected farms were also representative of all the CHF hatcheries supplying chicks and representative of the feed mills supplying feeds in the province of their practice, and were geographically distributed (i.e., not neighboring flocks). Additionally, these farms were demographically reflective of the veterinary practice and overall broiler industry profile (e.g., variety of flock management: poor to excellent performing flocks, variety in volume of chicks placed: low to high flock densities). These criteria helped ensure that the flocks enrolled were representative of most broiler flocks raised in Canada. The veterinarians were also asked to distribute their sampling visits across the year to account for seasonal variations in pathogen prevalence and diseases that may drive AMU at the hatchery and on farms.

Sentinel broiler flocks were visited during the last week of growth (chickens more than 30 days of age), once per year for sample and data collection. Four pooled fecal samples, representing 1 per floor quadrant with at least 10 fecal droppings were collected from randomly selected barns and floors (if multiple level/pen barn).

Grower-finisher pigs

Swine veterinarians recruited sentinel herds to participate in this voluntary national surveillance program. The number of sentinel herds allocated to each of the 5 participating provinces was proportional to the national total of grower-finisher pig units, except in Saskatchewan, where 10 additional sentinel herds were included. Support for the 10 extra herds, was provided by the Saskatchewan Ministry of Agriculture.

To preserve the anonymity of participating producers, herd veterinarians collected the samples and data and submitted coded information to PHAC. In the case of corporate herds, confidentiality was ensured through a single corporate herd code for all corporate veterinarians, thus preventing a corporate veterinarian from being associated with a specific herd and protecting anonymity.

All veterinarians practicing swine medicine in each participating province are eligible to participate in the program. Each veterinarian selected a predetermined number of sentinel farm sites by use of specific inclusion and exclusion criteria. To be included, herds were required to be CQA®validated, produce more than 2,000 market pigs per year, and be representative of the characteristics (i.e., similar production volumes and types of production systems) and geographic distribution of herds in the veterinarian's swine practice. Herds were excluded when they were regarded as organic with respect to animal husbandry, were fed edible residual material, or were raised on pasture. These criteria helped ensure that the herds enrolled were representative of most grower-finisher pig herds in Canada.