Natural Fibres – Canadian Conservation Institute (CCI) Notes 13/11

(PDF Version, 256 KB)

CCI Note 13/11 is part of CCI Notes Series 13 (Textiles and Fibres)

Introduction

Museum staff who care for textiles should have a basic understanding of the characteristics of fibres.

This Note provides an introduction to four natural fibres: cotton, flax, silk, and wool. Cotton and flax are vegetable fibres composed of cellulose. Silk and wool are protein fibres that are made up of various amino acids.

A burn test can provide basic information on fibre group, i.e. cellulose or protein, but a good light microscope is required to make a more definitive identification of a fibre.

Cellulose Fibres

Cellulose fibres are found in stems, leaves, and seed bolls of plants. Many varieties of plant fibre have been used throughout history. Hemp, jute, ramie, sisal, and coir are regularly used in various parts of the world. Cotton and flax are the most common vegetable fibres found in Western museum collections. Table 1 lists some of the properties of undegraded cellulose fibres. However, the characteristics of cellulose are altered by ageing and degradation, which is manifested in many different ways; for example, fibres are more vulnerable to light, and can weaken and change colour.

Cotton

Origin

Cotton fibres come from the seed heads or bolls of the cotton plant (genus Gossypium), a member of the Malvaceae or mallow family. The quality of cotton depends on the variety and the climatic conditions under which it is grown.

Physical Characteristics

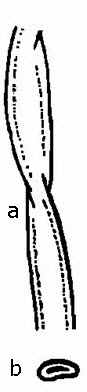

Cotton fibres are almost pure cellulose and are between 1 and 6 cm long. A cotton fibre consists of an outer cuticle, a primary and secondary wall (the bulk of the fibre), and a central core or lumen (Figure 1). Mature cotton fibres have thick walls and a small, discontinuous lumen. Mercerization (a process using caustic soda and tension) causes the fibre to swell, straighten, and become more cylindrical, thus promoting lustre, dyeability, and increased strength.

b, Cross section of cotton fibre showing central lumen.

Flax

Origin

Flax is a fibre obtained from the stem of the plant Linum usitatissimum. A considerable amount of processing is required to extract the useful fibre from the rest of the stem. After it is processed into threads and fabrics, it is called linen. The quality of flax depends on the growing conditions, the age of the plant, and fibre processing.

Physical Characteristics

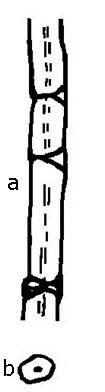

Though high in cellulose content, flax is not as pure a fibre as cotton and contains lignin, pectin, fat, and wax. Its fibre length can reach over 30 cm. The main parts of a flax fibre are the outer layer, fibre bundles or fibrils (the bulk of the fibre), and a central lumen (Figure 2).

b, Cross section of flax fibre showing central lumen.

Other causes of cellulose deterioration

- Wetting and slow drying of cellulosic textiles will cause a characteristic brown line staining, which is an area of weakness.

- Cotton and linen textiles tend to retain creases and folds. These areas may become brittle with time, requiring care in handling and storage.

- Manufacturing and finishing processes such as bleaching and dyeing may weaken cotton and linen fabrics.

| Property | Cotton Fibres | Flax Fibres |

|---|---|---|

| Strength |

|

|

| Absorbency |

|

|

| Elasticity |

|

|

| Fabric Handle |

|

|

| Resistance to acids and bases |

|

|

| Resistance to light |

|

|

| Resistance to mould and bacteria |

|

|

| Resistance to insects |

|

Protein Fibres

Protein fibres are animal in origin. These multicellular fibres are obtained from coats of mammals or are secreted by larvae of insects such as the silkworm. Hair from indigenous species of animals has been used worldwide to make textiles and garments. It can be spun into yarn, or converted directly into a non-woven textile by felting. There are many varieties of protein fibres. Silk and sheep's wool are the most common animal fibres in most parts of the world. Table 2 lists some of the properties of undegraded protein fibres. However, these properties are altered by ageing and deterioration.

Silk

Origin

Silk is a continuous protein filament produced by the silkworm when forming its cocoon. The principal species is Bombyx mori (cultivated silk). Tussah silk (produced by Antherea mylitta and Antherea pernyi moths) is darker in colour and is sometimes referred to as uncultivated or wild silk.

Physical Characteristics

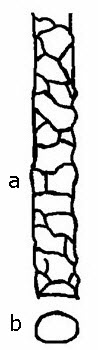

Silk fibres can be more than 2 km long. Unprocessed silk consists of two fibres of the protein "fibroin" held together with a soluble silk gum called "sericin". Sericin accounts for 10–20% of the weight of silk. Once the sericin is removed, silk separates into two filaments (Figure 3).

b, Cross section of silk fibre.

Wool

Origin

Wool is a protein fibre forming the protective coat of sheep. There are over 200 grades of sheep that produce varying qualities of wool. Merino is the finest quality of wool.

The fleece from some other animals is also used, e.g. the Angora goat (mohair), the Cashmere goat, the Angora rabbit, and members of the Camelidae family (alpaca, llama, vicuna, and camel).

Physical Characteristics

Wool fibres are sorted into various lengths for processing. Typically wool fibres are between 4 and 15 cm long, but can be as long as 38 cm. Sheep's wool consists mostly of keratinous proteins; all mammalian hair and wool fibres are similar in this respect. A wool fibre consists of a cuticle or outer layer that includes scales characteristic of the wool fibre; a cortex, which is the bulk of the fibre substance; and a medulla, the hollow central canal that may be lacking in very fine and immature fibres (Figure 4). The outer scales are important for fibre identification, and for making felt, a non-woven fabric. Often the scale pattern is altered or destroyed in very degraded fibres.

b, Cross section of wool fibre.

Other causes of protein fibre deterioration

- Deterioration of silk is accelerated by heat and moisture. When wool fibres are subjected to heat, moisture, and friction, the overlapping scales will interlock and cause irreversible matting and shrinkage (i.e. felting). Felting is considered to be a form of damage to wool fabrics if it occurs accidentally.

- Weighted silk is treated with metallic salts such as tin chloride. This process is used to compensate for the weight lost when sericin gum is removed before dyeing, and to give added body to the fabric. Weighted silk is more vulnerable to accelerated deterioration from light and air pollutants than unweighted silk. Similar deterioration can occur when silk is mordanted with metallic salts in the dyeing process.

- Both wool and silk are particularly vulnerable to damage by chlorine.

| Property | Silk Fibres | Wool Fibres |

|---|---|---|

| Strength |

|

|

| Absorbency |

|

|

| Elasticity |

|

|

| Fabric Handle |

|

|

| Resistance to acids and bases |

|

|

| Resistance to light |

|

|

| Resistance to mould and bacteria |

|

|

| Resistance to insects |

|

|

Bibliography

-

Bogle, M. Textile Conservation Center Notes Nos. 1, 2, 3, 4, 5, 6, 7, 8, and 11. North Andover, MA: Merrimack Valley Textile Museum, .

-

Burnham, D. Warp & Weft: A Textile Terminology. Toronto, ON: Royal Ontario Museum, .

-

Centre des technologies textiles. Dictionnaire des fibres et technologies textiles. Québec, QC: Centre des technologies textiles, .

-

Cook, J.G. Handbook of Textile Fibres — Natural Fibres, 5th edition 2 vols. Shildon, England: Merrow, .

-

Editors of American Fabrics and Fashions Magazine. Encyclopedia of Textiles, 3rd edition, Englewood Cliffs, NJ: Prentice-Hall Inc., .

-

Emery, I. The Primary Structures of Fabrics: An Illustrated Classification. Washington, DC: Textile Museum, .

-

Grayson, M., editor, Encyclopedia of Textiles, Fibers and Nonwoven Fabrics. Toronto, ON: John Wiley & Sons, .

-

Humphries, M. Fabric Glossary, 3rd edition Upper Saddle River, NJ: Pearson Education Inc., . [This book comes with fabric swatches.]

-

Humphries, M. Fabric Reference, 3rd edition Upper Saddle River, NJ: Pearson Education Inc., .

-

Joseph, M., P.B. Hudson, A.C. Clapp, and D. Kness. Joseph's Introductory Textile Science, 6th edition, New York, NY: Harcourt Brace College Publishers, .

By the staff of the CCI Textile Lab

Originally published

Revised ,

Copies are also available in French.

Texte également publié en version française.

©Minister of Public Works and Government Services Canada,

Cat. Nº NM-95-57/13-11-2008E

ISSN 0714-6221