LED Lighting in Museums and Art Galleries – Technical Bulletin 36

Stefan Michalski, Canadian Conservation Institute

Jim Druzik (retired), Getty Conservation Institute

CCI Technical Bulletins

Technical Bulletins are published at intervals by the Canadian Conservation Institute (CCI) in Ottawa as a means of disseminating information on current techniques and principles of conservation of use to curators and conservators of Canada’s cultural objects as well as collection care professionals worldwide. The authors welcome comments.

Abstract

Light-emitting diode (LED) lamps are in the process of replacing the incandescent and fluorescent lamps that have been used by museums and art galleries for decades, but the transition is not simple. LED lamps vary widely in the quality of light they provide, and concerns have been raised about elevated rates of damage. The majority of LED lamps on the market do not produce light of adequate quality—they do not match the quality of quartz halogen lamps or museum grade fluorescent lamps. Some LED lamps can cause up to double the rate of fading of a UV-filtered quartz halogen lamp. Fortunately, there are LED lamps available that produce high-quality light, and more are becoming available. These LED lamps cause less damage, not more, than the best lamps of the past (and much less than daylight). This Bulletin provides a definition of “good” and “excellent” LED lamps, explains the definitions, reviews the evidence on damage by all forms of lighting, and provides a step-by-step guide to LED lamp selection for both small and large institutions.

Authors

Stefan Michalski is a Senior Conservation Scientist at CCI. He earned a B.Sc. (Hons) in Physics and Mathematics (1972), trained as an objects conservator in the Queen's University Master of Art Conservation program and then joined CCI in 1979. He has created many CCI tools to help preserve collections: the Relative Humidity Control Module (1981), the Light Damage Slide Rule (1988), the Framework for Preservation of Museum Collections poster (1994) and the online Light damage calculator (2012). He wrote the temperature and humidity specifications section for the first edition of the museums chapter of ASHRAE – Applications Handbook (1999), and he contributed to its update in 2019. He was an invited contributor to PAS 198:2012, Specification for managing environmental conditions for cultural collections and is the author of CCI’s web pages on climate and lighting. In partnership with ICCROM (International Centre for the Study of the Preservation and Restoration of Cultural Property) and the Cultural Heritage Agency of the Netherlands (RCE; formerly the Netherlands Institute for Cultural Heritage, or ICN), he helped develop an international course on risk and co-authored its manual, The ABC Method: a risk management approach to the preservation of cultural heritage (2016).

Jim Druzik holds a B.S. in Chemistry. He was a Senior Scientist at the Getty Conservation Institute between 1985 and 2016, where he led research on the effect of pollutants and of light on collections. He created a full-scale gallery to study viewers’ responses to lighting. He brought the needs of museum conservation to the LED programs of the U.S. Department of Energy (DOE) and worked closely with their scientists from 2008 until 2016. Prior to his retirement, he was instrumental in the creation of the Managing Collection Environments Initiative. Before joining the Getty, he was at the Los Angeles County Museum of Art for five years and at the Norton Simon Museum from 1974 to 1980. He served in a wide variety of advisory capacities for the National Archives and Records Administration, the Library of Congress and the Smithsonian Institution.

Disclaimer: The information provided here is based on the current understanding of the issues presented. The guidelines given in this Technical Bulletin will not necessarily provide complete protection in all situations or protection against all possible adverse effects that LED lamps can cause in a museum environment.

Table of contents

- List of abbreviations

- Introduction

- What are LED lamps?

- Do LEDs provide good-quality light?

- Summary advice on the quality of light from LED lamps

- The incomplete and bumpy spectrum of many LED lamps

- Colour rendering (CRI, CIE Ra, IES Rf)

- Duv as a criterion for lamp selection

- Duv as a criterion for unacceptable lamp aging

- R9, seeing red

- Correlation of CRI with R9 and Duv

- Quality (CRI) versus energy savings (efficacy)

- Violet versus blue LED lamps

- Colour temperature and lux levels

- Historically accurate lighting, artists’ intent, fluorescent paints and optical brighteners

- Viewer preference versus correct colour

- Do LEDs damage objects and artworks?

- Heat, glare, dimmers and flicker

- A step-by-step outline for purchasing lamps

- Technical details for larger projects

- Warranties

- Lamp forms in transition

- Return on investment

- Lamp labels and markings

- Summary recommendations

- Acknowledgements

- Technical sources of information

- Bibliography

- Endnote

List of abbreviations

- µW/lm/nm

- microwatt per lumen per nanometer

- ANSI

- American National Standards Institute

- CCR

- constant current reduction

- CCT

- correlated colour temperature (or colour temperature)

- CFL

- compact fluorescent lamp

- CIE

- International Commission on Illumination

- CRI

- colour rendering index

- DOE

- U.S. Department of Energy

- Duv

- “Delta u,v” is the deviation from ideal white light (on UV coordinates)

- Hz

- hertz

- IES

- Illuminating Engineering Society

- L70

- LED lifespan

- lm

- lumen

- lm/W

- lumen per watt

- MR

- multifaceted reflector

- NBS

- National Bureau of Standards

- NEMA

- National Electrical Manufacturers Association

- nm

- nanometre

- PAR

- parabolic aluminized reflector

- PWM

- pulse-width modulation

- Ra

- colour rendering average (CIE method)

- R9

- colour rendering of 9th colour sample, red (CIE method)

- RAGB

- red, amber, green, blue

- Rf

- colour rendering fidelity (IES method)

- RGB

- red, green, blue

- SSL

- solid-state lighting

Introduction

Lamps based on LEDs (pronounced el-ee-dees) are gradually replacing all previous lamps (tungsten, halogen, fluorescent, etc.). There is concern in the museum and conservation community about whether the light from LEDs is of good quality, whether it causes extra damage to artworks and whether lamp life is as good as claimed. Many of us have been disappointed with early LED lamps bought for the home, and early adopters in museums were disappointed by LED lamps that died long before predicted. As the strange bumps in LED lamp spectra became widely known, concern mounted.

LED lamp technology is improving very quickly. The selection of directional LED lamps (spots, floods) with good-quality light has increased in just the last five years from a handful to dozens and will eventually become the norm rather than the exception. In order to keep this text relevant for more than a few months, the emphasis is on the why and how of LED lamp selection, rather than on specific models.

The majority of LED lamps on the market in 2018 did not meet the criteria for good or excellent light, but there is a growing minority of such lamps that do meet these criteria and also offer the long life and energy savings that justify switching to LEDs. LED lamps that provide good or excellent light do not cause extra damage to objects. This Bulletin explains the phenomena that distinguish good LEDs from bad ones and provides a step-by-step process for the selection and purchase of good lamps by museum and conservation professionals.

What are LED lamps?

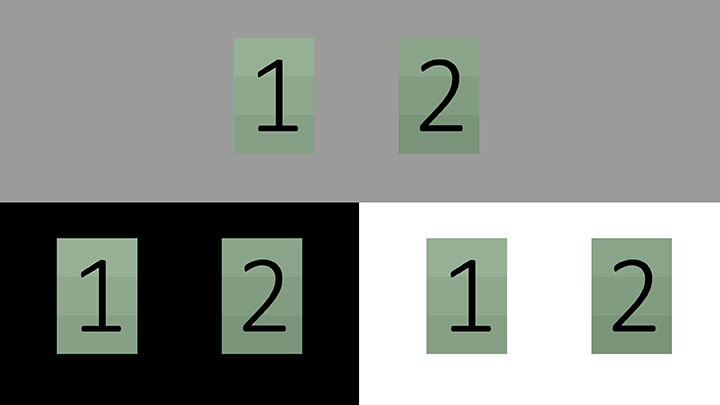

LED lamps are complex assemblies which comprise light-emitting diodes, phosphors, electronics and a housing. Some are designed to be part of a whole new installation of lamps and specially designed fixtures. Others are intended as replacements of older lamps, so the housing is designed to fit in the same fixtures as the older lamps (for example, a round bulb, a parabolic aluminized reflector [PAR] spot lamp, an MR16 [multifaceted reflector] low-voltage lamp or a fluorescent lamp). The most notable and unfamiliar feature of LED lamps is their elaborate cooling fins, as seen in Figure 1.

© Government of Canada, Canadian Conservation Institute. CCI 122894-0001

Figure 1. Top and front views of a pair of directional LED lamps (MR16, 12-V) with their plastic lenses disassembled. The small yellow patches are individual white LEDs; the phosphor layer has a yellow colour when the lamp is off.

LEDs produce coloured light

An LED can only produce strongly coloured light (a narrow band of wavelengths). Making white light with coloured LEDs requires some trickery. It is this fact that remains at the heart of all debates over the quality of LED lighting. The first LEDs were red, only capable of very low light levels and used as indicator lamps. The development of practical white lighting based on LEDs required more colours (green, then blue) as well as much higher light outputs—problems that were not solved until the 1990s.

Different ways to make white LEDs

Strictly speaking, there is no such thing as a “white” LED, but the term is used informally to mean a device that produces white light using LEDs. There are three methods of making white light from coloured LEDs:

- Phosphor-based: A single LED, either blue or violet, shines its light on a layer of phosphors which fluoresce in the green to red region. The LED is called the “pump” because it pumps energy into the phosphors. The principle is identical to that of fluorescent lamps, which use ultraviolet (UV) radiation from excited mercury vapour to pump the phosphors. The phosphor layer in an LED lamp is designed to allow some of the blue or violet light to escape, so that the final mix of light from the LED pump and the phosphors is white (that is, all the colours of the rainbow). Some manufacturers mix warm and cool white LEDs together to produce a neutral white colour. In Figure 1, the small yellow patches in each lamp are the phosphor layers on top of blue LEDs.

- Additive LEDs: These use no phosphors, but only a mix of red, green and blue (RGB) LEDs, which match more or less the three colour receptors of our eyes. This is the same RGB principle that is used in triphosphor fluorescent lamps. Some additive designs add an amber LED to become red, amber, green and blue (RAGB) designs.

- Hybrid: Some LED phosphor-based lamps with a blue pump add a red LED to compensate for weak red output from the phosphors.

The majority of white LED lamps on the market in 2018 were phosphor-based, and of those, most used a blue pump. Consult Do LEDs provide good-quality light? for more details on spectral issues of LEDs.

One LED lamp = one housing + one or more white LEDs + electronics

Each LED lamp (Figure 1) consists of a housing, one or more white LEDs and electronics to feed the correct electrical current to the LEDs. The housing plays an essential role in keeping the LED and the electronics cool, so it is made of metal for good heat conduction and is usually covered with fins to aid heat transfer to the air. The long lifetime of LED lamps depends on keeping both the electronics and the LEDs below a damaging temperature, typically 80°C.

There are only a few manufacturers of LEDs worldwide but many manufacturers of lamps based on LEDs. Whereas the manufacturer of the LED determines the quality of the light produced, the designer and manufacturer of the lamp determine almost all the other practical characteristics, such as lifetime (which depends on the operating temperature as well as the reliability of the electronics), the uniformity and distribution of the light beam, the efficiency of light usage and the control of glare.

As of 2018, most LED lamps consisted of several white LEDs, because the maximum output of each one is small, but this is changing. In Figure 1, both lamps produce similar light output, but the lamp on the left uses 12 individual LEDs, whereas the lamp on the right uses only 1. LED spot lamps in small forms such as an MR16 or PAR20 have only become possible with the advent of high-power LEDs, because the light source must be much smaller than the reflector or lens if one wants to produce a narrow and well-defined beam.

Lamp lifetime

LED lamps “die” in several different ways. Some die suddenly, within a few thousand hours, due to failure of the electronics or the LEDs. Others drift badly away from high-quality white light. (Consult Do LEDs provide good-quality light? for more information.) These are the unacceptable failures one wants covered by a warranty. The majority just fade away (the LEDs lose brightness), thus one must decide what amount of dimming is “the end” and cause for replacement. The convention for defining LED lifetime is 70% of original brightness, abbreviated as L70.

The lifespan (L70) of LED lamps is so much longer than all previous lamps (Table 1) that it changes the way one thinks of bulb replacement. Instead of the twice-a-year replacement needed for halogens, LED lamps will need changing just once a decade. Long lamp lifetime offers several advantages to museums, not just the reduction of labour but also the reduction of the risk to collections due to accidents during lamp changes.

| Lamp type | Average lifetime hours | Lifetime at 12 h per day, every day | Lamp failures per 100 lamps, assuming lamps fully mixed in age (ignoring premature failure) |

|---|---|---|---|

| TungstenTable 1 footnote 1 | 750 to 1500 | About 3 months | About 8 per week |

| Tungsten-halogenTable 1 footnote 1 | 2000 to 2500 | About 6 months | About 4 per week |

| Fluorescent, CFLTable 1 footnote 2 | 6000 to 12,000 | About 2 years | About 1 per week |

| White LEDsTable 1 footnote 3 | (L70) 20,000 to 50,000 | About 8 years | About 1 per month |

Table 1 Notes:

|

|||

Lumen output (brightness of LEDs)

Initially, white LEDs only came in low lumen (lm) ratings, often as low as 50 lm. For the museum situation of low-intensity lighting at close quarters (such as in display cases), this was a boon. For lighting at a distance from high ceilings, it was a problem. Those who considered LED lamps in 2011 faced problems finding ones with sufficient intensity, not to mention good-quality light. Today, most manufacturers provide reliable advice on which LED lamp to use when replacing a particular size of incandescent lamp. More sophisticated users can rely on the lumen and beam intensity data provided by manufacturers.

Why warranties matter

To make good LEDs, manufacturers must select phosphors with the right spectrum, arrange the phosphors and the blue (or violet) LEDs so that the correct portion of the LEDs is absorbed by the phosphors, manufacture them in large quantities that are identical and make sure the mix remains stable as the lamp ages. To make reliable lamps, the manufacturers must source reliable white LEDs, add a reliable driver (the electronics in the base of the lamp), then assemble everything inside an envelope that can keep the LEDs and electronics from overheating (hence the elaborate fins on most LED lamps). Each of these steps is imperfect, and the degree of imperfection varies between manufacturers. This complexity is much greater than that of traditional lamps, and the industry is still learning how to get it right, so warranties are important. To maintain a warranty, the user must install the lamp in a fitting and in a location that both allow proper cooling (that is, in a manner acceptable to the manufacturer).

Do LEDs provide good-quality light?

Yes, the best LED lamps do produce good-quality light, but they are in the minority. The majority produce mediocre light just above legislated minimums. This means, unfortunately, that museums and art galleries must take some care when choosing LED lamps. This is not a new issue for museums. Poor-quality light from LED lamps was preceded by poor-quality light from fluorescent lamps; but, as with fluorescent lamps, there are LED lamps that produce excellent-quality light. This section begins with the summary of our advice on selecting such lamps and then provides the technical details behind that advice.

Summary advice on the quality of light from LED lamps

We define two levels of light quality for museums and art galleries: good and excellent. We consider “good” as a minimum acceptable for viewing objects well in museums and art galleries, and we consider “excellent” as a reasonable aspiration.

First, a brief explanation of the technical parameters. For further details on each, consult the next sections.

- CRI (colour rendering index): measures how correctly a set of eight standard pastels appears under the lamp as compared to under an ideal white light source, where incandescent lamps are considered ideal for warm white sources and daylight is considered ideal for cool white sources. The maximum CRI score is 100. CRI is the most widely used measure of light quality in the industry and the easiest to obtain. Note that some product literature uses the term Ra rather than CRI. Ra and CRI are the same parameter. However, Ra and R9 are not the same parameter.

- R9: measures how correctly a deep red sample appears under the lamp as compared to under ideal white light. Although eight pastels are used to determine the overall CRI score, an additional set of saturated colour samples is also available. Of all the saturated colours used in the test, red (labelled R9) is the most difficult colour for most LED lamps and most fluorescent lamps to show well, even if their CRI score is high. The R9 score has become a practical indicator of the best LED lamps among those already scoring well on the average CRI.

- Duv: measures deviation of the light from ideal white, towards either a pink tone (negative number) or a green tone (positive number).

- CCT (correlated colour temperature of a light source, often shortened to colour temperature): refers to the temperature of a hot object that would emit the same kind of white light. It is measured in degrees Kelvin (K). An unfortunate confusion arises in terminology since “warm” light has a lower colour temperature and “cool” light has a higher colour temperature.

Here are our definitions of good-quality and excellent-quality light. (Energy Star is provided for reference.)

Excellent-quality light: CRI at least 90. R9 at least 90. Duv at purchase within a range between −0.003 and +0.003. Traditional incandescent lamps and halogen lamps meet these criteria.

Good-quality light: CRI at least 90. R9 at least 50. Duv at purchase within a range between −0.003 and +0.003. These CRI and R9 targets were also proposed in the 2012 draft of the Voluntary California Quality LED Lamp Specification (Flamm et al. 2012), but by the time of final ratification in 2016, this specification had dropped to a CRI of 82 and made no mention of R9 (Pasha et al. 2017). The CRI target of 90 has recently been proposed for a new Japanese standard on museum lighting (Yoshizawa et al. 2017).

We have discovered that with current technology, LED lamps with a CRI of 90+ will have a Duv that falls within specification. So a Duv specification becomes an unnecessary complication for most users and has been dropped in our advice in Summary recommendations. The Duv specification remains of value as a failure criterion during lamp aging.

Energy Star 2017: CRI at least 80. R9 over 0. Duv at purchase within a range between −0.006 and +0.006. Duv change over time not to increase or decrease by more than 0.007; Duv uniformity across beam not to exceed −0.006 or +0.006 (DOE 2017). This is the most widely used standard for general-purpose LED lamps in Canada and the U.S. In terms of CRI, R9 and Duv at time of purchase, we do not consider this specification to be adequate for museum and art gallery lighting, but its criteria for lamp stability over time are useful as a minimum acceptable performance under warranty. For museum and art gallery areas not displaying objects, where energy savings may be the priority, lamps below the good category but with Energy Star designation might be acceptable.

Colour temperature is a matter of preference, not quality. Our only recommendation is that one use the same colour temperature for all lamps within a given space. The longstanding belief that at museum lux levels of 50 lux to 200 lux, viewers always prefer warm light (2800 K to 3000 K) has been shown to be false. Colour temperatures as high as 5000 K may be preferred in some situations. Manufacturers have not responded fully to this new information, and the colour temperature of quartz halogen lamps (3000 K) is still the target of many manufacturers producing good and excellent LED lamps for the museum market. For those who do not wish to experiment with colour temperature, 3000 K is still a pleasant all-purpose choice for museum lighting. This issue is discussed further in the section Colour temperature and lux levels.

The incomplete and bumpy spectrum of many LED lamps

The undeniable elegance of incandescent lamps, both traditional and halogen, rests not only on their simplicity but also on the fact that they produce light in the same way as the sun’s surface, by making something hot enough to glow “white hot.” Unfortunately, incandescent lamps convert only a small fraction of the electricity supplied into light; the rest is lost as heat and infrared radiation. In addition, the life of the filament is short, hence the search for more efficacious and longer-lived lamps, such as fluorescents and LEDs. But efficacious lamps too often distorted colours, so they acquired a bad reputation.

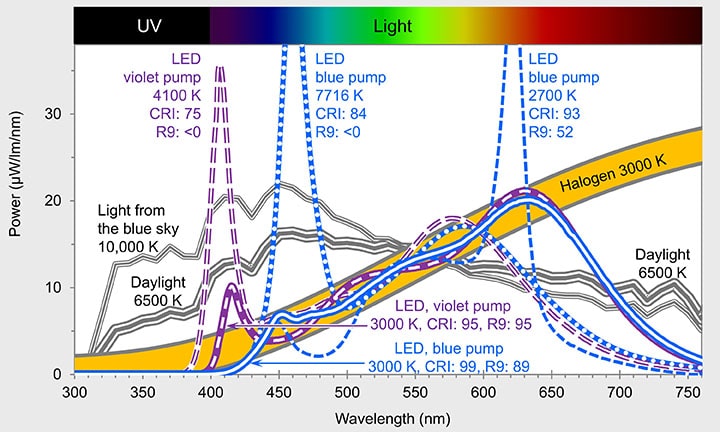

© Government of Canada, Canadian Conservation Institute. CCI 122894-0003

Figure 2. UV and light spectra of five white LED lamps of different quality, compared to the benchmarks of daylight (triple grey lines) and of a halogen lamp (wide orange line).

Description of Figure 2

Figure 2 contains a single graph, which shows the spectra of nine light sources. The x axis is wavelength, from ultraviolet at 300 nanometers to visible light up to 760 nanometers. The y axis is power, microwatts per lumen per nanometer. The spectrum of a quartz halogen lamp is shown as a broad orange line. Two of the spectra are for daylight and light from the blue sky. The remaining five spectra are for LED lamps, three of which have very large spikes that reach or exceed the top of the graph.

Figure 2 plots spectra of five LED lamps of various quality. The “LED, violet pump, 3000 K, CRI: 95, R9: 95” is an excellent lamp, with a small peak at 415 nm due to its violet pump. The “LED, blue pump, 3000 K, CRI: 99, R9: 89” is a good, almost excellent, lamp, with almost no bump due to its blue pump at 450 nm. There are three LED lamps with obvious spikes. Two have very poor R9, less than zero, one with a big violet spike, the other with a big blue spike—both are completely lacking in red output. The lamp “LED, blue pump, 2700 K, CRI: 93, R9: 52” (thin blue dashed line) just passes as a good source with the use of a red LED to boost the anemic phosphor output. It is included as an example for later calculations of possible damage from large red spikes in the spectra of LED lamps.

Spectra of the benchmark sources are provided for comparison: daylight (triple grey lines) and halogen 3000 K (wide orange line). The daylight spectra are published standards, representing outdoor light unfiltered by window glass. The halogen represents an ideal halogen lamp with no glass cover, calculated from tungsten at 3000 K. Actual halogen lamp spectra are slightly reduced in the UV and far red, depending on the thickness and tint of the glass envelope. The LED spectra are measurements of actual lamps or modules sold to luminaire makers. These spectra and more are used to calculate damage in Do LEDs damage objects and artworks?

The complex and still unsettled science of metrics for “good” white light can be broken into two parts: (1) what are the benchmark sources of light and (2) what are the essential characteristics of those benchmark spectra that imperfect sources must match?

- For the first part, one reasonably assumes that daylight is the benchmark, and since daylight varies (triple grey lines in Figure 2), the key must be whatever is invariable in those two spectra. One need only inspect them to note that aside from some minor ripples, they are both complete and smooth.

Our visual system evolved to see things as having constant colour despite changes in light due to time of day or the shade, but simultaneously to know that the light has indeed changed, not from correct to incorrect, but from cool to warm, bright to dim and back again. The only characteristic of these benchmark spectra that does change is their slope, measured in terms of the temperature of a glowing object that creates a spectrum with the same slope, hence “correlated colour temperature.” Incandescent lamps (such as the much-loved halogen lamp at 3000 K, the wide orange line in Figure 2) have also been defined as benchmark sources, an extension of the family of smooth and complete daylight spectra, albeit with a colour temperature that daylight reaches only near sunrise and sunset. - The simplest answer to the very difficult question about essential characteristics of good-quality light is that it must only replicate the benchmarks (be complete and smooth and within the range of colour temperatures that our eye still sees as white, which begins to diminish below 2700 K). One notes in Figure 2 that the best LED lamps in terms of CRI and R9 do come close to replicating the 3000 K benchmark (wide orange line). They are relatively smooth, but not quite complete at each end of the spectrum.

The day someone invents a lamp that is not hot to the touch (high efficacy) but which replicates the benchmark spectra in the visible band and has a competitive price, advice such as this will be unnecessary. Until then, the question remains: what is good enough and how can it be measured with just one or two numbers for consumers?

Colour rendering (CRI, CIE Ra, IES Rf)

The primary measure for the quality of light from a lamp is called colour rendering. To determine colour rendering, colourimetric calculations are made for a set of coloured samples illuminated by the lamp and illuminated by a reference source such as daylight. If there is no difference in the results from the lamp and that from the reference, then the lamp “renders” that sample well and scores 100. Points are lost depending on the size of the colour difference between the lamp and the reference. The final score is an average of the scores across all samples in the set.

Since 1974, the industry standard for calculating colour rendering has been the method developed by the International Commission on Illumination (CIE). This method uses fourteen colour samples. Eight are pastels. Their average colour rendering (Ra) by a light source defines the colour rendering index (CRI) of that light source. The six other colour samples are saturated colours and are used for individual colour rendering calculations. The most important of these is a saturated red, called R9. The CIE method for calculation of CRI remains the worldwide convention for lamp specifications. The CRI score is sometimes on the lamp carton and always available online from the distributor or manufacturer.

In the past, for fluorescent lamps, CCI recommended a minimum CRI of 85 and stated that a CRI of 90 or above was preferable. Acceptance of a CRI below 100 (below what benchmark lighting provides) has always been a compromise between the technology of the time and energy savings, mediated by the imprecise business of what discrepancies are perceptible in what situations with what colours and by whom. Given current LED technology, and the growing availability of very high-quality LED lamps, we have shifted to recommending a CRI of 90 and above.

In 2015, a new method for characterizing colour rendering, known as TM-30-15 (Royer and Houser 2015), was adopted by the Illuminating Engineering Society (IES). The method follows the same approach as the CIE above but uses a much wider selection of samples (99) and more modern colourimetric equations, in addition to other improvements. The score equivalent to the CIE Ra is called “rendering fidelity,” or Rf, and as with Ra, establishes 100 as the score for perfect rendering. The IES method also proposes a second parameter derived from the calculations on the 99 samples called “gamut.” Since the IES method promotes two parameters, not just one, the notion of a single CRI has been dropped, but for museum purposes of high-quality light, we focus on fidelity. For lamps with fidelity approaching Rf = 100, gamut does not vary anyway, so it tells us nothing extra. Gamut does become variable, and of interest to the designer, when fidelity falls substantially below 90. From a positive perspective, it allows one to select lamps of a particular gamut to intensify particular ranges of colour in particular situations, which viewers may prefer (Royer and Houser 2015). From a negative perspective, gamut simply calibrates the colour distortions that become feasible when fidelity is mediocre.

Expectations in the industry, especially in the western hemisphere, are that the IES method will supplant the CIE method in the coming years; however, CIE has stated: “Rf, is…not a replacement of the general colour rendering index, Ra, neither for the purpose of rating and specification of products nor for regulatory or other minimum performance requirements. Replacement of the CRI will be a matter of future study and discussion.” (CIE 2017)

Fortunately, for our purposes, such discussion becomes contentious only for lamps that are far from perfect. It will not change our definitions of good and excellent significantly since CRI and Rf scores converge as they approach 100. Conservatively, we can simply replace CRI by Rf in our definitions of good-quality and excellent-quality lamps. Preliminary studies (Royer and Houser 2015) show that LED lamps that score CRI over 90 tend to score an Rf of 3 to 5 points lower. As expected, Rf is a tougher measure than CRI. Its purpose, in fact, was to reduce the ability of LED manufacturers to design lamps that could do well on the eight colours for CRI but little else. A second CIE measure called “R9” is our current tool to confirm that a high CRI really does mean good rendering for museums and art galleries (consult R9, seeing red).

Duv as a criterion for lamp selection

Duv is a measure of the deviation of a light source from white light, with zero as perfectly white. (Download LED Color Characteristics [PDF format] for further information.) Whereas a difference in the overall slope of a spectrum (that is, a difference of colour temperature) only changes our perception of whether the light is warm white or cool white, waves and missing bits in the spectrum can make the light look slightly green (positive Duv) or slightly pink (negative Duv). If you have ever seen a long office or hallway with a mixed set of mediocre and aging fluorescent lamps, you have seen this range of green and pink tones. While this was never an issue with incandescent lamps, it became one with fluorescent lamps and is now one with LED lamps.

More important than how the lamp looks, a Duv number far from zero means that the colours being illuminated are not seen correctly. Although recent research suggests users may actually prefer a slightly pink output (Duv of −0.003) for LED lamps below 3200 K, our concern here is conservative—simply to specify a maximum deviation (between −0.003 and +0.003) from what is considered the ideal white.

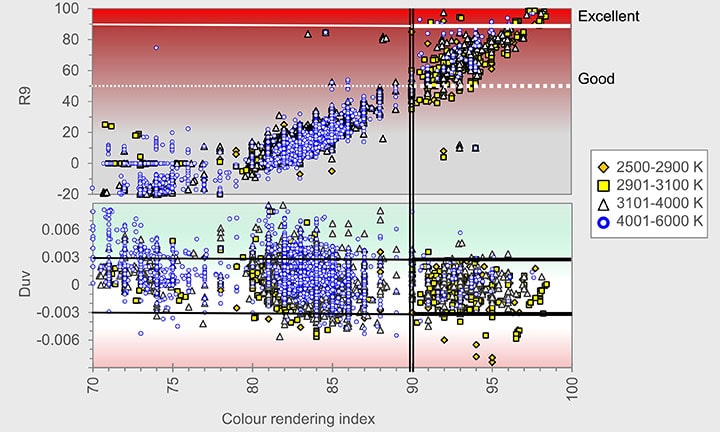

© Government of Canada, Canadian Conservation Institute. CCI 122894-0005

Figure 3. The dependence of R9 and Duv on the CRI of 8818 LED lamps and luminaires meant for indoor use. Data from the LED Lighting FactsEndnote 1 database of June 2018.

Description of Figure 3

Figure 3 contains two graphs, one above the other, sharing the same x axis, which is the CRI. Both graphs contain a single large cloud of many data points representing LED lamps. The data points are identified as one of four ranges of colour temperature. In the upper graph, the y axis is R9. The cloud of data extends from the bottom left corner to the upper right corner and is relatively narrow. In the lower graph, the y axis is Duv, and the data cloud is horizontal, covering most of the graph.

The LED Lighting Facts database (consult endnote 1) collects voluntary information from manufacturers on their products. Figure 3 shows the data from June 2018 for lamps and luminaires meant for indoor use, that have a CRI above 70, that were tested for Duv and for R9 and that have a CCT between 2500 K and 6000 K (8818 LEDs). In the bottom graph of Figure 3, the band of acceptable Duv (between −0.003 and +0.003) is defined by the two black horizontal lines. For CRI greater than 90 (to the right of the vertical double line), there are 872 LEDs, of which 97% fall within this acceptable Duv band. We can conclude, therefore, that with current LED technology, any lamps with CRI above 90 will have a 97% chance of having an acceptable Duv. The few terrible Duv scores, lower than −0.006, only occur in the CCT range of 2500 K to 2900 K, so it is best to avoid this overly warm range of CCT.

The great majority of LED lamps with CCT above 4000 K (blue circles) cluster in the CRI range of 80 to 85. They are designed to just meet the Energy Star standard (CRI = 80), and their Duv range expands from the −0.003 and +0.003 that museums need to the ANSI tolerance of −0.006 and +0.006.

Duv as a criterion for unacceptable lamp aging

The primary purpose of specifying Duv in a museum or art gallery lighting program that wants good or excellent lighting is establishing what is unacceptable aging. Stability is a very important quality for a lamp that is expected to function for the next decade or two, especially a lamp that just fades away rather than dying in the sudden and unambiguous way of incandescent lamps.

A small but significant fraction of LED lamps tested over time have shown a rapid drift of Duv to unacceptable values within 10% of the supposed lifetime of the lamp. Of course, CRI will have probably become unacceptable as well, but a poor Duv is much easier to see than a poor CRI, especially when the lamp is adjacent to lamps with good Duv. With reputable suppliers of reputable lamps, if some lamps fail visibly, one does not expect to need an expert with the tools to confirm the unacceptable Duv. Lamps that claim an Energy Star specification must conform to the following: after 6000 hours of operation, the Duv of 9 out of 10 samples of the lamp will have increased or decreased by less than 0.007.

R9, seeing red

A third measure for quality of light from a lamp is CIE R9, usually stated simply as R9. It is the colour rendering score (hence the “R”) of the ninth colour card in the series of fourteen used in the CIE method for colour rendering measurements. Number 9, a saturated red, has been singled out as an acid test of LED lamps because

- red is the most difficult colour for LED lamps to render well, and

- red is important not only for seeing reddish things well, but also for seeing our own skin well.

Many collections from numerous cultures require that red and brown tones be seen well (for example, artwork with the human figure, textiles, military collections, industrial collections and natural history collections). The same points were made in the staff report for the initial Voluntary California Quality LED Lamp Specification: “…high R9 value indicates improved rendition of important common materials (skin tones, earth tones, woods and vibrant red colors)…. Also…manufacturers wish to distinguish ‘good’ LEDs from ‘bad’ LEDs, and from typical triphosphor T8 lamps, which do not render the R9 color well.” (Flamm et al. 2012)

We consider the minimum acceptable R9 for museums to be at least 50 (good) and recommend that museums and art galleries strive for an R9 of at least 90 (excellent), especially if reds are important to the collections. In technical specifications, R9 is not stated as often as CRI, but manufacturers who go to the effort of making a lamp with high R9 will always make the R9 score a feature of their advertising. Conversely, if they hide it, there may be a reason. R9 values can be found in the LED Lighting Facts database (consult endnote 1) for many, though not all, lamps. Consult the Acknowledgements and Bibliography sections.

In Figure 3, the relationship between CRI and R9 is plotted for all the indoor LED lamps for which R9 measures were available in the LED Lighting Facts database (consult endnote 1). The general trend is clear: CRI and R9 get better together (top right corner) and get worse together (bottom left corner), but excellent CRI (to the right of the double black line) does not guarantee a good R9 (above the dotted white line), let alone an excellent R9 (above the solid white line). However, one can successfully turn the logic around: a good R9 score (above the dotted white line) almost always gives a CRI above 90, and an excellent R9 score (above the solid white line) guarantees that CRI is well above 90. And if CRI is above 90, then Duv is within our recommended values.

Thus, for a very simplified recommendation regarding museum-quality LED lamps, one can drop the reference to CRI and Duv and state the following: choose lamps with an R9 of at least 50 for good lighting and at least 90 for excellent lighting. Note: one should still confirm the Duv and CRI values, just in case the lamp is some new and strange technology for red lamps.

Figure 3 also shows that as of 2018, LEDs with good and excellent R9 tended to be made with a colour temperature below 4000 K, whereas LEDs made with a colour temperature above 4000 K (blue circles) clustered in the CRI range of 80 to 85, with R9 dropping to an average of 20.

Correlation of CRI with R9 and Duv

The fact that there are many variations on mediocre spectra but only one kind of ideal spectrum (smooth, complete and a slope like some kind of daylight) explains the narrowing of the cloud of data points on the Duv plot as it approaches the right-hand side of the graph in Figure 3. If CRI or its eventual replacement, Rf, approaches the ideal of the benchmark light sources (100 at the right-hand side of the graph), then all other parameters that capture some part of the colour vision puzzle must also approach their ideal (Duv must collapse to 0, R9 must approach 100). Since R9 measures only part of the spectrum, and CRI averages all of it, R9 can fall far from 100 even as CRI gets close to 100 (Figure 3). This is true of all other sample colours too, but for lamps dependent on fluorescence, like most LED lamps, far red, R9, is the most difficult. Hence the role of R9 as a top indicator for excellence.

The good news for museums and art galleries is that manufacturers of LED lamps of excellent CRI are well aware of the growing demand for R9, so they are taking the extra steps to add high R9 to their best lamps and to their marketing.

Quality (CRI) versus energy savings (efficacy)

The term for how well lamps turn electricity into light is “efficacy.” (The term “efficiency” has a different use in lighting technology.) LED manufacturers are still looking for the optimal design of both high efficacy and high quality of light. We can expect rapid development in the next few years, but currently, the bulk of LEDs on the market suffer the same compromise as fluorescent lamps and compact fluorescent lamps (CFLs): marketing favours high efficacy and low price. Quality of light comes a distant third.

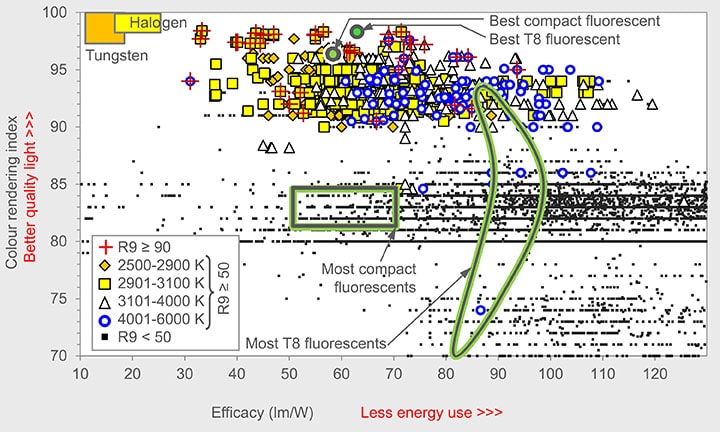

© Government of Canada, Canadian Conservation Institute. CCI 122894-0007

Figure 4. CRI and efficacy of LED lamps and luminaires (indoors) with a CRI over 70 and a measured R9 (10,497) from the LED Lighting Facts database of June 2018 (consult endnote 1). “Most T8 fluorescents” are from a study of 121 lamps (Gribbin and O’Rourke 2006); other fluorescent lamp data comes from manufacturers’ catalogues.

Description of Figure 4

Figure 4 contains a single graph plotting thousands of LED lamps in terms of their efficacy on the x axis, in units of lumens per watt (lm/W), and their CRI on the y axis, between 70 and 100. There are two main clouds of data points: one cloud is near the top third of the graph, with a CRI in the range of 90 to 100 and an efficacy in the range of 30 to 120 lm/W. Four categories of colour temperature are identified within this data cloud. A second cloud of data points, larger and more scattered than the first, covers the lower two-thirds of the graph. These are LED lamps with R9 below 50. The general location of incandescent and fluorescent lamps are also shown.

In Figure 4, in the top left corner, is a yellow box representing quartz halogen lamps: CRI near 100 and an efficacy around 20 lm/W. The black dots plot LEDs with an R9 below 50, the cut-off for good-quality light. These LEDs have high efficacy, starting around 80 lm/W and extending beyond 130 lm/W (data beyond 130 lm/W is not shown), but the CRI is mediocre, in the range of 80 to 85. The large data points without a red cross are good-quality LEDs, R9 between 50 and 89. Most have an efficacy in the range of 50 to 80, and thus require 2 1/2 to 4 times less electricity than a quartz halogen lamp to produce the same light.

The large data points with a red cross inserted are excellent-quality LEDs, R9 above 90; most have an efficacy between 40 and 80, so they use two to four times less electricity. Note that most have a colour temperature in the range of 2901 to 3100 K (yellow squares). Each year, more high-quality and high-efficacy LEDs reach the market, and we can expect it to become easier for museums to find what they need.

It is important to note that there are more excellent LEDs than indicated in Figure 4. Some companies known to supply high-quality LEDs have not entered their data in the LED Lighting Facts database (consult endnote 1).

Looking at Figure 4, one might wonder whether the best LED lamps are any improvement over the best fluorescent lamps. If the situation calls for area or wall wash lighting, and if energy costs are paramount and one is content with the high colour temperature (usually 5000 K) of high CRI fluorescent lamps, then waiting until LED lamps surpass this performance does make sense. The big practical difference between good-quality LED lamps and good-quality fluorescent lamps is that the LED lamps come in the reflector forms and smaller sizes that museums need. And as a big added bonus, LED lamps do not need UV filters and can be dimmed.

Violet versus blue LED lamps

The majority of LED lamps in 2018 used blue LED pumps, resulting in a bump in their spectra at ~450 nm to ~460 nm (for example, the three spectra in Figure 2 for LED lamps that use a blue pump). The “LED, blue pump, 3000 K” lamp in Figure 2 that scores as good, almost excellent, has almost no blue peak left. The manufacturer has carefully balanced the amount of blue light absorbed by the phosphors with the amount escaping.

CRI is not strongly affected by the absence of violet and R9 is not at all affected, so violet has not played a role in the discussion of light quality metrics to date; nevertheless, it has been known since the development of fluorescent lamps that the accurate differentiation of near-white colours requires violet light. For example, the subtle difference in appearance of the white paints used by artists over the centuries—lead white, zinc white and titanium white (warm to cool whites, respectively)—will diminish, maybe disappear, if violet is missing from a light source spectrum (Wei et al. 2014). For the same reason, the perceived change due to treatments such as varnish removal will also diminish if violet light is missing. If such distinctions are important to your collection, a violet pump LED should be included in any comparisons of lamps prior to purchase. As to the issue of UV damage, consult Do LEDs damage objects and artworks?

Colour temperature and lux levels

The CCT of a light source refers to the temperature of a hot object that would emit the same kind of white light. It is measured in degrees Kelvin (K). An unfortunate confusion arises in common terminology since “warm” light has a lower CCT and “cool” light has a higher CCT. For lamps based on a glowing filament, the colour temperature of the light is simply the temperature of the filament, about 2800 K for traditional incandescent lamps and 3000 K for quartz halogen lamps. The sun radiates at about 5900 K, but daylight varies from 3000 K to 10,000 K, depending on the time of day and cloud cover. Our visual system evolved to accommodate this wide range of colour temperatures and to still see the colours of the world as constant, more or less. The question of which CCT is best for museum lighting, and how much it matters, is complicated.

With the advent of fluorescent lamps in the 1950s, manufacturers were no longer restricted by the maximum temperature of an incandescent filament; they could simulate daylight and every other CCT in between it and an incandescent filament. Since then, advice has relied on a graph known as the Kruithof curve. It indicated that people preferred warm light (2800 to 3000 K) when illumination was at the low levels of museums (50 to 200 lux). This was a convenient conclusion for museums since incandescent (2800 K) and quartz halogen (3000 K) lamps operated in this range. The majority of LED lamps still cater to these two traditional temperatures (Figure 3), but since LEDs can be made at any CCT, the question of what is best for museums is once again under examination. Boyce and Cuttle (1990) studied “pleasantness” of the space and the ability to discriminate colours, and they found no significant relation to CCT. A recent literature review simply concluded that the Kruithof diagram had been misunderstood and that no relation at all had been shown between lux level and CCT preference in subsequent studies (Fotios 2017).

Of particular interest to heritage institutions is a rapidly growing group of studies that have examined preferences for the lighting of paintings in a gallery. In terms of lux levels, all authors find that people prefer the brightest light offered during the test, which is not surprising given our ability to see smaller and smaller details as light intensity increases up to full daylight (reviewed in Michalski 1997). The good news is that careful examination of the data shows that almost all the “pleasantness” reported at 600 lux had been achieved by 200 lux (Loe et al. 1982; Szabo 2017; Zhai et al. 2015). Studies that examined the 30 to 200 lux range in detail showed that over half of the pleasantness observed at 200 lux was achieved by 100 lux, and that the big jump in pleasantness occurred between 50 lux and 100 lux (Loe et al. 1982; Szabo 2017). Unfortunately, none of these studies framed preference judgements in terms of the dilemma that museums face: to either preserve artworks or provide access to today’s visitors. That is why the question should be: supposing that some colours in this painting will change noticeably in 200 years at 50 lux, in 100 years at 100 lux, in 50 years at 200 lux, etc., which lux level do you prefer today?

What about colour temperature preference? Unfortunately, the studies do not agree, partly because they asked the question in different ways. Zhai et al. (2015) found that “comfort” of the space was best at 2850 K, whereas the “definition” of the artworks was best at 6500 K. They conclude that “a low CCT around 3500 K would generate a positive perception for the majority of the scales investigated.” Szabo (2017) found that “pleasantness” was highest between 4000 K and 5000 K for all lux levels from 30 lux to 600 lux, although the changes in pleasantness with CCT were insignificant for 30 lux and 50 lux. Nascimento and Masuda (2014) examined 200 lux lighting and found that preferences centred on 5700 K, but the data also showed big differences in preferred CCT between the seven observers and eleven paintings. Pridmore (2017) argues that colourimetric calculations alone support 5000 K as the best balance between warm and cool colours.

In summary, it does appear that our eye is optimized to the intensity and the colour temperature of average sunlight (5000 to 6000 K), as one might expect, but it is also very well established that we like warm lighting and that our eye can adapt to see colours “correctly” in such lighting. The answer to the question of which CCT is best for low-level museum lighting has shifted from “only warm light is successful” to “warm light is pleasant but cooler light (5000 K) may be better for seeing some objects.”

Museums have other considerations besides allowing for paintings to be viewed in a neutral space. In historic buildings, especially for decorative arts, one may want to replicate the warm light of historic lighting. Most people prefer the appearance of human skin tones in warm light.

In conclusion, our current best advice is to test lamps with various colour temperatures in situ and to select the one that you and your colleagues prefer for the type of objects on display. The only fixed advice is to be consistent within each space. Our ability to adapt to a wide range of colour temperatures and see them all as white relies on visual adaptation, which takes many minutes to occur. Select only lamps of good or excellent colour rendering. Currently, the largest selection of good and excellent lamps occurs near 3000 K (yellow squares in Figure 3), and until manufacturers respond to the new evidence supporting higher CCT, 3000 K remains a very successful general-purpose choice for museums that do not wish to face a complex selection process.

Historically accurate lighting, artists’ intent, fluorescent paints and optical brighteners

Long before LED lamps, the issue arose of how to light artworks made by artists under their own preferred or historically unavoidable lighting, whether it was Michelangelo in the Sistine Chapel, the Impressionists outdoors, a modern artist under bank lights of their favourite fluorescent lamps or any sacred objects meant for candlelight. And what about all those objects meant to be seen properly with a healthy dose of UV, such as artwork based on fluorescent paints or the common situation of paper, costumes and textiles dependent on fluorescent whiteners?

There are four separate issues in the listed examples.

- All the situations of variable daylight and incandescent lighting (candles to tungsten lamps) can be addressed through the selection of appropriate colour temperature and intensity. Recommendations for good and excellent would remain unaffected.

- The issue of artists who chose fluorescent lamps with poor CRI is not easily solved with LED lamps, but it is not theoretically impossible. One would have to know the type of fluorescent lamp, check its spectrum and look through LED lamps of similar CRI for a similar spectrum.

- For fluorescent paints, the good news is that most of the green, yellow, orange and red paints can look almost as bright without UV. They are activated by violet through to green, but they do require a high colour temperature source like daylight to look as intended. The bad news is that they fade quickly; rates are equivalent to Blue Wool standards 1 to 3 (Connors-Rowe et al. 2005).

- Optical brightening agents in modern paper and textiles, also called “fluorescent whitening agents,” are designed to emit in the blue band, thereby compensating for yellowing of the material. To emit blue, they need excitation in the UV and violet. Our recommendations for good and excellent concerning the white light part would not change, but adding UV purposely to lighting based on LED lamps that are free of UV is a delicate issue, given the health concerns. Thus, the issue is outside the scope of this text. If one does have this type of object, however, when comparing a selection of LED lamps for consideration, one should certainly consider lamps that use a violet LED pump since the excitation band of many brightening agents does include violet. The bad news is that brightening agents themselves accelerate the rate of yellowing of some materials due to light (for example, the agents make wool look whiter for a while but at the cost of looking yellower later [Millington 2005]).

Viewer preference versus correct colour

At mediocre CRI values, one can observe strong viewer preferences for one kind of distortion over another, and current literature on the subject is concerned with what it all means and how to measure universal preferences amongst imperfect spectra. As noted previously, it is part of the ongoing search for a complete science of colour perception. Are there advantages to some of the colour distortions possible with imperfect light sources? Our approach is conservative: we recommend mimicry of benchmark spectra, and our categories of good and excellent reflect two levels of success.

Do LEDs damage objects and artworks?

In early 2013, newspapers around the world reported that “Van Gogh's masterpiece is slowly turning brown as a result of exposure to LED lighting.” (S. Manning, The Independent, January 13, 2013.) A few months later, a less newsworthy retraction followed: “Why online news reports claiming that LED exposure darkened the artist's colors were mistaken.” (S. Strasnick, ARTnews, March 3, 2013.) This belief that LED lamps might cause more damage per unit exposure than previous lamps was not new: it had appeared in the lighting and conservation communities as soon as the big blue bump in the spectra of LED lamps had become widely known. It was certainly plausible that this blue light might aggravate damage. The questions were by how much and from which LED lamps.

We compiled all the available studies that compared the fading of materials by LED lamps and conventional lamps. We entered all available data on the damage spectra of these materials, and the spectra of the LED lamps used, into the standard model for predicting relative damage (Thomson 1978) and found no surprises. The predicted fading of various LED lamps fits the studies within experimental errors. We then used the model to examine in detail the relative damage due to LED lamps on various materials as compared to traditional light sources.

The first section summarizes our advice and is followed by the presentation of the evidence behind it.

Summary advice about damage from LED lamps

White light from any source will cause discolouration, usually fading, of vulnerable surfaces, and UV from any source will cause gradual disintegration of vulnerable surfaces. If an LED lamp is selected on the basis of good-quality or excellent-quality light (that is, CRI over 90), it will not cause any more light damage to objects or artworks than light from halogens or traditional incandescent lamps or UV-filtered daylight.

In fact, we find the opposite for the most important type of light damage: the discolouration of fugitive colours. When comparing all LED lamps that produce good or excellent light to lamps that have been widely used in the past without UV filters, such as traditional incandescent lamps and halogen lamps, we notice that the good-quality LED lamps are all safer, whether based on blue or violet LEDs.

When comparing LED lamps to the benchmark of a halogen lamp with a perfect UV filter, we see that LED lamps of similar colour temperature and of good-quality light cause either similar rates of discolouration, if using a violet LED pump, or lower rates of discolouration, if using a blue LED pump. The lower rates of discolouration with blue LED lamps are due to the missing violet light (that is, their incomplete spectra). We do not consider this a reason to favour violet-deficient lamps any more than we would have recommended yellow filters for all incandescent lamps in the past.

Is fading by LED lamps ever significantly worse than that associated with traditional lamps? Yes. Early work by Ishi and colleagues (2008) showed some dyes faded up to twice as fast with the worst LED lamp tested compared to a source similar to our benchmark 3000 K halogen with UV filter, but such early LED lamps produced light of very poor quality (very high CCT, poor CRI) and should never be used in a museum or art gallery. In summary, the only evidence of significantly increased fading concerned LED lamps of very poor quality light.

For the other type of lighting damage (disintegration of media, such as chalking or cracking), blue LED lamps that provide good or excellent light are safer than a halogen lamp with a perfect UV filter, but good and excellent violet LED lamps are not. If, however, one compares good and excellent violet LED lamps to sources long considered acceptable in museums (for example, the traditional incandescent lamp without a UV filter and halogen lamps without a UV filter) and to the lighting sought in many architectural mega-projects, namely UV-filtered daylight, violet LED lamps are found to be less damaging. This form of damage is also much slower compared to fading of fugitive colours—millennia versus years, assuming museum intensities. In terms of damage, we consider lamps that use a 415 nm violet LED and which produce good or excellent light not only acceptable, but an improvement on most previous forms of museum lighting.

In terms of lighting decisions, looking for differences between electric lamps that produce good-quality light, of any type, once their UV is removed is splitting hairs; the big preservation impacts are obtained by reduction in intensity and duration of exposure. LED lamps based on blue pumps, which are currently the majority of LED lamps, or based on violet pumps above 415 nm, do have a huge museum advantage, though: one can dispense with UV filters and all their associated costs and maintenance issues.

Damage spectra of museum materials

The damage spectrum of a material, also called the “action spectrum,” plots the relative damage due to each wavelength of light and UV. A damage spectrum must specify the particular kind of damage that was measured and the particular material that was damaged (for example, fading of a particular paint, yellowing of a particular material or loss of strength of a particular fibre). Looking for a generic straight-line damage spectrum that can rank the risk from different lamps, although often attempted, is not meaningful.

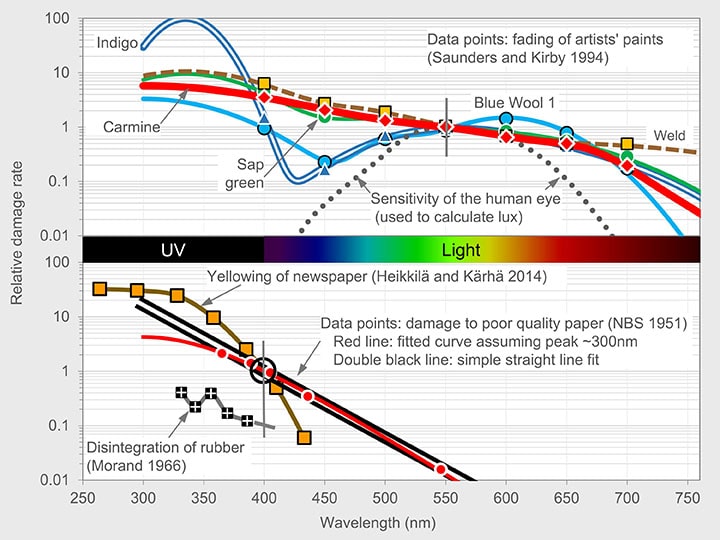

Figure 5 illustrates the two general forms of damage spectra: fading of colourants (upper plots) and disintegration and yellowing of media (lower plots).

© Government of Canada, Canadian Conservation Institute. CCI 122894-0009

Figure 5. Examples of relative damage spectra. The upper graph shows fading of various coloured materials, all adjusted to 1 at 550 nm; the lower graph shows disintegration and yellowing processes, all adjusted to 1 at 400 nm (except rubber, shifted to 0.1 at 400 nm for clarity).

Description of Figure 5

Figure 5 contains two graphs, one above the other, sharing the same x axis. The x axis is wavelength, from ultraviolet at 250 nanometers to visible light up to 760 nanometers. The y axis for both graphs is relative damage rate, shown on a logarithmic scale. The upper graph contains six plots, five of which are the fading of various colourants and tend to slope downwards from left to right. The sixth plot is the relative sensitivity of the human eye, which peaks in the middle of the graph. The lower graph contains four plots, which all slope downwards from left to right.

Within the damage spectra of colour fading (upper part of Figure 5), three groups with key examples are provided, all from the seminal work of Saunders and Kirby (1994). Extrapolation of their data into the UV band was done using known benefits of UV filtering on each colourant.

- Colourants with damage spectra that slope gradually from left to right with little variation. These include a red colourant (carmine), a green colourant (sap green) and a yellow colourant (weld). The damage spectrum is dominated by blue wavelengths. Although UV does contribute, UV filtering of a source such as daylight through glass only reduces fading by perhaps 20%, not 100%. These colourants are also fugitive (Blue Wool ratings 1 and 2).

- A fugitive colourant that has a pronounced trough in its damage spectrum: Blue Wool 1. The damage spectrum is dominated by green to red wavelengths. The rise of the spectrum in the UV is not pronounced, so as in Blue Wool 1, UV filtering light sources will not help much.

- A durable colourant that has a pronounced increase in sensitivity in the UV: indigo. The damage spectrum is dominated by UV and violet wavelengths, so UV filtering is important.

Within the damage spectra of media disintegration (lower part of Figure 5), the examples are as follows:

- The five data points (red dots) presented in an old National Bureau of Standards (NBS 1951) report, which then recommended a yellow filter for lighting of the U.S. Declaration of Independence. The material was “low-quality paper,” and the damage measured was not specified. It might have been loss in mechanical strength in terms of fold endurance, but was more likely a study of yellowing. Harrison (1953), the lighting engineer, subsequently extended these points into a table of damage factors which prevailed for decades (his table was similar to the double black line). Another curve we have fitted to the data (red line) presumes a bend towards a peak in the range of 200 to 300 nm, based on the general shape of damage spectra measured in that range for paper and polymers.

- Disintegration of rubber (Morand 1966). Of all the wavelength studies surveyed in Feller’s last major review (1994), this is the most precise study of strength loss of a material in the key band of 300 to 400 nm. Rubber is known to be particularly vulnerable to UV; hence, the cracking of rubber objects on the surfaces that faced daylight.

- Yellowing of paper (Heikkilä and Kärhä 2014). Yellowing is a difficult phenomenon to measure well due to counterbalancing bleaching processes. The paper industry has studied wavelength dependence for decades, but only recently have definitive results, such as what is shown in Figure 5, emerged.

For purposes of calculating media disintegration in general, the double black line of Figure 5 is used, close in slope to the NBS and rubber data, but also similar in slope to many material disintegration plots reviewed by Feller (1963, 1994) and Michalski (1987).

Damage calculations of various lamps

Also shown in the upper graph of Figure 5 is the sensitivity of the human eye, a plot used in all light meters to calculate lux. If a lamp produces a big spike in a region where our eye is not sensitive but the material is sensitive, such as the blue and violet bands or the UV band, of course, then we can expect the damage per unit lux for that source to jump.

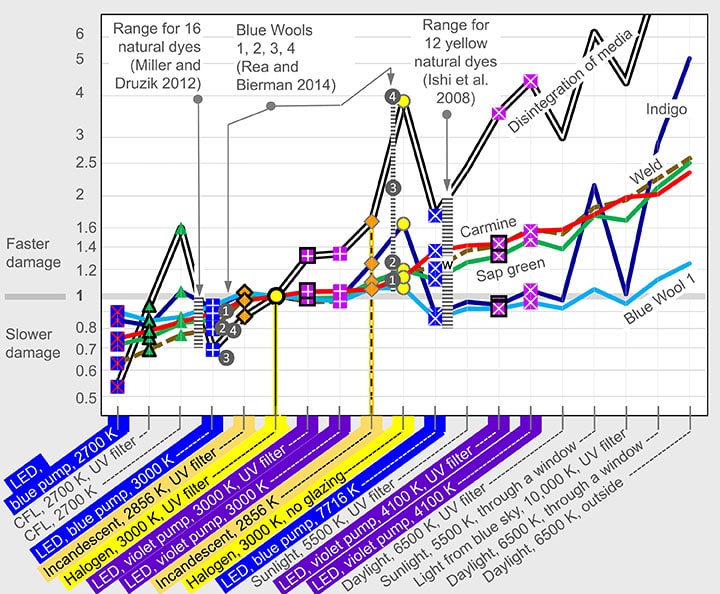

By combining the spectrum of a light source and the damage spectrum of a material, one can calculate the predicted rate of damage. Figure 6 presents the results based on the damage spectra of Figure 5, crossed with 19 light sources, including representative good and bad LED lamps whose spectra were provided in Figure 2 of the section Do LEDs provide good-quality light?

© Government of Canada, Canadian Conservation Institute. CCI 122894-0011

Figure 6. Calculated damage to materials in Figure 5 due to various light sources, relative to a 3000 K halogen lamp with a perfect UV filter. The LED spectra are as in Figure 2. Light sources are sorted left to right by their effect on carmine (red line).

Description of Figure 6

Figure 6 contains a single graph. The x axis lists 19 light sources, mostly electric lamps. The y axis is a relative damage rate, on a logarithmic scale. There are six plots, most of which tend to climb from left to right, but one of which (Blue Wool 1) is almost horizontal, and two of which (Indigo and Disintegration of media) zigzag much more than the others.

Figure 6 is built around the ideal benchmark of a 3000 K halogen lamp with all the UV perfectly removed (large yellow circle with a heavy black boundary). The relative damage plots are all anchored to this benchmark, so the vertical axis gives the relative damage rate, which varies from about 0.5 to beyond 6. The historic benchmark is the traditional incandescent lamp (Figure 6, orange highlight, vertical dashed line), which, ever since Thomson (1978), has been accepted as a suitable lamp to use in museums without a UV filter, other than the glass bulb itself.

The light sources are organized from left to right in terms of damage to carmine, a red paint that is both fugitive and widely used in many cultures, sometimes as simply the dye itself, cochineal. This red paint and other historic fugitive colours likely to have similar damage spectra are often the first to fade in objects such as oil paintings, watercolours, colour photographs and textiles.

The two other colourants with a similar damage spectrum to carmine, sap green and weld, follow carmine closely on this graph.

Damage data for various lamps

There are experimental studies that allow us to confirm the predictions of Figure 6. The first such study of LED lamps by Ishi et al. (2008) rightfully raised concerns about LED lamps because it showed that three out of the four LED lamps with blue pumps could fade some dyes more than twice as fast as a museum-quality fluorescent lamp labelled “NU.” The NU lamp had a colour temperature of 3000 K, negligible UV and a spectrum similar to our benchmark of the “Halogen, 3000 K, UV filter”. The blue LED lamps tested were typical consumer lamps of the time (CRI around 80 and very little red). The worst LED tested by Ishi et al. was the “LED, blue pump, 7716 K” in Figure 6. Its blue spike was more than twice the height of the remainder of the spectrum (Figure 2). After calculating the relative damage rates found by Ishi et al. in terms of the NU lamp, we have plotted the range of relative damage rates for the dyes that gave unambiguous results (12 out of 16 dyes) with a striped bar above “LED, blue pump, 7716 K.” Although a few colourants faded less, most faded more—as much as double in terms of our benchmark source. This is the clearest evidence of an exceptionally large blue bump causing extra damage, but this large bump also meant that the quality of light was awful. Particularly valuable in confirming the model is the datapoint of Ishi et al. for weld, marked by the letter “w” at a factor of 1.2. It agrees very nicely with the prediction for weld when using the damage spectra of Saunders and Kirby.

Miller and Druzik (2012) tested 16 natural dyes, 6 of them identical to those in the Ishi et al. set (including weld). This time the comparison was between excellent LED lamps (3000 K, CRI 95; 2900 K, CRI 96) and an MR16 halogen lamp (3000 K) with only a glass cover, not a complete UV filter. Thus, the maximum reduction of fading derived from their data, shown by the striped bar above the source “LED, blue pump, 3000 K,” is probably slightly exagerrated. Besides, 13 of the 16 dyes, including weld, showed no significant difference between the two lamps for the length of exposure studied.

A third study that provides LED data relative to our benchmark is one done by Rea and Bierman (2014). They compared fading of the blue wool reference samples themselves for LED lamps versus a 3000 K halogen lamp with a museum grade UV filter. The LED lamp was a programmable model, which is becoming more widely available, that uses a mix of a white LED plus other LEDs that shift the colour temperature. The fading study used only the warm white mode of about 3000 K. Unfortunately, the model had a very poor CRI of 52. The derived fading ratios are shown as numbers 1 to 4 adjacent to the source it most resembled, “LED, blue pump, 3000 K.” Within experimental errors, the agreement of prediction and experiment for Blue Wool 1 is good. More durable blue wools are helped even more.

Another set of relative damage rates derived from the Rea and Bierman study informs Figure 6 further: their ratio between the damage due to a halogen lamp with a UV filter and one without a UV filter, shown by the striped bar above “Halogen, 3000 K, no glazing.” Daylight studies of the blue wools done long ago by McLaren (1956) established that Blue Wool 4, unlike Blue Wool 1, is indeed faded primarily by UV rather than visible light, hence the remarkable increase in fading by a factor of four between a halogen lamp with a UV filter and a halogen lamp with no glazing.

At the time of writing, English Heritage had reported preliminary results for tests of a very large variety of paints including inorganic pigments, oil media and watercolours (Richardson 2017). They tested two LEDs that represent widely available models (CRI of 82 and 88, so not good-quality, but within the Energy Star criteria, colour temperature of 3000 K and 4000 K). These had moderate size blue bumps at 450 nm (between the smallest and biggest blue bumps of Figure 2.) They also tested daylight with a UV filter. The rate of damage was compared to that caused by a 3000 K quartz halogen lamp with a good UV filter. Their results are consistent with results shown for the blue pump LEDs of 3000 K and 7716 K in Figure 6: some pigments fade up to 30% faster, some up to 30% slower. Daylight with an imperfect UV filter was much worse (as in Figure 6): some inorganic pigments changed up to three times faster than under the 3000 K quartz halogen lamp with UV filter.

We can make the following judgements about LED lamps, based on Figure 6, where “benchmark” refers to the halogen lamp of 3000 K with a perfect UV filter:

- LED lamps that use a blue pump, that have a similar colour temperature to that of our benchmark and that have good or excellent colour rendering (“LED, blue pump, 3000 K,” blue squares with a white “+”) cause the same amount of damage or a slower rate of damage as our benchmark. On the other hand, LED lamps with large blue spikes (“LED, blue pump, 7716 K,” blue squares with a white “x”) can cause up to twice as much damage as our benchmark. Such large blue spikes cause not only a poor CRI but also colour temperatures far above our benchmark.

- LED lamps that use a blue pump and a red LED to achieve good-quality light at a low colour temperature (“LED, blue pump, 2700 K,” blue squares with a red “x”) do not have elevated damage. Their large red spike does not add significant damage.

- LED lamps that use a violet pump near 415 nm, and which produce good-quality or excellent-quality light (“LED, violet pump, 3000 K” violet squares with a white “+”), do not appear to increase colour fading, but they will cause faster media disintegration compared to the benchmark. Blocking UV only reduces this by a very small amount—as seen when comparing violet squares with and without black borders. The problem is not the trace UV but the presence of a modest violet bump in this lamp combined with a sharp increase in the rate of damage at violet wavelengths. That said, these violet pump LEDs are still less damaging than the traditional incandescent lamp, less damaging than a halogen lamp without a UV filter and much less damaging than daylight even if there is a perfect UV filter.

- LED lamps that use a violet pump near the UV boundary (405 nm for the “LED, violet pump, 4100 K,” violet squares with a white “x”) can cause 40% to 50% faster fading and four times the rate of media disintegration compared to the benchmark. These factors are not reduced much by removal of UV (violet squares with black borders) because the trace UV content is not the problem. The problem is the huge violet peak at 405 nm, which adds greatly to damage but little to lux level. This large violet spike also causes poor scores on quality of light, so we would not consider this lamp in the first place.

In other words, if one only selects LED lamps that have good-quality or excellent-quality light, then damage is not a concern, but if one accepts any LED lamp offered, then both the appearance of the objects and their preservation are at risk. To place the damage from even the worst violet LED in perspective, however, it is no more than, and sometimes less than, the damage by daylight, a source of lighting on which museums and art galleries around the world have expended enormous resources so as to bring it to their artworks because it is “natural.” Figure 6 shows that even if daylight could be filtered perfectly (“Daylight, 6500 K, UV filter”), it would cause damage rates similar to that of the worst violet LED lamps.

Does damage depend on colour temperature?

In Figure 6, the light sources have been sorted left to right according to their effect on the fading of carmine, and one can note that the colour temperature of the light sources does range from 2700 K on the left to 6500 K on the right, but that the progression is not perfect. Damage to the fugitive Blue Wool 1 barely changes across all the lighting sources. Unlike carmine, its damage spectrum (Figure 5) has a trough in the blue band, but unlike indigo, the spectrum does not climb dramatically in the UV. In other words, fugitive blues will fade the same regardless of colour temperature or UV filters.

In Figure 6, it is clear that the disintegration of media depends primarily on UV and violet and that the fading of a durable colour such as indigo also depends primarily on UV and violet. However, for fluorescent and LED lamps, UV and violet do not correlate well with colour temperature. Since any museum worried about lighting damage will have controlled UV, the better question becomes: assuming UV is absent, is colour temperature a useful indicator of relative damage to objects?

Colour fading does depend on colour temperature for most colours other than blues, but only to a modest extent—it is up to 50% faster for daylight at 6500 K compared to halogen at 3000 K. This is consistent with the work by Crewes (1989), showing that the use of an amber filter that removes UV, violet and some blue on a source simulating daylight could reduce fading of natural dyes (cochineal, madder, indigo, fustic, weld and turmeric) by only 35% more than a UV filter alone, which reduced by 15% on average the fading that would have occurred without a filter. The big jumps in Figure 6 do not signal a climb in colour temperature; they signal the presence of UV, such as “CFL, 2700 K” and “Halogen, 3000 K, no glazing,” in combination with the UV sensitivity of media disintegration and indigo fading.

The useful generalization for museum lighting in terms of the spectrum remains the same: if a source has UV, then filter it, and filter it well.

Material sensitivity still dominates lighting decisions

© Government of Canada, Canadian Conservation Institute. CCI 122894-0013

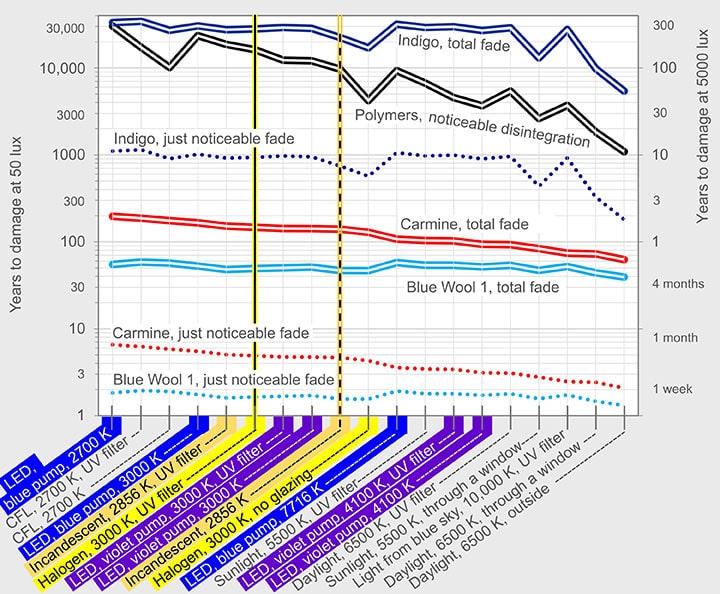

Figure 7. Time for damage to occur to various materials with various light sources.

Description of Figure 7

Figure 7 contains a single graph. The x axis lists 19 light sources, mostly electric lamps. This is the same list as in Figure 6. The y axis is the number of years to reach the specified damage. The left y axis is a scale of years to reach specified damage if the light intensity is 50 lux, while the right y axis is for a light intensity of 5000 lux. There are seven plots, most of which tend to drop slightly from left to right, but two of which (Blue Wool 1, total fade; and Blue Wool 1, just noticeable fade) are almost horizontal, and three of which (Indigo, total fade; Indigo, just noticeable fade; and Polymers, noticeable disintegration) zigzag much more than the others.

In Figure 7, the relative damage rate of Figure 6 has been converted into the time needed to reach various degrees of damage for the various materials. It has been calculated using relative rates from Figure 6, which determine the shape of each plot, combined with estimates from fading studies and outdoor aging of polymers, which determine the vertical position of each plot. The vertical axis gives times for 50 lux on the left-hand scale and for 5000 lux on the right-hand scale. At the bottom is a representative of high sensitivity colourants, Blue Wool 1, and at the top, five hundred times less sensitive, a representative of low sensitivity colourants, indigo on wool. The overwhelming message of Figure 7 is that the time to reach particular levels of damage due to electric lamps is determined primarily by the sensitivity of the material, the intensity of the light and the duration of the exposure, not the spectral details of the light sources. Choose light sources for their quality of light so that one sees things well; preserve things well by knowing which are highly sensitive and reducing their exposure.

Measuring UV from LEDs

Unfortunately, the simple UV meters widely used by museums will not measure correctly the small amount of UV from those LED lamps that do actually emit a trace of UV, and any reading above zero for the majority of LED lamps that use a blue LED pump is simply wrong. We and others in the health research field (Barlier-Salsi 2014) have found that even widely used portable spectrophotometers in the $2,000 to $5,000 range can give false noise signals in the UV band that are unimportant to users doing colourimetry but very important to those of us calculating harm caused by the rapidly climbing UV damage spectra. Published measurements using a sufficiently sensitive instrument (double monochromator, Rea and Biermann 2014) confirm that the output of blue LED pumps drops three orders of magnitude between their blue peak and the UV boundary at 400 nm, then drops another two orders of magnitude by 380 nm. This is a sharper cutoff than the one associated with even the best UV filters.

Heat, glare, dimmers and flicker

LED lamps produce much less heat than incandescent lamps, such as infrared in the light beam (zero with LEDs) and heat from the fixture (1/3 or even less). It is possible now to consider display case designs with the lamps inside without overheating of the case (consult Heat from LED lamps for clarification).