Key Issues and Speaking Points

On this page

Auditor General Recommendations

Planning and forecasting materiel requirements

Key Messages

- National Defence agrees with the Auditor General that we need to have the right material at the right place at the right time.

- As the Auditor General noted, we also need appropriate metrics in place to monitor whether stock levels are sufficient.

- That is why in our Management Action Plan we committed to launching a comprehensive review of materiel planning and forecasting policies, tools and processes.

- This includes reviewing how we measure the availability of our material both at the individual warehouse level and across the national supply system.

- We launched two reviews this summer. The first will review how we measure materiel availability. This will be done by July 2021 and we will update the Departmental Results Framework to reflect any changes.

- The second, larger review on planning and forecasting will be complete by June 2022, including a full implementation plan.

- Ultimately, these changes will be incorporated into a next-generation resource planning system that will be launched in 2028.

- This entire effort will be a multi-year process, but we are committed to getting it right so that our system is efficient and ready to support the Canadian Armed Forces.

Key Facts

- National Defence processes over 560,000 materiel orders per year and manages over 460 million items.

Auditor General Report

Key findings:

- 50% of all materiel requested during the audit period was received late.

- National Defence did not stock the right quantities of materiel at the right locations, resulting in additional steps to procure materiel or to transfer it between locations, which slowed deliveries.

- National Defence did not develop performance indicators to measure whether materiel was stocked at the right warehouses, and whether warehouses held sufficient stock.

Recommendation 1:

- Review materiel forecasting and positioning to ensure that sufficient stocks are maintained at the right locations.

- Review materiel availability measures at the warehouse and national levels and use them to monitor whether stock levels are met.

Details

- Materiel planning: ensures materiel is positioned in the right location at the right time to meet current and future operational requirements.

- Materiel forecasting: determines the quantity of materiel

Prioritizing Requests

Key Messages

- National Defence agrees with the Auditor General that improving oversight of high priority requests is crucial to reducing unnecessary costs.

- We also understand that the over-prioritization of requests creates an excessive burden on the supply chain.

- As noted in our Management Action Plan, National Defence is taking several steps to address the issue.

- In the short term, National Defence is in the process of reinforcing policy guidance on how to properly classify requests with the responsible personnel at our wings, bases, and commands.

- Further, National Defence has begun a thorough review of its freight distribution system to improve efficiency and optimize costs.

- National Defence will complete this review by March 2021, and decide on a way forward by March 2022.

- We will ensure that all improvements to the distribution system are complete by April 2024, paying particular attention to performance measurement and oversight.

- As we move forward, we will ensure that high-priority requests are only made when absolutely necessary, and that these classifications are justified.

Key Facts

- There are three levels of priority in National Defence's supply system:

- High priority: materiel for critical operational requirements that cannot be substituted with alternative equipment.

- Essential: materiel not critical, but with a significant operational impact.

- Routine: all other materiel and requests.

- The proportion of orders processed as high-priority requests has ranged from 7.15% to 8.79% between fiscal years 2016/17 and 2019/20.

Auditor General Report

Key findings:

- A large portion of high-priority requests were flagged as such without justification.

- National Defence could not justify the high-priority status of 65% of the requests reviewed (84 of 129).

Recommendation 2:

- Improve oversight of high-priority requests to ensure that such requests are only used when necessary.

Details

- On deployed operations and major exercises, oversight of high priority requests (HPRs) is generally conducted by a monitoring cell within a supply organization.

- This cell monitors and tracks high-priority requests, but does not vet or approve them.

- For day-to-day operations, HPR oversight is the responsibility of the individuals ordering the item, their immediate supervisor, and those with delegated oversight responsibility from the unit's commanding officer.

Policy on Prioritizing Requests

- The current method of prioritizing requests is based on guidance in the Supply Administration Manual and the judgement of the individual ordering the item.

- Prioritization is an assessment of time and risk. If an item is needed immediately and the operational impact assessed as 'severe', the item is considered high-priority.

- The Manual defines a high-priority request (HPR) as for urgent situations where planning was not a possibility, such as a mechanical failure of key equipment days before a deployment or while on deployment.

- HPRs must satisfy critical operational requirements that meet one of the following criteria:

- the materiel is critically required to ensure uninterrupted performance of an assigned international or domestic mission;

- the materiel is required to repair or replace damaged or inoperative major equipment in support of critical operational imperatives.

- the materiel is required to repair or replace minor equipment without which critical major equipment cannot meet mission commitments;

- the materiel is required to repair or replace critical operational telecommunication equipment;

- the materiel is required in support of civil emergency purposes;

- the lack of materiel would jeopardize the safety of personnel; and,

- the materiel requirement does not meet one of the above criteria but the criticality of obtaining the item on an immediate basis has been authorized in writing by the Commanding Officer of the requesting unit.

Defence and Materiel Inventory Network Optimization Initiative

- Through the Distribution and Materiel Inventory Network Optimization (DMINO) initiative, National Defence is seeking to improve its National Freight Run to produce a reliable system in which shippers can have increased confidence, reducing the need to over- prioritize requests and select commercial options of transportation.

- In February 2020, National Defence awarded a contract for DMINO to PwC Canada, who in turn evaluated over 5 million data points to provide a novel picture of how materiel distribution is flowing and recommendations to increase efficiency.

- National Defence is currently evaluating options and how to best improve its National Freight Run. National Defence will also solicit industry for a next-generation domestic ground distribution network solution for commercial freight movement.

Communicating Transportation Methods and Costs

Key Messages

- National Defence agrees with the Auditor General that we need to improve our communication and guidance on costs and selecting transportation options.

- We understand that both are vital to enabling sound decision making and an efficient supply chain.

- As we note in our Management Action Plan, National Defence is conducting a thorough review of its freight distribution system to improve efficiency and optimize costs.

- This review is underway and in February 2020, National Defence awarded a contract to Price Waterhouse Coopers Canada to identify potential options for more efficient material distribution.

- Price Waterhouse Coopers Canada has already evaluated over 5 million data points and we are currently evaluating their initial recommendations.

- As we gain an understanding of how we can improve our systems, we will revise and clearly communicate guidance on costs and selecting shipping methods to our personnel.

- National Defence will complete the full review by March 2021, and decide on a way forward by March 2022.

- We will ensure that all improvements to the distribution system are complete by April 2024.

- We believe these actions will result in a more efficient distribution system and help our personnel make more informed and cost-effective decisions.

Key Facts

- The Canadian Armed Forces moves 2 million tonnes of freight across Canada each year.

- 10% of freight volume is moved using National Freight Runs, with 90% contracted through commercial carriers.

Auditor General Report

Key findings:

- For materiel movements within Canada, National Defence did not have the right controls to determine the most appropriate transportation methods to fill requests and to oversee transportation costs.

- National Defence did not provide guidance on how to assess transportation costs and what constitutes high costs.

- The information system that supports transportation activities did not include the costs of all available modes of transportation.

Recommendation 3:

- Communicate the costs of all available transportation methods and provide clear guidance on how to select the mode of transportation to ensure that decisions are founded on a full understanding of costs.

Details

- Current method of communicating costs: varies based on standing offer agreements listed within the National Materiel Distribution System, which all shippers must use.

- Current guidance on selecting transportation methods: policies and manuals are in place that outline when premium, high cost, transportation is permitted (e.g. critical operational requirements). For all other routine transportation, including normal commercial shipments, supervision on the ground ensures compliance with policy guidance.

- The decision on methods of transportation is driven by the required delivery date. However, flexibility within National Defence's policies ensures shippers on the ground can make transportation decisions, and that the Canadian Armed Forces achieves its operational requirements, while ensuring accountability and value for money.

Review underway: Defence and Materiel Inventory Network Optimization Initiative

- Through the Distribution and Materiel Inventory Network Optimization (DMINO) initiative, National Defence is seeking to improve its National Freight Run to produce a reliable system in which shippers can have increased confidence, reducing the need to over- prioritize requests and select commercial options of transportation.

- Another aim of the DMINO project is to provide National Defence with a clear understanding of freight distribution requirements for which it is seeking commercial support. This will enable National Defence to enter into broader freight contracts with targeted suppliers at known costs, which is expected to increase effectiveness and generate efficiencies through market volume.

- National Defence will also solicit industry for a next-generation domestic ground distribution network solution for commercial freight movement.

Other Key Audit Issues

Performance Measurement

Key Messages

- We agree with the Auditor General that National Defence requires better performance measurement metrics to assess our supply chain.

- That is why, in our 2020 Management Action Plan, we committed to reviewing our metrics that measure the availability of materiel at the individual warehouse level and across the national supply system.

- Currently, we report one metric for measuring overall stock availability – our target stock-out rate – to Parliament annually in our Departmental Results Framework.

- This metric indicates whether we have enough of what we need in the national supply chain, but not whether it is stored at the optimal location.

- We are now working to develop additional indicators that will better measure whether we have inventory available to meet forecasted demand for up to twelve months, and whether the inventory is located at specific depots.

- As we collect and analyse our own data, we are also working with allies and industry partners to understand best practices for how to improve our efforts.

- Ultimately, we will integrate these measures into a new Supply Chain Performance Measurement Framework, which we began developing last year.

- Our goal is to complete this new system by the fall of 2022 and we will continue to keep Parliament informed of our progress.

Key Facts

- The current national stock-out rate was set in FY 2012-2013, based on the lowest average level between spring 2010 and March 2012.

- National Defence first included its national out-of-stock rate in annual reporting in the 2014/2015 Report on Plans and Priorities.

- The current target of 7.93% or better represents a benchmark of what was thought to be realistically achievable year-over-year.

Auditor General Report

Key findings:

- National Defence did not develop performance indicators to measure whether materiel was stocked at the right warehouses, and whether warehouses held sufficient stock.

- National Defence could not provide supporting documentation when asked for the method used to set its maximum national out-of-stock target at 8%.

- National Defence had not reviewed the target since 2012 to determine whether the measure was appropriate.

Recommendation 1:

- Review materiel availability measures at the warehouse and national levels and use them to monitor whether stock levels are met.

Details

- For several years now, Canada has been meeting regularly with its Five Eyes Allies to collaborate on critical supply chain and transformation issues.

- National Defence is represented by senior departmental and military leaders at the respective Joint Supply Chain and Quintilateral Logistics Forums, and participates actively in the working groups.

- The goal of these forums is to collaborate on supply chain business transformation, business information architecture and policies; to exchange best practices; and to foster interoperable solutions in support of operations.

Vignette: Search and Rescue Exercise Materiel

Key Messages

- We agree with the Auditor General that stock shortages and rerouting materiel requests are a problem that we need to address.

- We have looked into the specific example raised in the audit, where delays between September 2017 and March 2018 impacted the delivery of search and rescue equipment for a Canadian Armed Forces exercise.

- The delays did not negatively impact the exercise, as the Royal Canadian Air Force squadron was able to obtain the equipment from other squadrons.

- However, we did find that the situation resulted in additional costs and lost time.

- A number of factors contributed to the delays, including the equipment being ordered from the wrong location, and the error not being noticed until the requestor followed up months later.

- This example demonstrates that to improve our system, we need to ensure that our people are well trained and have the necessary tools in place to succeed.

- We will continue to improve our efforts in supply chain management to ensure errors like this are as rare as possible.

Key Facts

- 18 September 2017: A Royal Canadian Air Force squadron at CFB Trenton requests a new type of diving equipment from a local base warehouse to support a search and rescue exercise in Florida.

- 23 January 2018: The Air Force follows up on the order with the warehouse and is notified that the equipment had been routed to the wrong location.

- 2 February 2018: The Air Force submits a new high-priority request to the Montreal supply depot. The depot coordinates the order for the required equipment.

- 21 February 2018: The depot receives the equipment. In parallel, six other Air Force squadrons ship their equipment directly to Florida to support the exercise.

- 27 February 2018: CFB Trenton receives the ordered materiel from the Montreal supply depot, although not in time for the squadron's departure to Florida.

- March and April 2018: The Florida search and rescue exercise goes ahead as planned.

Auditor General Report

Key findings:

- In September 2017, a Royal Canadian Air Force unit at CFB Trenton requested materiel for a search and rescue diving exercise.

- Several months elapsed before any action was taken, and the materiel was not delivered in time for the exercise.

- In parallel, the unit located equivalent materiel and had it shipped to the exercise location, which duplicating effort and increasing shipping costs.

Canadian Armed Forces Medical Supply Chains

Key Messages

- We remain committed to ensuring that the Canadian Armed Forces has the medical supplies and equipment it needs to conduct operations and maintain readiness.

- Stockpiles of medical-grade personal protective equipment remained stable in the early months of the pandemic, as military personnel provided assistance in response to COVID-19.

- Since then, we have acquired additional supplies of medical-grade PPE a for the Canadian Armed Forces.

- It is important to note the distinction between our defence supply chain, which the audit examined, and our medical supply chain.

- The key difference is that National Defence's medical supplies and equipment are procured and tracked by the Canadian Armed Forces Health Services Group.

- This ensures that personnel with the appropriate healthcare expertise ensure specific medical standards.

- Together, both supply chains play a critical role in the support provided to Canadian Armed Forces members at home and abroad, and provides them with the appropriate materiel they need, when needed.

Key Facts

- Audit scope: The Auditor General did not analyze National Defence's medical supply chains in the audit, although some dental equipment managed in the Defence Resource Materiel Information System (DRMIS) is likely included in the audit's scope.

- COVID-19 testing capabilities: In March of 2020, National Defence procured deployable lab testing equipment to enhance its ability to conduct operational COVID-19 testing at home and abroad.

- This system is located in several clinics across the country and has recently been deployed in support of Royal Canadian Navy missions.

- Supply stocks are sufficient for CAF medical personnel.

- Medical personnel have been required to access the CAF stockpile more frequently due to the global shortages of masks and gloves.

- Procurement of non-COVID-19 related medical materiel continues to progress throughout the pandemic.

- For example, National Defence delivered a deployable CT scanner to the CAF Center (Atlantic) in Halifax on 19 June 2020.

Details

Medical Supply Chain

- National Defence's medical supply chain uses a separate management system than the defence supply system.

- For items such as vaccines, the Canadian Forces Health Services Group Headquarters is a member of the Public Health Agency of Canada-led Vaccine Supply Working Group.

- This group represents the Provincial, Territorial, and Federal governments, and uses a combined purchasing power to obtain preferred pricing and obtain vaccines in accordance with vaccination guidelines through the contracting authorities of PSPC.

Personal Protective Equipment (PPE) and other Supplies for COVID-19

- Medical grade PPE and other supplies required for COVID-19 are managed by the Canadian Forces Health Services Group. The Health Services Group operates their own warehouse for both clinical supplies and the medical materiel required for deployed capabilities.

- Non-medical PPE is normally purchased in accordance with industrial health and safety standards. There is no centralized procurement, holding, or management of domestic use medical consumable items.

- In the case of the COVID-19 pandemic, National Defence is coordinating a single CAF purchase of masks/gloves through Public Service and Procurement Canada to preclude competition for scarce local resources.

- Non-medical PPE includes dust masks and nitrile gloves, which are assessed as appropriate for the nature of the tasks assigned to our non-medical personnel.

CAF Stockpile of Personal Protective Equipment (PPE)

Key Messages

- Stockpiles of medical-grade personal protective equipment remained stable in February 2020 and fluctuated in March 2020, as the Canadian Armed Forces responded to the pandemic.

- Since then, we have acquired additional supplies of medical- grade personal protective equipment – or PPE – for the Canadian Armed Forces.

- This medical grade PPE is distributed weekly and as required to our Canadian Forces Health Services medical establishments.

- National Defence continues to closely monitor these stockpile levels to ensure that the military has the equipment it needs to carry out its important work in support of Canadians.

Key Facts

- As of October 16, 2020: Canadian Forces Health Services Group medical grade stockpile held:

- 446,536 gowns;

- 1,618,950 surgical masks;

- 89,213 N95 masks;

- 2,177,285 medical-grade gloves; and

- 98,808 face shields.

Details

- Between November 1, 2019, and February, 29, 2020, the Canadian Armed Forces (CAF) stockpile of medical-grade personal protective equipment contained approximately 4,800 gowns, 2,000,000 surgical masks, 145,000 N95 masks, 2,047,700 pairs of gloves, and 3,200 face shields.

- Work continues through governmental procurement specialists to identify and procure additional PPE stockpile; however, worldwide shortages pose continuing challenges across Canada.

- Stockpiled medical-grade personal protective equipment levels fluctuated during the month of March, as the CAF provided support to the Canadian repatriation efforts through Operation GLOBE, adopted measures to protect personnel and to maintain effective operational capabilities during the pandemic.

Recent Media and Parliamentary Interest

- There has been sustained media and parliamentary interest in overall Government-wide levels of personal protective equipment, including multiple Order Paper Questions on Whole-of-Government and National Defence stockpiles.

- Several Parliamentary Committees have also requested information on Government-wide levels of PPE through Motions to Produce Papers, and multiple questions to senior officials during Committee appearances.

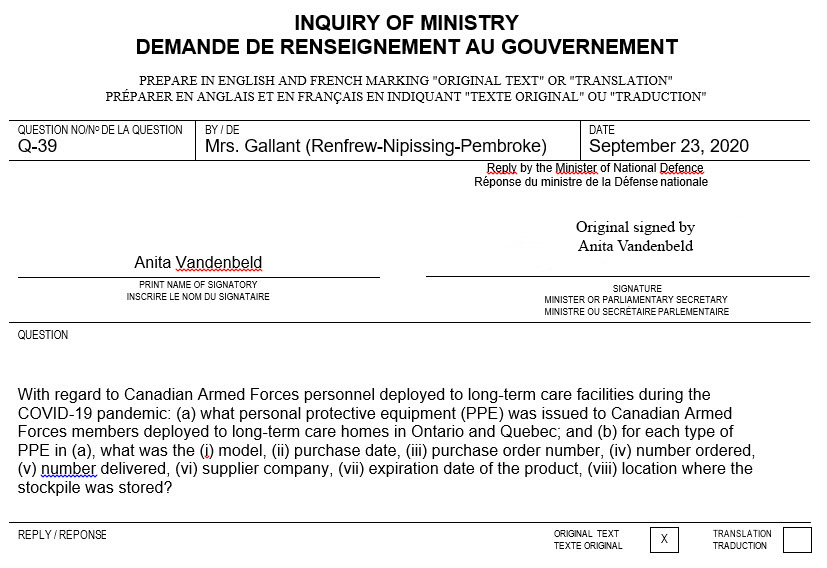

Q-39 Response – PPE Provided to CAF Personnel in LCTFs

Text version of Inquiry of Ministry form

Government of Canada letterhead

Inquiry of Ministry

Prepare in English and French marking "Original Text" or "Translation"

Question no: Q-39

By: Mrs. Gallant (Renfrew-Nipissing-Pembroke)

Date: September 23, 2020

Reply by the Minister of National Defence

Print name of signatory: Anita Vandenbeld

Signature, Minister or Parliamentary Secretary: Original signed by Anita Vandenbeld

Question: With regard to Canadian Armed Forces personnel deployed to long-term care facilities during the COVID-19 pandemic: (a) what personal protective equipment (PPE) was issued to Canadian Armed Forces members deployed to long-term care homes in Ontario and Quebec; and (b) for each type of PPE in (a), what was the (i) model, (ii) purchase date, (iii) purchase order number, (iv) number ordered, (v) number delivered, (vi) supplier company, (vii) expiration date of the product, (viii) location where the stockpile was stored?

The Canadian Armed Forces has provided unwavering support to Canadians across the country throughout the COVID-19 pandemic.

From April to June 2020, the Canadian Armed Forces deployed approximately 1,700 personnel under Operation LASER to provide support to vulnerable populations in long-term care facilities in Quebec and Ontario. This operation helped stabilize the situation in a total of 54 long-term care facilities, including 47 in Quebec and seven in Ontario.

TheTaCba1n3a.2dian Armed Forces carefully coordinated all deployments to long-term care facilities with on-site medical personnel, and established protocols to minimize the risk to Canadian Armed Forces members. Additionally, Canadian Armed Forces members received training on how to operate in environments with COVID-19, and they were issued medical-grade Personal Protective Equipment (PPE) to limit their risk of exposure to the COVID-19 virus while executing their duties.

At the onset of the COVID-19 pandemic, National Defence possessed an existing stockpile of PPE. National Defence quickly took action to replenish and increase this stockpile; however, pandemic- induced global shortages created challenges in the acquisition of additional PPE. National Defence worked closely with the Public Health Agency of Canada to source the PPE necessary, to ensure that Canadian Armed Forces members remained adequately prepared for deployment to long-term care facilities.

National Defence issued the following quantities of PPE on Operation LASER:

- 180,250 surgical masks

- 7,460 N95 masks

- 10,189 face shields

- 182 goggles

- 195,074 gowns

- 23,000 shoe covers

- 2,916,120 gloves

The enclosed table provides detailed information regarding the medical-grade PPE issued to Canadian Armed Forces members deployed to long-term care facilities in Ontario and Quebec during the COVID-19 pandemic.

National Defence's Medical Materiel Management System tracks items by expiry date. This is reflected in the attached table. In some instances, exact information for certain items is not available, as details of those PPE shipments were not registered in National Defence's Medical Materiel Management System. This is because certain PPE shipments were sent directly from the Public Health Agency of Canada to long-term care facilities in order to reduce shipping and processing time.

Given the global shortage of PPE during the beginning of the pandemic, National Defence drew upon all available resources. Of the nearly three million pairs of gloves used during this period, 85,800 pairs had reached their manufacturer expiry date. National Defence's Quality Engineering Test Establishment tested these gloves and deemed them compliant with industry standards and safe for use by Canadian Armed Forces' members.

National Defence continues to receive new shipments to replenish its PPE stockpile. This will ensure that the Canadian Armed Forces remains ready to respond to the needs of Canadians.

Previous Audit on Supporting and Sustaining CAF Operations

Key Messages

- In 2008, the Auditor General made three recommendations related to how we supported operations in Afghanistan.

- These recommendations focused on how we establish stock levels, track materiel, and measure our performance in supplying our personnel.

- We agreed with the Auditor General and have taken a number of steps to directly address the recommendations.

- For example, in 2009, we instituted a new software to manage materiel planning and forecasting, which we still use today.

- Further, in 2010, we developed a new performance measurement system to understand whether stock was received in a timely manner.

- These and other efforts have been captured in annual reports to this committee. However, it is clear from the Auditor General's 2020 report that we still have work to do.

- We recognize that this is a long-term challenge and will take a significant and sustained effort over a number of years.

- As noted in our most recent Management Action Plan, we are undertaking a comprehensive review of the policies, processes, and tools we use to plan and position our materiel, as well as our materiel availability metrics.

- We will continue to update this Committee on our progress on inventory management and will work to improve our supply chain so that we get the right materiel to our women and men in uniform when they need it.

Key Facts

Common issues in both the 2008 and 2020 audits:

- Issues with National Defence's ability to meet demands in a timely manner and sufficiently maintain stock levels.

- A high percentage of late deliveries.

- A high percentage of materiel requests coded as operationally critical or essential, resulting in increased transportation costs.

- In adequate performance measurement data to monitor how well user needs are met.

2008 Auditor General Report

- In 2008, the Auditor General conducted an audit to assess whether National Defence had met the needs of operations in Afghanistan.

- Recommendation 1: National Defence should review its practices for tracking materiel once the materiel has arrived to ensure the arrival and storage is accurately recorded in a timely manner.

- Departmental response: Agreed. National Defence has initiated the Asset Visibility Project to improve better track materiel.

- Recommendation 2: National Defence should continue to develop the performance measurement of its supply system, including assessing if supplies are received in a timely manner appropriate to priority and need.

- Departmental response: Agreed. National Defence initiated a performance measurement system for the supply chain, including key indicators focusing on a variety of areas within the supply system.

- Recommendation 3: National Defence should review how it establishes stock levels for parts needed to keep equipment operating at expected serviceability targets, to obtain and deliver parts to users in a timely way.

- Departmental response: Agreed. The Department is implementing a Distribution Resource Planning tool, complete with a modelling capability that is expected to improve the identification of inventory requirements.

Details

- In 2013, National Defence adopted a new IT system to manage materiel, in compliance with Treasury Board policy. This change degraded the 2010 performance measurement system.

- From 2013 to 2018, National Defence gradually reconstructed most 2010 performance measurement tools, including those to support Departmental Results Framework reporting.

- In 2019, National Defence began developing a new performance measurement framework for the supply chain to enable oversight and decision-making. Initial operational capability is anticipated in fall 2022.

Inventory Management Issues (on which National Defence reports to Parliament)

Governance

Key Messages

- We know that effective governance is a critical component in improving inventory management.

- In accordance with our 2016 inventory management action plan, we have developed a number of governance mechanisms to improve oversight.

- For example, in 2019, we signed a Defence Supply Chain Governance Charter, which established the Defence Supply Chain Oversight Committee to oversee the supply chain in its entirety.

- This Committee holds quarterly meetings to ensure Assistant Deputy Ministers and their advisors are up to date on supply chain performance, compliance, and departmental progress, and are able to provide strategic direction to their respective organizations.

- Further, in 2019 we created the Performance Measurement and Evaluation Committee.

- This committee meets biannually to advise the Deputy Minister and Chief of the Defence Staff on a variety of issues, including on improving inventory management.

- We will continue to improve our structures to ensure oversight, accountability, and direction in improving how we manage our inventory.

Key Facts

- Assistant Deputy Minister (Materiel) and the Director of Staff of the Strategic Joint Staff lead the Defence Supply Chain Oversight Committee.

- Committees at the Director General and Director level oversee the functioning of the supply chain and resolve specific issues.

Details

- In October 2018, a joint DM/CDS directive consolidated oversight of the defence supply chain, including inventory management, making it a joint civilian-military responsibility.

- Prior to October 2018, accountability for component pieces of the defence supply chain was distributed within National Defence, and were not managed as an end-to-end system.

Enhanced Materiel Accountability

Key Messages

- We agree with the Auditor General that we must continue improve how we record and value our inventory.

- That is why in 2016 we integrated a number of existing efforts into a new Enhanced Materiel Accountability initiative.

- We have made substantial progress in more accurately tracking the quantity, condition, location, and price of our inventory.

- For example, between 2012 and 2020, we counted and verified approximately $9 billion of materiel across Canada.

- In this period we also conducted 191 stock verification visits, verifying the local management of $5.27 billion of materiel.

- This past September, we reported to this Committee that we had met all of our objectives for the initiative, and have institutionalized these practices.

- Going forward, we will continue to carefully record our inventory, and will conduct stock verification visits at a minimum of ten sites per year to maintain an accurate picture of our materiel holdings.

Key Facts

- 2008-2009: National Defence introduced Annual Materiel Attestations, whereby senior officials attest that they are tracking materiel accurately.

- 2012: National Defence implemented the National Stocktaking Program (NSP), increasing the quantity and frequency of stocktaking.

- 2014: National Defence expanded the NSP to include biannual stock verification compliance visits to detect process issues and train personnel.

- 2015-2016: National Defence mandated action plans across its nine largest materiel users to ensure progress in addressing enduring issues.

- 2016: National Defence integrated existing efforts into the Enhanced Materiel Accountability initiative.

Automatic Identification Technology Project

Key Messages

- We agree with the Auditor General that more needs to be done to record, value, and manage our inventory.

- That is why we launched the Automatic Identification Technology project in 2017, to determine a solution that will provide a more accurate picture of the quantity, location, and condition of our material.

- Since launching the project, we have worked to identify our own requirements and understand best practices from our Five Eyes partners.

- We are currently working with industry to identify, refine, and cost a recommended option on how to move forward with new technology.

- This is a long term project that will take time and effort, but we believe this will make a lasting difference to how we manage our inventory.

- For example, when complete, we anticipate the use mobile devices to read barcodes on materiel, automatically uploading the data to our inventory management systems.

- We expect that in 2023, we will begin to distribute new technology to units, bases, and wings across Canada and overseas, and fully implement all elements of the project by 2028.

Key Facts

- June 2019: National Defence entered the definition phase of development.

Background

- The completion of the Automatic Identification Technology (AIT) Project is a key commitment in National Defence's 2016 Action Plan on Inventory Management. In this plan, National Defence committed to entering the definition phase in the 2019/2020 fiscal year. This commitment has been met.

- AIT is one of a number of efforts intended to modernize the defence supply chain. Other initiatives, including data remediation and marking, materiel identification, and the modernization and implementation of sustainment and logistics, will complement AIT in increasing the accuracy of inventory data.

- Canada shares best practices with our five eyes partners via the Joint Supply Chain Forum and actively participates in the NATO Asset Tracking Working Group which establishes data standards for asset tracking (e.g. unique identification for serialized materiel).

Inventory Management Modernization and Rationalization Project

Key Messages

- We agree with the Auditor General that more needs to be done to improve how we manage our inventory, including obsolete materiel.

- That is why in 2014 we launched the Inventory Management Modernization and Rationalization project, to modernize our business practices and better identify materiel that we no longer need.

- We formally completed the project this year, having successfully achieved all of our objectives for it in our 2016 Inventory Management Action Plan.

- For example, we have exceeded our action plan commitments by evaluating over 346,000 stock codes to determine which materiel should be retained for future use, and which should be disposed of.

- Through that process, we completed disposal documentation for over 138,000 stock codes in our materiel management system and removed over 1.5 million individual items marked for disposal from our warehouses.

- Most importantly, we continue to modernize our business processes and training, and refine the tools we use to manage oversight.

- Last year, the Auditor General stated that they were pleased with the progress we have made in achieving our action plan commitments.

- We will continue to build on this progress to better manage our inventory and improve our supply chain.

Key Facts

- August 2014: National Defence begins reviewing and archiving 254,000 stock codes with zero holdings, removing clutter in the system of record.

- January 2015: National Defence begins disposing of almost 24,000 stock codes marked for disposal in the Defence Resource Material Information System (DRMIS), representing 1.7 million individual items.

- September 2016: National Defence begins rationalizing 300,000 stock codes to determine whether they should be retained or disposed of.

Details

Modernization

- As of August 2016, DRMIS now contains codes to identify when materiel is in surplus, is approved for disposal, when partial disposal is required, and when disposal is completed.

- This allows for proper materiel valuation, supporting accuracy in the public accounts and the ability of management to generate reports to manage progress.

- Further, National Defence has improved the capabilities of DRMIS to include an updated disposal process.

- This is expected to improve data for decision making, better warehouse space usage, and prevent the re-accumulation of obsolete materiel.

- National Defence has also developed and implemented a process to facilitate the disposal of broken materiel into regular business.

- This is expected to improve accuracy of information on materiel quantity and condition, as well as its usage history for procurement planning.

Pricing Project

Key Messages

- We understand that effectively pricing our inventory is essential to the accuracy of the Public Accounts of Canada, given the scale of our holdings.

- And we agree with the Auditor General that we must improve.

- In 2015, we launched the Pricing Project to modernize the processes we rely on to price our inventory.

- Since then, we have made substantial progress by sampling our records to identify the cause of pricing errors, reviewing our accounting policies, and by standardizing our valuation process.

- We also amended prices in our departmental inventory records where appropriate, and implemented systems to monitor for future accounting discrepancies and ensure continued accuracy.

- We completed this project in March 2020 with a more modernized pricing process, revamped policies and training, and more accurate pricing information.

- With these improvements in place, we will continue to make progress in the valuation of our inventory.

Key Facts

National Defence addressed its pricing policies in three main areas:

- Kits: the assigned value of a completed "kit" was sometimes different than the value of its component parts.

- 2017-2018: National Defence standardized its processes for kit pricing and began monitoring of the process to ensure continued accuracy.

- Replacement costs: forecasted costs of replacing an item did not always match the eventual procurement cost.

- 2017-2018: National Defence revised its replacement cost processes to ensure its projected price is closer to the replacement value.

- Bulk acquisition of spare parts: bulk spare parts can be procured at a lesser price than individual items, which the accounting system could not accommodate

- 2019-2020: National Defence standardized the pricing policies for how the acquisition of spare parts must be accounted for in its records.

Details

- Pricing discrepancies were found due to unaligned policy between pricing requirements, financial accounting policies for determining inventory value, and functionalities within National Defence's system of record.

- Through the Pricing Project, National Defence reconciled the business requirements of its materiel and finance staff, and improved the ability of its personnel to value inventory within the resource management information system.

Pricing Legacy Data Clean-Up

Key Messages

- We agree with the Auditor General that we must continue to improve the quality of records to report accurate and complete data.

- This is why in 2016 we launched the pricing legacy data clean-up project to review and correct existing pricing errors in our inventory tracking system.

- We have made substantial progress, resulting in higher-quality records and more accurate financial reporting.

- For example, from 2016 to March 2019 we reviewed 50 million transactions for errors.

- Since 2016, we have validated the correct prices for a combined 402,000 stock codes worth $6 billion.

- In March 2019, we finished correcting our existing price data, and began monitoring ongoing transactions for errors.

- This past July, we implemented software to conduct weekly analyses and automatically report potential pricing errors, allowing our experts to investigate and identify any problems.

- We will update this software in March 2021 to include inventory updates for our ships at sea, the only piece missing from our current system.

Key Facts

- The legacy data cleanup included:

- FY 2016-2017: reviewing 2,000 stock codes worth $3.5B

- FY 2017-2019: reviewing 400,000 stock codes worth $2.5B

- Monitoring system: reviews approximately 150,000 transactions per month

- July 2021: National Defence will adopt a new, simplified monitoring tool.