Longevity of Recordable CDs, DVDs and Blu-rays — Canadian Conservation Institute (CCI) Notes 19/1

List of abbreviations

- BIS

- burst indication subcode

- BLER

- block error rate

- DL

- dual layer

- LDC

- long distance code

- PI8

- parity inner error rate averaged over eight blocks

Introduction

The longevity of recordable compact discs (CD-Rs), recordable digital versatile discs (DVD±Rs)Endnote 1 and recordable Blu-rays (BD-Rs) is uncertain, leading to a widespread lack of trust by libraries and archives. Research studies, anecdotal information and manufacturers’ literature suggest that the lifetime of recordable optical discs can range from a couple of years to more than 200 years. This Note explores several of the factors that affect whether a disc will fail within a short period or will continue to perform well for many years.

Manufacturing quality

Poor-quality discs (discs that do not meet standard specifications for proper manufacturing and function) will probably fail sooner than good-quality ones, due to rapid chemical degradation or physical damage. This was a significant problem when discs were introducedEndnote 2 and for at least two to three years afterwards. Poor manufacturing is still a problem to some extent, either because of cost-cutting to meet competitive pricing or because of the growing lack of quality manufacturers producing these materials.

Determining if a disc is poorly manufactured is an impossible task without thorough testing, which likely would include accelerated aging. This is not feasible for most archives, libraries and museums. In the absence of testing, discs with a recognized brand name can generally be assumed to be of good quality. Even though some large manufacturers label discs produced elsewhere with their own brand name, most have no desire to be associated with an inferior product. Information on where the disc was actually produced may be available by consulting the manufacturer and/or examining coding on the disc.

Materials used in disc manufacturing

CD-R

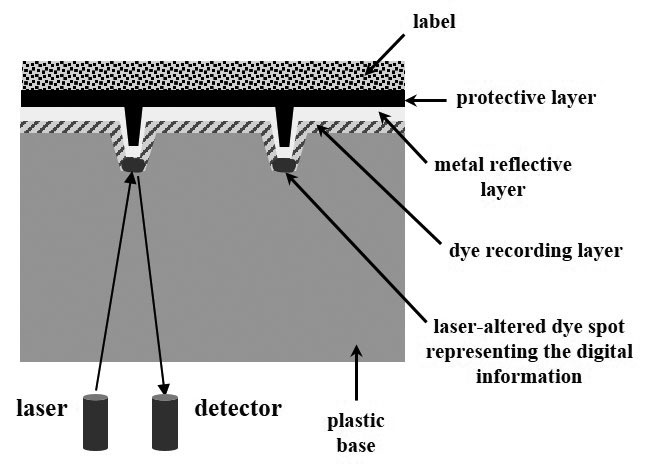

CD-Rs are composed of several layers (Figure 1):

- the base layer

- the dye layer

- the metal reflective layer

- the top protective layer

- the label layer (optional)

© Government of Canada, Canadian Conservation Institute. CCI 131906-0001

Figure 1. Cross-section of a CD-R.

Description of Figure 1

A cross-section of a CD-R shows that most of the thickness of the disc is the plastic base. Molded into the top of the plastic base is a spiral groove. Both the groove and non-groove areas of the top of the plastic base are covered with a dye recording layer. Within the dye layer in the grooves rest laser-altered dye spots representing the digital information. On top of the dye recording layer is a metal reflective layer, followed by a protective layer and then a label.

When a disc is read, a laser shines through the base of the disc, hits a laser-altered spot or non-spot area in the groove and gets reflected back by the metal reflective layer to a signal detector.

The base layer of a CD-R is always composed of polycarbonate. However, the dye and metal reflective layers can be composed of various materials, and each has its own inherent stability. The quality of the top protective layer is also important.

The CD-R specification was designed around cyanine dye (shades of blue) and, therefore, most of the early discs used it. Azo dye (deeper blue) was introduced in 1996. However, neither of these dyes matches the stability of light-green phthalocyanine, which is very stable to light, high temperature and high relative humidity (RH). Phthalocyanine was available in the early days of CD-R manufacture, but it was not widely used until around 2002.

The type of dye in a CD-R can sometimes be determined by transmitting light through the disc and viewing the colour (Table 1). However, the presence of a thick, dark label may make identification impossible with transmitted light. In these cases, reflective light can be used, although the colour of the metal reflective layer may alter the appearance of the dye colour. Note also that some discs have pigmented bases, such as black or possibly a variety of other colours; these colours do not indicate a different dye or metal layer than what is shown in Table 1. The type of dye in a disc can also be determined by consulting the manufacturer or their literature.

| Dye and dye colour | Reflective layer | Appearance from the non-labelled side of the disc with reflected light | Appearance from the non-labelled side of the disc with light transmitted through the disc |

|---|---|---|---|

| cyanine (blue) | gold | green | blue |

| phthalocyanine (light green) | gold | gold | light green |

| cyanine (blue) | silver alloy | blue or greenish-blue | blue or light blue |

| phthalocyanine (light green) | silver alloy | light green | light green* |

| azo (dark blue) | silver alloy | dark blue or light blue | dark blue or light blue |

* Because the phthalocyanine dye is very light green, the label on the top of the disc may change the appearance of the dye. In this case, the colour of the disc with reflected light is generally a better indication of the dye type than the colour of the disc with transmitted light.

A CD-player reads a disc by directing a laser light through the base and dye layers to the metal reflective layer, which reflects the laser light back to the player’s signal detector. If the reflective layer is altered in any way, it will not perform as expected and the disc cannot be read. The metal reflective layer in CD-Rs has generally been gold, silver or a silver alloy. Gold is very stable, thus discs with a gold reflective layer are not at risk for “laser rot” (a term used to describe the corrosion of the metal layer). Hence, they have excellent longevity. However, silver and silver alloys are susceptible to corrosion; CD-Rs with these kinds of reflective layers are more likely to fail, especially if they are exposed to pollutants.

The top protective layer should have good chemical resistance and be rugged enough to protect the sensitive metal layer underneath it from handling damage. If this layer is of poor quality or has not been applied evenly and completely on the disc, then early disc failure is likely. Some manufacturers may specifically mention that their discs contain rugged topcoats.

DVD±Rs

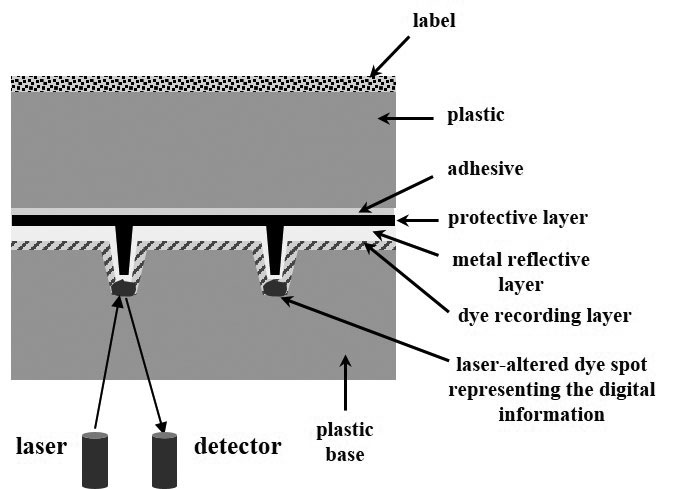

A DVD±R provides much more capacity than a CD-R and is, therefore, often the desired format for storing information. DVD±Rs are composed of two individual discs, which are each half the thickness of a CD-R. They are manufactured separately and then glued together. DVD±Rs can also have two information layers.

© Government of Canada, Canadian Conservation Institute. CCI 131906-0003

Figure 2. Cross-section of a DVD±R.

Description of Figure 2

A cross-section of a DVD±R shows that the first layer encountered, starting from the bottom, is a plastic base. Molded into the top of the plastic base is a spiral groove. Both the groove and non-groove areas of the top of the plastic base are covered with a dye recording layer. Within the dye layer in the grooves rest laser-altered dye spots representing the digital information. On top of the dye recording layer is a metal reflective layer and a protective layer. Next is an adhesive layer, which adheres the plastic disc (the same thickness as the plastic base) to the rest of the disc structure. The top layer of the disc is a label.

When a disc is read, a laser shines through the base of the disc, hits a laser-altered spot or non-spot area in the groove and gets reflected back by the metal reflective layer to a signal detector.

DVD±Rs are produced with an azo or cyanine type dye, giving the discs a blue, bluish-purple or purple appearance. It is difficult to provide specific details about the dyes, as there is significantly less information available on dyes used in DVD±Rs than in CD-Rs.

The metal layer in DVD±Rs is generally similar to that in CD-Rs (it is usually composed of silver, a silver alloy or gold). However, dual-layer discs use a semi-reflective metal to allow some laser light to pass through to the second information layer.

DVD±Rs do not require a top protective layer, as the metal and dye layers are situated in the middle of the disc structure, sandwiched between two layers of polycarbonate (Figure 2).

One concern about DVD±Rs is the bonding adhesive. There are some anecdotal reports that DVD±Rs have separated due to adhesive failure or that the metal layers have corroded due to the chemical reactivity of the adhesive. An accelerated aging study looking at the stability of DVD formats found this to be potentially an issue, at least under elevated temperature and RH conditions (Iraci 2011).

BD-Rs

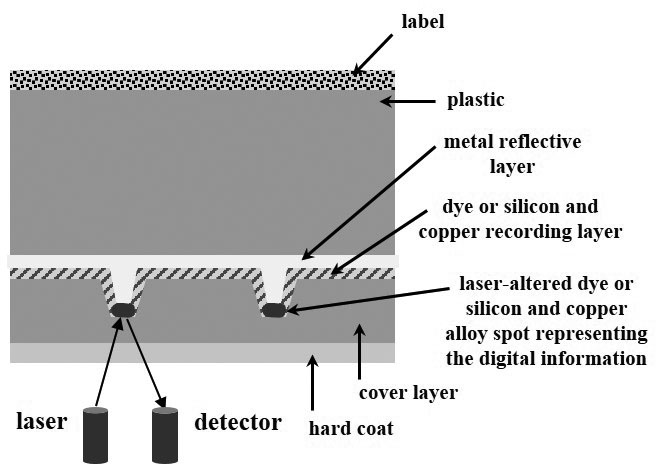

A BD-R provides seven times the capacity of a DVD±R. In addition, with BD-Rs, there is the option to have up to four information layers, thus providing even greater storage capacity (well beyond what DVD±Rs and CD-Rs can provide). This increased capacity makes it a suitable format for storing larger files associated with high-quality video.

There are two types of BD-Rs (Figure 3). The first type uses a dye to store information and can be identified by its yellow base colour. The other type uses a non-dye silicon and copper alloy as the data storage layer. This type of disc appears dark grey to greyish-brown in colour.

The unique feature of a BD-R is the additional hard coat layer applied to the base of the disc. Because the information-carrying layer and metal reflective layer are applied to the bottom, or the reading side, of the disc, it is important to offer extra protection on this side of the disc so that the disk can function properly.

A study looking at the stability of Blu-ray media has shown that overall, BD-Rs (whether they are the dye or the non-dye type) have rather poor stability compared to some CD-Rs and DVD±Rs (Iraci 2018).

© Government of Canada, Canadian Conservation Institute. CCI 131906-0005

Figure 3. Cross-section of a BD-R.

Description of Figure 3

A cross-section of a BD-R shows that the first layer encountered, starting from the bottom, is a thin hard coat layer followed by a thin cover layer. Molded in the cover layer is a spiral groove. Both the groove and non-groove areas are covered with a dye or silicon and copper recording layer. Within the dye or silicon and copper layer in the grooves rests either laser-altered dye or silicon and copper alloy spots representing the digital information. Next is a metal reflective layer, followed by a thick plastic, which makes up most of the disc thickness. The top layer of the disc is a label.

When a disc is read, a laser shines through the hard coat and cover layer of the disc, hits a laser-altered spot or non-spot area in the groove and gets reflected back by the metal reflective layer to a signal detector.

Disc recorder and reader compatibility

The original specification for CD-Rs accommodated discs with a maximum capacity of 650 MB of data (74 min. of audio recording). When CD-Rs with a capacity of 700 MB of data (80 min. of audio recording) were introduced around 1998, they caused numerous compatibility problems. However, once a new generation of equipment was introduced, incompatibility became less significant. Nonetheless, early high-capacity discs (produced from 1998 to 2000) may not perform well. In fact, they may perform no better than new high-capacity discs played in older equipment.

DVD-Rs generally have better disc and reader compatibility than DVD+Rs, especially when using older readers or drives.

Overall, single-layer recordable DVDs or Blu-rays have better disc recorder and player compatibility than multi-layer formats. To ensure that incompatibility of any optical disc type is not mistaken for disc failure or disc degradation, it is important to know which format the equipment was designed to read, as not all drives can read both.

Recording techniques

One of the primary reasons for premature failure of CD-Rs, DVD±Rs and BD-Rs is improper recording: the initial error rate was too high or the recording software created other problems.

All recorded discs have inherent error rates, which are the number of errors per second when the disc is played. These are measured by BLER (block error rate) for CD-Rs, by PI8 (parity inner error rate averaged over eight blocks) for DVD±Rs and by LDC (long distance code) plus BIS (burst indication subcode) for BD-Rs. Players and readers can correct errors up to a certain point (and some are more efficient than others); however, if there are too many errors or they are too severe, the disc will not play properly.

Specifications state that the maximum allowable BLER for CD-Rs is 220 and the maximum PI8 for DVD±Rs is 280, but it is preferable that the initial error rate for both of these types of discs be less than 50. For BD-Rs, it is recommended that the average LDC be less than 13 and the average BIS be less than 0.26, with a maximum BIS of less than 15. Satisfying the low error rate limits will ensure that discs are playable in a wide variety of players, even those with poor correction capability. This factor becomes increasingly important as technology obsolescence reduces the number of available players. A low error rate also leaves more room for additional errors before disc failure occurs. For example, a disc with a low error rate can tolerate the additional errors from a scratch or other damage without problems, whereas a disc with an error rate that is close to the limit will likely fail if more errors are introduced.

Low error rates can be achieved by following a few simple recommendations.

- Ensure the recorder is well maintained and the disc surfaces are clean. Dust on discs will interfere with the recording process and cause errors.

- Confirm that the disc is compatible with the recorder being used. (Check the recorder manufacturer’s literature to see if it recommends certain disc brands.)

- Use moderate recording speeds. CD-Rs were originally rated for speeds below 8×. Since 2000, these ratings have increased quickly, all the way up to 52×. However, using a recording speed between 4× and 12× for discs rated 52× will produce the lowest error rates. DVD±Rs currently have maximum recording speeds of 16× (2.4× for dual-layer DVR+R discs), but the lowest error rates for single-layer 16× DVD±Rs will be achieved at recording speeds between 4× and 8×. BD-Rs have maximum recording speeds of 10×. It is recommended that discs rated higher than 6× be recorded at 4× speed.

Before embarking on new recording projects, one or two discs should be recorded with the actual set-up (disc type, recorder, software, etc.) and then tested to ensure the error rate is sufficiently low. Specialized equipment is required for accurate error rate measurements. For large collections, it may be feasible to purchase the equipment and periodically test discs in the collection.

In the absence of specialized equipment, software such as Nero DiscSpeed can provide some information on disc quality. However, because the test results are specific to the drive being used, it is necessary to test the same disc in various drives. Also, because Nero DiscSpeed reports mainly the major uncorrectable errors, a disc with a high correctable error rate could still appear to be a good disc. Nevertheless, this software is free and can at least give a rough indication of disc quality. More information on using software to test optical discs can be found in CCI Note 19/2 Error Analysis and File Recovery Software for Digital Storage Media.

Poor quality software or inadequate recording methods, such as not finalizing the recording session properly, can also lead to poorly recorded discs. These problems are not related to disc degradation, but they still result in unreadable discs. Information can sometimes be extracted from these types of discs with specialized software (consult CCI Note 19/2).

Storage and handling

As with all other information carriers, storage and handling of optical media are critical factors in determining how long they survive. The following recommendations will help maximize longevity.

Enclosures

- Store discs vertically in standard-sized jewel cases. Paper or plastic sleeves are not recommended as they provide little physical protection, they may interact chemically with the disc and/or they can scratch the disc surfaces.

- Use one-piece polypropylene cases for storage of discs that are handled frequently or when greater durability is desired.

- Remove liner notes or other materials from the jewel case when storing the disc (this is not essential if the disc is constructed with a gold metal layer and phthalocyanine dye).

Handling

- Hold discs by the centre hole and the outer edge between the forefinger and the thumb.

- Avoid touching the disc surface with bare hands, as fingerprints will interfere with readability.

- Label discs with a water-based permanent marker on the clear inner hub. Do not apply adhesive labels of any type.

- For more detailed handling information, consult ISO Standard 18938:2014, Imaging Materials – Optical Discs – Care and Handling for Extended Storage.

Cleaning

- Remove loose debris with a compressed air duster or a soft, non-abrasive tissue or cloth, wiping from the centre of the disc outward in a radial direction. Never wipe in a circular direction.

- To remove fingerprints, apply a small amount of dishwashing liquid to the disc surface and gently wipe it with a wet soft cloth. Afterwards, rinse the disc in distilled water and carefully blot it dry to avoid the formation of water spots.

- Cleaning procedures can scratch the disc surfaces if not performed correctly.

Environmental storage conditions

- Limit exposure to pollutants and light as much as possible. Note that the negative effects of light (such as fading of the dye layer) are not a problem if discs are returned to their cases promptly after use.

- Suitable temperature and RH conditions are described in ISO Standard 18925:2013, Imaging Materials – Optical Disc Media – Storage Practices. The recommended RH range for extended storage is 20% to 50%, with RH never falling below 10%. The recommended temperature range is from -10°C to 23°C, with the temperature never exceeding 32°C.

- Storage of discs in a cool and dry area will significantly increase media longevity.

Periodic testing

- If discs are stored under recommended conditions, test error rate and playability of representative samples every 5 to 10 years.

- If storage conditions are poor, test more frequently.

Disaster preparedness and recovery

To minimize the impact of a disaster such as a fire or flood, ensure that media are properly stored and that recovery procedures will be available, if needed. Recovery procedures for optical disc media and other modern information carriers that have been subjected to various disasters are discussed in Technical Bulletin 25 Disaster Recovery of Modern Information Carriers: Compact Discs, Magnetic Tapes and Magnetic Disks.

Remedies for damaged discs

Degradation and/or damage can sometimes render recordable CDs, DVDs and Blu-rays unreadable. However, some damaged discs can be restored to normal playability. For example, there are treatments that can successfully restore scratched or warped discs. Also, a disc that cannot be played in one player or reader may play properly in another. Remedies for various degradation problems are discussed in Technical Bulletin 27 Remedies for Deteriorated or Damaged Modern Information Carriers. Software discussed in CCI Note 19/2 Error Analysis and File Recovery Software for Digital Storage Media can also be used to recover information form deteriorated media.

Summary

The longevity of recordable CDs, DVDs and Blu-rays can be maximized by adhering to the following guidelines.

Choose quality discs, which can be identified by:

- a well-known brand name or manufacturer

- a recent date of manufacture (after 1995 for CD-Rs, after 1999 for DVD-Rs, after 2004 for DVD+Rs and after 2010 for BD-Rs)

- a phthalocyanine dye layer (not available for DVD±Rs or BD-Rs)

- a gold metal layer

- a tough top protective layer (only for CD-Rs)

- no signs of damage to layers

Record the information properly to ensure a low error rate (<50 maximum and average BLER for CD-Rs; <50 maximum and average PI8 for DVD±Rs; <13 average LDC, <0.26 average BIS and <15 maximum BIS for BD-Rs).

Handle the discs carefully:

- hold by the centre hole and outer edge between the forefinger and the thumb

- do not use adhesive labels or write on the top surface of the disc

Store the discs properly:

- in a standard-size jewel case without additional materials in the case

- in a vertical orientation

- in a cool and dry environment

Ignoring these guidelines can lead to premature failure of discs, perhaps in as little as 2 to 10 years.

The relative stability of optical disc formats

Table 2 compares the relative stability of the various optical disc formats. The most stable, and the one recommended for use when maximum longevity is desired, is a CD-R with phthalocyanine dye and a gold metal layer (Iraci 2000). However, lack of storage capacity and cost may limit the use of this type of media.

The relative stability ratings shown in Table 2 are based on temperature and RH effects only. In the real world, if the storage environment contains pollutants, any discs without a gold metal layer (regardless of dye type) would likely rate lower than the ranking shown below. Therefore, although the CD-R with phthalocyanine dye and a silver alloy metal layer shows good relative stability here, it may not be an appropriate choice for practical applications where longevity is important.

| Optical disc formats | Average longevity |

|---|---|

| CD-R (phthalocyanine dye, gold metal layer) | >100 years |

| CD-R (phthalocyanine dye, silver alloy metal layer) | 50 to 100 years |

| DVD-R (gold metal layer) | 50 to 100 years |

| CD (read-only, such as an audio CD) | 50 to 100 years |

| CD-RW (erasable CD) | 20 to 50 years |

| BD-RE (erasable Blu-ray) | 20 to 50 years |

| DVD+R (silver alloy metal layer) | 20 to 50 years |

| CD-R (cyanine or azo dye, silver alloy metal layer) | 20 to 50 years |

| DVD+RW (erasable DVD) | 20 to 50 years |

| BD-R (non-dye, gold metal layer) | 10 to 20 years |

| DVD-R (silver alloy metal layer) | 10 to 20 years |

| DVD and BD (read-only, such as a DVD or Blu-ray movie) | 10 to 20 years |

| BD-R (dye or non-dye, single layer or dual layer) | 5 to 10 years |

| DVD-RW (erasable DVD) | 5 to 10 years |

| DVD+R DL (dual layer) | 5 to 10 years |

Important note

One key to preserving information on optical discs, magnetic tapes and magnetic disks is to make copies. Ideally, three copies of the information should be created on at least two different types of storage media and one of the copies should be stored off-site. If the same type of storage media is used for one of the copies, then different brands should be used.

Suppliers

Note: The following information is provided only to assist the reader. Inclusion of a company in this list does not in any way imply endorsement by CCI. Other companies may exist that offer similar products.

Polypropylene jewel cases

Phthalocyanine and gold-metal layer CD-Rs and DVD-Rs

Bibliography

International Organization for Standardization. ISO 18925:2013, Imaging Materials – Optical Disc Media – Storage Practices. Geneva, Switzerland: International Organization for Standardization, 2013.

International Organization for Standardization. ISO 18938:2014, Imaging Materials – Optical Discs – Care and Handling for Extended Storage. Geneva, Switzerland: International Organization for Standardization, 2014.

Iraci, J. Disaster Recovery of Modern Information Carriers: Compact Discs, Magnetic Tapes and Magnetic Disks. Technical Bulletin 25. Ottawa, ON: Canadian Conservation Institute, 2002.

Iraci, J. Remedies for Deteriorated or Damaged Modern Information Carriers. Technical Bulletin 27. Ottawa, ON: Canadian Conservation Institute, 2005.

Iraci, J. “The Relative Stabilities of Optical Disc Formats.” Restaurator 26,2 (2005), pp. 134–150.

Iraci, J. “The Stability of DVD Optical Disc Formats.” Restaurator 32,1 (2011), pp. 39–59.

Iraci, J. “Blu-ray Media Stability and Suitability for Long-term Storage.” Restaurator 39,2 (2018), pp. 129–155.

Iraci, J. Error Analysis and File Recovery Software for Digital Storage Media. CCI Notes 19/2. Ottawa, ON: Canadian Conservation Institute, 2019.

By Joe Iraci

Revised in 2019

Originally published in 2010

© Government of Canada, Canadian Conservation Institute, 2020

Cat. No.: NM95-57/19-1-2020E-PDF

ISSN 1928-1455

ISBN 978-0-660-33406-6