Pesticides Compliance and Enforcement Report for 2014-2015

Mission and Vision

Our Mission

The mission of Health Canada's National Pesticide Compliance Program is to help protect the health and environment of Canadians by promoting, monitoring and enforcing compliance with the Pest Control Products Act and its Regulations.

Our Vision

The vision is to strive for excellence in pesticide compliance.

Executive Summary

This report outlines activities and results for Health Canada's (HC) National Pesticide Compliance Program (NPCP) in Fiscal Year (FY) 2014-2015.

The NPCP is responsible for promoting, monitoring and enforcing compliance with the Pest Control Products Act (PCPA) and its Regulations. The program is administered jointly by HC's Pest Management Regulatory Agency (PMRA) and the Regions and Programs Bureau (RAPB). PMRA sets the strategic direction, program priorities and policies, and determines how those priorities are nationally implemented. RAPB is responsible for the delivery of compliance and enforcement activities and to maintain valuable relationships with regional partners and stakeholders.

2014-15 Statistics - Highlights

This report outlines compliance and enforcement activities conducted by PMRA in partnership with RAPB in FY 2014-2015. These activities fall into the following main areas: Active Prevention; Targeted Oversight; Rapid Response; and Border and International Activities. Highlights from each of those areas are noted below, with details provided in later chapters.

Active Prevention

The objective is to provide regulatory guidance to industry and the public while identifying safety concerns at an early stage to encourage compliance with the PCPA and its associated Regulations.

- The key priority was to continue to educate stakeholders in priority areas of their obligations under the PCPA, for example, pollinator protection and use of proper personal protective equipment.

- A total of 233 outreach activities were completed, including presentations to associations, meetings or exhibit booths at trade shows. Communication materials were distributed on risk mitigation measures to be taken during the use of pesticides.

- Outreach elements such as the provision of verbal or written regulatory requirements were included during the delivery of many targeted oversight activities.

Targeted Oversight

The objective is to conduct an early detection of health, safety and environmental concerns at the appropriate stage of the pest control product life cycle.

- The key priority was to monitor compliance with the PCPA with agricultural and structural users, registrants, manufacturers and vendors.

- Over 1000 formal inspections and 342 interviews focusing on 15 key priority areas were conducted. In addition, 299 compliance verifications stemming from complaints, incidents and enquiries were also conducted.

- A total of 319 soil, plants, tissues or other samples were analysed by PMRA's laboratory to verify compliance, with an additional 811 samples collected and analysed for bee-related incidents and bee health issues.

Rapid Response

The objective is to conduct timely interventions when unacceptable risks of non-compliance are identified.

- The key priority was risk-based action in response to non-compliance situations noted during inspections, as well as responses to complaints and incidents reported from the public.

- In 2014-15, inspections resulted in a total of 1619 enforcement responses. Enforcement responses included education and enforcement letters (484), verbal education (51), issuance of Compliance Orders (2), issuance of notices of violations (NOVs) under the Agriculture and Agri-Food Administrative Monetary Penalties (AMPs) Act with warnings or penalties (16), requests to stop the sale or dispose of a pest control product (841), requests to return or recall a pest control product (57), requests for relabeling (19), orders to cease sale or dispose products (11), collection of investigative samples (16), denials of entry at the border (93), and other actions (29).

Border and International Activities

The objective is to implement an international strategy to facilitate the global cooperation in pesticide compliance and enforcement issues, as well as border activities and monitoring processes with the Canada Border Services Agency (CBSA) to reduce risks posed by imported pesticides.

- Key priorities were to continue analysing the border data to perform subsequent follow-up inspections and to build international partnerships.

- Following the analysis of CBSA importation data, 143 targeted inspections were conducted, and 47% of these inspections indicated instances of non-compliance. The enforcement responses to non-compliant importations were verbal education (34%), written education (57%), and enforcement letters (9%). Referrals from various border points resulted in 93 denials of pesticide entry into Canada.

Summary of Key Observation

In 2014-15, levels of compliance with the PCPA for inspected entities varied depending on the sector of activity. Most of the detected instances of non-compliance involved the sale of an unregistered product, as well as the import and use of unregistered products, or use contrary to the label approved by PMRA. Most violations were among retailers, importers, and distributors, followed by users.

Surveillance inspections conducted under Targeted Oversight verified whether compliance had been restored in sectors of concern. Regulated parties who were previously non-compliant with the regulations, and for whom the risks to re-offend were significant, were targeted for such inspections with a seventy-six percent return to compliance. The NPCP took active steps, including application of escalated enforcement measures, to induce the non-compliant regulated parties to fully comply with the PCPA and its associated Regulations.

Table of Contents

- Chapter 1 - Overview of the National Pesticide Compliance Program

- Chapter 2 - Active Prevention

- Chapter 3 - Targeted Oversight

- Chapter 4 - Rapid Response

- Chapter 5 - Border Activities

- Chapter 6 - National and International Partnerships to Further Reduce Risk for Canadians

- Chapter 7 - Compliance Overview

- Chapter 8 - Forward Planning

- Glossary

Chapter 1 - Overview of the National Pesticide Compliance Program

The NPCP is coordinated from Ottawa and is delivered by regional inspectors located in Burnaby, Kelowna, Edmonton, Calgary, Lethbridge, Regina, Saskatoon, Winnipeg, London, Guelph, Toronto, Montreal, Quebec City, Ottawa, Moncton, Charlottetown, and Kentville. In Newfoundland and Labrador, the NPCP is implemented by the Provincial inspectors located in St. John's, Corner Brook, and Gander. The NPCP is supported by a laboratory located in Ottawa.

Figure 1 - Map of Regional Offices and Headquarters (Ottawa)

Text description

Image showing a map of Canada with locations of the National Pesticide Compliance Program regional offices and headquarters. Regional offices in Burnaby, Kelowna, Calgary, Edmonton, Lethbridge, Saskatoon, Regina, Winnipeg, Guelph, London, Ottawa, Toronto, Montreal, Quebec City, Moncton, Kentville, Charlottetown, Corner Brook, Gander, St. John's. Headquarters in Ottawa.

NPCP Planning

Annual compliance promotion and inspection priorities are determined after consultation with PMRA science directorates, RAPB officers and their provincial and territorial partners. Also considered are results from previous inspection programs, stakeholder concerns and changes in product registration status or use patterns. NPCP activities also cover specific sectors periodically in order to remain aware of challenges faced by stakeholders, changes in compliance levels, and to maintain a presence with the regulated community.

Every fall, all relevant inputs are assessed on a risk basis, for which priority sectors and activities are selected for the next fiscal year. These risk-based work plans include activities according to the three pillars of HC's compliance and enforcement framework. Figure 2 represents the activities which fall under each pillar of compliance and enforcement.

Figure 2 - PMRA Compliance and Enforcement Continuum

Text description

Flowchart showing the activities categorized under each pillar.

Active Prevention:

- Education and outreach,

- Workshops,

- Presentations,

- Consultations,

- Booths at trade shows.

Targeted Oversight:

- Interviews,

- Inspections,

- Sampling,

- Surveillance.

Rapid response:

- Enforcement responses,

- Investigations.

Implementation

The following is a description of current PMRA and RAPB measures used in the delivery of compliance promotion, inspection, and enforcement activities under the PCPA and its Regulations.

Identifying Compliance

Compliance issues may be identified to the PMRA and RAPB through the following avenues:

- ongoing compliance activities;

- voluntary reporting of suspected infractions; and/or

- information reported from other government agencies.

When a situation of non-compliance has been recognized, a compliance risk analysis is performed to determine an appropriate management option.

Active Prevention - Encouraging and Promoting Compliance

There are a number of activities conducted by regional and headquarters officers that encourage and promote compliance. These activities support the collection, distribution and exchange of information and include the following:

- compliance education and outreach;

- working agreements, partnerships and consultations with other regulators of pesticides; and

- sector consultations with the regulated community.

Targeted Oversight - Inspecting for Compliance

Inspections are conducted to assess or verify compliance by registrants, distributors or pesticide users. The types of inspections include the following:

- monitoring inspections;

- surveillance inspections; and

- compliance verification inspections.

During an inspection, the inspector assesses activities conducted by the regulated party and records all deviations from regulatory requirements in accordance with the PCPA and its Regulations. When required, samples are taken and submitted to PMRA's ISO 17025 accredited laboratory in Ottawa for chemical analysis.

Rapid Response - Managing the Risk Resulting from Situations of Non-Compliance

A compliance risk management approach is taken where actual/known or suspected non-compliance would result in an unacceptable risk of harm. All violations are assessed as to whether there is knowledge/understanding, intent and lack of the ability to comply with regulatory requirements. The following factors are also considered:

- the history of compliance, including corrective action already taken;

- the degree of actual harm or potential harm (human health and the environment) as a result of non-compliance; and

- the level of response necessary to achieve and maintain continuing compliance by the violator and others in the regulated community.

Since the majority of the regulated community will generally comply if they understand the requirements, many violations are addressed through education. Education is typically used where the resulting infraction has limited health or environmental impact, the offender clearly does not understand or know of their obligations, or in some circumstances, where it is not clear that they were responsible. Other enforcement options include: enforcement letters, NOVs with warning or penalty, prosecution, amend, suspend or cancel registration, recall, seizure and detention or forfeiture, and denial of entry into Canada.

Chapter 2 - Active Prevention

In 2014-2015, HC delivered four national compliance promotion programs to promote awareness about requirements under the PCPA and its Regulations,several of which focused on agricultural communities. A number of other compliance promotion activities were undertaken to support targeted inspection programs. A total of 233 compliance promotion activities were conducted (Table 1).

| Active Prevention | Type of Activity | ||

|---|---|---|---|

| Description | Booths | Presentations | Meetings |

| Pollinator Protection | 2 | 15 | 25 |

| Endosulfan | 0 | 1 | 0 |

| Personal Protective Equipment | 27 | 33 | 4 |

| Municipal Outreach | 0 | 0 | 20 |

| From Targeted Inspection Programs | 0 | 5 | 1 |

| Other compliance promotion activities | 0 | 100 | 0 |

| Total | 29 | 154 | 50 |

National Program: Pollinator Protection Measures

This outreach program responds to ongoing concerns about the potential impact of pesticides on bees in Canada. Activities delivered included education, information gathering, sampling and spot-checking with stakeholder organizations such as beekeepers, corn and soybean growers, and treated seed distributors, to communicate best practices and mitigation measures for the protection of pollinators. These measures included the need to follow new seed tag label requirements and use of a new fluency agent, a seed lubricant for corn and soybeans. Over 800 samples of soil, honeycomb, vegetation and water were collected for laboratory analysis.

Altogether, 42 compliance promotion activities were conducted including booths, presentations and meetings. In addition, 311 questionnaires were completed during interviews with growers, seed retailers, beekeepers to help determine if there is any connection between potential bee losses and the planting of neonicotinoid-treated corn and soybean seeds.

More information can be found on HC's pollinator protection webpage.

National Program: Endosulfan

An outreach program was conducted in British Columbia, Ontario, Quebec and the Atlantic Provinces in response to the interim risk mitigation measures resulting from the re-evaluation of endosulfan. Measures have been incorporated into end-use product labels currently in the distribution chain. This program assessed user awareness of label and use-pattern changes in sectors such as stone fruit, potatoes, ornamental, berries and vegetables. Where necessary, this assessment was followed up by the distribution to growers of educational material promoting the safe use of endosulfan.

Of the 70 surveyed pesticide users, 44 users (63%) were using the product. Fourteen (32%) had the most recently updated label in their possession and 24 (34%) were aware of the endosulfan label changes before the survey. Sixteen percent were aware of the phase out of endosulfan but not the specific label changes. During the survey, all surveyed pesticide users (70) were given factsheets about the label changes and the phase out dates. In addition to discussions with individual users, one presentation was provided to endosulfan stakeholders.

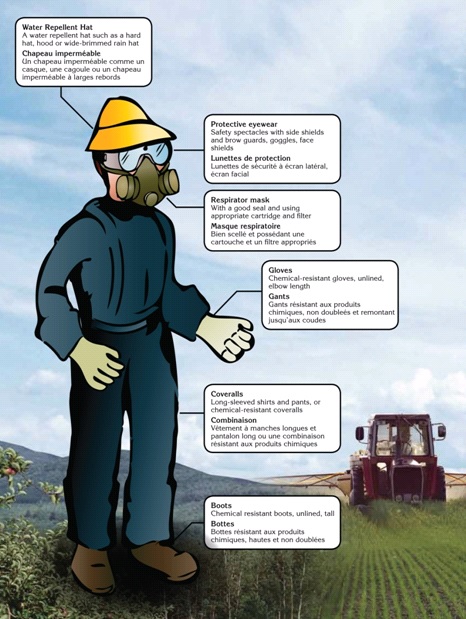

National Program: Personal Protective Equipment

There are continuing challenges with proper use of Personal Protective Equipment (PPE). The Education on Personal Protective Equipment and Post Application Mitigation Measures for Agricultural Workers Program provided growers and pesticide users with information on the importance of wearing PPE and complying with pesticide labels. Partnerships with provincial counterparts and grower groups were deemed to be the best mechanism to deliver PPE information to a broader audience.

Compliance promotion included information displayed at 27 booths, 33 presentations and four meetings. Multi-language videos, fact sheets and posters on PPE requirements were distributed, and a slide show presentation provided information on how PPE requirements are determined and tips for the proper use and care of PPE. Outreach materials to support this program, such as the poster depicted in Figure 3, was provided to various stakeholders including agricultural retailers, farmers, rural municipalities and businesses as a reminder to their staff to wear the necessary PPE.

Awareness of the importance of PPE varied and was dependent on the background of the grower and their perception of the risks associated with pest control products. The majority were aware of PPE information on labels. Those less likely to recognize the risks associated with the use of pest control products tended not to use PPE. However, there is generally more care taken when handling insecticides compared to fungicides, herbicides and plant growth regulators, and commercial pesticide applicators are often hired to ensure that prescribed label directions are followed when applying pesticides to reduce exposure.

Figure 3. Personal protective equipment

Text description

Image showing examples of personal protective equipment.

- Water Repellent Hat: A water repellent hat such as a hard hat, hood or wide-brimmed rain hat.

- Protective eyewear: Safety spectacles with side shields and brow guards, goggles, face shields.

- Respirator mask: With a good seal and using appropriate cartridge and filter.

- Gloves: Chemical-resistant gloves, unlined, elbow length.

- Coveralls: Long-sleeved shirts and pants, or chemical-resistant coveralls.

- Boots: Chemical resistant boots, unlined, tall.

Regional Program: Municipal Outreach

Quebec Region piloted an outreach program targeting municipal employees responsible for the enforcement of by-laws on pest control products and other activities involving pesticides. In Quebec, many municipalities further regulate the use of pesticides, impacting approximately 50% of the population. Twenty meetings were conducted with representatives responsible for extermination in buildings that belong to or are managed by the municipality. The program sought to increase awareness for structural and indoor building uses where bystander exposure may be high, such as those dealing with bedbug infestations. Specific focus included: legislative requirements and the consequences of non-compliance, use of appropriate products, and risks of using pest control products that are not registered for specific uses.

Other Compliance Promotion Activities

Health Canada participated in approximately 100 compliance promotion activities across Canada that were not part of these planned compliance promotion programs. The activities consisted primarily of presentations at trade shows, annual general meetings of associations, and conferences. Additionally, every inspection included outreach elements through the provision of relevant fact sheets and other resources.

Summary

A total of 233 compliance promotion activities involving over 50 unique communication materials were distributed in 2014-2015. Through these activities, the NPCP effectively increased awareness among targeted regulated groups of their regulatory obligations under the PCPA. Moving forward, PMRA and RAPB will continue to place priority on communicating regulatory requirements with all affected stakeholders.

Chapter 3 - Targeted Oversight

In 2014-2015, 15 inspection programs were delivered across Canada and covered a wide range of sectors, including registrants, retailers, commercial pest control operators, and other pesticide users. Areas of known or suspected non-compliance were targeted, which led to higher rates of non-compliance. Within targeted oversight inspections, 1395 monitoring activities were conducted, as well as 299 responses to complaints and incidents of suspected non-compliance.

Monitoring inspections were conducted in two general categories: user programs and distributor programs. The latter included inspection programs of the registrants and retailers of pest control products. Surveillance inspections were also conducted to assess the return to compliance.

User Inspection Programs

Seven targeted oversight inspection programs to determine compliance of users with the PCPA were delivered in 2014-2015, several of which were focused on agricultural communities.

Approximately 450 inspections were conducted through these programs:

Phosphine Inspection Program

This program was implemented due to the high acute toxicity of the product, and the reported incidents with phosphine. The 2014-2015 inspection program continued with outreach to stakeholders and user groups to promote compliance with label requirements and mitigation measures related to the use of phosphine.

As well, thirty-two inspections were conducted nationally. Results of these inspections indicated that many applicators were not aware of mitigation measures resulting from the re-evaluation of phosphine products (i.e. last implementation of changes in 2010), and that some applicators had been using the product unsafely (Figure 4).

Twenty-seven of thirty-two (84%) user inspections were non-compliant. The most common non-compliance situation included incomplete personal protective equipment (PPE) when phosphine levels were above 0.1 ppm or unknown, followed by incomplete or no fumigation management plan and incomplete placarding. All applicators with non-compliance were educated verbally on site and all received letters indicating the non-compliance noted and corrective measures required. Follow-up inspections in 2015-16 will determine if non-compliant users have returned to compliance.

Figure 4. Non-compliance related to phosphine use

Text description

Bar chart showing the number of inspected users found to have contravened the Pest Control Products Act, by violation category.

- Unsafe personal protective equipment = 14 users.

- Incomplete fumigation management plan = 10 users.

- Incomplete placards = 10 users.

- Misuse of phosphine = 4 users.

- Failure to monitor phosphine = 2 users.

- Deficient licensing = 4 users.

Pest Control Operators Inspection Program

The Pest Control Operators (PCO) inspection program was delivered nationally. Sixty-seven PCOs were inspected and 90 violations were detected. Some pest control operators had more than one violation. The main violations included the use of pest control products contrary to label directions, as well as PPE safety violations (Figure 5). Enforcement responses included verbal education, provision of outreach materials to all inspected PCOs, nine education letters, and 16 enforcement letters.

Figure 5. Types of pest control operator non-compliance

Text description

Bar chart showing the number of Pest Control Operators inspected and non-compliance found during inspections, by violation category.

- Personal protective equipment and safety measures = 19 Pest Control Operators, 35 instances of non-compliance.

- Product misuse = 18 Pest Control Operators, 42 instances of non-compliance.

- Expired product in storage = 4 Pest Control Operators, 6 instances of non-compliance.

- Unregistered product in storage = 6 Pest Control Operators, 7 instances of non-compliance.

Liquid Strychnine Concentrate Inspection Program

In 2013, results from Alberta and Saskatchewan on-farm inspections of users indicated a widespread concern regarding compliance with the product label requirements for proper storage of 2% Liquid Strychnine Concentrate (LSC). Consequently, the 2014-15 program placed more emphasis on the requirements to store 2% LSC and mixing/application equipment in a locked compartment away from food and feed. This program verified that purchasers and users of 2% LSC complied with label directions, and that only valid agricultural producers were buying and using these pest control products. Regional pesticide compliance officers in Alberta and Saskatchewan worked with provincial counterparts to monitor the sale and use of 2% LSC.

One hundred and seven on-farm inspections were conducted in Alberta and Saskatchewan, resulting in 22 violations, 5 related to not following label use directions, and 17 related to improper product storage (Figure 6). Instances of non-compliance are largely attributed to the users' failure to read and understand the directions contained on the product label. Verbal education and enforcement letters were used to address the non-compliance observed.

Figure 6. Compliance related to liquid strychnine users

Text description

Bar chart showing the percentage of inspected Liquid Strychnine users found to be compliant, by violation category.

- Use according to label = 95%.

- Storage = 84%.

- Sale = 100%.

Aquaculture Inspection Program

The salmon aquaculture industry in Atlantic Canada includes approximately 140 farms. Over the last several years, the industry has used pest control products to control sea lice, a marine pest which attaches itself to salmon. These products are potentially harmful to the marine environment when not used according to the label directions.

The 2014-2015 aquaculture inspection program monitored compliance with the conditions of emergency registration usage of Salmosan 50WP and Paramove 50 pest control products by salmon growers in Atlantic Canada. In total, 57 farms were inspected. Health Canada worked with numerous provincial partners to design and deliver the program. No violations of the PCPA were detected during inspections or from analysis of the 57 samples collected. Due to logistical issues with marine transportation provided by provincial partners, 78% of planned inspections and 87% of planned samples were delivered.

Saskatoon Berry Inspection Program

Information obtained from compliance activities in 2012 and from provincial partners indicated potential situations of non-compliance with producers of Saskatoon berries by the use of unregistered pest control products on their orchards.

This program focussed on 19 on-farm inspections of Saskatoon berry producers early in the 2014 growing season to verify that growers used registered products and that their use was in accordance with label directions. Information was gathered on the products used by growers to control insects and diseases, use of PPE, and knowledge of and compliance with re-entry intervals (REI) and post-harvest Intervals (PHI). Saskatoon berry growers were found to be knowledgeable with regards to pesticide usage, REIs and PHIs, with an observed compliance level of 89%. Nineteen of 20 samples did not indicate misuse. The 2014-15 surveillance inspection related to the one positive sample confirmed a return to compliance. Education letters were delivered in response to all non-compliance found.

Fruiting and Cucurbit Vegetable Grower Inspection Program

In 2014-15, 87 growers of fruiting and cucurbit vegetables were inspected across Canada with the intent of mitigating non-compliance risks associated with pest control products. Fifty-four percent of growers inspected were found to be non-compliant. Inspection results revealed instances of non-compliance involving PPE violations and the storage of expired product. Seventy-five percent were fully compliant with use consistent with the label (Figure 7). Forty seven growers found to be non-compliant received the appropriate enforcement response, generally education or enforcement letters.

Figure 7. Types of non-compliance among inspected fruiting and cucurbit vegetable growers

Text description

Bar chart showing the number of inspected fruiting and cucurbit vegetable growers found to have contravened the Pest Control Products Act, by violation category.

- Insufficient/inappropriate personal protective equipment = 7 growers.

- Use of a product inconsistent with the label = 24 growers.

- Possession of discontinued product = 27 growers.

Emergency Registrations Inspection Program

Emergency registrations are time-limited registrations, granted by the PMRA for a period of one year or less. In 2014-2015, nine inspections were conducted to confirm that products registered to address an emergency need were being used as directed. No notable non-compliance was observed.

Summary of Compliance Rates for User Programs

Across all targeted oversight programs directed toward users of pest control products, varying levels of compliance were observed. In 2014-2015, levels of non-compliance were highest among phosphine users. Non-compliance was not observed among aquaculture users (Figure 8).

Figure 8. Compliance levels observed at targeted oversight inspections of users

Text description

Bar chart showing the percentage of compliant and non-compliant users found during targeted oversight inspections, by program.

- Pest Control Operators (PCOs) = 63% compliant, 37% non-compliant.

- 2% LSC Strychnine = 74% compliant, 26% non-compliant.

- Aquaculture = 100% compliant, 0% non-compliant.

- Fruiting and cucurbit vegetables = 43% compliant, 57% non-compliant.

- Emergency registrations = 100% compliant, 0% non-compliant.

- Saskatoon berries = 89% compliant, 11% non-compliant.

- Phosphine = 16% compliant, 84% non-compliant.

Distribution Inspection Programs

Six targeted oversight inspection programs to determine compliance of stakeholders along the distribution chain were conducted in 2014-2015.

Over 500 inspections were completed through these programs:

Diazinon Inspection Program

The 2009 PMRA re-evaluation decision on diazinon required the phase-out of most uses due to health and environmental risk concerns. Some product uses were identified for short-term phase-out (March 2012). Critical uses, with no registered alternative pest control products, were identified for longer-term phase-out and managed under a risk management plan (RMP) which was targeted for inspection in 2014-2015.

The inspection program verified compliance with the PMRA's diazinon RMP and phase-out requirements among distributors/retailers and growers. Forty-three growers and thirty-five retailers were inspected in all provinces. Results indicated that 20 of 35 inspected retailers sold diazinon products in 2014, and 13 of these 20 retailers were not aware of the diazinon RMP and phase-out schedule. All RMP non-compliant retailers were verbally educated onsite. Seventeen compliance verifications were generated following 43 grower inspections. In 16 of 17 cases, education letters were issued and the non-compliant parties were advised to respect the RMP and phase-out requirements. In one case, a compliance "stop order" was immediately issued followed by a NOV for harvesting before the end of the 10-day required interval from the last application.

Registrant Inspection Program

The objective of this program is to prevent and correct compliance issues prior to reaching the supply chain. This program was designed to verify compliance of registrants' products that are being or have recently been re-evaluated, those with poor compliance history or who have not been inspected in the past five years.

A total of 39 inspections were conducted. A lack of knowledge of the sales and incident reporting requirements or difficulty using the electronic reporting system were reported for 13 registrants inspected. Thirty-six registrants were compliant with the formulation and/or labelling of their pest control products. Five registrants had non-compliance with their product distribution and packaging. Non-compliance related to end use product labels and company websites was recorded for 15 registrants. The majority of label and website issues included: missing or outdated information and spelling errors. Enforcement letters were sent to 15 non-compliant registrants and the rest were verbally educated on the requirements of the PCPA and its Regulations.

Guarantee Verification Program

Registrants of pest control products are required to ensure the levels of active ingredients in their products are within guarantee limits. Inspectors collected samples of 17 insecticides or insect repellents available to consumers from registrants of fewer than ten registered products. PMRA's laboratory analyzed samples of each product to assess if the levels of active ingredients in the samples were consistent with the label guarantee.

Laboratory results revealed that five (29%) products were non-compliant as the active ingredient levels in one or more samples for these products were above or below the guarantee limits. PMRA scientists determined that the non-compliant guarantees did not represent a risk to human health. Enforcement letters were sent to registrants of non-compliant products to inform them of sample results and to require specific corrective measures to address the non-compliance.

Research Authorization Inspection Program

The Pest Control Products Regulations allow for the use of unregistered pest control products for research purposes if specified conditions are met. This program monitors for compliance with regulatory requirements and collects information for the PMRA's Re-evaluation Program. Forty-two research sites were inspected across the country, with 33 being in compliance (79%). The majority of violations were related to use that was inconsistent with label directions. All researchers and co-operators were informed of legislative requirements. This program allows the Agency to maintain contact with the research community and increase awareness of new pest control products and techniques under development.

Rodenticides Inspection Program

In 2010, PMRA required additional measures for several rodenticides as part of an overall risk-reduction strategy for rodenticides in Canada. As of January 1, 2013, use restrictions for several commercial and domestic class rodenticides came into effect on product labels (re-evaluation decision on rodenticide). The objective of the compliance program for 2014-15 was to inspect the use of rodenticides in commercial and/or agricultural areas including oilfields, field crops and horse barns according to label restrictions and new mitigation measures added to labels to further protect children, domestic animals and non-target wildlife.

Of the 348 products inspected, 322 (93%) products found for sale were compliant. Products no longer registered or never registered with the PMRA were removed from sale, and education and enforcement letters were issued to the non-compliant vendors and distributors.

Fifty-six percent of vendors and distributors inspected were compliant. Eighty-four percent of horse farms and fur farms inspected were compliant. Follow-up enforcement responses were taken for the non-compliant users on these farms.

Marketplace Inspection Program

Every year, the NPCP monitors pesticide retailers for sale of unregistered pest control products and pest control products no longer approved for sale. In 2014-2015, the program focussed on inspections of retailers, distributors, and manufacturers, and internet retailers, including those that previously sold unregistered citronella, neem, and naphthalene products. The goal of this program is to verify compliance, strengthen knowledge of regulatory requirements and collect information regarding distributors of unregistered products.

Two hundred and nineteen inspections determined that 62% of inspected vendors had one or more unregistered product for sale, and their distributors were identified for future follow-up as necessary. However, only 8% of the 3226 inspected products were non-compliant, and those products were removed from store shelves. Non-compliance resulted from a lack of knowledge regarding regulatory requirements and challenges in determining if a product is in fact a pest control product. Forty-one percent of vendors were aware that a registration number is required for sale of these products. Follow-up inspections in 2015-16 will determine if non-compliant retailers have returned to compliance.

Summary of Compliance Rates for Distribution Programs

Across all targeted oversight programs directed toward distributors of pest control products, varying levels of compliance were observed. In this regard (Figure 9), the highest level of compliance was observed among registrants.

Figure 9. Compliance levels observed at targeted oversight inspections of distributors

Text description

Bar chart showing the percentage of compliant and non-compliant distributors found during targeted oversight inspections, by program.

- Guarantee verification = 71% compliant, 29% non-compliant.

- Rodenticide vendors = 56% compliant, 44% non-compliant.

- Diazinon vendors = 61% compliant, 39% non-compliant.

- Marketplace = 38% compliant, 62% non-compliant.

- Research Authorization = 79% compliant, 21% non-compliant.

- Registrant = 90% compliant, 10% non-compliant.

Surveillance Inspection Program

The surveillance program helps to determine the effectiveness of our compliance and enforcement responses with a focus on higher risks for repeat violations, and possible health and safety and regulatory impacts of continued non-compliance.

In 2014-2015, the surveillance program verified whether compliance had been restored in sectors of concern. Selected regulated parties and individuals who have previously been known to be non-compliant with regulations, and for whom the risks to re-offend were significant, were targeted in 66 surveillance inspections. Seventy-six percent of these inspections found a return to compliance. The NPCP is taking active steps, including application of escalated enforcement measures, to induce the remaining regulated parties and individuals to fully comply with the PCPA and its associated Regulations.

Summary

Targeted Oversight delivery in 2014-2015 included inspections and interviews with growers, pest control operators, retailers, registrants and distributors. Non-compliance was detected across several sectors. The most frequent violations were possession of an unregistered product; sale, import, and use of unregistered products; and use contrary to the label approved by PMRA. Lack of awareness of regulatory obligations and decisions was the primary reason for non-compliance.

Chapter 4 - Rapid Response

In 2014-15, 1619 enforcement responses were completed regarding non-compliance issues. Approximately 1100 of those enforcement responses resulted from planned inspection programs, with the remaining 519 from unplanned compliance verifications.

Enforcement actions from planned activities included 762 requests to address non-compliant products, and 324 enforcement responses against offenders. Enforcement actions from unplanned activities included 287 requests to address non-compliant products, and 229 enforcement responses against offenders (Figures 10 and 11).

In total, 319 samples of soil, plants, seeds and grains, animal tissues, liquid and surface wipes were submitted to PMRA's laboratory to verify compliance with the PCPA. Pesticide monitoring programs for guarantee verification, rodenticides, aquaculture, cucurbits, Saskatoon berries and tomatoes resulted in 220 samples collected for analysis. Unplanned compliance verifications resulted in 99 samples collected for analysis.

Figure 10. Enforcement actions for products in 2014-2015

Text description

Bar chart showing the number of enforcement actions taken on products, by type of enforcement action taken.

- Denial of entry = 86 unplanned, 6 planned.

- Stop sale - dispose = 162 unplanned, 678 planned.

- Stop sale - return/recall = 15 unplanned, 42 planned.

- Order to cease/dispose = 3 unplanned, 8 planned.

- Relabel = 8 unplanned, 11 planned.

- Other = 12 unplanned, 17 planned.

Figure 11. Enforcement actions against offenders in 2014-2015

Text description

Bar chart showing the number of enforcement actions taken against offenders, by type of enforcement action taken.

- Written education = 144 unplanned, 218 planned.

- Verbal education = 38 unplanned, 13 planned.

- Enforcement letter = 31 unplanned, 91 planned.

- Compliance order (CO) = 1 unplanned, 1 planned.

- Agriculture and Agri-Food Administrative Monetary Penalties = 15 unplanned, 1 planned.

Response to Incidents and Complaints Reported by Stakeholders

In 2014-15, PMRA and RAPB responded to 299 reported incidents of suspected non-compliance and complaints received from the public and regulated parties. When instances of non-compliance with the PCPA were detected, measures were taken appropriate to the circumstances and the risks involved.

Two examples of higher risk incidents are summarized below:

Agricultural products sold to homeowners: Health Canada became aware of a company selling repackaged agricultural class products for domestic class use. Chemical analysis confirmed that the products were agricultural insecticides and herbicides not registered for domestic class use. Non-compliant products were seized and disposed. Compliance Orders were issued to stop the non-compliant repackaging and sale activities, and NOVs were issued.

Phosphine used to treat a bedbug infestation: Health Canada became aware of an incident involving the suspected use of a highly toxic pest control product to treat a domestic bedbug infestation. In response to this incident, HC worked with local law enforcement and fire authorities, as well as provincial officials, regarding the safe removal and disposal of any remaining pest control products on the premises.

Health Canada developed a public advisory to warn the public against using unregistered products to treat bedbug infestations.

Summary

Compliance verification of 299 complaints and suspected incidents of non-compliance resulted in 520 enforcement responses. Health Canada also collaborated with provincial counterparts and other stakeholders to reduce the risks associated with the use of pesticides.

Chapter 5 - Border Activities

Internet commerce has led to a dramatic increase in the number of pest control products being shipped into Canada via international mail and private courier services. Many of these products are domestic class pest control products purchased by Canadian residents from online distributors, a practice that, with few exceptions, is illegal. Pest control products purchased online and shipped by mail or private courier may not have been subjected to the safety and quality checks that HC places on legally imported products, and may pose health risks to consumers. Working side by side with other federal agencies, including Canada Border Services Agency (CBSA), PMRA and RAPB deploy risk-based strategies, including blitzes at border points nationwide to effectively and efficiently identify, examine, and intercept these shipments.

CBSA Pathfinder

CBSA's Pathfinder import data has been used by HC's pesticide program since 2012 to identify trends in pesticide imports and to gather evidence to respond to non-compliant importations. An inspection program targeted at importers identified through this import data was delivered in 2014-2015 to address non-compliance and to educate importers regarding the PCPA. More than 80% of the pest control products used in Canada are imported. Unregistered products offered for sale constitute the most common violation of the PCPA found in the marketplace.

Of the 143 targeted Pathfinder inspections, there was a 47% rate of non-compliance, primarily with retailers importing unregistered pest control products. Commercial (growers and industrial facilities) and distribution violations were the next most frequent area of non-compliance (Figure 12). Eighty-six responses to instances of non-compliance included written education (57%), verbal education (22%) and enforcement letters (9%) (Figure 12).

Figure 12. Import related violations by group inspected

Text description

Bar chart showing the number of import-related violations, by group inspected.

- Retailer = 37 violations.

- Commercial = 16 violations.

- Distributor = 12 violations.

- User = 9 violations.

- Registrant = 3 violations.

CBSA Admissibility Referrals

Additional admissibility referrals from CBSA at various border points resulted in 93 denials of entry into Canada.

Summary

Importation data from the CBSA enables the NPCP to develop and implement a compliance program focussed on the verification of suspect imports and removal of unregistered pest control products from the Canadian market. The launch of the CBSA's Single Window Initiative is expected to assist the NPCP in identifying trends and deal with non-compliant imports.

Chapter 6 - National and International Partnerships to Further Reduce Risk for Canadians

National Collaboration

There are a number of collaborative initiatives with HC regional offices and provincial, territorial and municipal partners. A few examples:

- PPE for seasonal agricultural workers;

- PMRA policy and regulatory updates;

- Spray drift concerns and application best practices;

- Education and support of provincial counterparts; and

- Use of unregistered ozone for control of bedbugs.

PPE for seasonal agricultural workers: Health Canada staff and provincial partners developed a video in English, French, and Spanish to explain how to prevent pesticide exposure of seasonal agricultural workers, including migrant workers. The video was distributed to recruitment organisations and worker support centres and was seen more than 1000 times since April 2014, including 319 times in Spanish.

PMRA policy and regulatory updates: In support of continuing efforts to improve consumer pesticide sector compliance, a bi-annual information bulletin is being distributed electronically to approximatively 300 Pest Control Operators. The Bulletin provides information on PMRA regulatory and policy updates, product registration news and best practices.

Spray drift concerns and application best practices: The NPCP collaborated with provincial ministries and industry to prevent or reduce spray drift complaints and to proactively support pesticide application best practices in the rural/urban interface. Reducing spray drift results in better efficacy (product hits the target rather than elsewhere) and less off target damage.

Education and support of provincial counterparts: The NPCP worked with Non-Government Organizations such as WorkSafeBC to train, educate and support agriculture field inspectors, management and technical staff of this growing organization. This work facilitates the reduction of risk to human health and the environment from the use of pest control products. Ongoing information exchange with provincial colleagues as well as joint inspections (where required) assist with the delivery of both the federal and provincial/territorial mandates with respect to compliance and enforcement related to pesticides.

Use of unregistered ozone for control of bedbugs: The NPCP worked with provincial counterparts to develop a strategy to deal with the increasing commercial use of unregistered ozone for bed bug control. The information piece created by HC was disseminated by provincial ministries and Pest Management Associations. Educating the public can be the quickest, most efficient method to decrease numbers of ozone applications for bedbugs and thereby hopefully decrease the number of companies offering such non-compliant ozone treatments.

International Collaboration

With world commerce growing larger, more complex, and even more intricately interconnected, surveillance is increasingly essential to protect the health of Canadians. The NPCP engages with a wide variety of organizations, including other government agencies and international organizations, to leverage resources. Through effective engagement with selected partners, the NPCP expands its reach to protect health and the environment with finite resources.

During 2014-2015, the NPCP strengthened working relationships with its international regulatory partners through the Organisation of Economic Cooperation and Development's (OECD) Network of Officials for Pesticide Compliance and Enforcement. This network provides a venue in which regulators from OECD member countries can regularly and proactively share real-time information and coordinate pesticide compliance and enforcement strategies. The NPCP has led the development of a website aimed at sharing information and best practices, promoting global cooperation and discussing issues related to pesticide compliance and enforcement among the OECD countries.

In addition, the NPCP joined the OECD Network of Illegal Trade of Pesticides (ONIP) through the OECD Rapid Alert System in December 2014 to facilitate quick sharing of information when illegal or unsafe shipment of pest control products is identified by one of its member countries. ONIP's goal is to foster the cooperation among OECD Member and Partner countries by assisting the Working Group on Pesticides in the creation of a Global Alliance against Illegal International Trade of Agricultural Pesticides, which can have significant impacts in the fields of human health, food chain safety, and the environment. The NPCP has access to the Rapid Alert System, notably to ensure the immediate reaction to questions from foreign authorities, and is developing the necessary structure and procedures to enable international cooperation at both the technical and legal levels.

Summary

By collaborating with our international partners and working with other federal and provincial/territorial ministries, PMRA and RAPB have rapid access to compliance information for promoting and verifying compliance with the PCPA and to educate individuals, local officials and grower groups as to regulatory requirements.

Chapter 7 - Compliance Overview

Trend of Non-Compliance: Activities carried out by the NPCP in 2014-2015 indicated that compliance exists to varying degrees depending on the sectors of activity. Sale, unregistered use and importation of unauthorised products were the major types of non-compliance encountered during the inspections (Figure 13).

Surveillance inspections conducted under Targeted Oversight verified whether compliance had been restored in sectors of concern. Selected regulated parties who were previously non-compliant with the regulations, and for whom the risks to re-offend were significant were targeted, with a 76% return to compliance. The NPCP took active steps, including application of escalated enforcement measures, to induce the non-compliant regulated parties to fully comply with the PCPA and its associated Regulations.

Figure 13. Types of violations in 2014-2015

Text description

Pie chart showing the types of violations observed in 2014-2015.

- Sale = 30%,

- Unregistered use = 24%,

- Manufacturing = 5%,

- Importation = 20%,

- Advertising = 4%,

- Possession = 11%,

- Contrary to the label = 2%,

- Unclassified = 4%.

In partnership with RAPB, PMRA implemented a robust compliance and enforcement program. This program included 233 compliance promotion activities, 1052 inspections, 299 compliance verifications and 1619 enforcement responses, and 636 samples analyzed by the PMRA laboratory.

Chapter 8 - Forward Planning

Several priorities were identified by the NPCP for the 2015-2016 fiscal year and include:

- Delivering the 2015-2016 NPCP commitments, including outreach and inspection for sectors of higher non-compliance, refining internal processes and continued development of policies and processes;

- Identifying and addressing compliance-related risk, at the border and in Canada, through new and existing tools, improved information sharing with regulatory partners, and strengthened compliance and enforcement relationships with governments and organizations;

- Sharing information more effectively with Canadians, through the posting of compliance and enforcement information online; and

- Enhancing support within PMRA through collaboration on re-evaluations, phase-outs, label changes, treated articles and laboratory analysis and methodology development.

Glossary

- Administrative Monetary Penalties:

- The Agriculture and Agri-Food Administrative Monetary Penalties Act provides a system of penalties and warnings for violations of several federal Acts including the Pest Control Products Act. The Agriculture and Agri-Food Administrative Monetary Penalties Act allows Canadian pesticide regulatory officials to impose penalties without having to pursue formal prosecution.

- Active Prevention:

- Promotion of appropriate import, manufacture, distribution, sale, and use of pest control products. See also the definition of compliance promotion.

- Candidate:

- The person or business reported or suspected of being in contravention of the Pest Control Products Act or its associated Regulations.

- Compliance:

- The full implementation of legal requirements. It is the state of conformity of a regulated party (including a corporation, institution, individual or other legal entity) or a pest control product with the Pest Control Products Act and its associated Regulations.

- Compliance Monitoring:

- Collecting and analysing information on compliance status of a pest control product or a facility (place or operation where pest control products are manufactured, held, stored, marketed, sold, distributed, transported, used or disposed or where records relating to such activities are maintained) or of an industry or use sector. Compliance monitoring involves interviews, inspections and sampling.

- Compliance Orders:

- A tool to inform the regulated party of a violation of the Pest Control Products Act and its associated Regulations which requires timely action to prevent risk to health and safety.

- Compliance Promotion:

- Action taken to assist regulated enterprises, individuals and other legal entities to comply with the Pest Control Products Act and its associated Regulations. These actions include educational activities and the provision of information on legislation and policies.

- Compliance Verification:

- Inspections that are not part of a planned program that are in response to specific violations, suspected violations, or complaints. They can be surveillance inspections which are planned to target specific individuals or groups for follow-up on previous findings or concerns.

- Contravention:

- The act of coming into conflict with a provision of legislation. Under the Pest Control Products Act and its associated Regulations, a contravention can lead to either a violation or an offence.

- Detention:

- The act of holding a pest control product in custody of the Pest Management Regulatory Agency, which nullifies the rights of the owner over this product, until the provisions of the Pest Control Products Act and its associated Regulations have been complied with.

- Education Letters:

- Primarily provides an individual or company with information about their regulatory obligations.

- Emergency Registrations:

- Registration of a pest control product, for a period not exceeding one year, for the emergency control of seriously detrimental pest infestations.

- Enforcement Letters:

- In addition to informing stakeholders of their regulatory obligations, enforcement letters require that action be taken to restore compliance.

- Enforcement Responses:

- Actions that may be taken by Health Canada's pesticide program to induce, encourage or compel compliance by the regulated party with the Pest Control Products Act and its Regulations or to cause a contravention to cease, to prevent future contravention or to impose sanctions for non-compliance. Enforcement responses include education letters, enforcement letters, compliance orders, Administrative Monetary Penalties, and Prosecution.

- Forfeiture:

- The loss or surrendering of an item to the Crown as part of the enforcement response to a contravention, where an item has been seized and detained and subsequently forfeited using either section 55 of the Pest Control Products Act or section 22 of the Agriculture and Agri-Food Administrative Monetary Penalties Act.

- Guarantee Limits:

- The active ingredient(s) levels in the pest control product must be in compliance with its declared guarantee statement and product specifications.

- Inspection:

- The review and examination of the compliance status of a pest control product or any place or operation where pest control products are manufactured, held, stored, marketed, sold, distributed, transported, used or disposed, or where records relating to such activities are maintained.

- Interview:

- A compliance monitoring activity that is part of the National Pesticide Compliance Program and involves a questionnaire. Health Canada's pesticide program officer gathers information for the determination of the risk of non-compliance. The consideration of this risk determines the nature, type and frequency of oversight in a given situation.

- Investigation:

- Actions taken to gather evidence to support a case referral for potential judicial determination regarding specific violations of the Pest Control Products Act and its associated Regulations. This includes taking statements and activities carried out under the Criminal Code, i.e., executing search warrants.

- Phase-Out:

- The gradual elimination of registered product uses, product formulations, or product registrations, through Pest Management Regulatory Agency's Re-evaluation Program.

- Pre-harvest Interval (PHI):

- The time between the last application of the pesticide and harvest.

- Rapid Response:

- Enforcement responses to non-compliance, which can vary depending on a number of factors, such as the harm or potential harm caused by the infraction, compliance history, whether the regulated party acted with indifference or premeditation, the likelihood that the problem will reoccur, and the probable and likely outcome of each enforcement action.

- Registrant:

- A person in whose name a pest control product is registered.

- Restricted Entry Interval (REI):

- A restricted-entry time after the application of a pest control product.

- Seizure:

- The act of taking possession of a product under the authority of the Pest Control Products Act without the person's consent for the purposes of placing the product under detention. Seizure deprives the owner of the item from freely doing anything with the item, but unlike forfeiture, he/she retains ownership of the item.

- Surveillance:

- Follow-up inspections conducted to verify the effectiveness of previous programs.

- Targeted Oversight:

- Early detection of health, safety and environmental concerns at the appropriate stage of the pest control product's life cycle. This is achieved by undertaking a variety of activities including inspections, sampling and surveillance to identify risks.

- Violation:

- A contravention of the Act or the Regulations that may be proceeded with in accordance with the Agriculture and Agri-Food Administrative Monetary Penalties Act (see subsection 2(2) of the Pest Control Products Act).

This document does not constitute part of the Pest Control Products Act (Act) or its associated Regulations and in the event of any inconsistency or conflict between that Act or Regulations and this document, the Act or the Regulations take precedence. This document is not intended to provide legal advice regarding the interpretation of the Act or Regulations. If a regulated party has questions about their legal obligations or responsibilities under the Act or Regulations, they should seek the advice of legal counsel.

Page details

- Date modified: