Low-Cost Plastic/Aluminum Barrier Foil – Canadian Conservation Institute (CCI) Notes 1/9

(PDF Version, 3.24 MB)

CCI Note 1/9 is part of CCI Notes Series 1 (Care of Collections - General Guidelines)

Introduction

WoodFootnote 1 used to make supports or containers for artifacts is often sealed with commercially available aluminum barrier foils. This Note describes a low-cost method for making a similar product from readily available plastic and aluminum foil.

Use of Plastic and Aluminum Barrier Films

Wood emits volatile organic compounds that can harm some materials (such as metals); direct contact with wood can also stain objects (Tétreault ). To prevent these problems, it is generally preferable to use materials other than wood when making supports or containers for artifacts. However, in many instances wood is still chosen because it is strong, rigid, readily available, easily worked, and relatively inexpensive. If wood is used, it should be sealed to prevent unnecessary damage.

Wood can be easily (although sometimes inefficiently) sealed with paints. However, oil-based paints are not recommended because they emit high levels of organic acids, and they should certainly never be used inside enclosures (e.g. display cases or storage cabinets). Even recommended paints, which include emulsion paints (i.e. latex), two-part epoxies, two-part urethanes, and shellacs, emit some harmful organic compounds. When these are used inside enclosures, they should be allowed to dry for at least 4 weeks to allow all the possible harmful compounds to evaporate (Tétreault ).

As an alternative to painting wood, plastic-laminated aluminum foil can be applied as a seal or barrier. Plastic-laminated aluminum foil is one of the best vapour or gas barriers on the market (Burke ; Thickett ), and can be purchased from various distributors. One type commonly used by conservators is Marvelseal 360, an aluminum foil coated with nylon on one side and polyethylene film on the other. The nylon side is usually shinier than the polyethylene side and often has the brand name printed on it. Plastic-laminated aluminum foils can be adhered to wood with heat. Place the polyethylene side adjacent to the surface of the wood and then apply heat with an iron or hot spatula. Because polyethylene melts at a fairly low temperature, about 170°C (335°F), domestic irons set to the "permanent press" setting are usually adequate to fuse the polyethylene to the surface beneath. However, the heat must be applied evenly to the entire surface to ensure proper melting and good adhesion. Any holes or tears can easily be repaired by ironing a patch of the same aluminum barrier foil over the damaged area.

Another option to attach the plastic-laminated aluminum foil to wood is double-sided tape. Apply the tape in a grid pattern to ensure that the foil is attached uniformly over the entire surface area.

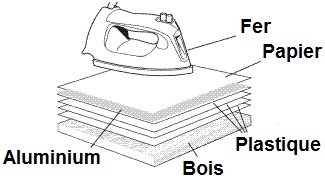

Once applied, the surface of the plastic-laminated aluminum foil is susceptible to scratches. However, because the surface is usually covered with layers of padding and fabric or matboard (Figure 1), this does not generally cause problems.

Low-Cost Alternative

A low-cost alternative to commercial products such as Marvelseal can be created using aluminum foil and polyethylene grocery bags, garbage bags, or sheeting (look for the triangle recycling logo with the letters LDPE or the numeral 4 to ensure the plastic is low-density polyethylene) (Figure 2).

To protect the aluminum foil from tearing when assembling the barrier, insert a paper sheet between the iron and the foil, as in Figure 3. If the plastic sheet is thin, up to 3 layers may be needed. Plainaluminum foil is even more susceptible to scratches than commercial products that have a nylon covering,so special care is important. However, if scratches orperforations do occur, they can be easily repaired by ironing on a patch of the same aluminum foil and polyethylene.

Bibliography

-

Bosworth, J. "Retrofitting Old Exhibit Cases: A Search for Economic and Safe Cabinetry." Exhibitionist 20 (), pp. 20–24.

-

Burke, J. "Vapour Barrier Films." WAAC Newsletter 14 (), pp. 13–17.

-

Phipps, H. "Microenclosures for Framed Collections." Exhibitionist 20 (), pp. 37–40.

-

Tétreault, J. "Oak Display Cases:Conservation Problems and Solutions."

-

Tétreault, J. Coatings for Display and Storage in Museums. CCI Technical Bulletin, Nº 21. Ottawa: Canadian Conservation Institute. .

-

Tétreault, J. "Guidelines for Selecting and Using Coatings." CCI Newsletter 28 (), pp. 5–6.

-

Tétreault, J. Airborne Pollutants in Museums, Galleries, and Archives: Risk Assessment, Control Strategies, and Preservation Management. Ottawa: Canadian Conservation Institute, .

-

Thickett, D. "Sealing of MDF to Prevent Corrosive Emissions." The Conservator 22 (), pp. 49–56.

by Jean Tétreault

Copies are also available in French.

Texte également publié en version française.

©Minister of Public Works and Government

Services Canada,

Cat. Nº NM95-57/1-9-2010E

ISSN 0714-6221