Environmental Code of Practice for Non-Integrated Steel Mills: section 1

Section 1: Introduction

- 1.1 Sector Description

- 1.2 Scope of the Code

- 1.3 Code Development

- 1.4 Code Structure

- 1.5 Implementation of the Code

Environment Canada and Health Canada have joint responsibility for the management of toxic substances under the Canadian Environmental Protection Act (CEPA), which provides for actions, including regulations, relating to the quantity or concentration of a toxic substance that may be released to the environment.

Responsibilities under the Act include identifying substances that may be toxic, assessing them to determine whether they are toxic as defined in CEPA 1999 Part 5 and, for substances that are found to be toxic, establishing and applying controls to prevent harm to human health or the environment. The CEPA Schedule 1 List of Toxic Substances is available on Environment Canada's website.

Sixteen substances that are released, produced, or used by the Canadian steel manufacturing sector were assessed as toxic under Section 11 of CEPA (1988). Those substances are: benzene, polycyclic aromatic hydrocarbons (PAHs), inorganic arsenic compounds, inorganic cadmium compounds, hexavalent chromium compounds, lead, mercury, oxidic, sulphidic and soluble, inorganic nickel compounds, inorganic fluorides, dichloromethane, tetrachloroethylene, 1,1,1-trichloroethane, trichloroethylene, polychlorinated biphenyls, polychlorinated dibenzodioxins (dioxins), and polychlorinated dibenzofurans (furans). Dioxins and furans have been identified as substances targeted for virtual elimination.

A Strategic Options Process (SOP) was launched in April 1995 to assess potential options for the management of these substances in the steel sector. A multi-stakeholder Issue Table was established under the SOP for the sector, with representatives from various government and non-government organizations. Eight meetings of the Issue Table were held starting July 24-25, 1995, and ending November 25-26, 1996.

The SOP culminated in the development of a Strategic Options Report (SOR). Recommendations advanced by the SOR for the steel sector included: the development of an Environmental Code of Practice for Non-Integrated Steel Mills, the development of pollution prevention plans, and the conduct of environmental audits. It was also recommended that the Codes of Practice address best management practices for achieving continual improvement in the design, operation, and maintenance of air and water pollution control systems. The Environmental Code of Practice for Non-Integrated Steel Mills was developed in response to these recommendations.

A second group of substances, the CEPA Priority Substances List (PSL2), is being assessed by Environment Canada and Health Canada.

The Code identifies good environmental protection practices for various production processes and operations of a non-integrated steel plant, with air emission and water effluent considerations as the highest priorities. It also includes multimedia and other considerations consistent with a comprehensive and life cycle approach to environmental protection.

1.1 Sector Description

The Canadian steel sector comprises the 17 facilities listed in Table 1.1 and shown in Figure 1.1. The sector consists of five integrated mills, including QIT-Fer et Titane Inc., and 12 non-integrated mills (10 mini-mills and two specialty steel mills).

| Plant No. | Plant Company/Name | Location | Manufacturing Process | Steel Shipments1(tonnes) |

|---|---|---|---|---|

| 1 | AltaSteel Ltd. | Edmonton, Alberta | mini-mill (MM) | 225,0002 |

| 2 | IPSCO Inc. | Regina, Saskatchewan | MM | 800,000 estimated (e) |

| 3 | Gerdau MRM Steel Inc. | Selkirk, Manitoba | MM | 254,000 |

| 4 | Algoma Steel Inc. | Sault Ste. Marie, Ontario | Integrated mills (IM) | 1,907,000 |

| 5 | Dofasco Inc. | Hamilton, Ontario | Integrated and Electric Arc Furnace Mills (IEM) | 3,400,0003 |

| 6 | Stelco Inc., Hilton Works | Hamilton, Ontario | IM | 2,672,0004 |

| 7 | Lake Erie Steel Co. (Stelco) | Nanticoke, Ontario | IM | 1,485,0005 |

| 8 | Slater Steels, Specialty Bar Division | Hamilton, Ontario | MM | 306,000 |

| 9 | Gerdau Courtice Steel Inc. | Cambridge, Ontario | MM | 250,000 |

| 10 | Atlas Specialty Steels | Welland, Ontario | Specialty steel mill (SS) | 200,000 e |

| 11 | Co-Steel Lasco | Whitby, Ontario | MM | 672,000 |

| 12 | Ivaco Inc. | L'Orignal, Ontario | MM | 525,000 e |

| 13 | Ispat Sidbec Inc. | Contrecoeur, Quebec | Direct reduction mini-mill (DRM) | 1,367,000 |

| 14 | Stelco-McMaster Ltée | Contrecoeur, Quebec | MM | 417,0006 |

| 15 | Atlas Stainless Steels | Tracy, Quebec | SS | 73,000 |

| 16 | QIT-Fer et Titane Inc. | Sorel, Quebec | IM | 350,000 e |

| 17 | Sydney Steel Corporation | Sydney, Nova Scotia | MM | 137,000 |

Plant Numbers refer to locations on Figure 1.1

Figure 1.1 Steel Plant Location by Province (1997)

Nine of these facilities, including four integrated mills, are located in Ontario. There are four mills in Quebec and one each in Alberta, Saskatchewan, Manitoba, and Nova Scotia. Ontario accounts for about 70% of Canadian steel capacity. Plant locations are shown in Figure 1.1.

In 1998, the 17 plants shipped 15.5 million tonnes of steel with a sales value of $11.2 billion and employed approximately 34,500 people.7

Canada plays a major role in the international steel trade, exporting 5.2 million tonnes and importing 7.4 million tonnes in 1998. The United States, Canada's traditional major trade partner in steel, accounted for 88% of Canada's exports and 42% of imports in 1998.8International competitiveness is a significant issue for the industry.

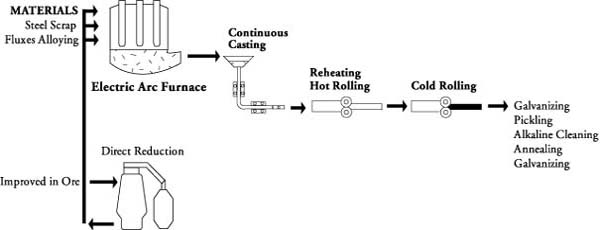

Steel making is a very complex, capital and energy intensive operation involving a progression of manufacturing processes that transform raw materials into iron and steel products. Figure 1.2 illustrates the iron and steel manufacturing processes.

Figure 1.2 Simplified Steel Manufacturing Flowsheet

Description of Figure 1.2

This figure provides a simplified graphic representation of major steps to produce steel using the non-integrated steelmaking process. Steel scrap, fluxes, direct reduced iron and alloying materials are processed in an electric arc furnace. The steel thus obtained is further treated to impart desired properties and then cast, hot rolled or cold rolled to various shapes. Additional treatments such as anodizing, galvanizing etc., are performed depending on the requirements. This is described more detail in Section 2 (Operational Activities).

Steel is produced in Canada by two main steelmaking processes: basic oxygen furnaces (58.5% in 1998) and electric arc furnaces (41.5% in 1998).9The basic oxygen furnace is used in integrated mills in conjunction with cokemaking, sintering, and blast furnace ironmaking operations. The integrated mills, which smelt iron ore and melt scrap, produce the greatest diversity of products including bars, rods, structural shapes, plates, sheets, pipes and tubes, and wire rod. The integrated mills are gradually changing their product mix towards a greater concentration in flat-rolled products. While electric arc furnace technology is gaining importance, it is usually used in non-integrated mills (mini-mills or specialty steel mills) fed by scrap or direct reduced iron (DRI) to produce a wide product range of carbon and alloy steels. Dofasco Inc. operates the only integrated steel plant in Canada that produces part of its steel by the electric arc furnace process. Ispat Sidbec Inc. operates the only Canadian steel mill that produces and uses DRI as part of its raw material feed.

Ancillary or secondary steelmaking processes that are common to both integrated and non-integrated steelmaking include ladle metallurgy, continuous casting, hot forming, cold forming, and finishing. Three of the integrated mills have finishing operations, which may include acid pickling, pickle acid regeneration, annealing, and coating. Lake Erie Steel Co. Ltd. produces hot-rolled flat product only. Two non-integrated mills (Ispat Sidbec Inc. and Atlas Stainless Steels) have some finishing operations (acid pickling, cold rolling, and annealing).

QIT-Fer et Titane Inc. was grouped with the integrated mills because it operates a basic oxygen furnace, a ladle metallurgy station, and a continuous casting machine for secondary steelmaking.10 QIT-Fer et Titane Inc. also produces titanium (TiO2) slag and high-quality pig iron from smelting calcined ilmenite ore and coal in rectangular electric arc furnaces. The iron oxide slag from the electric arc furnaces is fed to a basic oxygen furnace to produce high-quality steel billets.

1.2 Scope of the Code

The non-integrated mills segment of the steel sector includes all facilities that use scrap steel and direct reduced iron (DRI) as raw materials to produce primary steel products. Primary steel production processes include direct iron reduction, steelmaking, hot and cold forming, coating operations, and associated production and ancillary processes and facilities. It does not include pipe or tube making or steel fabricating facilities.

This Code of Practice outlines environmental concerns and alternative methods, technologies, designs, practices, and procedures that will minimize the adverse environmental effects associated with non-integrated steel mills. It also contains recommendations considered to be reasonable and practical measures to preserve and enhance the quality of the environment that is affected by these mills. Environmental performance standards are included for atmospheric emissions, water and wastewater, solids, and environmental management practices. These recommended practices may be used by the steel sector, regulatory agencies, and the general public as sources of technical and policy guidance in the development and implementation of site-specific environmental protection practices and requirements.

While Code recommendations are intended to be clear and specific with regard to expected results, they are not intended to discourage the use of alternative technologies and practices that can achieve an equivalent or better level of environmental protection. The Code is intended to be applied with some flexibility, recognizing that some recommendations will require interpretation to allow for site-specific conditions and concerns, particularly in the context of existing facilities. However, interpretations of Code recommendations should be undertaken in consultation with the appropriate regulatory authorities and stakeholders.

The overall objective of the Code is to identify minimum environmental performance standards for new non-integrated steel mills and to provide a set of environmental performance goals for existing mills to achieve through continual improvement over time. However, all municipal, provincial, and federal legal requirements must be met, and a commitment by companies to be consistent with Code recommendations does not remove obligations to comply with all regulatory requirements.

1.3 Code Development

The Code was developed by Environment Canada and provincial environmental agencies in consultation with industry representatives and other stakeholders. Federal, provincial, and international environmental guidelines and standards of relevance to the operation of non-integrated steel mills were considered in the development of these recommendations, as were the environmental management practices recommended by various national and international organizations. Sources of standards-related information included environmental agencies in the United States, various countries in the European Union, Japan, the World Bank, and the United Nations Economic Commission for Europe (UNECE). Information on best management practices was drawn from various reports and literature produced by provinces, Environment Canada, the Canadian Council of Ministers of the Environment (CCME), the United States Environmental Protection Agency (U.S. EPA), the United Nations Environment Programme (UNEP), the World Bank, the International Iron and Steel Institute (IISI, steel companies, and technical journals.

1.4 Code Structure

The Code describes operational activities (Section 2) and related environmental concerns such as atmospheric emissions, wastewater discharges, and waste management (Section 3). Recommended environmental protection practices are presented in Section 4.

1.5 Implementation of the Code

This Code of Practice will be adopted by Environment Canada and others as a guidance document that delineates appropriate environmental protection standards and practices for non-integrated steel mills. Some elements of the Code may be adopted under the Federal-Provincial/Territorial Environmental Harmonization Accord and associated sub-agreements such as Canada-Wide Standards (CWS) (CCME).

Some elements of the Code may be used in the development of initiatives or programs to achieve the objectives of cooperative agreements including the Canada-Ontario Agreement (COA) and St. Lawrence Vision 2000.

The Code may be adopted on a voluntary basis by individual steel sector corporations and facilities and by the Canadian Steel Producers Association and its members. It may be included as a commitment to Code recommendations in Environmental Performance Agreements among Environment Canada, provincial environment departments, and steel companies or facilities. It may also be adopted in whole or in part by regulatory agencies.

The Code may be used for benchmarking best practices to achieve continual improvement in the environmental performance of non-integrated steel mills in Canada and other countries. Code recommendations may also be used as benchmark criteria for the conduct of audits aimed at assessing the environmental performance of sector facilities or companies.

FootNotes

- 1 Canadian Steel Producers Association, Producer Information,, downloaded February 11, 1998.

- 2 Ibid.

- 3 Dofasco Inc., Annual Report 1996.

- 4 Stelco Inc, Annual Report 1996.

- 5 Ibid.

- 6 Ibid.

- 7 Canadian Steel Producers Association, Steel Facts 1992-1998, 29/03/99.

- 8 Ibid.

- 9 International Iron and Steel Institute, World Steel in Figures, 1999 Edition, Brussels, Belgium.

- 10 QIT-Fer et Titane Inc., corporate brochure.