Updated risk management scope for TCPP and TDCPP

Official title: Updated Risk Management Scope for 2-Propanol, 1-chloro-, phosphate (3:1) (TCPP) and 2-Propanol, 1,3-dichloro-, phosphate (3:1) (TDCPP)

Chemical Abstracts Service Registry Numbers:

- 13674-87-8

- 13674-84-5

Environment and Climate Change Canada

Health Canada

October 2020

Summary of proposed risk management

This document outlines the risk management options under consideration for TCPP and TDCPP, substances that are part of the Certain Organic Flame Retardants Grouping, which have been proposed to be harmful to human health. In particular, the Government of Canada is considering:

Regulatory or non-regulatory actions to help reduce dermal exposure of the general population to TCPP and TDCPP in certain products made with polymeric foams such as polyurethane foam. These products may include upholstered furniture, mattresses, mattress toppers, and other foam-based products to which prolonged skin contact may be expected.

Stakeholders are requested to provide any information on the following items to the contact specified in section 8 of this document, to inform risk management decision-making:

- Ongoing and anticipated changes in the use of TCPP and TDCPP in upholstered furniture, mattresses, mattress toppers, and other foam-based products available to consumers, whether in response to:

- changes in performance-based flammability requirements and/or standards;

- market forces; and/or

- other reasons (please provide information on these reasons).

- The use of TCPP and TDCPP in textiles, including textile backings in furniture.

- The use of TCPP and TDCPP in polymeric foams other than polyurethane foams, which may be used in products such as furniture, mattresses, and other foam-based products to which prolonged skin contact may be expected.

The risk management options outlined in this Risk Management Scope document may evolve through consideration of assessments and risk management options published for other Chemicals Management Plan substances as required to ensure effective, coordinated, and consistent risk management decision-making.

1. Context

The Canadian Environmental Protection Act, 1999 (CEPA) (Canada 1999) provides the authority for the Minister of the Environment and the Minister of Health (the Ministers) to conduct assessments to determine if substances are toxic to the environment and/or harmful to human health as set out in section 64 of CEPAFootnote 1, Footnote 2, and if so, to manage the associated risks.

As part of the second phase of the Chemicals Management Plan (CMP), the Ministers plan to assess and manage, where appropriate, the potential health and ecological risks associated with approximately 500 substances, in nine substance groupings (Canada 2011). The substances 2-propanol, 1-chloro-, phosphate (3:1), Chemical Abstracts Service Registry NumberFootnote 3 (CAS RN) 13674-84-5, referred to throughout this document as TCPP (see Annex A), and 2-propanol, 1,3-dichloro-, phosphate (3:1), Chemical Abstracts Service Registry Number (CAS RN) 13674-87-8, referred to throughout this document as TDCPP, are included in the Certain Organic Flame Retardants Grouping of the Substance Groupings Initiative of the Chemicals Management Plan (ECCC, HC 2020).

2. Issue

2.1 Updated draft screening assessment conclusion

In 2016, Health Canada and Environment and Climate Change Canada published a joint screening assessment of TCPP and TDCPP in Canada. New information was received after that publication that led to changes in the proposed conclusions for TDCPP. As a result, Health Canada and Environment and Climate Change Canada have updated the draft screening assessment of TCPP and TDCPP and a notice summarizing the updated draft screening assessment for these substances was published in the Canada Gazette, Part I, on October 17, 2020 (Canada 2020).

Based on the information available, the updated draft screening assessment proposes to conclude that TCPP and TDCPP are harmful to human health under section 64 of CEPA because they are entering the environment in a quantity or concentration or under conditions that constitute or may constitute a danger in Canada to human life or health.

The updated draft assessment also proposes to conclude that TCPP and TDCPP are not entering the environment in a quantity or concentration or under conditions that have or may have an immediate or long-term harmful effect on the environment or its biological diversity, or that constitute or may constitute a danger to the environment on which life depends (Canada 2020).

The updated draft assessment also proposes to conclude that TCPP and TDCPP meet the criteria for persistence but not the criteria for bioaccumulation, as defined in the Persistence and Bioaccumulation Regulations made under CEPA (Canada 2000).

The exposure source of concern, identified in the updated draft screening assessment, is dermal exposure to TCPP and TDCPP from certain products made with polyurethane foam (PUF), a type of polymeric foam. Specifically, the potential concern is for infants, children or adults who have prolonged skin contact with certain manufactured products made from PUF that contains TCPP or TDCPP (ECCC, HC 2020). These products include upholstered furniture, mattresses, mattress toppers, and other foam-based products to which prolonged skin contact may be expected. As such, this document will focus on exposures to these products.

2.2 Recommendation under CEPA

Based on the findings of the updated draft Screening Assessment conducted as per CEPA, the Ministers propose to recommend that TCPP and TDCPP be added to the List of Toxic Substances in Schedule 1 of the ActFootnote 4.

The Ministers will take into consideration comments made by stakeholders during the 60-day public comment period on the updated draft Screening Assessment Report for TCPP and TDCPP, and the associated Risk Management Scope document in the preparation of the final screening assessment and Risk Management Approach document. If the Ministers finalize the recommendation to add TCPP and TDCPP to Schedule 1, risk management instrument(s) will be proposed within 24 months from the date on which the final screening assessment is published, and finalized within 18 months from the date on which the risk management instrument(s) are proposed.

3. Proposed risk management

3.1 Human health objective

Human health objectives are quantitative or qualitative statements of what should be achieved to address human health concerns.

The proposed human health objective for TCPP and TDCPP is to reduce exposure of the general population to levels that are protective of human health.

3.2 Risk management objective and options under consideration

Risk management objectives set quantitative or qualitative targets to be achieved by the implementation of risk management regulations, instrument(s) and/or tool(s) for a given substance or substances.

The proposed risk management objective is to help reduce dermal exposure of the general population to TCPP and TDCPP in certain products made with polymeric foams, such as polyurethane foam.

To achieve the risk management objective and to work towards achieving the human health objective, the risk management options under consideration for TCPP and TDCPP are:

Regulatory or non-regulatory actions to help reduce dermal exposure of the general population to TCPP and TDCPP in certain manufactured items made with polymeric foams such as polyurethane foam. These products include upholstered furniture, mattresses, mattress toppers, and other foam-based products to which prolonged skin contact may be expected.

Following the publication of this Risk Management Scope document, additional information obtained from the public comment period and from other sources will be considered, along with the information presented in this document, in the instrument selection and development processFootnote 5. The risk management options outlined in this document may evolve through consideration of assessments and risk management options published for other CMP substances to ensure effective, coordinated, and consistent risk management decision-making.

3.3 Risk management information gaps

In order to make informed decisions on proposed risk management, more information is needed on the following:

- Ongoing and anticipated changes in the use of TCPP and TDCPP in upholstered furniture, mattresses, mattress toppers, and certain other polyurethane foam-based products available to consumers, whether in response to:

- changes in performance-based flammability requirements and/or standards;

- market forces; and/or

- other reasons (please provide information on these reasons).

- The use of TCPP and TDCPP in textiles, including textile backings in furniture.

- The use of TCPP and TDCPP in polymeric foams other than polyurethane foams, which may be used in products such as furniture, mattresses, mattress toppers, and other foam-based products to which prolonged skin contact may be expected.

4. Background

4.1 General information on TCPP and TDCPP

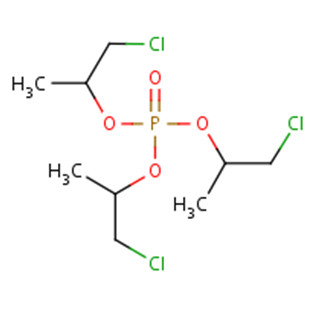

TCPP and TDCPP are chlorinated alkyl phosphate esters. These substances are structurally similar to tris(2-chloroethyl) phosphate or TCEP (CAS RN 115-96-8), which was evaluated and managed under the Challenge Initiative under the CMP (Canada 2009).

4.2 Current uses and identified sectors

Internationally, TDCPP and TCPP are generally used as flame retardants and plasticizers, with some other minor uses (Umweltbundesamt, 2001; ECCC 2013-2014EU 2008a,b; ECCC 2013-2014). They are used as additive flame retardants mainly in polyurethane and polyisocyanurate foam, with some use in other plastics and in back coating in textiles. As additive flame retardants, these two substances are not chemically bound to the polymer in finished products. End uses of polyurethane foams containing TDCPP and TCPP include insulation, furniture, upholstery, mattresses, and car seats, as well as products such as carpet underlay made from recycled foam, among other foam-based products (Umweltbundesamt, 2001; EU 2008a,b; ECCC 2013-2014; Health Canada 2015).

TCPP is primarily used in rigid foam in building applications, particularly insulation, with some use in flexible foam for upholstered furniture (EU 2008a, ECCC 2013-2014). It is also used in spray polyurethane foam (EU 2008a; ECCC 2013-2014; Health Canada 2015). TDCPP is used primarily in furniture made with flexible polyurethane foam and in automotive applications (e.g. in vehicle seating) (EU 2008b). TCPP and TDCPP are also used in the backcoating of textiles (i.e. upholstery) in the United States and Europe (US CPSC 2005a,b, Danish EPA 2014, 2015). TDCPP also has international uses in lacquers, paints and glues (Sundkvist et al. 2010).

In Canada, responses to a survey conducted in 2013 pursuant to a section 71 notice under CEPA (ECCC 2013-2014) indicated that 1 000 000 to 10 000 000 kg of TCPP and 100 000 to 1 000 000 kg of TDCPP were imported into Canada in 2011, both as the neat substance and a small portion in commercial products or products available to consumers. This estimate may not fully capture quantities of these substances in imported manufactured items. Neither substance was manufactured in Canada. Uses of TCPP and TDCPP identified in Canada include in flexible foam products (e.g. foam-based furniture, mattresses, as well as certain foam-based toys); building and construction materials, including rigid foam insulation; in spray foam insulation; in carpet cushion; in plastic and rubber materials; and in paints and coatings (ECCC 2013-2014; CEH 2013a,b; Health Canada 2014). TCPP is also present in a waterproofing spray for textiles, intended for consumer use (ECCC, HC 2020).

5. Exposure sources and identified risks

As outlined in the updated draft assessment, dermal exposure to TCPP and TDCPP from prolonged contact with upholstered furniture or mattresses made with flexible polyurethane foam was identified as a source of exposure of concern for all age groups.

As TCPP and TDCPP are additive flame retardants, they are able to migrate out of materials in which they are contained, potentially resulting in exposure.

The critical effects associated with exposure to TCPP are reproductive and developmental toxicity. The critical effects associated with exposure to TDCPP are carcinogenicity and non-cancer effects on kidneys and testes.

Estimated exposures to TCPP and TDCPP which were not a concern included exposures from environmental media and food, oral exposures through mouthing of foam products, such as toys, and dermal and inhalation exposures from using spray foam insulation and waterproofing tent spray containing TCPP.

6. Risk management considerations

6.1 Alternatives and alternate technologies

Flame retardant substances are generally used to meet performance-based flammability requirements or standards. These requirements do not specify that chemical flame retardants need to be used; rather they may require a product or components thereof to pass a laboratory test such as a cigarette smoulder or open flame ignition test. Performance-based flammability requirements exist internationally for various types of products, including electronics, building materials, mattresses and upholstered furniture, among others (UL 2014; ASTM 2014; Canada 2016a; California 2013; US CPSC 2004 & 2006). They can be regulatory, and may exist at different levels of government (Canada 2016a; California 2013). Voluntary standards for flammability are also developed by independent standard development organizations (ASTM 2014; ISO 2014; UFAC 2014; UL 2014; ULC 2017).

Using chemical flame retardants in their products is one means through which companies can help ensure that their products meet performance-based flammability requirements. However, technologies other than chemical flame retardants that allow products to meet performance-based flammability requirements also exist. Products may be made of materials with a low flammability or materials that require lower quantities of flame retardants to meet standards. For example, concentrations of flame retardants tend to be higher in lower density foams, which tend to ignite more easily than higher density foams (CEC 2015b). Materials such as foams may also be covered with a protective barrier made of a material that does not burn easily (US EPA 2005).

Where chemical flame retardants are concerned, a number of factors come into play in determining whether one flame retardant is a good alternative to another. Different flame retardants are appropriate for application to different materials and for different end uses. Their physical and chemical properties affect their ability to meet performance-based flammability requirements as well as the uses in which they can be effective. Flame retardant properties such as pH, viscosity, the ability to mix evenly and stability in exothermic reactions can impact the quality of end products such as foams (CEC, 2015b; Danish EPA 2016a). The potential for effects on health and the environment are key considerations in the selection of alternatives. The United States Environmental Protection Agency updated its ‘Design for the Environment’ report comparing the health and environmental properties of a variety of flame retardants for use in flexible polyurethane foam in 2015 (US EPA 2015). The Danish Environmental Protection Agency (Danish EPA 2016b) also recently published a report on some flame retardants which may be used as alternatives to TCPP (as well as structurally similar flame retardants TDCPP and TCEP). Finally, cost is also a factor companies consider in decisions regarding alternative flame retardants.

TCPP has been used as an alternative to TCEP in polyurethane foams. Concerns about the health effects of TCEP have increased the use of TCPP as a substitute for TCEP (EU, 2008a). The Phosphate Ester Flame Retardant Consortium has indicated that replacement of TCEP by TCPP is essentially complete at this time for all applications where replacement is possible in Europe (EU 2008a). The European Union’s 2008 assessment of TCPP (EU 2008a) notes, however, that TCPP was not able to meet the California performance-based flammability standard for upholstered furniture in place prior to 2013 – California TB 117 – therefore different flame retardants such as TDCPP were used for products regulated by that standard. While initially identified as a substitute for the commercial pentabromodiphenyl ether product (PentaBDE) in Europe, the flame retardant industry has indicated that increases in the use of TCPP are linked mostly with the decline in TCEP use and increase in the market for polyurethane generally (EU 2008a).

TDCPP has been used in the same market as TCPP, but is generally the more expensive of the two flame retardants (EU, 2008b). Its use is believed to be predominantly in applications where a more efficient flame retardant is required to meet specific standards. In particular, TDCPP may be used in the manufacture of furniture and mattresses where the less expensive and more volatile TCPP cannot meet applicable standards (EU, 2008a,b).

6.2 Technical considerations, current industry practices and economic context

Changes to performance-based flammability requirements are affecting the need for chemical flame retardants, particularly flame retardants used in flexible polyurethane foam. While uncovered polyurethane foam products such as mattress toppers are often excluded from flammability standards for mattresses or furniture (California 2013; US CPSC 2016; Canada 2016a), the standards may nevertheless affect the use of flame retardants in these products, as they can drive the use of flame retardants in flexible foam used for a wide variety of products. Companies producing foam may manufacture their foam so that it can pass the most stringent flammability standards for any product in which it is used, even if many of the end products containing the foam are not subject to those stringent flammability standards. For example, it has been reported that 80% of the foam manufactured in the U.K. contains flame retardants, even though only specific products are subject to flammability standards (EU 2008a). Foam-based products containing TCPP and/or TDCPP, but not subject to regulatory flammability standards, have been identified in several studies (Stapleton et al. 2011; Danish EPA 2015, 2016a).

Within North America, California standard TB 117 previously required that upholstered furniture in the California marketplace pass an open flame test, creating a market for flexible polyurethane foams containing certain flame retardants (Stapleton et al. 2011, 2012). The revised standard, California Technical Bulletin 117-2013 (California 2013), which came into effect on January 1, 2015, no longer requires an open flame test, but still requires a cigarette smoulder test. It also allows the use of upholstery cover fabrics and resilient filling materials (such as polyurethane foam) that fail testing if a barrier material that passes testing is used between the cover fabric and the filling. Flexible foam manufacturers and members of related trade associations expect that both the concentrations of flame retardants in the foam, and the percent of foam that contains flame retardants, will be generally reduced as a result of the change in the California standard, according to a study by the Commission for Environmental Cooperation (CEC 2015b).

Two federal flammability rules exist for mattresses in the US: The Standard for the Flammability of Mattresses and Mattress Pads, 16 CFR 1632 (US eCFR, 2017); and the Standard for the Flammability (Open Flame) of Mattress Sets,16 CFR 1633 (US CPSC, 2006). The Open Flame rule for mattress sets (16 CFR 1633) was recently reviewed and some commenters raised concerns about the possible need for flame retardants to meet either the open flame test or the cigarette smoulder test of 16 CFR 1632. However, in a briefing document (not reviewed or accepted by the US Consumer Product Safety Commission (CPSC), CPSC staff pointed out that the tests are performance-based (they do not prescribe the use of flame retardants) and indicated that they are aware of several mattress models that do not require the use of flame retardant chemicals to pass the tests. They also pointed to the availability of flame-retardant treated barrier materials that can help mattresses to pass the tests (US CPSC 2016). The US CPSC Standard for the Flammability (Open Flame) of Mattress Sets (16 CFR 1633) applies to mattresses or mattress sets with resilient material enclosed by a cover material; as such, it does not apply to uncovered foam mattress toppers or pads (US CPSC 2006). The Standard for the Flammability of Mattresses and Mattress Pads (16 CFR 1632; eCFR, 2017) excludes convoluted foam pads which are not totally encased in a cover material.

In the United Kingdom (UK) and Ireland, regulatory requirements such as the Furniture and Furnishings (Fire) (Safety) Regulations 1988 (UK 1988) and the Industrial Research and Standards (Fire Safety) (Domestic Furniture) Order, 1995 (Ireland 1995) may be contributing to the use of flame retardants, including TCPP and TDCPP (EU 2008a; Danish EPA 2016). The UK has consulted on proposed changes to its Furniture and Furnishings (Fire) (Safety) Regulations 1988, which could reduce the use of flame retardants and better reflect modern furniture manufacturing processes, while maintaining safety (UK Department for Business, Energy and Industrial Strategy, 2016). New regulations have yet to be published.

Canada has regulations under the Canada Consumer Product Safety Act (CCPSA) that set out performance-based flammability requirements for mattresses and other textile products that are manufactured, imported, sold or advertised in Canada (e.g., Canada 2016a, 2016b). As with other performance-based standards, the applicable regulations under the CCPSA do not prescribe how the requirements are to be met. Various options are available to manufacturers to meet the flammability requirements, including the use of materials that are less flammable or that are inherently flame resistant (such as wool), fire barrier systems or chemical flame retardants. It is not expected that Canada’s Mattresses Regulations (Canada 2016a) drive the flame retardant market as they prescribe a cigarette smoulder test; open flame testing is not required for mattresses marketed in Canada. Foam mattress pads are not considered mattresses, but they are subject to the flammability requirements for bedding under the Textile Flammability Regulations (Canada 2016b) if they have a textile cover. There are no flammability requirements for uncovered foam mattress pads. Canada also does not have a federal regulation for the flammability of upholstered furniture.

7. Overview of existing risk management

7.1 Related canadian risk management context

TCPP and TDCPP are not currently subject to any substance-specific risk management in Canada.

7.2 Pertinent international risk management context

Internationally, a number of risk management actions have either been taken for TCPP and/or TDCPP, or have implications for these substances:

United States

Actions that apply to both TCPP and TDCPP:

- California has passed legislation prohibiting the sale of new covered upholstered furniture, children's products, and mattresses that contain flame retardants above 1000 ppm. The repair of upholstery with foam containing flame retardants above 1000 ppm is also prohibited. The prohibition will take effect on January 1, 2020 (California 2018).

- Maine has passed legislation to prohibit the sale of new residential upholstered furniture containing flame retardants above 1000 ppm starting on January 1st, 2019 (Maine 2017).

- Rhode Island has passed legislation to prohibit any manufacturer, wholesaler, or retailer from manufacturing, knowingly selling, offering for sale or distributing for use in Rhode Island any residential upholstered bedding or furniture containing 1000 parts per million or greater of any non-polymeric organohalogen flame retardant chemical. The prohibition came into effect January 1, 2020 (Rhode Island 2019)

- The US Consumer Product Safety Commission (CPSC) has started work towards a ban of additive organohalogen flame retardants, including TCPP and TDCPP, in children’s products, mattresses and mattress pads, residential upholstered furniture, and plastic electronics casings, under the Federal Hazardous Substances Act (FHSA). As an interim measure, the CPSC published guidance requesting that manufacturers voluntarily eliminate the use of these substances in these products and recommending that importers, distributors, retailers and consumers obtain assurances from the seller that the product(s) do not contain organohalogen flame retardants (US CPSC 2017).

Actions that apply to TDCPP, but not TCPP:

- Products for children under age 3 are prohibited from containing TDCPP or TCEP in the state of New York (New York 2014).

- A number of flame retardants, including TDCPP, are prohibited at concentrations of greater than 1000 ppm in children’s products or residential upholstered furniture in the state of Washington (Washington 2016).

- Products for children under age 3 are prohibited from containing TDCPP or TCEP at concentrations above 0.1% by weight, in Maryland (Maryland 2014).

- A number of flame retardants, including TDCPP, are prohibited at concentrations of greater than 0.1% by weight in products for children under 12 or residential upholstered furniture in Vermont (Vermont 2013).

- A number of flame retardants, including TDCPP, are prohibited at concentrations of greater than 1000 ppm in children’s products or residential upholstered furniture in the state of Minnesota (Minnesota 2018).

Europe

- Commission Regulation (EC) No 506/2007 imposes testing and information requirements on the importers or manufacturers of certain priority substances, including TCPP and TDCPP, in accordance with Council Regulation (EEC) No 793/93 on the evaluation and control of the risks of existing substances (EC 2007).

- Due to potential concerns for carcinogenicity for TCPP and TDCPP, a concentration limit for TCPP and TDCPP, individually, in toys, has been set at 5 mg/kg by the European Commission (EC 2014).

- TCPP is found on the List of Undesirable Substances issued by the Environmental Protection Agency of Denmark (Danish EPA 2009).

8. Next steps

8.1 Public comment period

Industry and other interested stakeholders are invited to submit comments on the content of this Risk Management Scope or other information that would help to inform decision-making (such as outlined in section 3.3). Please submit additional information and comments prior to December 16, 2020.

The Risk Management Approach document, which will outline and seek input on the proposed risk management instruments, will be published at the same time as the finalized screening assessment report. At that time, there will be further opportunity for consultation.

Comments and information submissions on the Risk Management Scope should be submitted to the address provided below:

Environment and Climate Change Canada

Gatineau, Quebec K1A 0H3

Telephone: 1-800-567-1999 (in Canada) or 819-938-3232

Fax: 819-938-5212

Email: substances@ec.gc.ca

Companies who have a business interest in TCPP and/or TDCPP are encouraged to identify themselves as stakeholders. The stakeholders will be informed of future decisions regarding TCPP and/or TDCPP and may be contacted for further information.

8.2 Timing of actions

Electronic consultation on the updated draft screening assessment report and Risk Management Scope: October 17, 2020 to December 16, 2020. This should include the submission of public comments, additional studies or information on TCPP and/or TDCPP.

Publication of responses to public comments on the draft screening assessment report and Risk Management Scope: concurrent to the publication of the screening assessment and, if required, the Risk Management Approach document.

Publication of responses to public comments on the Risk Management Approach, if applicable and if required, the proposed instruments: At the latest, 24-month from the date on which the Ministers recommended that TCPP and TDCPP be added to Schedule 1 of CEPA.

Consultation on the proposed instruments, if required: 60-day public comment period starting upon publication of the proposed instrument

Publication of the final instruments, if required: at the latest, 18-month from the publication of the proposed instrument

These are planned timelines, and are subject to change. Please consult the schedule of risk management activities and consultations for updated information on timelines.

9. References

[ASTM] ASTM International. 2014. Fire Standards and Flammability Standards.

[California] California Department of Consumer Affairs, 2013. Technical Bulletin 117-2013: Requirements, Test Procedure and Apparatus for Testing the Smolder Resistance of Materials Used in Upholstered Furniture [PDF].

Canada. 1999. Canadian Environmental Protection Act, 1999. SC 1999, c 33.

Canada. 2000. Persistence and Bioaccumulation Regulations, SOR/2000-107.

Canada. 2009. Final screening assessment for the Challenge. Ethanol, 2-chloro-, phosphate (3:1) (Tris (2-chloroethyl)phosphate, TCEP). Chemical Abstracts Service Registry Number 115-96-8.

Canada. 2011. CEPA 1999: Announcement of planned actions to assess and manage, where appropriate, the risks posed by certain substances to the health of Canadians and the environment. Canada Gazette, Part I, vol. 145, no. 41 – October 8, 2011, p. 3125-3129.

Canada. 2015. Red Tape Reduction Act.

Canada. 2016a. Mattresses Regulations (Canada Consumer Product Safety Act). SOR/2016-183.

Canada. 2016b. Textile Flammability Regulations (Canada Consumer Product Safety Act). SOR/2016-194.

Canada. 2020. Dept. of the Environment. Canadian Environmental Protection Act, 1999: Notice with respect to certain organic flame retardants. Canada Gazette, Part I, vol. 154, no. 42 – October 17, 2020.

[CEC] Commission for Environmental Cooperation. 2015a. Enhancing Trilateral Understanding of Flame Retardants and Their Use in Manufactured Items: Analysis of Select Flame Retardants in Office and Household Furniture [PDF].

[CEC] Commission for Environmental Cooperation. 2015b. Enhancing Trilateral Understanding of Flame Retardants and Their Use in Manufactured Items: Supply Chain Analysis of Select Flame Retardants Contained in Manufactured Items Used in Indoor Environments [PDF].

[CEH] Center for Environmental Health. 2013a. Playing on poisons: harmful flame retardants in children’s furniture.

[CEH] Center for Environmental Health. 2013b. Naptime nightmares: toxic flame retardants in child care nap mats.

Danish EPA [Environmental Protection Agency]. 2009. List of Undesirable Substances 2009 [PDF]. Environmental Review No. 3 2011.

Danish EPA. 2014. Survey, health and environmental assessment of flame retardants in textiles. Survey of chemical substances in consumer products [PDF] No. 126. Miljøstyrelsen.

Danish EPA. 2015. Chemical substances in car safety seats and other textile products for children. Survey of chemical substances in consumer products [PDF] No. 135.

Danish EPA. 2016a. Chlorinated phosphorous-based flame retardants in children’s articles containing foam. Background for content and possibilities for prevention in the EU [PDF]. Environmental project No. 1855.

Danish EPA. 2016b. Environmental and health screening profiles of phosphorous flame retardants: A LOUS follow-up project [PDF].

[EC] European Commission. 2007. Commission Regulation (EC) No 506/2007 of 8 May 2007 imposing testing and information requirements on the importers or manufacturers of certain priority substances in accordance with Council Regulation (EEC) No 793/93 on the evaluation and control of the risks of existing substances.

[EC] European Commission. 2014. Commission Directive 2014/79/EU amending Appendix C of Annex II to Directive 2009/48/EC of the European Parliament and of the Council on the safety of toys, as regards TCEP, TCPP and TDCP. Official Journal of the European Union. L 182/49.

[ECCC] Environment and Climate Change Canada. 2013-2014. Data collected pursuant to section 71 (CEPA) and in accordance with the published notice “Notice with respect to certain organic flame retardant substances” Canada Gazette, Vol. 147 no. 13”. Data prepared by: Environment Canada, Health Canada, Existing Substances Program.

[ECCC, HC]. Environment and Climate Change Canada, Health Canada. 2020. Updated Draft Screening Assessment for the Certain Organic Flame Retardants Grouping, 2-Propanol, 1-chloro-, phosphate (3:1), (TCPP), Chemical Abstracts Service Registry Number 13674-84-5, and 2-Propanol, 1,3-dichloro-, phosphate (3:1), (TDCPP), Chemical Abstracts Service Registry Number 13674-87-8.

[ECHA] European Chemicals Agency. 2018. Screening Report: An Assessment of Whether the Use of TCEP, TCPP and TDCP in Articles Should Be Restricted [PDF]. [Accessed 2018 Dec 6].

[Empack] Empack Spraytech Inc. 2014. Safe n Dry fire retardant and water repellent.

[EU] European Union. 2008a. European Union Risk Assessment Report. Tris(2-chloro-1-methylethyl)phosphate (TCPP) [PDF]. Luxembourg: Office for Official Publications of the European Communities. [cited 2014 Jun 18].

[EU] European Union. 2008b. European Union Risk Assessment Report. Tris[2-chloro-1-(chloromethyl)ethyl]phosphate (TDCP) [PDF].Luxembourg: Office for Official Publications of the European Communities. [cited 2014 Jun 18].

Health Canada. 2015. Determination of TDCPP and TCPP in a Survey of Polyurethane Children’s Products. Unpublished. Health Canada, Ottawa, Ontario.

Ireland. 1995. Industrial Research and Standards (Fire Safety) (Domestic Furniture) Order, 1995. S.I. No. 316/1995.

[ISO] International Organization for Standardization 2014. Standards Catalogue.

Maryland. 2014. Chapter 391 - Public Health - Child Care Products Containing Flame-Retardant Chemicals - TDCPP – Prohibition. [Accessed 2018 Dec 6].

Minnesota. 2018. 325F.071: Flame-Retardant Chemicals: Prohibition. [Accessed 2018 Dec 6].

New York. 2013. An Act to amend the environmental conservation law, in relation to expanding the TRIS-free children and babies act. [Accessed 2018 Dec 6].

Rhode Island. 2019. An Act Relating To Health and Safety - Upholstered Furniture and Child Products Safety [PDF]

Stapleton, H.M., Klosterhaus, S., Keller, A. et al. 2011. Identification of flame retardants in polyurethane foam collected from baby products. Environmental Science and Technology 45: 5323-5331.

Stapleton, H.M., Sharma, S., Getzinger, G., et al. 2012. Novel and high volume use flame retardants in US couches reflective of the 2005 PentaBDE phase out. Environmental Science and Technology 24(24): 13432-13439.

Sundkvist A, Olofsoon U, Haglund P. 2010. Organophosphorus flame retardants and plasticizers in marine and fresh water biota and in human milk. J Envi Monit 12:943–951.

[TBS] Treasury Board of Canada Secretariat. 2018. Cabinet Directive on Regulation. Ottawa (ON): Government of Canada.

[TBS] Treasury Board of Canada Secretariat 2012. Red Tape Reduction Action Plan.

[UFAC] Upholstered Furniture Action Council. 2014. Test methods.

[UK] United Kingdom. 1988. Furniture and Furnishings (Fire) (Safety) Regulations 1988, No. 1324.

UK Department for Business, Energy and Industrial Strategy. 2016. Consultation on updating the Furniture and Furnishings (Fire)(Safety) Regulations.

[UL ] Underwriters Laboratories. 2014. UL 94: Standard for Tests for Flammability of Plastic Materials for Parts in Devices and Appliances.

[ULC] Underwriters Laboratories of Canada. 2017. CAN/ULC-S137, Standard Method of Test for Fire Growth of Mattresses (Open Flame Test) (Second Edition) [PDF].

Umweltbundesamt. 2001. Substituting Environmentally Relevant Flame Retardants: Assessment Fundamentals [PDF].[Accessed 2018 Dec 6].

[US eCFR] Electronic Code of Federal Regulations, 2017. Title 16: Commercial Practices, part 1632 – Standard for the Flammability of Mattresses and Mattress Pads (FF4-72, amended).

[US CPSC] United States Consumer Product Safety Commission. 2004. Standard for the Flammability of Mattresses and Mattress Pads – 16 CFR Part 1633.

[US CPSC] US Consumer Product Safety Commission. 2005a. Analysis of FR Chemicals Added to Foams, Fabrics, Batting, Loose Fill, and Barriers [PDF]. Washington (DC): Directorate for Laboratory Sciences, US CPSC.

[US CPSC] US Consumer Product Safety Commission, 2005b. Migration of Flame Retardant Chemicals in Upholstered Furniture Foam [PDF]. Washington (DC): Division of Chemistry, US CPSC.

[US CPSC] United States Consumer Product Safety Commission. 2006. Standard for the Flammability (Open Flame) of Mattress Sets: 16 CFR Part 1633 [PDF].

[US CPSC] Consumer Product Safety Commission. 2017. Guidance document on hazardous additive, non-polymeric organohalogen flame retardants in certain consumer products. US Federal Register, vol 82, No. 187, September 28.

[US CPSC] Consumer Product Safety Commission. 2016. Staff briefing package: Rule Review of 16 C.F.R. Part 1633 –Standard for the Flammability (Open Flame) of Mattress Sets [PDF].

[US EPA] United States Environmental Protection Agency. 2005. Furniture Flame Retardancy Partnership: Environmental Profiles of Chemical Flame-Retardant Alternatives for Low-Density Polyurethane Foam [PDF].

[US EPA] United States Environmental Protection Agency. 2015. Flame Retardants Used in Flexible Polyurethane Foam: An Alternatives Assessment Update [PDF].

Vermont. 2013. No. 85. An act relating to the regulation of octaBDE, pentaBDE, decaBDE, and the flame retardant known as Tris in consumer products [PDF]. [Accessed 2018 Dec 6].

Washington. 2016. HB 2545-S. AN ACT Relating to reducing public health threats that particularly impact highly exposed populations, including children and firefighters, by establishing a process for the department of health to restrict the use of toxic flame retardant chemicals in certain types of consumer products; amending RCW 70.240.050; adding a new chapter to Title 70 RCW; prescribing penalties; and providing an expiration date [PDF].[Accessed 2018 Dec 6].

ANNEX A. Substances targeted for risk management

| CAS RN | 13674-84-5 (TCPP) | 13674-87-8 (TDCPP) |

|---|---|---|

| Chemical formula | C9H18Cl3O4P | C9H15Cl6O4P |

| Chemical structure |  |

|