Guidance on Sampling and Mitigation Measures for Controlling Lead Corrosion

Download the alternative format

(PDF format, 1,303 Kb, 148 pages)

- Organization: Health Canada

- Date published: February 2025

Background on guidance documents

Health Canada, in collaboration with the Federal-Provincial-Territorial Committee on Drinking Water, may choose to develop guidance documents for two reasons. The first is to provide operational or management guidance related to specific drinking water–related issues (such as boil water advisories or corrosion control), in which case the documents would provide only limited scientific information or health risk assessment.

The second instance is to make risk assessment information available when a guideline is not deemed necessary. Guidelines for Canadian Drinking Water Quality are developed specifically for contaminants that meet all of the following criteria:

- exposure to the contaminant could lead to adverse health effects;

- the contaminant is frequently detected or could be expected to be found in a large number of drinking water supplies throughout Canada; and

- the contaminant is detected, or could be expected to be detected, at a level that is of possible health significance.

If a contaminant of interest does not meet all these criteria, Health Canada may choose not to establish a numerical guideline or develop a guideline technical document. In that case, a guidance document may be developed.

Guidance documents undergo a similar process as guideline technical documents, including public consultations through the Health Canada website. They are offered as information for drinking water authorities, and in some cases to help provide guidance in spill or other emergency situations.

Part A of this document provides guidance on sampling for the purposes of controlling lead corrosion in distribution systems as defined in this document. Part B provides the scientific and technical information, including citations, to support this guidance. Part C provides the references and abbreviations; and Part D includes tools and information required to develop specific corrosion control programs and activities. Part E includes a framework for a residential corrosion control program while Part F provides an alternative (2-tier) monitoring protocol for non-residential and residential buildings. Part G lists a number of resources on topics such as corrosion control planning, operational considerations and implementation.

Executive summary

Corrosion is a common issue in Canadian drinking water distribution and plumbing systems. Although there are no direct health effects linked to corrosion in distribution and plumbing systems, it may cause the release of lead and other contaminants that would be a concern for the health of people who live in Canada. This document focuses on lead as the main contaminant of concern for health. The results of lead monitoring are used as the trigger to initiate corrosion control programs to control or mitigate its release.

Corrosion is the deterioration of a material, usually a metal, that results from a reaction with its environment. In drinking water distribution systems, materials that could be affected by corrosion–and consequently release increased amounts of contaminants such as lead –include metal pipe and fittings. Corrosion control treatment can effectively minimize lead concentrations at the point of consumption. However, when water is supplied through a lead service line, treatment alone may not be sufficient to reduce lead to concentrations below the maximum allowable concentration (MAC) of 0.005 mg/L (5 µg/L) for total lead established in the Guidelines for Canadian Drinking Water Quality. Therefore, the removal of the full lead service line is considered the most effective and most permanent solution. However, plumbing components may also be contributors to elevated lead concentrations even after the removal of lead service lines.

In this document, corrosion refers to the internal corrosion of the distribution system but not external corrosion of the infrastructure. Additionally, "corrosion control" refers to the action of controlling or mitigating the release of metals, primarily lead, that results from the corrosion of materials in drinking water distribution systems. Information on components of a corrosion control program is provided. Resources for these components are listed in Part G. Certain aspects of corrosion control are beyond the scope of this document, including details on developing a corrosion plan, removal of lead service lines, and microbiologically influenced corrosion.

Although corrosion itself cannot readily be measured by any single reliable method, the lead levels at a consumer's tap can be used as an indication of corrosion and can be complemented with other approaches and/or tools, such as pipe loops, and water quality monitoring. Corrosion control programs will vary depending on the responsible authority. They can range from extensive system-wide programs implemented by the water treatment system to localized programs implemented by a building owner, to ensure a safe and healthy environment for the occupants of residential and non-residential buildings.

This guidance document was prepared in collaboration with the Federal-Provincial-Territorial Committee on Drinking Water and assesses all available information on corrosion control in the context of drinking water quality and safety.

Assessment

The intent of this document is to provide responsible authorities, for example, municipalities, with guidance on assessing corrosion and triggers for implementing corrosion control measures for distribution systems in residential settings. It also provides sampling protocols and corrective measures for multi-dwelling buildings, schools, day care facilities and office buildings. These are intended for the authorities, such as school boards, building owners or employers, that are responsible for the health and safety of the occupants of such buildings. The goal of the guidance is to minimize exposure to lead at the tap. Generally, drinking water falls under provincial jurisdiction and the drinking water treatment plant and distribution system, up to private property lines, are the responsibility of a public, private or municipal drinking water system. The responsibility for the implementation of corrosion control plans and related activities may vary within jurisdictions and/or at the municipal level. It may also include the need to collaborate with public health officials.

This document briefly outlines the steps that should be taken to reduce exposure to lead in drinking water, which may also reduce the consumer's exposure to other corrosion-related contaminants such as copper. Concerns related to other contaminants whose concentrations may be affected by corrosion, such as iron, are also briefly discussed to help ensure a holistic approach to corrosion control is considered.

This guidance is intended to complement the information provided in the Guidelines for Canadian Drinking Water Quality – Lead. The guideline for lead in drinking water provide detailed information on the application of the guideline, sources of lead in drinking water, exposure, health effects, treatment and distribution system considerations (including lead service line issues). The guideline for lead in drinking water should be read in conjunction with this guidance to ensure an understanding of the link between monitoring for community exposure to total lead and the need to minimize exposure to lead by identifying sources of lead and using mitigation approaches such as, but not limited to, lead service line removal and corrosion control programs.

Table of Contents

- Part A. Guidance on Sampling and Mitigation Measures for Controlling Corrosion

- A.1 Goal and scope

- A.2 Introduction and background

- A.3 Corrosion control monitoring programs and protocols

- A.3.1 Sampling considerations

- A.3.2 Two-tier monitoring protocols for residential dwellings

- A.3.3 Follow-up sampling (demonstrating CCT optimization and successful mitigation)

- A.3.4 Frequency of sampling for residential monitoring

- A.3.5 Number and selection of sites for residential monitoring

- A.3.6 Monitoring protocol for non-residential and multi-dwelling residential buildings (two-tier)

- A.3.7 Considerations for small systems

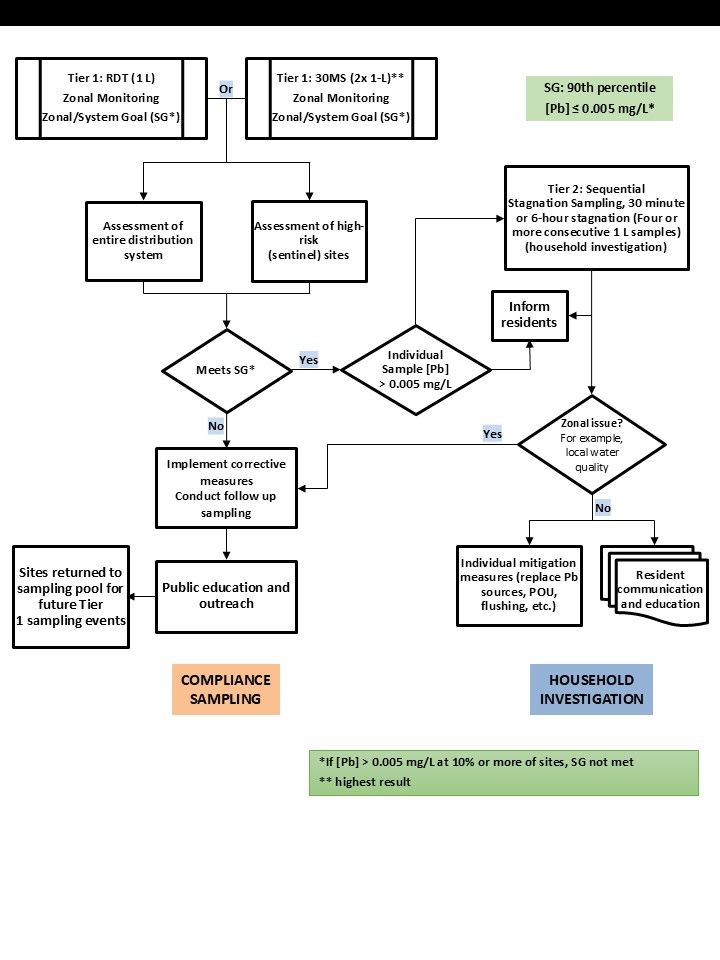

- A.4 Flow charts for lead sampling protocols

- Part B. Supporting information

- B.1 Principles of corrosion in drinking water distribution systems

- B.2 Challenges in measuring corrosion

- B.3 Methods for measuring corrosion

- B.4 Treatment and control measures for lead, copper and iron

- B.5 Rationale for monitoring programs to assess corrosion

- Part C. References and abbreviations

- Part D. Tables

- Part E. Framework for residential corrosion control program

- Part F. Alternative monitoring protocol for non-residential and residential buildings (two-tier stagnation)

- Part G. Additional resources on corrosion control related topics

- Part H. International considerations

Part A. Guidance on Sampling and Mitigation Measures for Controlling Corrosion

A.1 Goal and scope

The intent of this guidance document is to provide responsible authorities such as drinking water suppliers and municipalities with the knowledge, tools and approaches to assess and address corrosion.

This guidance establishes sampling protocols to evaluate and identify corrective measures to reduce lead concentrations at the tap. The main focus of this document is lead because, when it comes to corrosion, this metal is the main contaminant of concern for health. It is important to reduce exposure to lead as much as possible because health effects of lead may occur even at low concentrations. The goal of the monitoring described in the guideline for lead in drinking water is to evaluate community exposure to total lead. In contrast, the goal for the monitoring described in this guidance is to identify sources of lead in the distribution system, including in building plumbing systems (residential and commercial) and evaluate the effectiveness of mitigation approaches such as, but not limited to, lead service line removal and corrosion control programs. These are complimentary goals, and the guideline for lead in drinking water should be read in conjunction with this guidance.

In this document, "corrosion control" refers to the action of controlling or mitigating the release of metals, primarily lead, that results from the corrosion of materials in drinking water distribution systems. Information on key elements of a corrosion control program is provided; however, the detailed operational and implementation aspects of a corrosion control plan or the removal of lead service lines are site-specific and outside the scope of this document.

Microbiologically influenced corrosion is briefly discussed but detailed information is beyond the scope of this document.

A.2 Introduction and background

Corrosion is a common issue in Canadian drinking water distribution and plumbing systems. Corrosion is the deterioration of a material, usually a metal, which results from a reaction with its environment. In drinking water distribution systems, materials that could be affected by internal corrosion and release increased amounts of contaminants include metal pipes (such as lead service lines) and fittings. Corrosion tends to increase the concentrations of many metals in tap water (that is, corrosion by-products) at the consumer's tap. Corrosion deposits in pipes also provide a major reservoir for a broad variety of contaminants, some of which are a health concern. This document complements the guideline for lead in drinking water and uses the sampling approaches described in that guideline. The sampling protocols serve three purposes by helping to: assess population exposure to lead; identify lead issues; and determine if corrosion measures are successful.

The term corrosion is also commonly applied to the dissolution and carbonation (precipitation of CaCO3) reactions of cement-based materials. This reaction often results in an increase in pH, which can be detrimental to disinfection and the aesthetic quality of the water, as well as reducing the effectiveness of corrosion control chemicals. In some cases, the chemical attack on the pipe by the water may reduce structural integrity and subsequent infrastructure failure.

Corrosion in drinking water distribution systems can be caused by several factors, including the type of materials used, the age of the piping and fittings, the stagnation time of the water and the water quality in the system, including its pH. The most influential properties of drinking water when it comes to the corrosion and leaching of distribution system materials are pH and alkalinity. Other drinking water quality parameters affecting corrosion include temperature, calcium, free chlorine residual, chloramines, chloride, sulphate, dissolved inorganic carbon (DIC), hardness, iron, manganese, aluminum, dissolved oxygen (DO) and natural organic matter (NOM) (see Table D.1). These parameters should be monitored and/or addressed to ensure optimal water quality for effective corrosion control (see Table D.2). For example, removing NOM, manganese and iron will make pH adjustment easier and minimize interference with corrosion control treatment (CCT). Any change to the drinking water treatment process or to water quality (including from blending) may impact corrosion in the distribution system and in household plumbing. More detailed information on sampling of water quality parameters can be found elsewhere (WRF, 2023).

In this document, "corrosion control" refers to the action of controlling or mitigating the release of metals, specifically lead, that results from the corrosion of materials in drinking water distribution systems. Although corrosion itself cannot readily be measured by any single, reliable method, the levels of lead at a consumer's tap can be used as an indication of corrosion. Monitoring of lead levels at the tap can help identify sources of lead and aid in the selection of strategies to effectively control corrosion and reduce lead levels at the tap.

There are no direct health effects linked to corrosion in distribution systems. However, corrosion may cause the release of contaminants at levels that would be a concern for the health of people living in Canada. The main contaminant of concern is lead, which is used as the trigger to initiate corrosion control programs, including mitigation measures. The current guideline value for lead (total) in drinking water, based on health effects in children, is a maximum acceptable concentration (MAC) of 0.005 mg/L. Corrosion control treatment can effectively minimize lead concentrations at the point of consumption. However, when water is supplied through a lead service line, treatment alone may not be sufficient to reduce lead to concentrations below the MAC. As such, removal of the full lead service line is considered the most effective and most permanent solution. Partial lead service line replacements are generally not recommended. Any portion of the service line which contains galvanized iron should also be replaced.

Other contaminants that can be released as a consequence of corrosion in drinking water distribution systems include copper and iron. The guideline value for copper in drinking water is 2.0 mg/L (total copper). The proposed guideline value for (total) iron is an aesthetic objective of ≤ 0.1 mg/L in drinking water. This corrosion control guidance is meant to complement the information on sampling and mitigation measures provided in the Guidelines for Canadian Drinking Water Quality for lead. Microbiologically influenced corrosion is briefly discussed but detailed information is beyond the scope of this document. However, maintaining biologically stable water quality is an important step in assuring good corrosion control (see B.4.1.5).

Although the protocols described in this document represent the best approach to assess corrosion in drinking water distribution systems based on available science and monitoring data, they may not be practical or feasible in all systems. In such cases, a different or scaled-down version of this approach may provide some improvement in health protection and water quality (see A.3.7).

In this document, the term "distribution system" is used broadly to include both the system of conduits by which a public water supply is distributed to its consumers as well as the pipes, fittings and other apparatus adjacent to and within a building or dwelling for bringing in the water supply. This definition does not imply a change in responsibility established by a jurisdiction or municipality as it relates to any portion of a service line or the plumbing system located on private property.

Key messages

- Determining levels of lead at the tap is critical to assessing exposure

- Removal of the full lead service line is the most effective and most permanent solution to reduce lead

- pH and alkalinity control are key components for effective corrosion control

- The occurrence of discoloured water should trigger sampling of lead and other metals

- Stable water quality in the distribution system and good maintenance practices are key to effective corrosion control

A.3 Corrosion control monitoring programs and protocols

Corrosion can occur in any size of drinking water distribution system. Therefore, it is important for responsible authorities to conduct a monitoring program to assess if and to what degree corrosion may be occurring in a system and to take appropriate corrective measures. As noted in A.1, corrosion control refers to the action of controlling or mitigating the release of lead (primarily). As such, a corrosion control program for a drinking water system should be based on the levels of specific contaminants at the consumer's tap. Although corrosion will affect the release of several contaminants, the primary focus of corrosion control should be lead, since it is the contaminant that is most likely to result in adverse health effects at concentrations typically seen in residences and distributions systems. Distribution system water quality is an important factor in controlling corrosion. Maintaining water quality includes considering microbial and chemical monitoring as well as physical/hydraulic processes. This will ensure a holistic approach to corrosion control (see B.4.1).

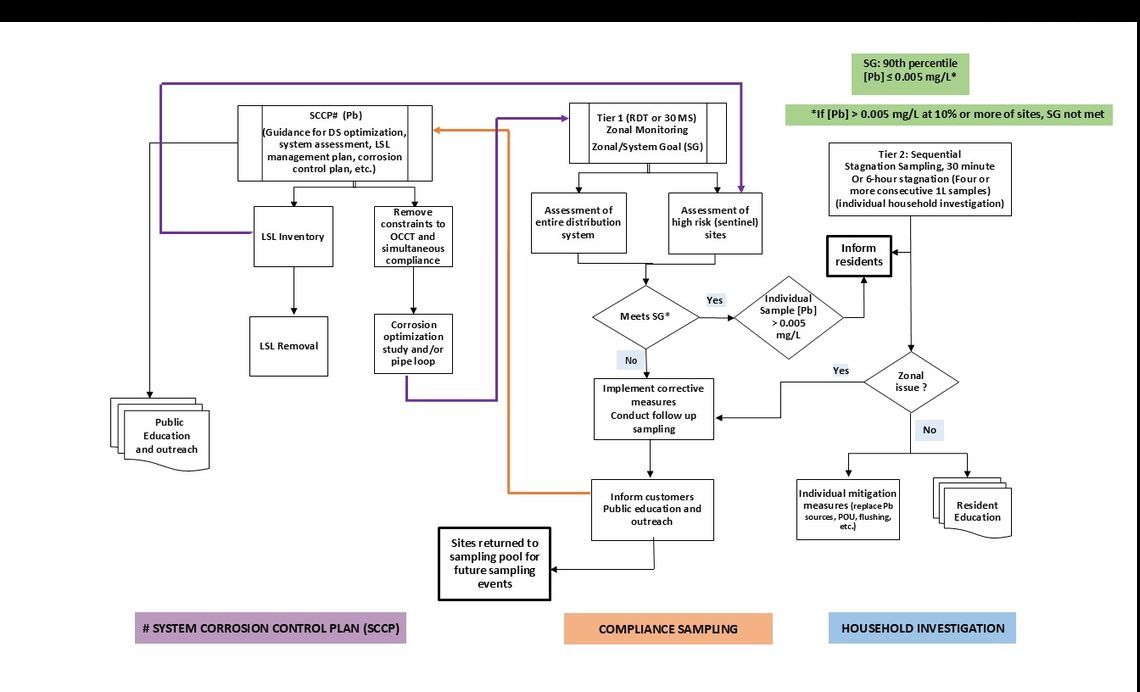

Figure E.1 provides a framework on activities and steps to undertake in a holistic approach to corrosion control and corrosion control treatment (that is, the use of chemicals). This framework outlines the interconnection between the various elements of a "System Corrosion Control Plan" (SCCP) found in List 1 with those of the monitoring protocols found below. Although an example of some of the elements to include in an SCCP for lead can be found in List 1, a full description is beyond the scope of this document. Resources to aid in the development of the SCCP are found in Table G.1 and some detailed information on some of the SCCP can be found in part B (for example, B.3 and B.4).

List 1. Example of elements to include in an SCCP

System Corrosion Control Plan for lead

- Lead risk assessment

- types, locations of lead sources

- system demographics/population at risk

- lead service line inventory & timeline for initial and updated inventory

- lead sampling and water quality parameter monitoring

- potential disturbances (planned or urgent road work or distribution system repairs/upgrades, etc.)

- types, locations of lead sources

- Mitigation measures

- full lead service line replacement plan

- notification prior to repair work

- point-of-use (POU) filter/bottled water for use after disturbances

- flushing (temporary measure) after disturbances

- construction, distribution system/site repair

- partial lead service line replacement

- corrosion control treatment (CCT)

- Assessment of constraints on lead optimization

- Plant optimization studies for simultaneous compliance

- Treatment plant water quality targets (set operational ranges)

- Set ranges and limits for important water quality goals in distribution system (inhibitor and disinfectant residual, pH, etc.)

- Distribution system characterization and operation in relation to lead (or copper) release

- Mitigation of sediment/deposition/biofilm/discolouration (i.e., cleaning) prior to implementation of CCT or optimization

- Repair and recommissioning of service lines as supplementary lead CCT measure

- Establish a public education and communication strategy

An effective corrosion control program contains some or all of the following elements:

- Measurement of corrosion-related water quality parameters, particularly pH and alkalinity, within the distribution system several times per year to:

- assesses changes in water quality within the system

- identify the need for corrosion control

- Lead pipe loops for sampling within treatment plant owned infrastructure to:

- evaluate full scale impacts of treatment

- evaluate corrosion control changes

- At-the-tap sampling under controlled and consistent conditions; this could include data collected from the sampling for lead compliance.

- Desktop studies

- Pipe loops/racks

A.3.1 Sampling considerations

Corrosion control protocols

The major source of metals in drinking water is related to corrosion in distribution and plumbing systems, so measuring the contaminant at the tap is the best tool to assess corrosion and reflect population exposure. Thus, some of the first steps in implementing a corrosion control program are to monitor lead levels at consumers' taps as well as to characterize water quality. This provides responsible authorities with information on the corrosiveness of the water towards lead. A monitoring program provides the information needed to determine which corrective measures should be undertaken if total lead concentrations above the MAC are observed in the system. It also provides information on the level of future monitoring to conduct. Water quality monitoring for parameters including, but not limited to, pH and alkalinity are essential both to assess corrosion issues and help determine the effectiveness of a corrosion control program (see Table D.1.2). Additional tools such as pipe loops can be used to aid in assessing corrosion control. Ultimately, sampling lead at the tap is needed to verify the effectiveness of corrosion control measures and ensure reduced exposure to the population.

Sampling protocols will differ depending on the desired goal (see Table 1). As different sampling protocols can be used to monitor lead at the tap, it is important to select a protocol that is appropriate to meet the desired goal and the type of dwelling. The rationale and supporting information on monitoring protocols, including benefits and limitations, can be found in section B.5 of this document. A list of resources, with references, on topics such as corrosion control planning, operational considerations and implementation can be found in Part G. Provinces and territories may have established regulatory approaches and protocols. Utilities should consult the relevant drinking water authority to determine water quality monitoring requirements and for any questions related the protocol selected.

| Goal | Sampling type | Protocol |

|---|---|---|

| Regulatory compliance for lead and/or Corrosion control efficacy |

First draw (U.S. EPA) see section H: International considerations |

|

| RDT (UK/EU) |

|

|

| 30MS (Ontario) |

|

|

| 30MS (Quebec) |

|

|

| Determination of lead sources (plumbing/lead service line) and/or Identification of type of lead |

Profile (or sequential)Table 1 footnote a sampling –traditional |

|

| Profile (or sequential)Table 1 footnote a sampling (Quebec) |

|

|

| Profile sampling that stimulates particle release | Traditional profile sampling at increasingly higher water flow rate (low, medium and high) | |

| Fully flushed sampling |

|

|

| 3Ts for schools and childcare facilities: revised manual, U.S. EPA |

|

|

Abbreviations: RDT, random daytime; 30MS, 30 minutes stagnation time |

||

The goals of the sampling protocols in this document are to characterize whether distributed water is corrosive to the materials found in the distribution system and household plumbing, and to determine if corrosion control measures are effective.

If monitoring and additional sampling as noted in section A.3 as part of a corrosion control program shows lead concentrations in excess of the MAC of 0.005 mg/L (total lead), then any or several of the suggested corrective measures should be undertaken. The effectiveness of the corrective measures should then be determined by further monitoring. This is important to ensure that the corrosion control program is optimized to minimize lead concentrations and reduce exposure to lead and other related contaminants.

Building types

When monitoring for lead as part of a corrosion control program, two different situations need to be addressed:

- residential dwellings (up to six residences)Footnote 1; and

- non-residential and residential buildings, which include schools, multi-dwelling buildings and large (commercial) buildings.

In a residential setting, which includes residential dwellings such as single-family homes and multiple-family dwellings (up to six residences), monitoring will seek to assess lead concentrations across the system and to identify sources of lead in both the distribution system and the residential plumbing. The purpose of residential monitoring programs is generally to identify and diagnose systems in which corrosion is an issue and, when needed, to determine the best corrective measures. Subsequent monitoring is needed to assess the effectiveness of a system-wide corrosion control program and determine if corrosion control has been optimized.

Due to the complex nature of buildings, monitoring in schools, multi-dwelling (that is, more than six residences) buildings and large (commercial) buildings will focus primarily on the source of lead within the building's plumbing system. The purpose of the monitoring program for non-residential and residential buildings is to locate specific lead problems and identify where and how to proceed with remedial actions. Given that the goal of the sampling protocols for residential dwellings and for non-residential and residential buildings are different, the number of samples, sampling frequency, and corrective measures will differ for these two types of settings.

Corrosion control treatment (CCT)

The implementation of CCT is intended to minimize leaching from distribution system materials to protect consumers' health. Other benefits include extended pipe life, reduced leakage and decreased plumbing repairs and replacements. It is generally expected that the costs of implementing corrosion control would both protect human health and extend the life of distribution system materials.

Utilities should ensure that changes made to treatment processes or a change in supply do not make the water corrosive towards lead. Any changes to the treatment (including optimizing corrosion control) or water supply should trigger monitoring of lead and other metals that may be impacted by the resulting water quality changes (see Table D.1.2). Managing water quality by controlling inputs of sources (such as blending water from two sources) and other contaminants (such as iron, manganese) is crucial for effective CCT. Although it is recognized that a treatment system's responsibility does not generally include residential plumbing systems, most of the MACs established in the Guidelines for Canadian Drinking Water Quality are intended to apply at the consumer's tap. As such, corrosion control programs need to ensure that the delivered water is not corrosive for all components of the distribution system and the plumbing system.

For the purposes of this document, the distribution system includes the supply pipe that connects the water main to the dwelling and/or building and the plumbing system. Although the drinking water authority has control of the distribution system only up to the private property line, it is important to consider how corrosion affects it beyond that point. This will require good communication and collaboration with building owners and managers. Corrosion control programs will vary depending on the responsible authority. They can range from extensive, system-wide programs implemented by the water treatment system to localized programs implemented by a building owner, to ensure a safe and healthy environment for the occupants of residential and non-residential buildings.

Sampling at the tap

As lead levels at the consumer's tap may be significantly higher than levels at the treatment plant or in the water mains, strategies to reduce exposure to lead should focus on controlling corrosion within the distribution system and on removing lead-containing components, such as lead service lines, from these systems. Although it is recognized that a treatment system's responsibility does not generally include residential plumbing systems, consumers expect the water at theirs taps to be safe to drink. For some of the MACs, this can only be verified by monitoring at the consumer's tap. Compliance sampling is undertaken by collecting samples representative of the population served in a discretely supplied area (zonal sampling). Supply zones are geographical areas within which the quality of drinking water is considered approximately uniform. All zones should be sampled such that the entire distribution system is assessed and therefore all problem zones identified across the entire system.

Lead service line inventory

A lead service line inventory is an important tool in selecting both compliance and sentinel sites when implementing corrosion control. The inventory will be critical in managing lead service lines as well as developing and implementing plans for their removal. Sentinel sites are defined as sites with the greatest likelihood of finding elevated lead levels. They are used to reflect potential lead issues in the community and to assess the efficacy of corrosion control programs. To assess corrosion control efficacy, comparative analysis between areas should be benchmarked by using samples collected from a particular property location (sentinel site).

The sentinel sites are selected from a pool of residents interested in participating in ongoing lead monitoring. If a site is being used as a sentinel site, this should not influence any decisions on when to implement mitigation measures, such as lead service line replacement. Due to the voluntary nature of these monitoring sites, a database of potential sites should be maintained to replace any site that is no longer available (for example, if the lead service line is replaced) or if a resident chooses to no longer participate in the monitoring program.

Sentinel sites should focus on areas confirmed to have high risks such as the presence of lead service lines or lead goosenecks, and include zones supplied by potentially corrosive water (such as dead ends in a chloraminated system) and consecutive systems (that is, public water systems whose drinking water supply comes from another public water system). A sampling-based framework (for example, using profile or flushed samples) for determining the presence of lead service lines can be a helpful tool in developing a lead service line inventory. For resources, see Table G.1.

Corrective measures

An exceedance of the MAC should be investigated and, if appropriate, followed by corrective actions. These actions include, but are not limited to, resampling, removal of lead service lines and other lead sources, public education, temporary filter installation at the POU and/or CCT measures. Although CCT can effectively minimize lead concentrations at the point of consumption, treatment alone may not be sufficient when water is supplied through a lead service line. For this reason, removal of the full lead service line is considered the most effective and most permanent solution. Corrective measures could also include distribution system maintenance such as removing iron, manganese and aluminum, as these metals interfere with CCT and can also contribute to lead release. Flushing the cold water tap has not been found to sufficiently reduce lead exposure in schools, multi-dwelling residences and large (commercial) buildings in a consistent fashion. Any corrective actions should be based on an assessment of the cause of the exceedance using appropriate protocols.

A.3.2 Two-tier monitoring protocols for residential dwellings

Sampling at residential sites (for up to six dwellings) is a two-tier approach for assessing corrosion of a variety of lead materials in residential distribution systems. There are two options in this protocol: Option 1 – random daytime (RDT) sampling and Option 2 – 30-minute stagnation time (30MS) sampling.

A.3.2.1 Tier 1 sampling

It is important that the selected protocol be consistently applied in subsequent sampling events for the purpose of comparing results. For both options, the first-tier sampling provides an indication of lead concentrations throughout the system and the need to take action to control corrosion and reduce exposure to lead. A subset of sentinel sites is included in the Tier 1 sampling to characterize zones/areas of highest concern and to assess the effectiveness of planned corrosion control measures. Once a corrosion control program is in place, Tier 1 sampling also provides the data needed to assess if corrective measures have been effective in reducing corrosion of different types of lead-containing material throughout the system. The system/zonal goal (SG) is a 90th percentile lead concentration of 0.005 mg/L or less. Thus, when more than 10% of sitesFootnote 2 exceed a (total) lead concentration of 0.005 mg/L, corrective measures and follow-up sampling are triggered. Tier 2 sampling should be undertaken for any individual sample that exceeds a lead concentration greater than 0.005 mg/L.

A.3.2.2 Tier 1, Option 1, RDT sampling protocol

RDT captures typical exposures for a population, including potential exposure to particulate lead. It identifies priority areas for actions to reduce lead concentrations and assesses compliance system-wide.

A first-draw 1 L sample is taken at the consumer's cold drinking water tap (without removing the aerator or screen) randomly during the day in each of the residences. There is no stagnation period prescribed and no flushing should occur directly prior to collecting the sample, to better reflect actual consumer use.

A.3.2.3 Tier 1, Option 2, 30MS sampling protocol

This sampling protocol measures the concentration of lead in water that has been in contact for a transitory and short period of time (30 minutes) with the lead service line as well as with the interior plumbing such as lead solder or lead brass fittings. Two 1 L samples are taken at the consumer's cold drinking water tap without removing the aerator or screen, after the water has been fully flushed for 5 minutes and then left to stagnate for 30 minutes. Each 1 L sample is analyzed individually, and the highest sample result is then used in assessing if more than 10% of sites have lead concentrations (total lead) above 0.005 mg/L. This will ensure worst-case lead concentration is captured. In contrast, the guideline for lead in drinking water rely on calculating the average of two 1 L samples collected after 30 minutes stagnation to better reflect actual exposure (Health Canada, 2019). Since flushing occurs prior to the 30MS sampling, this protocol will likely not capture particulate lead release. Analysis of other metals (such as copper, cadmium, iron, manganese) in the collected samples can help in identifying source of lead (for example, brass, galvanized steel). It can also reveal interferences that impair CCT and should be addressed, for example, CaCO3 (interfering with orthophosphate).

A.3.2.4 Tier 2 sampling

The Tier 2 profile sampling protocol is an investigative tool that can help identify the source of the lead. It provides a profile of lead contributions from the faucet, plumbing (lead in solder, brass and bronze fittings, brass water meters, etc.) and any contribution from the lead service line. If Tier 1 sampling identifies more than 10% of sites with lead concentrations (total lead) above 0.005 mg/L, then corrective measures and follow-up sampling are required. However, if the SG is met, any site with an individual sample that exceeds 0.005 mg/L should be sampled using the Tier 2 sampling protocol to determine if it is a household or zonal issue.

The Tier 2 sampling protocol is applicable to Tier 1 options 1 and 2 (RDT and 30MS sampling). Tier 2 sampling takes place at a reduced number of sites from Tier 1. It provides more detailed information on the concentrations of lead contributed from different lead -containing materials in the distribution system. This is known as a lead profile. It enables responsible authorities to determine the likely source(s) and potentially the largest contributor(s) of lead so that the suitable corrective measures can be selected and corrosion control can be optimized.

In some cases, the responsible authority may wish to collect samples for both tiers during the same site visit. This step eliminates the need to return to the residence if the SG for Tier 1 is not met, but it may not be feasible in some situations such as when using 6-hour stagnation sampling.

Tier 2 profile sampling is conducted at 10% of the sites sampled in Tier 1, specifically the sites at which the highest lead concentrations were observed. For smaller systems (those serving 100 or fewer people), a minimum of two sites should be sampled to provide sufficient lead profile data for the system. Selection of the stagnation time is based on practical considerations and to generate higher lead concentrations, and thus make it easier to evaluate any changes.

In Tier 2 sampling, samples are collected after the water has been stagnant for a defined period of either:

- 30 minutes (30MS): this profile sampling protocol measures the concentration of lead in water that has been in contact for a transitory and short period of time (30 minutes) with the lead service line as well as with the interior plumbing (such as lead solder or lead brass fittings). The water at the consumer's cold drinking water tap is fully flushed for 5 minutes and then left to stagnate for 30 minutes. Then, four (or more) consecutive 1 L samples are taken at that tap without removing the aerator or screen. Each 1 L sample is analyzed individually to obtain a profile of lead contributions from the faucet, plumbing and a portion or all of the lead service line. Utilities may choose to collect four 1 L samples during the site visits for Tier 1 sampling and proceed with Tier 2 analysis of the remaining samples, only if needed, at the 10% of residences with the highest lead concentrations; OR

- 6 hours (minimum): this profile sampling protocol measures the concentration of lead in water that has been in contact for a longer period of time (compared to 30MS) with the lead service line as well as with the interior plumbing (such as lead solder or lead brass fittings). Lead approaches maximum concentration at greater than 5 hours stagnation time and this makes it easier to evaluate any changes. Four (or more) consecutive 1 L samples are taken at the consumer's cold drinking water tap (without removing the aerator or screen) after the water has been stagnant for a minimum of 6 hours. Each 1 L sample is analyzed individually to obtain a profile of lead contributions from the faucet, plumbing (lead in solder, brass and bronze fittings, brass water meters, etc.) and the lead service line. It is impractical to collect the 1 L samples during the site visits for Tier 1 sampling if a 6 hours (minimum) profile sampling protocol is planned.

Note: Under certain circumstances, it may be of benefit to collect smaller cumulative volumes for each 1 L sample to more precisely identify the source of lead. Since four consecutive 1 L samples may not identify the lead service line contribution in larger plumbing systems, the collection of additional 1 L samples can be beneficial in this regard.

Despite meeting the SG, when a sample exceeds a total lead concentration of 0.005 mg/L, utilities should notify the customers in the affected dwellings and provide information on ways to reduce their exposure to lead. Examples are listed in measure #1 in List 2. It is recommended that utilities conduct follow-up sampling for these sites to assess the effectiveness of the corrective measures undertaken by consumers. When more than 10% of the sitesFootnote 2 exceed a (total) lead concentration of 0.005 mg/L (SG), utilities should take the measures found in List 2.

Profile sampling results

Results from either the 30MS or 6 hours (minimum) profile sampling options will inform the selection of mitigation measures that utilities can implement or recommend to the consumer found in List 2.

List 2. Measures utilities should take when more than 10% of sites have a total lead concentration greater than 0.005 mg/L

- Communicate the results of the testing to consumers and inform them of the measures that they can take to reduce their exposure to lead, particularly for children and formula-fed infants. Consumers may take one or more of the following measures:

- flushing the system by running the tap after any extended period of stagnation;

- using drinking water treatment devices certified to NSF/ANSI Standard 53 for the removal of lead, until the lead sources can be replaced;

- replacing their portion of the lead service line (ideally, in coordination with the replacement of the municipality's portion);

- replacing galvanized iron pipe and lead-lined galvanized iron pipe;

- replacing brass fittings or in-line devices; and/or

- replacing copper pipes that have lead solder.

- Initiate a public education program to encourage consumers to flush the water after a period of stagnation while appropriate corrective measures are being assessed or undertaken. Flushing should be conducted so that any water that has been in contact with lead present in faucets, fittings and the associated solders as well as the lead service line following a period of stagnation is removed.

- Consider supplying or recommending the use of drinking water treatment filters certified to NSF/ANSI Standard 53 and 42 for the removal of lead (see Table G.1 for selecting a lead filter).

- Conduct additional sampling (as outlined in the Tier 2 sampling protocol) at 10% of the sites sampled in Tier 1 at which the highest lead concentrations (above 0.005 mg/L) were observed.

- Implement corrective measures to control corrosion in the system. Analysis of individual 1 L samples will help provide information on the source of lead in the system; however, if the source of the lead problem cannot be identified by the lead profile in the four 1 L samples, further investigation may be required. Depending on the source of lead and the number of residences affected, corrective measures may include any or a combination of the following:

- replacing lead service lines (as well as pigtails and gooseneck, if present);

- replacing galvanized iron pipe and lead-lined galvanized iron pipe;

- adjusting the pH and alkalinity;

- adjusting the pH (if needed) and adding corrosion inhibitors; and/or

- replacing brass fittings, in-line devices.

- Encourage homeowners to periodically clean debris from the screens or aerators of drinking water outlets. If a substantial amount of debris is removed from the aerator or screen, authorities may want to retest the water from these outlets following the same protocol. If results of the retesting show total lead concentrations below 0.005 mg/L, utilities should investigate whether particulate lead may be contributing significantly to elevated lead levels and whether regular cleaning of the aerator or screen is an appropriate corrective measure.

A.3.3 Follow-up sampling (demonstrating CCT optimization and successful mitigation)

Over time, monitoring data collected through follow-up sampling can be used by utilities to assess the effectiveness of corrosion control and to optimize their programs. Comparison of the highest lead levels at the sentinel sites and in the system before and after corrosion control is implemented is the best approach for accurately quantifying the effects of CCT on reducing lead levels and for demonstrating optimization. The frequency and duration of follow-up sampling will depend on the type of corrosion control measures selected. General guidance for the frequency and duration of monitoring for different corrective measures can be found in section A.3.4. Follow-up sampling should be conducted until the results of a minimum of two consecutive sampling rounds show that compliance has been achieved. Depending on the most significant source of lead in a system, utilities may need to supplement follow-up Tier 1 sampling with Tier 2 sampling to assess whether corrosion control has been optimized.

Once it has been determined that corrosion control is optimized, annual monitoring can be resumed.

A.3.4 Frequency of sampling for residential monitoring

For compliance purposes, lead levels should be monitored at the tap at least once a year (for each site in the sampling program) to assess whether corrosion is occurring in a water distribution system. When a corrosion control program is first implemented, monitoring needs to be more frequent than once per year, the frequency depending on the control measures selected. This increased monitoring frequency must be maintained until the control measures are optimized. Because lead corrosion and lead levels are easily influenced by small changes in the quality of the distributed water, annual sampling for lead should continue even when corrosion control has been optimized. More frequent monitoring (at sentinel and sampling sites) is recommended when changes in the water quality in the distribution system (for example, nitrification), in treatment processes (including changes in the disinfectant, oxidant or coagulant), or in the source water may alter water quality parameters which in turn affect corrosion (such as pH and alkalinity). Under certain circumstances, additional sampling may be required when localized changes are made in the distribution and/or plumbing systems.

When pH and alkalinity adjustments or pH adjustment and corrosion inhibitors are used as system-wide corrosion control methods, the water quality monitoring should occur at least weekly at the entry point to the distribution system and monthly within the distribution system, including at the tap. When implementing a corrosion control program, it must be done so as to capture conditions that are representative of the variations in the water quality (for example, temperature, pH, alkalinity). If corrosion control is carried out over a period of less than a year, then it is necessary to demonstrate that seasonality issues (for example, temperature, colour, pH, alkalinity) have been taken into account in analyzing the effectiveness of corrosion control measures. Online, real time monitoring of all process control parameters should be considered for capturing water quality variability.

Water quality parameters such as pH, alkalinity, lead concentration and corrosion inhibitor residuals (where applicable) should be monitored for at least 6 months when pH and alkalinity adjustments are used. Since corrosion inhibitors, such as orthophosphate, take longer to control corrosion, water quality parameters should be monitored for at least 18 months after they are introduced. Best practice is to continue to monitor parameters affecting corrosion control or those that measure its effectiveness. During the implementation stage, copper, iron, disinfectant residuals and microbial indicators (including the nucleic acid adenosine triphosphate) should also be monitored within the distribution system. More detailed information on sampling of water quality parameters can be found elsewhere (WRF, 2023).

Generally, utilities should strive to achieve a full replacement of the lead service line to minimize the consumer's exposure to lead. However, it is recognized that mitigation measures may include partial or full replacement of the lead service line, depending on a number of factors. When lead service lines are replaced, extensive flushing of the cold water by the consumer should be encouraged, and weekly or biweekly sampling at the tap should be conducted until lead levels stabilize. This is especially important when only partial lead service line replacement can be achieved. Once it has been determined that corrosion control is optimized, annual monitoring can be resumed.

Routine annual (compliance) sampling should be conducted during the same period every year, since lead leaching and the release of other contaminants within the distribution system are influenced by changes in temperature as well as seasonal variations. Across Canada, the warmer season from May to October is the recommended sampling period both for practical purposes and because levels of lead are expected to be highest in those months.

A.3.5 Number and selection of sites for residential monitoring

The number of residences to be monitored is determined based on the size of the drinking water system, as outlined in Table 2. The suggested number of monitoring sites is considered to be the minimum required to characterize the distribution of lead levels in a system. A minimum of 20 samples per year is required in a water supply zone (a geographical area within which the quality of drinking water is considered approximately uniform), regardless of sampling methodology. The grouping of different distribution systems with similar water quality can be done to produce supply zones large enough to achieve a sufficient number of samples in a cost effective manner. Generally, 20–60 samples from a water supply zone are needed (per year) to provide a statistically robust assessment of corrosion control effectiveness. A smaller number of corrosion control monitoring sites (see Table 2) should continue to be monitored once the corrosion control program has been optimized. Characterizing the lead levels in a very small system (for example, for a population served of 500 or less) may require aggregating a smaller number of samples over longer period of time.

For routine (compliance) sampling in small water systems, fewer samples may be appropriate, depending on local circumstances. The frequency may be reduced if no failures have occurred in a period defined by the responsible authority.

RDT sampling is used system-wide and 30MS sampling is typically used at sentinel sites. Due to its random nature, RDT sampling requires 2–5 times more samples than 30MS to be statistically robust. Whereas RDT sampling is relatively inexpensive, more practical to implement and generally more acceptable to the consumer than 30MS sampling, the 30MS sampling protocol can also be used for investigating the cause of exceedances and identifying appropriate mitigation measures.

High-risk residences, such as those being supplied with a lead service line, should be chosen as sentinel sites to reflect potential lead problems in the community and to adequately reduce population exposure to lead. Sentinel sites can also be used for assessing the effectiveness of corrosion control. Generally, a minimum of 6 sentinel sites is recommended and periodic sampling is recommended when assessing corrosion control. Establishing a lead service line inventory will help identify water supply zones or residences that are more likely to have high lead concentrations and provide alternate sites if a sentinel site is no longer available. Targeting these supply zones will also provide a better assessment of corrosion control. Monitoring sites should be determined based on the selected sampling protocol.

Monitoring programs for RDT sampling are conducted within defined water supply zones, which can vary in size but ideally should not exceed 100 000 residents each. Increased sample size can be achieved by either increasing the number of samples collected or by aggregating several years' worth of data. In these cases, sampling of properties using other approaches (such as sentinel sites) will provide a more reliable method of estimating public exposure and the effectiveness of corrosion control measures and optimization. Determining water use (low volumes, long periods of no use, etc.) at sampling sites may also be helpful in determining the potential impact on lead levels and CCT effectiveness.

Regardless of the protocol used, all samples should be collected in wide-mouth sample bottles and without removing the aerator from the tap. Preservation (acidification) of the sample can occur at the laboratory under defined conditions. The samples need to be acidified using a 2% nitric acid solution (by volume) and held for a minimum of 16 hours after preservation with nitric acid before analysis. Each sample should be thoroughly mixed prior to analysis using an appropriate method. The addition of 2% nitric acid should be undertaken by qualified personnel and using appropriate precautions. To this end, if sampling is conducted by homeowners, the sample should only be acidified and held upon arrival at the laboratory. Further information on sample preservation can be found in the guideline for lead in drinking water (Health Canada, 2019a).

| Supply zone size (number of people served) |

Number of sites per supply zoneTable 2 footnote a (annual monitoring) |

Minimum number of sites per supply zoneTable 2 footnote b (corrosion control monitoring) |

|---|---|---|

| 100 001–500 000 | 4-12 | 20 |

| 50 001–100 000 | 3-4 | 20 |

| 5 001–50 000 | 2-4 | 20 |

| 501–5 000 | 1 | 20 |

| <100-500 | 1 | <20 |

Further investigation may be required to identify the lead source in some cases. This additional investigation, using profile sampling, could include the collection of several 1 L (or smaller cumulative volumes, for example, 8 x 125 mL, 4 x 250 mL, 2 x 500 mL, depending on plumbing configuration) sequential samples to more accurately identify the lead profile of a residence. In general, the pipe's internal diameter and the volume of water collected can be used to calculate the length of pipe corresponding to each volume. This pipe length can then be used to identify the locations of fittings suspected to have a lead source by mapping the length along the plumbing system. It is important that responsible authorities develop an inventory of monitoring sites where lead materials are likely to be present. Historical records, such as plumbing codes, building permits and water meter records, may provide utilities with useful information on the materials used during certain time periods or in certain areas of the distribution system, which can be used to identify potential monitoring sites. Historical information may be limited or incorrect, and utilities may need to assess the sampling results to determine if additional monitoring sites are needed to ensure that the system has been adequately assessed. A sampling-based framework for determining the presence of lead service lines can be a helpful tool in developing a lead service line inventory, and thus in identifying supply zones for targeted sampling. Where contaminant concentrations are highly variable—as with lead—it is impossible to design a selective monitoring protocol that will reflect with complete confidence the concentrations throughout the entire system.

If at any time a system does not meet the system goal outlined in section A.3.1 in a reduced annual monitoring program, corrective measures should be re-evaluated and the appropriate action should be taken. Subsequent sampling should be conducted at the number of sites used for annual monitoring until a minimum of two monitoring events demonstrates that corrosion control has been effective.

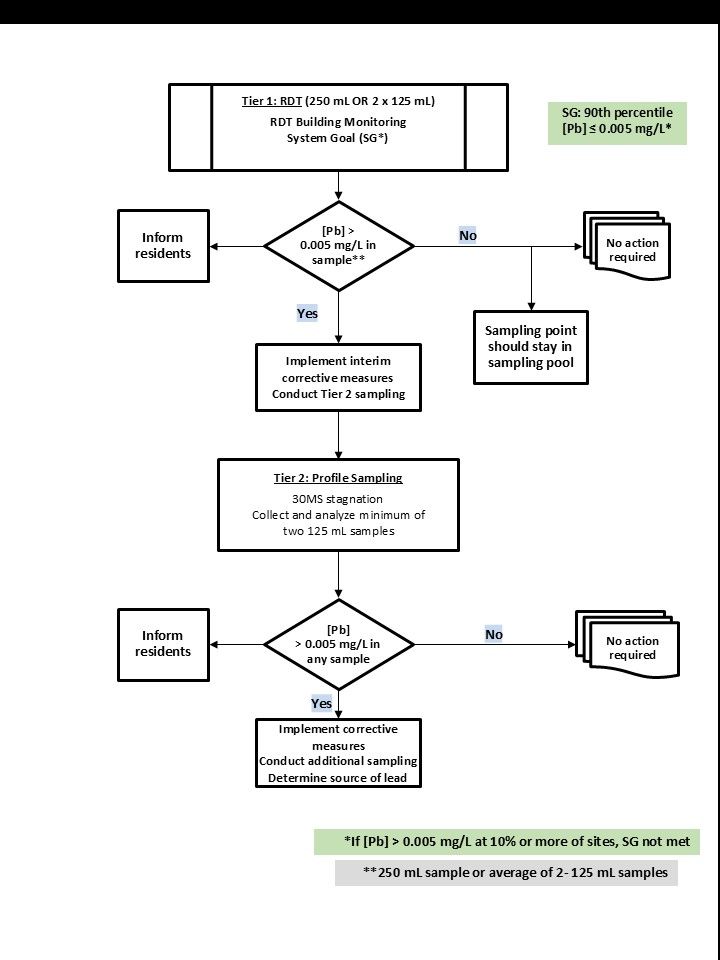

A.3.6 Monitoring protocol for non-residential and multi-dwelling residential buildings (two-tier)

The goal of the sampling protocols and SG for non-residential buildings, such as schools, child care centres and providers as well as multi-dwelling residential (greater than six dwellings) and larger buildings, is to locate specific lead problems within the buildings and identify where and how to proceed with remedial actions. The intention is to minimize lead concentrations at the cold drinking water outlets (that is, fittings and fixtures such as faucets and fountains) used for drinking and cooking and therefore protect occupants' health from exposure to lead. The sampling protocols are aimed at gaining an understanding of the lead concentrations observed at various outlets in the buildings. Concentrations at the outlets will vary depending on the sources of lead within the plumbing and water use patterns in the building.

A sampling plan should take into consideration the type of building being sampled and target priority sites for each sampling event (that is, each cycle of sampling identified in the sampling plan). It is recommended that a plumbing profile of the building be developed to identify potential sources of lead and areas of stagnation and to assess the potential for lead contamination at each drinking water fountain, cold drinking water outlet or cooking outlet.

Stagnation periods will be influenced by such things as the frequency of use of the outlet, whether bottled water is distributed in the building, how many hours per day and number of days per week the building is occupied and the number of occupants. Establishing the source of the problem within a specific building is a critical tool in assessing which measures to take to reduce lead exposure. The locations of specific lead problems are determined by measuring lead levels at water fountains and cold drinking water outlets. When elevated concentrations of lead occur at an outlet, they can be from lead-containing material within the outlet itself (such as a faucet, bubbler, or water cooler), from the plumbing upstream of the outlet or from the water entering the building. A -two-tier sampling approach is used to identify the source of the elevated lead concentration.

This protocol for non-residential and multi-dwelling residential building is intended for the responsible authorities, such as building owners or managers and school boards, as part of the overall management of the health and safety of the occupants of schools, child care centres and other non-residential buildings. This protocol may also be followed by utilities that want to include non-residential or residential buildings such as schools and multi-dwelling buildings in their corrosion control monitoring programs. The extent of sampling conducted by an individual responsible authority within a building may vary depending on the goal of the sampling and the authority conducting the sampling.

Sampling with fixed stagnation is difficult to implement, especially in multiple-unit dwellings and large (commercial) buildings. Larger buildings present particularly difficult sampling challenges due to the complexity of use patterns, the variability in age of the plumbing, the variability in plumbing configuration between rooms and the lack of a detailed inventory of the plumbing products installed in the buildings. Maintaining stagnation in larger buildings can be very difficult. To this end, an RDT sampling protocol is recommended in this context and will also capture typical exposures, including potential exposure to particulate lead. Samples should be collected, preferably in wide-mouth sample bottles, at a medium to high flow rate (> 5 L/min) without removing the aerator or screen. An alternative stagnation protocol for non-residential buildings, modelled on the United States (U.S.) Environmental Protection Agency's (EPA) 3Ts monitoring, can be found in Part F.

A.3.6.1 Tier 1 sampling protocol

The goal of Tier 1 sampling is to identify specific cold drinking water outlets that have elevated levels of lead using the RDT protocol. This sampling protocol captures typical exposures, including potential exposure to particulate lead. It identifies priority areas for actions to reduce lead concentrations and exposure to lead.

Collection of a smaller sample volume helps to pinpoint whether the source of lead is from the specific outlet and to direct the appropriate corrective measures. Tier 1 sampling should be conducted at the locations of the cold drinking water outlets identified in the sampling plan for the non-residential or multi-dwelling residential building. A sample that is representative of the water that is entering the building (water main sample) should be collected at each monitoring event. Water main samples that are representative of water that has been flowing in the main should be collected from a drinking water faucet in close proximity to the service line following a period of approximately 5 minutes of flushing (longer flushing may be necessary). All other samples in the building should be collected using the protocol described below.

A 250 mL total sample is taken randomly at the cold drinking water outlets identified in the sampling plan (without removing any aerator or screen that may be present) during the day at each of the sampling sites. There is no stagnation period prescribed and no flushing should occur directly prior to collecting the sample, to better reflect actual consumer use. It is recommended that samples be collected in smaller volumes (2 x 125 mL) to aid in determining, with greater confidence, the source of the lead. This is a form of profile sampling that helps in the investigative phase if the analysis of the sample(s) indicates that lead is present. The smaller samples represent the water from the fitting (fountain or faucet) and a smaller section of plumbing, providing a better indication of the source of lead at an outlet. It can be helpful to collect the Tier 2 samples at this step, to avoid having to return to the location to resample to identify the source of lead.

The use of wide-mouth sample bottles allows the sampler to fill the bottle at a typical medium to high flow rate, which provides a more representative result. Sample bottles with a smaller opening will be difficult to fill at a typical flow rate and provide inaccurate results with respect to potential exposure and for investigative or remediation purposes. Where two 125 mL volumes are collected, the concentration of lead is determined by averaging the results from both samples.

When the (total) lead concentration is less than 0.005 mg/L, the associated monitoring location should remain in the sampling pool.

If the (total) lead concentration exceeds the MAC of 0.005 mg/L at any of the monitoring locations, it is recommended that the following measures be undertaken:

- Notify and educate the occupants (such as teachers, child care providers, and students) of the building and other interested parties (for example, parents, occupational health and safety committees) about the sampling results and the interim measures that are being undertaken, as well as the plans for additional sampling.

- Conduct additional sampling at the outlets with (total) lead concentrations that exceed 0.005 mg/L to determine the source of lead, as outlined in the Tier 2 protocol. Replace the identified components (sources of lead).

- Implement interim corrective measures immediately to reduce the occupants' exposure to lead in water. These measures may include any or a combination of the following:

- taking the outlet out of service;

- cleaning debris from the screens or aerators of the outlet;

- flushing the plumbing system following periods of stagnation;

- installing drinking water treatment devices that are certified for lead removal until the lead sources can be replaced; and/or

- providing an alternate water supply.

- Where a substantial amount of debris was removed from the aerator or screen from specific outlets, authorities may want to retest the water from these outlets following the same protocol. If results of the retesting show lead concentrations below 0.005 mg/L (total lead), authorities should investigate whether particulate lead may be contributing significantly to elevated lead levels and whether regular cleaning of the aerator or screen should be implemented as part of the maintenance or a rigorous cold water flushing program.

A.3.6.2 Tier 2 sampling protocol

Tier 2 sampling is used in combination with Tier 1 sampling results to determine the source of the lead in the plumbing within the building. Sampling in sequential volumes will help determine the concentration of lead in the water that has been stagnant in the plumbing upstream of the outlet. This sampling protocol measures the concentration of lead in water that has been in contact for a short period of time (30 minutes) with the interior plumbing (for example, lead solder, lead brass fittings). This is a form of profile sampling that helps in the investigative phase if the analysis of the sample(s) indicates that lead is present. These smaller samples represent the water in contact with the fitting (fountain or faucet) and a smaller section of plumbing, and thus is more effective at identifying the source of lead at an outlet.

At those cold drinking water outlets (without removing the aerator or screen) with lead concentrations that exceeded 0.005 mg/L (total lead) for Tier 1, a minimum of two consecutive 125 mL samples are taken after the water has been fully flushed for 5 minutes and then left to stagnate for 30 minutes. Each 125 mL sample is analyzed individually to obtain a profile of lead contributions from the faucet and plumbing. Utilities may choose to collect a larger number of samples of varying volumes during the site visit to better characterize the source of lead.

When the lead concentration in any of these second samples exceeds 0.005 mg/L (total lead), any or a combination of the following corrective measures should be undertaken immediately until a permanent solution can be implemented:

- routine flushing of the outlet before the facility opens (a minimum of 5 minutes to obtain cold water from the water main; longer flushing may be necessary);

- removing the outlet from service;

- using drinking water treatment devices that are certified for lead removal until the lead sources can be replaced; and/or

- providing an alternate water supply.

In addition, depending on the results of the Tier 1 and 2 sampling, one or a combination of the following corrosion control measures should be initiated:

- Notify and educate the occupants of the building (such as teachers, child care providers, students) and other interested parties (for example, parents, occupational health and safety committees) about the sampling results and the interim and long-term corrective measures that are being undertaken

- Compare the Tier 1 and Tier 2 sampling results to determine whether the source of the lead contamination is the fitting, fixture or internal plumbing. If the results of the Tier 1 and Tier 2 sampling both indicate lead contamination, conduct additional sampling from the interior plumbing within the building to further determine the sources of lead contamination

- Flush the outlets

- Install drinking water treatment devices that are certified for lead removal until the lead sources can be replaced

- Replace the outlets, fountains or pipes

- Remove the outlets from service

- Replace lead brass fittings or in-line components

- Work collaboratively with the water supplier to ensure that the water delivered to the building is not corrosive

- Provide an alternate water supply

A.3.6.3 Selection of monitoring sites and monitoring frequency

The number of sites sampled in a building may vary depending on the goal of the sampling, the responsible authority conducting the sampling and the type of occupants within the building. Where schools, day care facilities and other non-residential and multi-dwelling residential buildings fall under the responsibility of utilities, the priority for sampling should be schools and child care facilities.

Other authorities that are responsible for maintaining and monitoring water quality within non-residential buildings will need to do more extensive sampling at individual outlets based on the sampling plan developed for the buildings. The sampling plan should prioritize drinking water fountains and cold water outlets used for drinking or cooking based on information obtained in the plumbing profile, including areas with lead solder or brass fittings containing lead, areas of stagnation areas with galvanized iron pipes or components and areas that provide water to high-risk populations, such as infants (particularly formula-fed infants), children and pregnant people.

Utilities, building owners and other responsible authorities (for example, school boards) should work collaboratively to ensure that sampling programs are designed to be protective of the health of the occupants, including high-risk populations such as young children and pregnant people. Large variations in lead concentrations can be expected between individual outlets in a building. As such, sampling programs should be carefully designed and implemented so that outlets with potentially elevated levels of lead are correctly identified.

When outlets with elevated lead concentrations have been identified, corrective measures should be implemented. Depending on the type of corrective measure selected (for example, replacement of outlets, routine flushing), additional sampling should be conducted to ensure that the lead levels have been effectively reduced. When routine flushing programs are implemented as a corrective measure, further sampling should be used to verify that flushing is effective at reducing lead concentrations throughout the period of the day when the building is occupied. Similarly, when outlets are replaced, sampling should be conducted for up to 3 months following replacement to ensure that lead levels have been adequately lowered.

Once appropriate corrective measures are in place, subsequent sampling should be conducted at the sites used for initial monitoring until a minimum of two monitoring events demonstrates that the corrosion control program is effective. Once sampling has been completed at all sites identified in the sampling plan of a non-residential building and a corrosion control program has been implemented effectively, only priority (high-risk) sites need to be monitored annually. Localized changes in the distribution system, such as changes in the piping, faucets or fittings used as a result of repairs or new construction as well as changes in water use patterns, should also trigger additional monitoring.

It is also recommended that, at each monitoring event, samples be taken from an outlet close to the point where the water enters the non-residential building to determine the level of lead in the water contributed by either the service line or the main water distribution system (the water main). Ideally, samples should be collected after an appropriate period of flushing so that they are representative of water from the service line and from the water main. The volume of water to flush will depend on the characteristics of the building plumbing system (such as the distance between the service line and the water main, pipe diameter and flushing flow rate).

a) Schools and child care facilities

The sampling plan for public schools, private schools and child care centres or providers should take into consideration that the types of occupants in these buildings are among the most susceptible to adverse health effects from lead. Consequently, sampling plans for these facilities should prioritize every drinking water fountain and cold water outlet used for drinking or food preparation over infrequently used outlets. Total lead should be monitored at least once per year. It is recommended that sampling be conducted in either June or October for schools. For other building types, when the buildings are fully occupied and functional, sampling should take place between the months of June and October. Responsible authorities may choose to reduce monitoring once they have established that the lead issues have been identified and addressed.

Other sampling sites, such as outlets in classrooms that are used infrequently for drinking or first-aid rooms that are not identified as priority sites, could then be sampled during the year. The goal is that all sites identified in the sampling plan will have been tested within a 1-year period.

b) Other non-residential and multi-dwelling residential buildings

In building types that are not schools and child care centres, sampling plans should also target drinking water fountains and cold water outlets used for drinking or food preparation. Every priority site identified in the sampling plan should be sampled first. The remaining sites in the plan should then be sampled during the year. The goal is that all sites identified in the sampling plan have been tested, ideally, within a 1-year period.

In multi-dwelling (more than six residences) buildings or large (commercial) buildings, it is recommended that total lead be monitored such that each of the drinking water fountains and a proportion of cold water taps where water is used for drinking or food preparation is sampled within a specified period. When sampling multi-dwelling residential buildings, priority should be given to sites suspected or known to have full or partial lead service lines.

A.3.7 Considerations for small systems

Although the measures described in this document represent the best approach to address corrosion in drinking water distribution systems, they may not be practical or feasible in some small systems. In such cases, a different approach may be needed to improve health protection and water quality. For example, it may be more reasonable for small systems to consider materials replacement since CCT requires studies and monitoring of water quality and lead. These types of activities may be more resource intensive and complex than a small system's capability or budget allows. The need for pipe loop, coupon and desktop studies for CCT may be a long-term commitment. A similar output of resources in a shorter time frame may provide an equally effective result by removing the sources of lead such as lead service lines.

Developments in immersion (coupon) testing protocols offer possible alternatives for evaluating corrosion mechanisms, as well as determining and screening CCT alternatives. These protocols, described in B.3.2, provide a low-cost and low-complexity approach, requiring fewer resources, and are suitable for small- and medium-sized systems.

There are options available to the operator to implement some CCT that could provide relief with fewer operational complexities and chemical handling and occupational challenges compared to other approaches. For example, the use of a combination of aeration and limestone contactors can achieve the same result as the use of sodium silicates, which have occupational health and safety protocols that are more demanding than the former. The use of software such as WaterPro© can also help simplify CCT in systems that have relatively straightforward water quality. Some of the small system challenges, basics and strategies for CCT are listed below.

A.3.7.1 Challenges

Challenges for small systems include fewer available resources to address corrosion issues and the need for an external consultant. The footprint of the existing treatment system may also limit the available options. Operator availability and the need for accreditation to a specific level or advanced training needs may limit system operations. For example, challenges may include:

- health and safety requirements that are not achievable for certain treatment chemicals, meaning that they cannot be used due to health;

- adjustments to water quality that cannot be implemented due to their complexity;

- not enough sampling capacity to do all necessary sampling, including sampling for determining the presence of lead service lines.

A.3.7.2 Basic (need to know) information

Water quality data can provide information on possible issues and inform the best strategies for mitigating the presence of lead. Monitoring of water quality of parameters (see Table D.1.2) is essential to maintaining a stable water quality and achieving effective corrosion control. Parameters to monitor should include, at minimum:

- pH (Field measurement of pH should be done to ensure accuracy)

- alkalinity

- cations (such as calcium, magnesium)

- anions (such as chloride, sulphate)

- iron

- manganese

- chlorine residual

- distribution system

Simplified testing for biofilm growth using mild steel coupons can provide helpful information on the biostability of the distribution system. Further information can be found in Health Canada's Guidance on monitoring the biological stability of drinking water in distribution systems.

It is important to know the materials in a system and be able to answer questions such as:

- Are there lead service lines, lead gooseneck or pigtails present?

- Are there galvanized or lead-lined galvanized pipes present?

- Is it a newer home or building (< 10 years) with copper plumbing?

- Are there galvanic connections or other materials of concern?

A.3.7.3 Strategies

Removing manganese and iron helps with corrosion control and can:

- make pH adjustment easier;

- minimize accumulation and release of metals in distribution system and plumbing;

- reduce oxidant/disinfectant demand; and

- minimize interference with CCT.