Hazard Prevention Program Guide

Alternate formats

Work places contain a wide range of hazards, some known, others less so. We have learned to control most of them, sometimes instinctively, sometimes intentionally. Given the ever-increasing complexity of work places, we can no longer rely on instinct alone. Risk must be managed just like any other business function. The negative impacts are so costly in human and financial terms that we must control them. For this reason, paragraph 125(1)(z.03) of the Canada Labour Code requires employers under federal jurisdiction "to develop, implement and monitor (…) a prescribed program for the prevention of hazards in the work place…"

Notice to the reader

Part II of the Canada Labour Code deals with occupational health and safety, and its purpose is to "prevent accidents and injury to health arising out of, linked with or occurring in the course of employment".

This guide is designed jointly to assist you as an employer, as a member of a policy or work place committee, or as a health and safety representative to develop a hazard prevention program that complies with Part XIX of the Canada Occupational Health and Safety Regulations (COHSR). It suggests a simple, practical procedure to be followed with a view to supporting you in developing, implementing and controlling the application of the prescribed program for the prevention of hazards in the work place, including the employee education program on occupational health and safety.

Part XIX of the Regulations, entitled Hazard Prevention Program, covers obligations concerning the identification of hazards, the assessment of those hazards, the choice of preventive measures, and employee education.

The following pages contain a decision-making framework and sample work sheets to help you better understand the regulatory requirements. To facilitate understanding, section 19.2 dealing with the implementation of preventive measures is not presented at the beginning of the guide but rather between the sections on employee education and program evaluation.

The sample work sheets in this guide illustrate certain steps in the program development process. The guide and the work sheets do not form part of the Regulations and are therefore not compulsory.

1. Purpose of the regulations

Work places contain a wide range of hazards, some known, others less so. We have learned to control most of them, sometimes instinctively, sometimes intentionally. Given the ever-increasing complexity of work places, we can no longer rely on instinct alone. Risk must be managed just like any other business function. The negative impacts are so costly in human and financial terms that we must control them. For this reason, paragraph 125(1)(z.03) of the Canada Labour Code requires employers under federal jurisdiction "to develop, implement and monitor (…) a prescribed program for the prevention of hazards in the work place … "

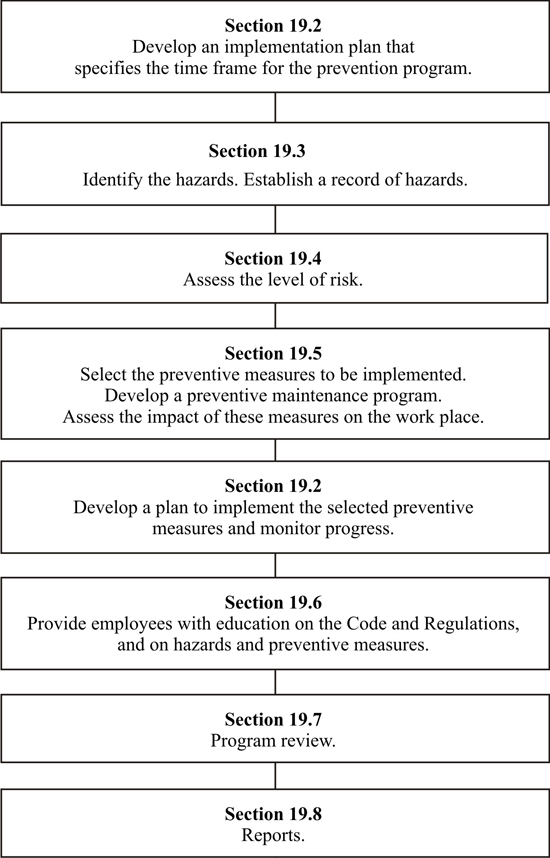

It is not possible to develop a standard prevention program that would work for all businesses. Transporting bags of flour by truck does not involve the same hazards as those inherent in producing flour in a mill. The prevention program will vary depending on the type of work performed, the size of the work place and the nature of the hazards. That is why Part XIX of the Regulations presents a prevention process and not a specific program model. By following the process described in subsection 19.1(1) of Part XIX of the Regulations, you will be able to implement and maintain useful, practical and effective precautionary measures enabling you to prevent the occurrence of accidents, diseases and a number of other losses. The decision-making framework below illustrates the prevention process, which includes the following six components:

- the implementation plan

- the hazard identification and assessment methodology

- hazard identification and assessment

- preventive measures

- employee education

- program evaluation

Since employees constantly face hazards at work, the Regulations require that the policy committee, the work place committee and/or the health and safety representative be consulted and participate from the outset in the prevention process. By ensuring their cooperation, you increase the chances that your prevention program will be successful.

As outlined in Part XIX of the Regulations, an employer shall develop, implement and monitor a program for the prevention of hazards in the work place, in consultation and with the participation of the committee*. This means that the committee will be consulted and shall participate in the development and monitoring of the implementation plan, the development of the hazard identification and assessment methodology. As well, the policy committee shall be consulted and shall participate in respect to hazard identification and assessment, by outlining the role of the work place health and safety committee and/or health and safety representative with respect to hazard identification and assessment.

*Note: For the purpose of this guide, committee means policy committee, or if there is no policy committee, the work place health and safety committee or the health and safety representative.

The committee shall also participate in the development and implementation of the preventive measures that will address the assessed hazards, and shall participate in the development and review of the educational materials established for employees' health and safety education.

The committee shall also participate in the evaluation of the effectiveness of the hazard prevention program, and in any necessary revisions of the program.

The hazard prevention program is a tool that brings together all the efforts undertaken in support of occupational health and safety in the work place.

Decision-making framework (Sections 19.2 to 19.8 of the regulations)

Description of the decision-making framework image

Section 19.2

- Develop an implementation plan that specifies the time frame for the prevention program

Section 19.3

- Identify the hazards

- Establish a record of hazards

Section 19.4

- Assess the level of risk

Section 19.5

- Select the preventive measures to be implemented

- Develop a preventive maintenance program

- Assess the impact of these measures on the work place

Section 19.2

- Develop a plan to implement the selected preventive measures and monitor progress

Section 19.6

- Provide employees with education on the Code and Regulations, and on hazards and preventive measures

Section 19.7

- Program review

Section 19.8

- Reports

2. Definitions

The prevention program only covers hazards arising out of, linked with or occurring in the course of employment over which you have control, whether within or outside the work place. Hazards in the work place include:

- work accidents

- occupational diseases

- hazards related to the safe occupancy of the work place

- all other hazardous situations

2.1 Work place accidents

The Code does not provide a definition of a work place accident. It is generally agreed that a work place accident is an unpleasant and unwanted event attributable to any cause, happening to any person due to or during work and causing death, physical injury or acute poisoning when there is exposure to a toxic product over a very short period of time.

2.2 Occupational diseases

The Code does not define the term occupational disease. The term generally covers deaths and illnesses contracted due to or during work and which are a characteristic of this work or directly related to chemical, physical or biological agents that are used, produced, handled or stored at a work place and which gradually affect the health of employees. The main hazards that may give rise to health problems or occupational diseases are:

- physical, chemical and biological agents, including controlled products

- hazardous substances that can have long-term effects on health and reproductive health

- poor indoor air quality

- poor sanitary conditions

- exposure to a toxic gas or an oxygen deficient atmosphere

In the event that employees are excessively exposed to these hazards, they may contract a short-, medium-, or long-term reversible or irreversible occupational disease.

2.3 Hazards related to the safe occupancy of the work place

Hazards related to the safe occupancy of the work place specifically mentioned in the Code and the Regulations must be covered by your prevention program, even if no person is injured or affected. These are:

- fire hazards

- explosion hazards

- risks of damage to a boiler or a pressure vessel that results in fire or the rupture of the boiler or pressure vessel

- risks of damage to an elevating device that renders it unserviceable, or a free fall of an elevating device

- confined spaces

- all other hazards that may require implementation of rescue, revival or other similar emergency procedures

2.4 Other hazardous situations

Where a particular work place hazard is not specifically addressed in the Regulations, the Hazard Prevention Program Regulation is designed to provide the framework to effectively address that hazard to prevent accidents and injury to health arising out of, linked with or occurring in the course of employment.

3. Guide to the regulatory requirements

Section 19.3: Hazard identification and assessment methodology

-

The employer shall develop a hazard identification and assessment methodology, including an identification and assessment methodology for ergonomics-related hazards, taking into account the following documents and information:

- any hazardous occurrence investigation reports;

- first aid records and minor injury records;

- work place health protection programs;

- any results of work place inspections;

- any employee reports made under paragraph 126(1)(g) or (h) of the Act or under section 15.3;

- any government or employer reports, studies and tests concerning the health and safety of employees;

- any reports made under the Safety and Health Committees and Representatives Regulations;

- the record of hazardous substances; and

- any other relevant information, including ergonomics-related information.

- The hazard identification and assessment methodology shall include:

- the steps and time frame for identifying and assessing the hazards;

- the keeping of a record of the hazards; and

- a time frame for reviewing and, if necessary, revising the methodology.

Explanation

The purpose of hazard identification is to highlight the operations of critical tasks, that is, those tasks posing significant risks to the health and safety of employees, as well as highlighting those hazards pertaining to certain equipment due to energy sources, working conditions or activities performed.

Consult your files first

You already have information about the hazards in your work place. Start the identification process by carefully going over them. Paragraphs 19.3(1)(a) to (h) provide you with a list of items for this purpose.

Identification techniques

To complete your hazard identification, you can use techniques to identify hazards such as:

- work place inspections

- task safety analysis

- preliminary investigations

- potential accident factors

- failure analysis

- accident and incident investigations

For each of these techniques, the hazards are identified by observing tasks that are actually performed at the various work stations.

Adaptation to the size of your business

It is in your interest to adopt your own process and your own identification techniques so that they match your management procedures and the size of your business. In fact, the identification method may vary depending on the size of the work place. If your business is small, it may be to your benefit to identify hazards "per individual," as each individual performs specific tasks. For example, in a small road transport business, Kim is a truck driver, while Paul is a truck driver who also takes care of welding and the mechanical maintenance of trucks; Yvon is a lift truck driver and repairs tires and bodywork, while Claire is a fuel pump attendant and dispatches the drivers. Therefore, the hazards for Kim, Paul, Yvon and Claire must be identified.

If your business is larger, it is more likely that several employees hold the same positions. You can then carry out the identification "per work station." In a larger road transport business, hazards can be identified for truck drivers, lift truck drivers, welders, mechanics, body workers, body painters, fuel pump attendants and office staff.

If your business is larger still, you could proceed by "work area," grouping individuals and work stations by similarity of tasks, hazards and management; this is a commonly used method. For example, there are specific hazards and preventive measures associated with pressure boilers. Since everyone who works in a boiler room is exposed to much the same hazards, you can identify the hazards for all boiler room workers. Another example would be in large warehouses, where a number of lift trucks are often used, doors are frequently open even in winter, heavy loads are handled, and so on. You could group together the hazards for all shipping and receiving employees in one work area.

If the areas are too large, you can divide them so that each foreman or department head would be responsible for both production and his or her prevention program. In very large businesses, the identification method might differ among facilities.

Hazard record

After having identified the hazards, you must establish and maintain an identification record, either in print or electronic format.

The identification technique used in the example is very simple. It identifies five components of work: equipment (machines and tools), materials (substances and products), environment, personnel and work organization. When the interaction among these five components is normal, the desired products and services are delivered: in this case, transporting material with a lift truck to load a truck, a railway car, a container, and so on. On occasion, the interaction among components may work in an unexpected way and result in incidents such as an accident, an occupational disease or a fire. To identify the hazards involved in driving a lift truck you must 1) identify the work components and 2) ask what may go wrong. For example, the lift truck is the equipment. There may be the potential of a breakdown of a truck part, collision or a back injury, for example. As for materials being transported, the operator may be hit by falling material, there may be a fire hazard because of flammable material, and so on.

Time frame for identification and review

You must define the steps for the identification of hazards and a time frame for this identification. The following information should be included:

- who will be responsible for the identification: for example, it may be the work place health and safety committee, or an individual or individuals appointed by the committee

- the way in which the identification reports are processed: for example, they may be compiled and processed by the committee, or by individuals appointed by the committee

- the identification time frame: for example, the identification of hazards for workshop A must be completed in December, for workshop B in April and for workshop C in November

- the date for the review of the identification: for example, the review of the identification method will be carried out every two years

These steps cannot be completed in one day. A minimum amount of time will have to be spent on them. Remember that emphasis must be placed on identification, because follow-up of the prevention program depends upon it, that is, the assessment of hazards, the implementation of preventive measures and employee education.

Section 19.4: Hazard Identification and Assessment

The employer shall identify and assess the hazards in the work place, including ergonomics-related hazards, in accordance with the methodology developed under section 19.3 taking into account:

- the nature of the hazard;

(a.1) in the case of ergonomics-related hazards, all ergonomics-related factors such as:- the physical demands of the work activities, the work environment, the work procedures, the organization of the work and the circumstances in which the work activities are performed, and

- the characteristics of materials, goods, persons, animals, things and work spaces and the features of tools and equipment;

- the employees' level of exposure to the hazard;

- the frequency and duration of employees' exposure to the hazard;

- the effects, real or apprehended, of the exposure on the health and safety of employees;

- the preventive measures in place to address the hazard;

- any employee reports made under paragraph 126(1)(g) or (h) of the Act or under section 15.3; and

- any other relevant information.

Explanation

In the identification step you inventoried all the hazards encountered in your business. It is very likely that they are numerous, which makes any single action to control all of them impossible. Therefore, you must critically examine all of the hazards in order to establish an order of priority. In this way, you can prioritize your preventive measures, without losing sight of the final objective, which is to eliminate all hazards in the work place or, if they cannot be eliminated, control them.

Consult your files

You can consult the employee reports, the first aid record, the minor injuries record, the hazardous occurrence reports and your workers' compensation statements. This will enable you to assess the level of hazard exposure to employees.

Other assessment methods

You can use any other assessment method, provided it takes into account all the factors mentioned in paragraphs 19.4(a) to (g).

Caution!

For hazardous substances, you must use the assessment method described in section 10.4 of Part X of the Regulations, for noise, the one contained in section 7.3 of Part VII, and for confined spaces, the one stipulated in section 11.2 of Part XI. In each of these three instances, the assessment must be made by a qualified person, and the assessment criteria are determined by the Regulations.

Section 19.5: Preventive Measures

- The employer shall, in order to address identified and assessed hazards, including ergonomics-related hazards, take preventive measures to address the assessed hazard in the following order of priority:

- the elimination of the hazard, including by way of engineering controls which may involve mechanical aids, equipment design or redesign that take into account the physical attributes of the employee

- the reduction of the hazard, including isolating it;

- the provision of personal protective equipment, clothing, devices or materials; and

- administrative procedures such as the management of hazard exposure and recovery periods and the management of work patterns and methods.

- As part of the preventive measures, the employer shall develop and implement a preventive maintenance program in order to avoid failures that could result in a hazard to employees.

- The employer shall ensure that any preventive measure shall not in itself create a hazard and shall take into account the effects on the work place.

- The preventive measures shall include steps to address:

- a newly identified hazard in an expeditious manner; and

- ergonomics-related hazards that are identified when planning implementation of change to the work environment or to work duties, equipment, practices or processes.

- The employer shall ensure that any person assigned to implement ergonomics-related prevention measures has the necessary instruction and training.

Explanation

Preventive measures mean all useful, practical and effective methods that make it possible to avoid the occurrence of a hazardous situation. There are multiple methods to help you find solutions to a given problem, but Part XIX of the Regulations has established a hierarchal order: elimination, reduction, protection, and administrative control.

First, try to eliminate the hazard

Of all the existing prevention techniques, the elimination of a hazard is the most effective. To achieve this, the machine, thing, condition or activity, that constitutes the hazard, is replaced by another machine, thing, condition or activity that eliminates the original hazard, and which does not create a new hazard. For example, if you prohibit everyone from walking in a warehouse, you eliminate the hazard of collision between staff and a lift truck.

If not, reduce it

If you cannot eliminate the hazard, you can attempt to reduce it through control techniques that aim to diminish the intensity of the hazard should it occur, prevent the hazardous situation from occurring, or eliminate hazardous tasks. For example, in a warehouse, you can identify corridors and areas that are safe for pedestrians by using yellow stripes painted on the floor.

If this is not possible, protect yourself

Protection techniques make it possible to counter a hazardous occurrence or diminish the scope of potential damage. There are two types of protection: group and personal. Group protection involves blocking or separating the hazard from the employee. For example, you can install buffers in strategic locations to prevent the lift truck from entering areas where people circulate. Personal protection involves providing employees with protective equipment or clothing. For example, the use of high-visibility apparel.

Other administrative measures

Part XIX of the Regulations require that administrative measures be considered only after the preceding preventive measures have been considered, not because they are without value, but because technical solutions are more effective than solutions that focus on individuals. This category encompasses all management techniques that aim to reduce the hazard.

Preventive maintenance

Regardless of the preventive measures proposed, the preventive maintenance program is mandatory. Its purpose is to prevent failure in the long term of structures, equipment, machinery and tools through routine inspections and the repair of worn parts. For example, planned inspections, mechanical maintenance and the replacement of worn brakes on a lift truck are indispensable prevention measures.

Since Part XIX of the Regulations require a preventive maintenance program, you must establish a list of the structures, machinery, equipment and tools that need to be inspected, adjusted, cleaned, lubricated, replaced, and so on. You must draw up a maintenance schedule, describe the maintenance procedures, record the work completed, verify the progress of work and assess effectiveness.

Hazard-free preventive measure

Since a preventive measure is a control of a present hazard, a current working condition or an existing activity, make sure that the measure itself is not a source of a hazard before implementing it. For example, if you install a conveyor belt to replace a lift truck, make sure it is in compliance with current safety standards.

A preventive measure must not create a new hazard. If such a hazard arises, it must be dealt with as soon as possible. For example, when indicating areas for pedestrian traffic, make sure it does not cause an unsafe congestion of lift trucks in another location, install mirrors so that the operator can see pedestrians before turning a blind corner, and so on.

Record preventive measures

Keeping a record of implemented preventive measures is important to the success of the hazard prevention program. You will need this record to complete the subsequent steps in the prevention process.

Section 19.6: Employee Education

- The employer shall provide health and safety education, including education relating to ergonomics, to each employee which shall include the following:

- the hazard prevention program implemented in accordance with this Part to prevent hazards applicable to the employee, including the hazard identification and assessment methodology and the preventive measures taken by the employer;

- the nature of the work place and the hazards associated with it;

- the employee's duty to report under paragraphs 126(1)(g) and (h) of the Act and under section 15.3; and

- an overview of the Act and these Regulations.

- The employer shall provide education to an employee:

- whenever new hazard information in respect of a hazard in the work place becomes available to the employer; and

- shortly before the employee is assigned a new activity or exposed to a new hazard.

- The employer shall review the employee education program, and, if necessary, revise it:

- at least every three years;

- whenever there is a change in conditions in respect of the hazards; and

- whenever new hazard information in respect of a hazard in the work place becomes available to the employer.

- Each time education is provided to an employee, the employee shall acknowledge in writing that they received it, and the employer shall acknowledge in writing that they provided it.

- The employer shall keep, in paper or computerized form, records of the education provided to each employee, which shall be kept for a period of two years after the employee ceases to be exposed to a hazard.

Explanation

Content and duration of education

Although the detail of instruction and its duration may vary depending on the requirements of each work position, the requirements of 19.6(1) must be addressed.

Education schedule

As soon as the content and the duration of the education sessions have been determined, you must prepare the education schedule.

There is no requirement to educate every employee every three years, although refresher sessions in between are a good idea. However, they must be educated before performing their tasks, before being exposed to a hazard and every time you receive new information about the hazards they are exposed to. You must review your education program accordingly. If there is no change in the hazards, you must review the program every three years.

Confirmation of education

Whenever an education session is given, the employer must acknowledge in writing that the education took place, and employees must also acknowledge in writing that they have received such education. In many cases, a simple learning report such as the one presented below is all that is required.

Education record

Lift Truck

Defensive driving, maintenance and inspection

| No. | Name | Signature | PIN | Department/Section |

|---|---|---|---|---|

| 1 | Thomas Fisher | 234 | Warehouse | |

| 2 | Kim Hasley | 40 | Warehouse | |

| 3 | Paul Duchesneau | 119 | Shop | |

| 4 | ||||

| 5 | ||||

| 6 | ||||

| 7 | ||||

| 8 | ||||

| 9 | ||||

| 10 |

Signature of the person responsible for training:

William Brown

Date: 12/04/09

Date of training:12/04/09

Education record

For each employee, you must create and regularly update a record of all occupational health and safety education you have provided. This record must be kept for two years following the date the employee ceases being exposed to a hazard. Here is an example of a education record:

Employee Education Record

234

Fisher

Thomas

2002-2009

| No. | From - To - Duration | Course Title | Description |

|---|---|---|---|

| 1 | 12/04/02 - 12/04/02 - 3½ hrss | Tire repair | Work procedures on a new machine |

| 2 | 15/02/03 - 16/02/03 - 14 hrss | Work procedures on a new machine | Preventive maintenance |

| 3 | 05/07/03 - 05/07/03 - 1 hr | LPG | Handling of tanks, refuelling safety |

| 4 | 10/04/09 - 12/04/09 - 3 days | Lift trucks | Defensive driving, maintenance and inspection |

| 5 | |||

| 6 | |||

| 7 | |||

| 8 | |||

| 9 | |||

| 10 |

Section 19.2: Implementation Plan

- The employer shall:

- develop an implementation plan that specifies the time frame for each phase of the development and implementation of the prevention program;

- monitor the progress of the implementation of the preventive measures; and

- review the time frame of the implementation plan regularly and, as necessary, revise it.

- In implementing the prevention program, the employer shall ensure that ergonomics-related hazards are identified and assessed and that they are eliminated or reduced, as required by subsection 19.5(1), as much as is reasonably possible and that any person assigned to identify and asses ergonomics-related hazards has the necessary instruction and training.

Explanation

All activities planned for the hazard prevention program must be listed and given a specific time frame for completion.

One way to monitor implementation of a prevention program is to verify whether the scheduled activities took place as planned. Most of the time, the implementation process involves four steps. For each step, you should verify your progress. The four steps are:

- describe the measure to be implemented and the work to be performed (new work, new conditions, new technical activities or new tasks)

- approve the work to be performed

- document new work procedures

- provide employee training

A second way to monitor implementation of a prevention program is to verify whether the preventive measures were implemented as planned. If for any reason implementation of a scheduled measure of the prevention program is delayed, it is best to revise the work schedule immediately because other work planned to follow may have to be shifted.

Section 19.7: Program Evaluation

- The employer shall evaluate the effectiveness of the hazard prevention program and, if necessary, revise it:

- at least every three years;

- whenever there is a change in conditions in respect of the hazards; and

- whenever new hazard information in respect of a hazard in the work place becomes available to the employer.

- The evaluation of the effectiveness of the prevention program shall be based on the following documents and information:

- conditions related to the work place and the activities of the employees;

- any work place inspection reports;

- any hazardous occurrence investigation reports;

- any safety audits;

- first aid records and any injury statistics, including records and statistics related to ergonomics-related first-aid and injuries;

- any observations of the policy and work place committees, or the health and safety representative, on the effectiveness of the prevention program; and

- any other relevant information.

Explanation

At least once every three years you must evaluate the overall effectiveness of your prevention program and revise it if necessary. The effectiveness evaluation may be conducted more often if hazard conditions change, for example, when you buy new machinery, fit out new offices, reorganize work, rearrange equipment or change tasks. You must also evaluate your prevention program if you discover additional information about the hazards in your business. For example, pentachlorophenol used to treat wooden railway sleepers, telephone poles and docks has been classified by the International Agency for Research on Cancer (IARC) as group 2B (agents which may be carcinogenic to humans). As soon as you are made aware of this information, you must re-analyze the risk and modify your program as needed.

Consult your files first

The evaluation of the prevention program must be quantified as much as possible because Part XIX of the Regulations require an evaluation of its effectiveness. It is very difficult to evaluate effectiveness without supporting figures. Subsection 19.7(2) provides the list of documents to be consulted.

Written report

There is no standard format for the evaluation report but it should generally answer the following questions:

- What are the main hazards in your business?

- Which hazards did you address over the period covered by the report?

- Do some hazardous occurrences recur on a regular basis? What have you done to control them? Are there any new ones?

- Has there been a change in the nature of accidents, diseases and lost time?

- Has there been a change in the frequency of the hazardous occurrences?

- Has there been a change in the duration of the hazardous occurrences?

- Has there been a change in the level of exposure of employees to hazards in the work place?

Section 19.8: Reports

- If a program evaluation has been conducted under section 19.7, the employer shall prepare a program evaluation report.

- The employer shall keep readily available every program evaluation report for six years after the date of the report.

Explanation

An employer is required to prepare an evaluation report at least once every three years. Also, whenever there is a change in the work place in respect of the hazards or whenever the employer becomes aware of new information about a particular hazard or hazards, the employer is required to prepare a new evaluation.

Conclusion

A good hazard prevention program can prevent work place accidents and injuries while streamlining an employer's health and safety activities. The Labour Program can also assist you in identifying resources to help you get started. Contact us at one of our district offices today.