Caring for audio, video and data recording media

Joe Iraci

Caring for audio, video and data recording media is part of CCI’s Preventive conservation guidelines for collections online resource. This section presents key aspects of managing the care of audio, video and data recording media materials in heritage collections based on the principles of preventive conservation and risk management.

Table of contents

- List of abbreviations and symbols

- Understanding audio, video and data recording media

- Causes of damage to audio, video and data recording media and preventive conservation strategies

- Preserving audio, video and data recording media: issues and challenges

- Damage and strategies for preservation by agent of deterioration

- Examples of preventive conservation practices

- Bibliography

List of abbreviations and symbols

Abbreviations

- BD-R

- Blu-ray Disc–recordable

- BD-RE

- Blu-ray Disc–rewritable

- CCI

- Canadian Conservation Institute

- CD

- compact disc

- CD-R

- compact disc–recordable

- CD-ROM

- compact disc–read only memory

- CD-RW

- compact disc–rewritable

- DVD

- digital versatile disc

- DVD-R and DVD+R

- recordable digital versatile disc

- DVD-RAM

- digital versatile disc–random access memory (rewritable)

- DVD-ROM

- digital versatile disc–read only memory

- DVD-RW and DVD+RW

- rewritable digital versatile disc

- ISO

- International Organization for Standardization

- MO

- magneto-optical

- PDD

- professional data disc

- portable document format

- PVC

- poly(vinyl chloride)

- RH

- relative humidity

- SSD

- solid state drive

- UDO

- ultra-density optical

- USB

- Universal Serial Bus

- VHS

- video home system

- WORM

- write-once, read many

Symbols

- °C

- degree Celsius

Understanding audio, video and data recording media

Audio, video and data recording media can be classified into four categories: grooved audio media (music cylinders and music discs); magnetic audio, video and data media (tapes and disks); optical audio, video and data discs (CDs, DVDs, Blu-rays, etc.); and flash digital media (flash cards, USB flash drives or sticks, solid state drives, also known as SSDs). Each type is made quite differently and is susceptible to damage in unique ways.

Grooved audio media

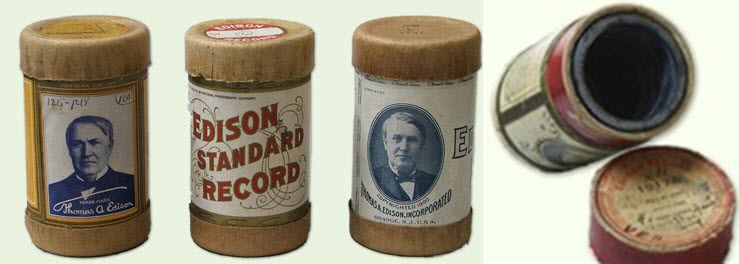

Grooved media includes all types of music cylinders and music discs (Figures 1a, 1b and 2). In 1876, Thomas A. Edison produced the first recording of a human voice on a tinfoil cylinder phonograph. Shortly afterwards, music cylinders made of cardboard with a wax coating were pioneered by Alexander Graham Bell. Early wax cylinders were made by a needle that engraved sound waves into soft wax. The recording was then played via mechanical playback with a needle. In 1901, a mass production process was developed and the grooves were moulded into harder wax. Some of the mass replicated cylinders were made from cellulose nitrate plastic on a cardboard or plaster core. The production of cylinders ceased in 1929.

© Canadian Museum of History, D2006-11049

Figure 1a. An Edison wax cylinder case.

© Canadian Museum of History, D2006-11051

Figure 1b. An example of a wax cylinder.

© Canadian Museum of History, Archives, 78-6-E-00137.2, D2007-01498

Figure 2. A grooved record.

Grooved music discs first appeared in 1888. As with cylinders, a needle or stylus is used to track the groove in the disc in order to create sound. A variety of grooved discs have been produced, some of which are described in Table 1.

| Disc type | Date of production | Composition | Other information |

|---|---|---|---|

| Vulcanite records (Berliner records) | 1888 to 1897 | Hardened latex rubber | First major type of grooved disc |

| Shellac discs (78s) | 1898 to mid-1950s | Various mineral substances held together by shellac or similar binding material | Main audio format of the first half of the 20th century |

| Instantaneous or acetate discs | 1930s to 1960s | Aluminum base (sometimes glass, steel or cardboard) with primarily a cellulose nitrate lacquer | Only grooved discs that could be played back immediately after recording; least stable of the grooved discs |

| Vinyl discs (LPs, microgroove discs) | 1950s to present | Poly(vinyl chloride) (PVC) and a small percentage of fillers | Most stable of grooved discs |

Magnetic audio, video and data media

Magnetic media are read by magnetic heads and include tapes and disks. Magnetic tape for recording was first introduced in 1935 when sound was recorded on moving cellulose acetate tape. Since then, tapes for recording audio, video and data have been produced using different magnetic materials and on a variety of base materials (Figure 3).

© Government of Canada, Canadian Conservation Institute. CCI 121696-0002

Figure 3. A variety of magnetic tape audio reels and cassettes.

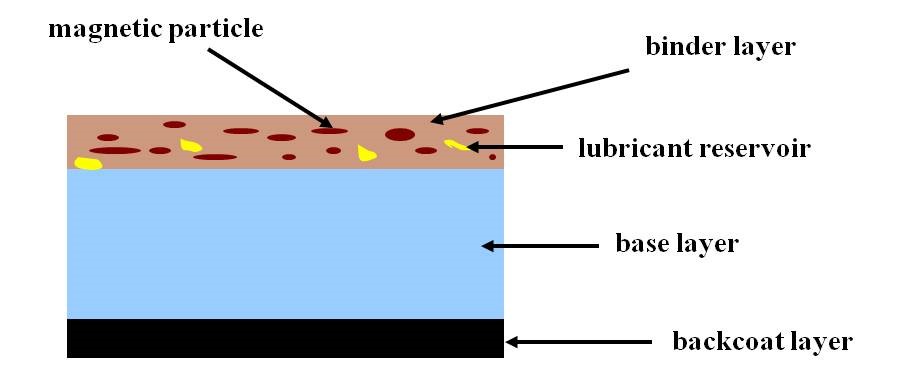

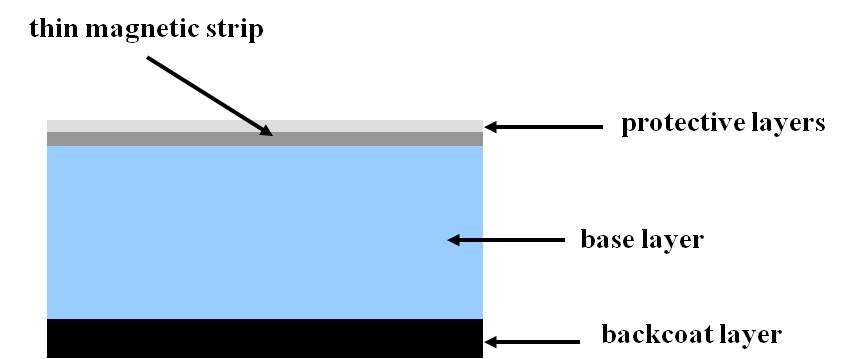

The structure of magnetic tapes generally falls into one of two categories: metal-particulate or metal-evaporated (Figures 4a and 4b). Metal-particulate tapes are composed of a base layer usually coated with a binder made of polyester urethane, but newer tapes use a different binder material. The binder holds the magnetic particles that store the recorded signal onto the tape base. Many tapes have a back-coat layer of polyester urethane as well in order to promote better tape winding and to eliminate static electricity. Metal-evaporated tapes have a base layer that is coated with a thin film of magnetic material. These tapes have additional layers for lubrication and protection of the magnetic layer.

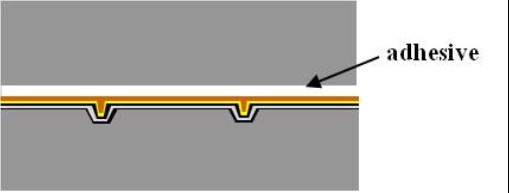

© Government of Canada, Canadian Conservation Institute. CCI 125773-0098

Figure 4a. Cross-section of a metal-particulate magnetic tape.

© Government of Canada, Canadian Conservation Institute. CCI 125773-0099

Figure 4b. Cross-section of a metal-evaporated magnetic tape.

Magnetic disks can be floppy diskettes or hard disks. Floppy diskettes are similar in construction to particulate magnetic tapes except that there are binder and magnetic particles on both sides of the flexible plastic base. Hard disks resemble metal-evaporated tapes because they are composed of a thin magnetic film, but the film of a hard disk is on a rigid platter usually made of aluminum, although ceramic or glass have also been used as base materials. Hard disks are usually encapsulated in a tightly sealed case (Figure 5), whereas floppy diskettes are housed in flexible or rigid jackets that are not tightly sealed (Figures 6 and 7).

© Government of Canada, Canadian Conservation Institute. CCI 92389-0005

Figure 5. An opened hard disk case showing the hard disk platter and various mechanical components that are necessary for the hard drive to function.

© Government of Canada, Canadian Conservation Institute. CCI 92389-0002

Figure 6. Floppy diskette removed from its flexible jacket (5 1/4-inch format).

© Government of Canada, Canadian Conservation Institute. CCI 92389-0003

Figure 7. Floppy diskette removed from its rigid jacket (3 1/2-inch format).

Optical audio, video and data discs

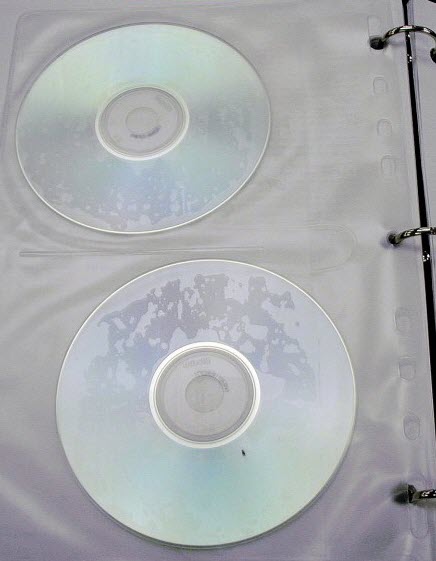

Optical discs refer to a class of media that is played or read by laser light (Figure 8). The first optical disc introduced commercially was the Laserdisc in 1978, and it was used for video. Soon afterwards, a variety of other optical discs appeared, starting with the CD for music in 1982.

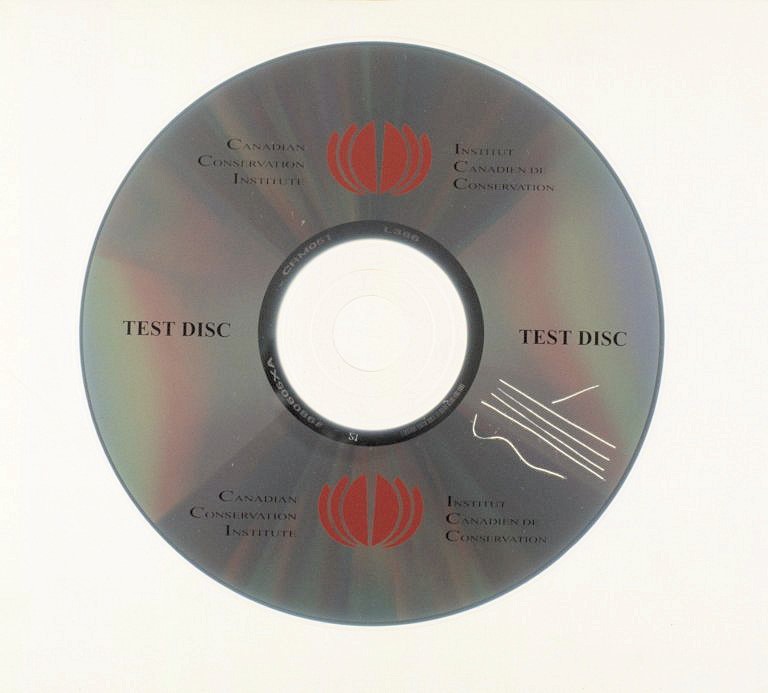

© Government of Canada, Canadian Conservation Institute. CCI 83365-0024

Figure 8. Examples of CDs.

Advances in technology have produced three categories of optical discs: read-only, recordable and erasable. The properties of each are as follows:

Read-only

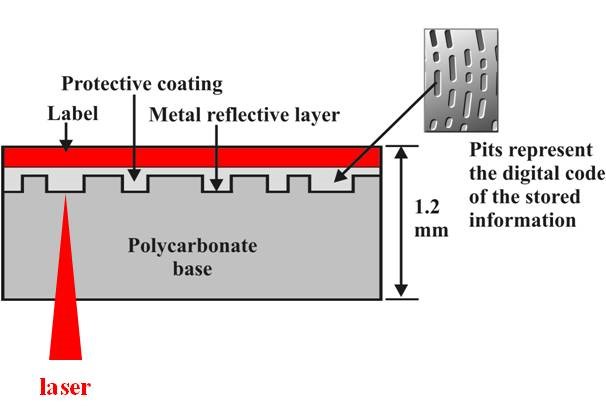

- The information is placed on the disc at the same time that the disc is manufactured and is stored in the form of “pits” that are imbedded into the polycarbonate plastic base (Figures 9a, 9b and 9c).

- A series of pits of different sizes make up the binary code (0s and 1s) that represent the digital content.

- All optical discs contain a metal reflective layer that is imperative to the functioning of the disc.

- Examples of read-only discs include:

- laserdisc

- CD-audio

- CD-ROM

- CD-video

- DVD-video

- DVD-audio

- DVD-ROM

- Blu-ray Disc-video

- Blu-ray Disc-ROM

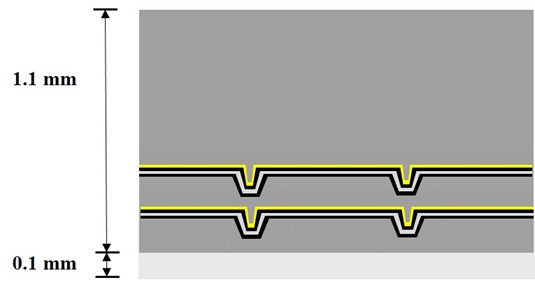

© Government of Canada, Canadian Conservation Institute. CCI 125773-0100

Figure 9a. Cross-section of a read-only CD.

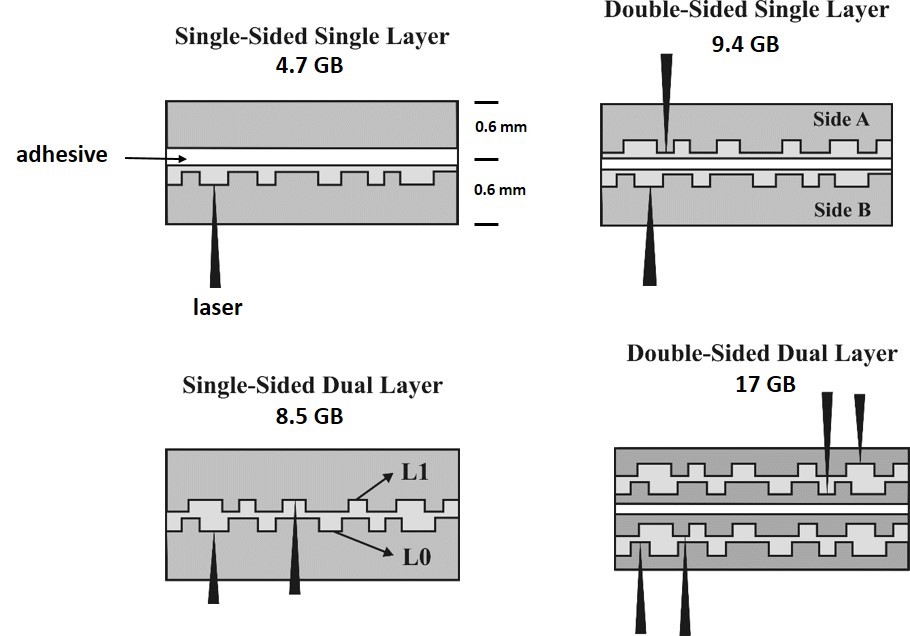

© Government of Canada, Canadian Conservation Institute. CCI 125773-0167

Figure 9b. Cross-sections of a read-only DVD. Two major differences from a read-only CD are the ability to have two information layers readable from one side and the option to have information layers on either side of the disc. Another difference is that DVDs are two discs half the thickness of a CD and are glued together. Therefore, an adhesive layer is present in the middle of the disc structure.

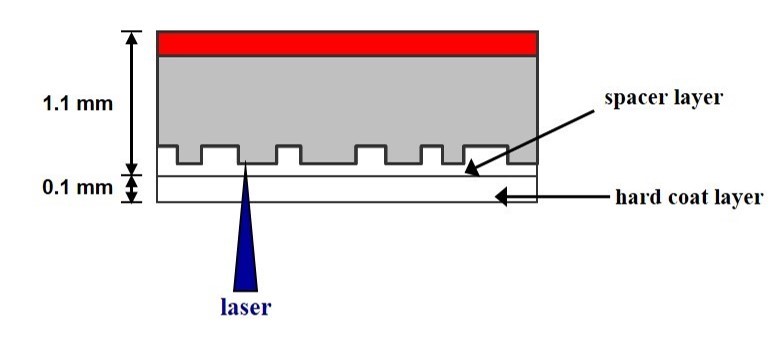

© Government of Canada, Canadian Conservation Institute. CCI 125773-0172

Figure 9c. Cross-section of a read-only Blu-ray Disc. As for the other read-only optical discs, the digital information is represented on the disc as “pits” in the polycarbonate plastic. CDs have the largest pit size, whereas Blu-ray Discs have the smallest, therefore allowing more information to be stored.

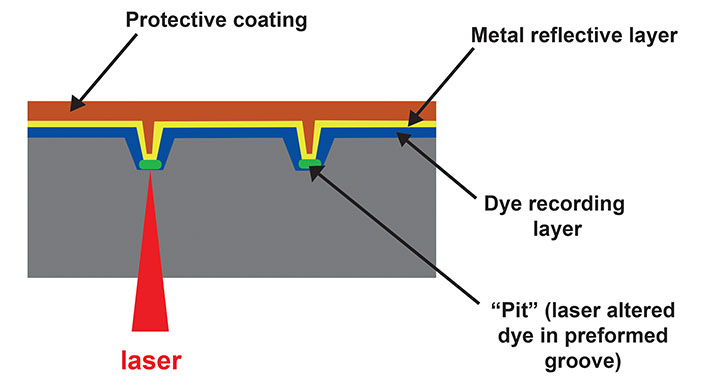

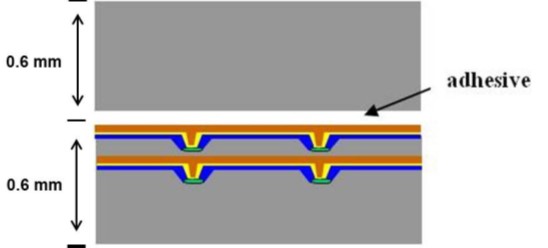

Recordable

- The discs are purchased blank and information is recorded onto the disc with no erasing of the information from the disc possible.

- The information is stored as microscopic spots (which act as the “pits” in read-only discs) produced by altering the dye layer (except for most recordable Blu-ray Discs where a silicon/copper alloy is used to record the information) (Figures 10a, 10b and 10c).

- Examples of recordable discs include:

- WORM discs (“write-once, read many” — several sizes are available)

- CD-R

- DVD-R and DVD+R

- Blu-ray Disc-R (BD-R)

© Government of Canada, Canadian Conservation Institute. CCI 125773-0103

Figure 10a. Cross-section of a recordable CD (known as a CD-R).

© Government of Canada, Canadian Conservation Institute. CCI 125773-0104

Figure 10b. Cross-section of a recordable DVD (known as DVD-R or DVD+R). The DVD-R shown is a double information layer disc. These discs are also available with a single information layer. The layers are similar to what are found in CD-Rs.

© Government of Canada, Canadian Conservation Institute. CCI 125773-0168

Figure 10c. Cross-section of a recordable Blu-ray Disc (known as a BD-R) with two information layers. Up to four information layers are possible in one disc.

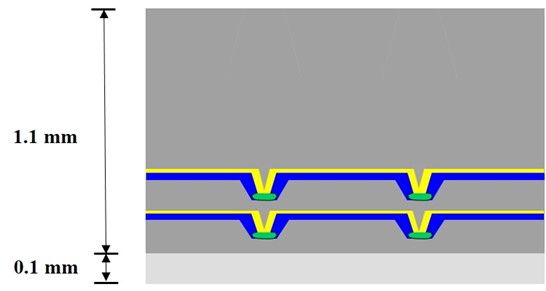

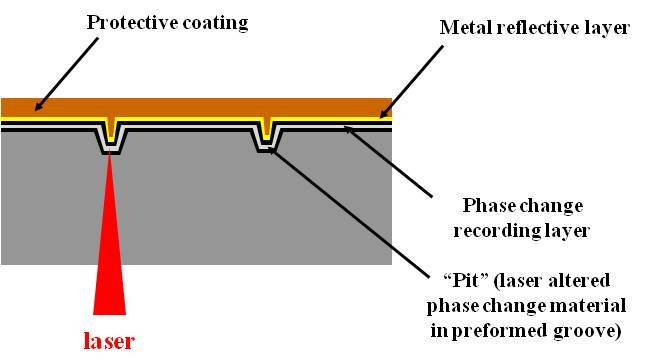

Erasable

- The discs are purchased blank, and the information recorded on each disc can be erased so that the disc can be reused.

- Information is stored in the form of tiny spots (which act as the “pits” in read-only discs) produced by altering the phase-change recording layer material (Figures 11a, 11b and 11c).

- Examples of erasable discs include:

- magneto-optical (MO) discs

- ultra-density optical (UDO) discs

- professional disc for data (PDD)

- CD-RW

- DVD-RW and DVD+RW

- DVD-RAM

- Blu-ray Disc-RE (BD-RE)

© Government of Canada, Canadian Conservation Institute. CCI 125773-0106

Figure 11a. Cross-section of an erasable CD (known as CD-RW).

© Government of Canada, Canadian Conservation Institute. CCI 125773-0107

Figure 11b. Cross-section of an erasable DVD (known as DVD-RW or DVD+RW). The layers are similar to what are found in CD-RWs.

© Government of Canada, Canadian Conservation Institute. CCI 125773-0170

Figure 11c. Cross-section of a two layer erasable Blu-ray Disc (known as BD-RE). Up to three information layers are possible in a single disc.

Flash media

Flash memory is composed of a memory chip that can be electrically erased and reprogrammed (Figure 12). The memory chip is composed of millions of tiny memory cells that store the digital information. A low electrical current is used to read flash media and a higher electrical current is used to write or erase the information. Flash media are available in several different forms, such as various types of cards (often associated with storage for digital cameras), USB flash drives or sticks, and solid state drives (SSDs), which are beginning to replace magnetic hard disks in computers.

© Government of Canada, Canadian Conservation Institute. CCI 123861-0004

Figure 12. A disassembled USB flash drive showing the data storage chip, which is composed of millions of memory cells.

Causes of damage to audio, video and data recording media and preventive conservation strategies

This section describes the causes and types of damage to audio, video and data recording media and the preventive conservation strategies that reduce the risks of damage.

Preserving audio, video and data recording media: issues and challenges

Preserving content and content migration

The preservation of audio, video and data recording media significantly differs from more traditional recording media like print material, such as books, paper documents or photographs. For print media, preserving the paper, or the “information carrier,” preserves the content. Preserving recording media involves more than simply keeping the media in good condition. It requires equipment to read them (Figure 13), and in some cases, software to interpret the stored information. The state of the technology of the media affects the preservation and access to their contents.

© Government of Canada, Canadian Conservation Institute. CCI 121696-0004

Figure 13. An audiotape cassette player/recorder with an audio cassette inside.

Strategies to deal with content preservation for audio, video and data recording media, such as emulation and migration, have been studied, experimented with and, in some cases, implemented. While there is no perfect solution and work continues in this area, various options do exist that can be used to deal with this issue. Some resources on managing the preservation of content stored on audio, video and data recording media include:

- Digital Preservation Handbook – Preservation Issues (Digital Preservation Coalition)

- Selecting the right preservation strategy (Paradigm)

- An Introduction to Digital Preservation (PDF format) (JSC Digital Media)

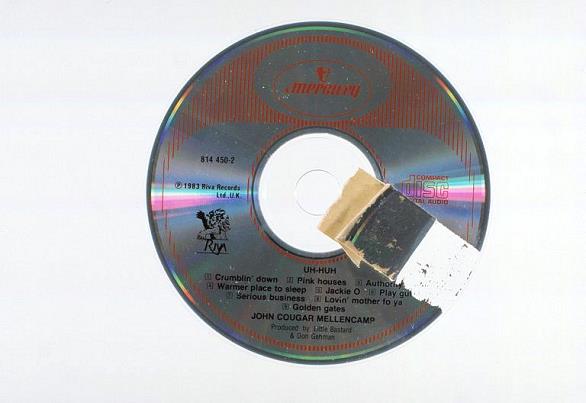

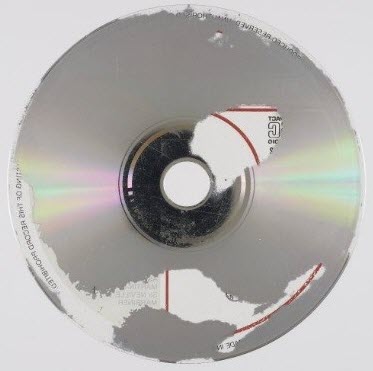

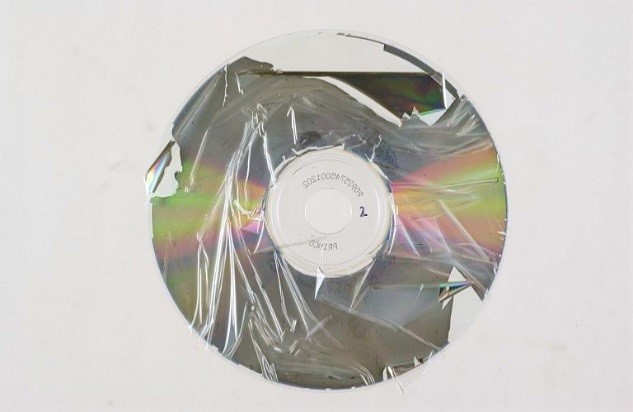

The focus of this Canadian Conservation Institute resource is on preserving the audio, video or data information carrier, as opposed to preserving its content. If, for example, a CD or magnetic tape is in such a poor enough condition that it cannot be read or played, then the issues of emulation and migration are moot. Figure 14 shows an example where damage makes it difficult, if not impossible, to access the CD’s content. Of course, long before such damage manifests, content preservation must still be a priority.

© Government of Canada, Canadian Conservation Institute. CCI 88899-0003

Figure 14. Damage to the plastic base layer of this recordable CD has affected its readability.

Two key issues must be considered regarding the preservation of audio, video and data recording media:

- Preservation of the media

- Preservation of the equipment or technology that reads or plays the media

The obsolescence of playback equipment is a real preservation issue and must be carefully considered. Without the machine, the media in good condition are worthless (Figure 15).

© Government of Canada, Canadian Conservation Institute. CCI 124716-0028

Figure 15. Preserving the content of a unique oral history collection on magnetic tapes must be a priority before the equipment to read the tapes becomes obsolete.

For grooved media, this is not a significant issue. Equipment to play such media is quite simple and can be reconstructed without much problem. There is no software required to interpret the information recorded on the media and no sophisticated parts involved that need to be produced in highly technical factories. However, for magnetic tapes and disks or optical discs, the situation is different. The technologies and equipment involved in reading them are very sophisticated and, once equipment disappears through obsolescence, the information they contain cannot be accessed and will be lost regardless of their physical condition.

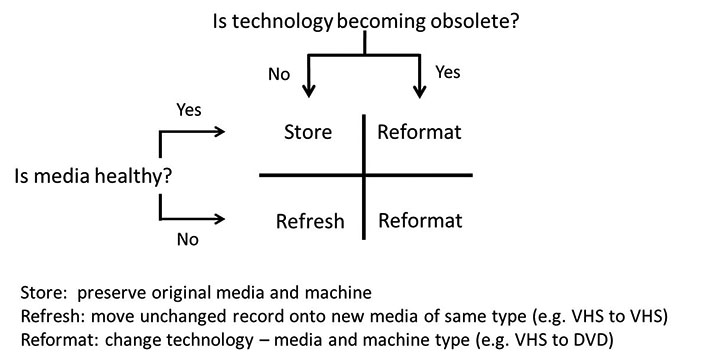

Careful monitoring of marketplace trends is an essential aspect for preserving information on audio, video and data recording media. This allows for the formulation of a preservation plan in a timely fashion. Figure 16 summarizes the key decisions that need to be made and the actions that must be taken in order to devise such a plan.

© Government of Canada, Canadian Conservation Institute. CCI 125773-0109

Figure 16. The various decisions and actions that must be undertaken when preserving content on audio, video and data recording media. This schematic helps with the decision to either store the content on the same media, move it to a new media of the same type, or reformat it onto a new form of technology.

Damage and strategies for preservation by agent of deterioration

Physical forces

Audio, video and data recording media need to be played on equipment and, in order for media to play properly, they have to conform to certain specifications. Therefore, any changes in the structural integrity of the media can lead to performance problems or to complete loss of access to the content.

One of the most significant problems with recording media is scratches, which can affect the playability, readability or performance of all recording media except flash. Scratches can occur because of poor handling, poor cleaning or the use of playback equipment that is not clean or properly maintained. (Consult Scratches on an audio CD for more information on the effects of scratches on playing audio discs.)

© Government of Canada

Source: Library and Archives Canada

Figure 17. Broken music cylinder.

Other types of physical damage to audio, video and data recording media can occur. For example:

- Grooved discs (including wax cylinders and vinyl records) are fragile and can be cracked or easily broken (Figure 17).

- Optical discs are also fragile and can break or crack if they are dropped or bent (Figure 18). Another important issue is that their metal layer integrity is critical to disc performance and readability. The metal layer is very important because it reflects the reading laser light back to the signal detector of the player after the data layer has been read. Without this layer present, there would be no signal. The metal layer is very thin and susceptible to deformation from pressure or damage due to scratching of the top side (label side). The metal layer may also delaminate due to the physical force applied by the removal of an adhesive label (Figure 19).

- Magnetic tapes are vulnerable to tears, stretching, folds, wrinkling (Figure 20) and breakage. Plastic reels can easily break, exposing the magnetic tape to higher risks of physical damage (Figure 21).

© Government of Canada, Canadian Conservation Institute. CCI 92389-0001

Figure 18. Chipped CD.

© Government of Canada, Canadian Conservation Institute. CCI 80112-0011

Figure 19. The pressure exerted to remove this adhesive label has caused the metal layer on this CD to delaminate.

© Government of Canada, Canadian Conservation Institute. CCI 92389-0006

Figure 20. Wrinkled VHS tape.

© Government of Canada, Canadian Conservation Institute. CCI 83365-0007

Figure 21. A damaged reel of magnetic audiotape. In this case, the reel and tape were damaged by the same event. Whenever a broken reel is encountered, it should be replaced, since the unprotected tape becomes more vulnerable to physical damage.

- Floppy diskettes may be vulnerable to wrinkling and can become unreadable as a result of such types of damage.

- Magnetic hard disk drives are susceptible to damage caused by vibrations and shock, which may not only damage the hard disk media but also the mechanical components necessary for the functioning of the hard drive.

- Flash media are fairly durable and resistant to physical damage. However, damage can occur to the connector portion of the media. If the connector is damaged, the media cannot be properly inserted into the reading device and the content is unreadable. Most often, connector damage occurs when flash media are forced into the reading device due to improper insertion.

For most recording media, the greatest source of physical damage is from the equipment. Optical discs are the exception because there is no physical contact between the medium and the reader, and the same is true for flash media, except for the initial connection between the media and the machine. Scratching of grooved media or magnetic tapes and floppy diskettes is a common problem that occurs when equipment is dirty. For magnetic tapes, equipment that is not aligned properly will lead to broken and wrinkled tape (Figure 20) or tape that gets stretched or deformed in a variety of ways, making playback difficult. For any recording media that require physical contact with the reader and are chemically degrading, continued use will lead to more damage.

Delamination, flaking and peeling of layers are other possible problems with recording media because most have a layered structure that can be damaged by poor handling. This is most likely to occur with optical discs and some grooved media, which can delaminate if stressed by bending. In addition, exposure to rapid and large changes in temperature and relative humidity (RH) can weaken metal layers of some optical discs and make them more vulnerable to physical stresses, thus exacerbating the peeling off of layers. Chemically degraded magnetic tapes are also very susceptible to the loss of magnetic tape binder and magnetic oxide recording material since these materials flake off from the tape base during play or with handling. Cheaply made media are particularly vulnerable to the layer delamination problem.

Manufacturing quality is a key aspect in the aging and durability of recording media. For the most part, higher quality media will be able to withstand physical forces significantly better than poorly constructed media.

Recommendations

- Follow general handling recommendations; for example, handle media with lint-free gloves to avoid getting fingerprints on the media, do not drop or bend media, keep areas where the media is stored and used clean by avoiding activities such as eating and drinking in them.

- Train staff to follow proper handling procedures.

- Do not play degraded media often, otherwise partial or complete loss of content may occur. Depending on the type of damage, it may be unwise to attempt to play the media at all, unless remedial treatment is performed beforehand. In some cases, remedial actions can be performed in-house (consult Technical Bulletin 27 Remedies for Deteriorated or Damaged Modern Information Carriers) but, in other cases, degraded or contaminated media should be handled by experienced professionals. This limits further damage or loss.

- Cleanse recording media prior to use (only if dirty or contaminated) by following proper cleaning procedures for the specific type of media (consult the Bibliography for resources on each type of media). Since some recording media (grooved media, floppy diskettes and magnetic tapes) require physical contact between them and the reader, cleanliness is essential in reducing the risk of scratching the media and damaging the equipment. In addition, the quality of the playback will be dramatically improved with proper cleaning. Avoid frequent or improper cleaning, which may cause more problems than if the media were left alone.

- Keep clean all playing equipment that may require periodic cleaning, otherwise physical damage, such as scratching of media (except optical discs and flash media) or tearing of magnetic tape, can occur. Clean equipment also gives a better playback signal. Although equipment can be cleaned with commercial products, the effectiveness of such products is limited and may actually damage the equipment. A qualified service technician should service equipment in order to ensure that it will not be damaged and will perform at its optimum.

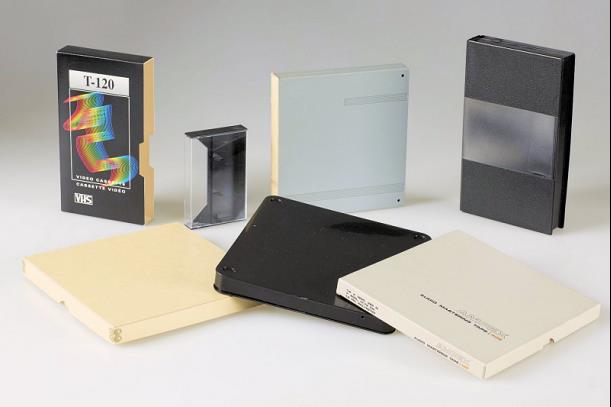

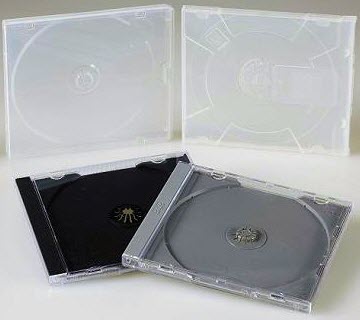

- Store recording media in appropriate containers when not in use. This is an essential element in protecting recording media from damage. Store wax cylinders in their original containers (Figure 22). Store grooved discs in soft polyethylene sleeves and then in their original jackets with the cellophane wrap removed. Store reel or cassette magnetic tapes, ideally, in rigid and inert plastic cases. Paper jackets/boxes may be used for small and light reels or cassettes, as long as the jackets are in good condition, keeping in mind that paper will provide less protection than rigid plastic containers (Figure 23). Store CDs, DVDs and Blu-rays in regular-sized jewel cases (Figure 24). Store flash media in the plastic containers they came with (although not always available) and, where caps are present for USB flash drives, ensure that these are placed on the connection point of the flash media. Alternatively, where the connector portion can be retracted or protected in some other fashion, then this should be done.

© Canadian Museum of History, D2006-11050, D2006-11055

Figure 22. Wax cylinders are best kept in their historic containers.

© Government of Canada, Canadian Conservation Institute. CCI 124703-0028

Figure 23. An assortment of plastic and paper storage boxes for storing reel or cassette magnetic tapes.

© Government of Canada, Canadian Conservation Institute. CCI 124703-0027

Figure 24. Regular-sized jewel cases for the proper storage of CD-sized optical discs. Shown at the bottom are standard polystyrene cases with separate holding trays. Shown at the top are one piece, more durable polypropylene jewel cases.

- Store all recording media in a vertical orientation to limit distortion and other types of damage (not applicable to flash media since orientation is not an issue). Note that this may lead to an increase in the storage space required for a collection.

- Do not use adhesive labels on optical discs as removing them can cause damage to the metal layer of the disc (Figure 19). Labels on tape cassettes should be minimized and placed only on the recessed portion of the cassette. Avoid labelling magnetic reels as much as possible.

- Avoid writing on optical discs, especially CDs, with a pen or pencil. Any writing should be done with a water-based permanent felt tip marker on the hub portion of the disc. Labelling in this way will prevent metal layer damage and possible delamination problems, but will limit the amount of information that can be written on the disc.

More detailed handling and storage recommendations can be found in the following resources:

Grooved recordings

- National Library of Canada. The Care and Handling of Recorded Sound Materials

- UNESCO. “The Care of Grooved Recordings” in Audiovisual Archives: A Practical Reader (PDF format)

- Library of Congress. Care, Handling, and Storage of Audio Visual Materials

- Library of Congress. Preservation and Conservation of Sound Recordings (PDF format)

Magnetic tapes

- ISO 18923:2000, Imaging Materials – Polyester-base Magnetic Tape – Storage Practices

- ISO 18933:2012, Imaging Materials – Magnetic Tape – Care and Handling Practices for Extended Usage

- CCI Technical Bulletin 27 Remedies for Deteriorated or Damaged Modern Information Carriers

Optical discs

- ISO 18925:2013, Imaging Materials – Optical Disc Media – Storage Practices

- ISO 18938:2014, Imaging Materials – Optical Discs – Care and Handling for Extended Storage

- CCI Technical Bulletin 27 Remedies for Deteriorated or Damaged Modern Information Carriers

- CCI Note 19/1 Longevity of Recordable CDs, DVDs and Blu-rays

Hard disk drives

- ISO 18943:2014, Imaging Materials – Magnetic Hard Drives Used for Image Storage – Care and Handling

Theft, vandalism, dissociation

In most cases, recording media have little artifactual value, unlike some other collection material. The value rests with the information that is stored on the media. Often, the content on the media is not easily identifiable, making theft less likely. On the other hand, electronic media are very portable and can be easily taken without detection.

Like other types of collection material, vandalism can be an issue. Damage to recording media can lead to media that are not playable and, subsequently, to loss of content.

Dissociation is a risk if the accession number or associated information is lost, as is the case for other types of materials. In addition, recording media are machine readable and therefore, without proper labelling, dissociation is even more problematic since the contents cannot be easily identified without actually playing the media. Loss of the ability to access information from recording media due to technology obsolescence is also a form of dissociation, as is loss of information due to improper migration to a new format (for example, loss of video details when migrating analog video content, such as VHS, to a digital format, such as DVD).

Recommendations

- Monitor the marketplace by consulting the Internet and technology magazines for the popularity of old technologies and the appearance of new ones. By identifying early which technologies are starting to become obsolete, there will be time for a transfer of information from old to new technologies before losing the ability to play the recording media and retrieve stored information.

- Follow accepted standards where they exist for the migration of audio, video and other types of electronic information stored on recordable media (consult Audio digitization and Video digitization in the Bibliography).

- Follow the general strategies to protect a collection from theft, vandalism and dissociation as outlined in Agent of deterioration: thieves and vandals and Agent of deterioration: dissociation.

Fire, water

The effects of fire on recording media can be divided into 1) the effects of soot, ash and debris and 2) the effects of heat. Recovery from debris, although in some cases requiring significant effort, is possible and usually successful. On the other hand, heat from a fire can lead to the melting of media (Figures 25a and 25b), the fusing together of magnetic tape strands, significant distortion and warping of grooved media and optical discs (Figure 25c) and, possibly, complete destruction. All of these scenarios will likely result in unplayable media that cannot be repaired.

© Government of Canada, Canadian Conservation Institute. CCI 122142-0002

Figure 25a. Heat-damaged USB flash drive.

© Government of Canada, Canadian Conservation Institute. CCI 80112-0006

Figure 25b. A fire-damaged CD started to melt on its edge (as shown on the left portion of the disc).

© Government of Canada, Canadian Conservation Institute. CCI 124703-0029

Figure 25c. Exposure to high temperatures can lead to warping of optical disc media, resulting in an unplayable disc.

In general, most recording media are not as susceptible to damage from water exposure as are paper documents, books, photographs, etc. However, acetate and shellac grooved media have some water sensitivity and can be damaged with exposure. Certain types of magnetic tapes have passivation layers or coatings that may dissolve with water exposure (especially chlorinated tap water) and lead to degradation of the magnetic metal particles that hold the electronic information. Non-inert metal reflective layers in poorly constructed optical discs can corrode with water exposure, which may lead to making the discs unreadable.

Metal components, such as metal reels or the contact points of USB keys, risk corroding if exposed to water. This may, in turn, cause problems in terms of accessing the information. For example, magnetic tapes will be contaminated with corrosion products that may cause scratches, there may be signal losses, or there may be poor contact between the USB key and the reader, making it unreadable.

Recommendations

- Ensure recording media are kept in their storage containers when not in use in order to minimize exposure to debris and water.

- Apply the strategies for protecting collections from fire and water as outlined in Agent of deterioration: fire and Agent of deterioration: water.

Pests

Recording media are generally not susceptible to pests, although, like other materials, damage or contamination may occur in some cases. Mould can grow on recording media if left wet or stored under damp conditions. Mould can be very problematic to deal with, especially with magnetic tapes where it can infiltrate between wound layers, which would necessitate an extensive cleaning effort.

Recommendations

- Store recording media in their appropriate containers and in recommended storage environments.

- Keep areas where the media is stored and used clean.

- Apply the strategies for protecting collections from pests as detailed in: Agent of deterioration: pests.

Pollutants and contaminants

Depending on the optical disc format, the metal reflective layer may be composed of aluminum, aluminum alloy, silver, silver alloy or gold. With the exception of gold, which is inert to corrosion, the other materials will corrode with exposure to atmospheric pollutants and moisture. The source of the pollutants may also be from storage enclosures or from materials stored with the disc inside the enclosure. Corrosion of the metal in CDs will readily occur if the protective top layer is poorly applied and permeable and leads to discolouration, pitting or even complete disappearance of the metal. This degradation has come to be known as “laser rot” (Figure 26), even though the degradation has nothing to do with the laser that reads or records these discs. The adhesive layer in DVDs may also cause this corrosion effect over time.

© Government of Canada, Canadian Conservation Institute. CCI 123861-0009

Figure 26. Base side view of an audio CD with metal layer corrosion or “laser rot.”

Corrosion of certain magnetic tape types, such as metal-particulate tapes and metal evaporated tapes, is also possible. Both of these tapes have protective or passivating layers for corrosion protection. When the protective layer is not of good quality, corrosion of the magnetic components will occur in polluted environments.

For flash media, corrosion of the connectors will result in poor connection with the reader.

Dust and debris are problematic for recording media, excluding flash media, and can lead to physical damage or playability problems. For optical discs, because there is no contact between the reader and the disc, the presence of dust can affect playability but will not damage the disc itself. For other media types, such as grooved media or magnetic tapes and disks, when dust and debris are present, physical damage and playing problems are likely.

Fingerprints are a problem for some recording media. Not only will they affect playability of the media, but they can also attract and trap dirt that can lead to scratching. Chemical interactions between fingerprints and media may occur. Grooved recordings, optical discs, magnetic tapes and floppy diskettes are particularly vulnerable to this type of contamination.

PVC sleeve holders will stain or damage media due to the migration of plasticizer out of the plastic as it degrades (Figure 27). This transfer of plasticizer residue happens even faster if the sleeves are in close contact or under pressure; for example, if they are kept together in a binder. For optical discs, a sleeve provides little physical protection for the disc and no type of plastic sleeve should be used for storage (even if the plastic is stable) because debris can get trapped in the sleeve, which eventually causes the disc to become scratched as it is inserted or removed from the sleeve.

© Government of Canada, Canadian Conservation Institute. CCI 120210-0144

Figure 27. Plasticizer from the PVC sleeve has come in contact with the CD and left an oily residue on the disc surface.

Recommendations

- Wear lint-free gloves when handling media surfaces since fingerprints will smear and attract dust and debris.

- Maintain clean room conditions for handling and playing.

- Keep recording media in their appropriate sleeves or containers when not in use in order to prevent contaminants from settling.

- Avoid poor-quality storage containers, such as PVC and acidic cardboard sleeves. Instead, choose inert, non-debris producing, sealable materials for containers (Figures 23 and 24). These provide excellent protection from dust, debris and external pollutants and will not themselves emit harmful products. The use of better quality containers will help to limit damage caused by aggressive agents.

- Do not place any materials, like poor quality acidic paper products, in the storage container with the media. Off-gassing of such products can lead to deterioration. This is a simple procedure to follow, although it introduces an organizational problem in trying to keep enclosures, materials and media together (Figure 28).

- Place recorded media that is already in its proper storage container (for example, an optical disc in a jewel case) in suitable bags, such as sealable polyethylene. This is a very simple and cheap way of providing protection from external pollutants when the air quality is poor in a storage area. Alternatively, use molecular sieves (that is, adsorbents or desiccants) in the appropriate type of bag to maximize protection against external pollutants. Avoid placing acetate audio reel tapes in bags, as this may accelerate the degradation of the tapes.

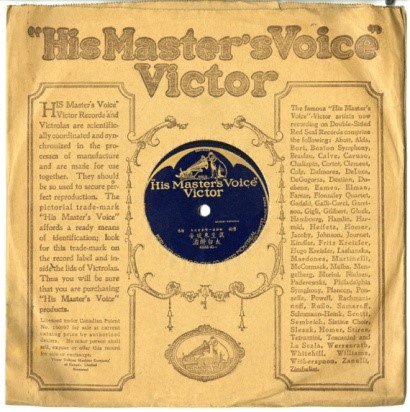

Berliner Gram-o-phone Co. Limited/Victor Talking Machine Company of Canada Ltd. The Great Poet Tai Bai is Drunk Now (Tai Bai zui jiu). © Canadian Museum of History, 78-6-E-00073, IMG2009-0062-0035-Dm

Figure 28. Original paper or cardboard sleeves are often made of acidic paper. Old records should be kept in separate polyethylene sleeves, away from their original sleeves. Or, if possible to do so without stressing the original sleeve, polyethylene sleeves can be used as interleaves in between the record and the original sleeve so as to keep the two elements together. The original sleeve is an important part of the historic record.

Light and ultraviolet

Light and ultraviolet light can cause damage to recording media. Examples of possible damage include oxidation of vulcanite grooved discs, degradation of vinyl grooved discs, fading of dyes in recordable optical disc media, and yellowing of the plastic base of optical discs. Overall, however, the risk of light damage to recording media is low.

Recommendation

- Store media in their recommended storage containers when not in use. Avoid leaving media out in the open, exposed to light or sunlight for long periods of time. Short exposures will not be problematic.

Incorrect temperature

High temperature can cause a number of problems with recording media. Types of damage due to high or fluctuating temperatures, sometimes in conjunction with high humidities, are outlined below by type of media. Problems related to intense heat due to fires are described under the section Fire, water.

Grooved media

Heat should be avoided in the case of wax cylinders. Shellac discs are also susceptible to shrinkage with heat.

Heat will accelerate chemical degradation processes inherent to vulcanite discs (leading to brittleness) and to the lacquer in acetate discs (leading to delamination problems) (Figure 29a). Nitrocellulose-coated aluminum discs, such as some old phonograph records (Figures 29b and 29c), are also chemically unstable and will degrade at a faster rate at higher temperatures and RHs.

© Government of Canada

Source: Library and Archives Canada

Figure 29a. Flaking acetate disc. Generally, loss of plasticizer from the lacquer degradation causes shrinkage of the coating and, therefore, flaking. The lacquer’s degradation rate increases with higher temperatures and RHs.

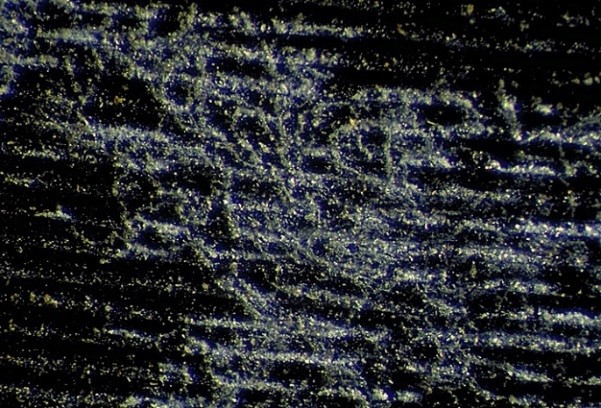

© Government of Canada, Canadian Conservation Institute. CCI 120210-0007

Figure 29b. A phonograph record made of aluminum coated with cellulose nitrate. Exudation of additives forms crystalline or greasy accretions on the disc surface. The nitrate coating is also flaking off on the lower right-hand side of the record perimeter.

© Government of Canada, Canadian Conservation Institute. CCI 120210-0091

Figure 29c. Microscopic observation of the phonograph disc reveals glittering crystals or greasy waxy films. To the naked eye, these deposits are sometimes mistaken as mould.

Fluctuations in temperature are problematic for all media in general, but more so with vinyl discs, which tend to become easily deformed.

Optical discs

Some types of optical discs, such as recordable CDs and recordable DVDs, contain a dye layer (Figures 10a and 10b). When data is recorded or “burned” to these discs, changes representing the digital information occur in the dye layers. Therefore, the stability of the dye is critical if the disc is to be read properly. There are three basic dye types used: phthalocyanine, cyanine and azo. The phthalocyanine type is very stable to light, heat and moisture and is not a concern for longevity. However, the other two types are less stable and tend to fade with light exposure and/or exposure to higher temperatures and humidity.

Metal layers of some optical discs can weaken if exposed to rapid and large changes in both temperature and RH which, in combination with poor handling or other physical stresses, can lead to the peeling off of layers.

Magnetic tapes

Binder hydrolysis, or “sticky shed syndrome” as it is commonly known (Figure 30), is a significant problem with many magnetic tapes. This degradation is a reaction between the polyester urethane binder polymer, which holds the magnetic particles onto the tape base, and moisture. High RH and warmer temperatures will accelerate it. The result is the breakdown of the polymer, causing the tape to become sticky and also causing the binder and magnetic material to shed from the tape base. Tape in this condition is extremely difficult or impossible to play properly, and attempts to play it will lead to high squealing, the tape stopping during play, or the binder possibly being ripped completely off the base. Fortunately, for tapes with extensive degradation, there are specialist remedies to make the tapes playable. These remedies do not reverse the chemical damage, but allow the tape to be played so that a copy can be made and the information saved (consult Technical Bulletin 27 Remedies for Deteriorated or Damaged Modern Information Carriers and “Soft Binder Syndrome” on the A/V Artifact Atlas online resource).

© Government of Canada, Canadian Conservation Institute. CCI 83365-0023

Figure 30. Detail image of a magnetic tape suffering from sticky shed syndrome.

The hydrolysis reaction is also an issue for the plastic tape base material and, as for the binder, the chemical reaction increases with higher temperatures. This is a particular concern for older reel-to-reel audiotapes with a cellulose acetate base. With hydrolysis, the tapes become deformed, very brittle and difficult to play. Tapes also exude plasticizer and other components to the surface, making frequent cleaning a requirement. Tapes also usually shed magnetic material in advanced states of cellulose acetate base hydrolysis (also known as “vinegar syndrome” because the tapes smell like vinegar as they degrade).

Changes in temperature will lead to changes in the tension of a wound tape. When a tape is placed in storage, it is wound at a constant and even tension in order to prevent it from becoming deformed while in storage. With higher temperatures (higher than the temperature under which it was initially wound), tension in the wound tape increases, leading to tape stretching and deformation. At lower temperatures, the tension of the wound tape decreases, leading to a loosening of the wind and possible creasing or wrinkling of the tape.

Older audiotapes are vulnerable to “print-through.” Print-through is the transfer of audio signal from one layer of wound tape onto an adjacent layer. The result is an echo signal before or after the original signal. Higher temperatures lead to increases in print-through. Print-through can be greatly reduced by winding the tape using fast-forward and rewind modes a couple of times prior to playing the tape.

Storage temperatures higher than recommended can lead to lubricant evaporation in magnetic tapes. This results in tapes that play with a lot of friction, with significant signal distortion and the possibility of physical damage. Lower temperatures (< 8°C) may lead to lubricant migration to the tape surface, especially with some older tapes.

Hard disk drives

Hard disk drives are composed of various mechanical components. Exposure to constant warm temperatures can contribute to failure of these mechanical components and the functioning of the hard drive. Hard drives should not be operated in a warm environment.

Recommendations

- Avoid warm temperatures or temperatures greater than standard office conditions.

- Do not store or display media near areas that radiate heat, such as heating vents or radiators.

- Store media away from windows or external walls. Avoid direct sunlight and heat-radiating lights.

- Avoid basement or attic storage.

- Avoid large temperature fluctuations and keep the number of fluctuations low. Small to moderate fluctuations will limit such physical problems, such as delamination of grooved discs or optical disc layers, and a variety of deformation problems for all media.

- Maintain heating and cooling systems, and service annually.

- Equilibrate media before playing when media storage conditions have been substantially different than use conditions.

- Consult the Bibliography for more resources on appropriate storage temperatures.

- Not all recording media can be safely stored at lower temperatures, so identification of problem items and correct storage conditions are important. For example, most CDs can be stored at temperatures as low as -10°C, but the lower temperature limit for magnetic tape storage is 8°C.

Although the above steps generally ensure a reasonable lifetime for audio, video and data recording media, they still leave more sensitive media vulnerable. Examples of sensitive media are poorly manufactured optical discs, recordable CDs and DVDs with less stable dyes, certain types of grooved discs, wax cylinder recordings and magnetic tapes with cellulose acetate base or polyester urethane binder. These need to be identified and dealt with individually.

Incorrect relative humidity

At high RH, mould is a concern for all recording media. Grooved discs, such as acetate and shellac, and wax cylinders can be significantly damaged by mould.

Other deleterious effects that can occur due to RHs that are too high, too low, or fluctuating are outlined below for different types of media.

Grooved discs

Some effects of incorrect RH on grooved discs closely follow those of incorrect temperature. Such effects include shrinkage and delamination of the lacquer coating in acetate grooved discs with low or high RH, embrittlement of shellac-grooved discs with high RH, and degradation of vulcanite discs with elevated RH.

Optical discs

The structure of optical discs involves a series of discrete layers. Excluding the base, the other layers are very thin. Rapid and large changes in RH can lead to delamination of these thin layers (Figure 31).

© Government of Canada, Canadian Conservation Institute. CCI 83365-0003

Figure 31. An example of delaminating layers on a CD, due to inadequate climatic conditions.

High RH can accelerate the corrosion of metal reflective layers in optical discs, as noted in the Pollutants and contaminants section (for example, “laser rot” in Figure 26).

Some types of optical discs that contain dyes are less stable at high humidity (as noted under Incorrect temperature).

Magnetic tapes

High RH is responsible for an increase in polyester urethane binder hydrolysis (sticky shed syndrome) and acetate base hydrolysis (vinegar syndrome) in magnetic tapes, as described under Incorrect temperature.

Wound tape has specific problems. If stored at high RH for a long time, wound tape can experience layer-to-layer adhesion. Once tape layers stick together, they can be extremely difficult to separate. Attempts to separate by using force usually result in the binder layer being stripped off the tape base. Furthermore, as with changes in temperature, a change in the wound tape tension occurs with changes in RH. High RH (higher than when the tape was initially wound) increases the tension in the wound tape, leading to stretching and tape deformation. Low RH causes a reduction in tension that can lead to physical damage, such as creasing or wrinkling of the tape.

Recommendations

- Store items in sealable polyethylene bags. This is a cheap and easy method to keep recording media at a reasonable RH. Media can be conditioned at a desired RH and then placed in the bags with all residual air squeezed out. The use of bags also provides RH buffering, protects from water should a disaster occur and keeps dust out. Avoid placing acetate audio reel tapes in bags, as this may accelerate the degradation of the tapes.

- Keep RH low and RH fluctuations small to increase chemical stability, and limit physical damage to recording media. Caution: avoid very low RH because some grooved acetate discs may delaminate at lower RH due to the brittleness of the lacquer layer, and optical discs may also delaminate.

- Equilibrate media before playing when media storage conditions have been substantially different than use conditions.

- Consult the Bibliography for more resources on appropriate storage humidity levels.

Examples of preventive conservation practices

White deposit on a grooved audio disc

Problem:

A grooved audio disc was removed from storage so that a CD copy of the recording could be made. Upon removal of the disc from the sleeve, a white waxy substance with a crystalline appearance was noticed on the disc’s surfaces (Figure 32). Further examination showed that the disc was an acetate or instantaneous disc, and the white deposit on the disc was palmitic acid. Its presence was due to hydrolysis of the castor oil plasticizer that resided in the lacquer layer of the disc.

© Government of Canada

Source: Library and Archives Canada

Figure 32. White, waxy appearance on the surface of an acetate disc.

Solution:

In order to play the disc, it needed to be cleaned thoroughly. Otherwise, the presence of debris on the disc would lead to sound distortion and scratching or other damage to the disc grooves. Discs with palmitic acid deposits are best cleaned with a record cleaning machine such as Keith Monks, VP1 or Nifty Gritty. A solution of a non-ionic surfactant such as 0.25 parts Tergitol 15-S-3, 0.25 parts Tergitol 15-S-9, and 1 part ammonia per 100 parts distilled water can be used for the cleaning. Following the detergent cleaning, rinse with distilled water to eliminate all traces of the surfactant. Once the disc is dry, any dust can be blown off with a compressed air duster. Degradation of the plasticizer cannot be reversed.

Magnetic material shedding from videotape

Problem:

A 10-year-old VHS tape was pulled out of storage. Before playing the tape, an inspection revealed debris within the cassette housing. Inspecting the tape further revealed that only a small amount of rubbing was needed to cause flaking off of the binder and magnetic material from the tape base. This is a common symptom when the binder of the tape undergoes hydrolysis. The binder has degraded to the point where it has lost its integrity and will no longer adhere to the base of the tape when any kind of force is applied (Figure 33). If a tape is played in this condition, it will likely lead to an extensive amount of binder flaking off due to the friction. Loss of information, equipment contamination and equipment damage can also occur.

© Government of Canada, Canadian Conservation Institute. CCI 83365-0023

Figure 33. Badly deteriorated VHS tape with a binder layer that readily flakes off the tape base.

Solution:

Binder hydrolysis cannot be permanently reversed. However, there are some remedies that can temporarily restore playability to the tape so that a copy can be made. The tape can be cleaned using an appropriate wiping cloth (Pellon) plus tape cleaning equipment so that sticky products on the surface of the tape are removed. Another possible solution is to dry out the tape in a cool environment, which consolidates the binder so that it does not flake off the tape base and reduces the tape stickiness. The most popular treatment is to expose the tape to moderate dry heat (less than 50°C) for at least 10 hours. This method, known as “baking” the tape, has been very successful and also reduces stickiness and consolidates the binder. These techniques are not for the novice.

Careful control of the temperature, time and several other key variables are essential. Consult a professional if this problem is encountered. Note that, although the binder hydrolysis problem can be temporarily remedied to some extent, any binder flaking that has occurred cannot be repaired. Information that existed on the flaked portions of the tape is lost. Also, flaking of the binder may not be due to a binder hydrolysis problem, in which case the above treatments may be ineffective.

Scratches on an audio CD

Problem:

An audio CD does not play properly. Occasionally, the disc hesitates or makes a clicking noise during play. Inspecting the play (non-label) side of the disc reveals that the CD is clean with no dust, debris or fingerprints being present. Holding the disc up to the light shows light shining through the disc where scratches are present. The metal reflective layer of the disc has been damaged from the label (top) side (Figure 34) and, when the reading laser encounters the damaged portion, problems occur.

© Government of Canada, Canadian Conservation Institute. CCI 80112-0009

Figure 34. Scratches affecting the metal reflective layer of a CD.

Solution:

Scratches to the top (label) side of a CD can cause damage to the metal reflective layer of the disc because the metal layer is very close to the top surface of the disc and is directly beneath the lacquer protective layer (Figure 9a). A disc that has metal reflective layer damage cannot be repaired. Only the error correction system associated with CD technology can alleviate the problems. If the error correction system is overwhelmed by the damage, then problems will be audible. Scratches in the radial direction, like spokes in a bicycle wheel, are less problematic for the error correction system to deal with than concentric scratches, which follow the direction of play. On the other hand, if the scratches occur on the base or bottom of the disc (the side from which the disc is read), metal layer damage will not occur. However, depending on the severity of a scratch, it may cause problems. It may interfere with disc readability because the laser light reading the disc from the base may scatter when encountering the scratch. To remedy this, the disc can be sanded and repolished with specialized equipment in order to possibly restore good playability.

Note: This is only for CD formats. For DVD formats, a scratch that results in metal layer damage is unlikely because the metal reflective layer is sandwiched between layers of plastic (Figure 9b). Blu-ray Discs are the opposite of the audio CD: the thin layers are near the read side (bottom or laser side) of the disc (Figure 9c). Thus, for DVDs and Blu-ray Discs, only scratches to the read-side are critical and not those to the label side.

Bibliography

General

A/V Artifact Atlas. Soft Binder Syndrome, 2013.

Gibson, G.D. Preservation and Conservation of Sound Recordings (PDF format). Champaign, IL: Graduate School of Library and Information Science, University of Illinois at Urbana-Champaign, 1991.

International Organization for Standardization. ISO 18923:2000, Imaging Materials – Polyester-base Magnetic Tape – Storage Practices. Geneva, Switzerland: International Organization for Standardization, 2000.

International Organization for Standardization. ISO 18933:2012, Imaging Materials – Magnetic Tape – Care and Handling Practices for Extended Usage. Geneva, Switzerland: International Organization for Standardization, 2012.

International Organization for Standardization. ISO 18925:2013, Imaging Materials – Optical Disc Media – Storage Practices. Geneva, Switzerland: International Organization for Standardization, 2013.

International Organization for Standardization. ISO 18938:2014, Imaging Materials – Optical Discs – Care and Handling for Extended Storage. Geneva, Switzerland: International Organization for Standardization, 2014.

International Organization for Standardization. ISO 18943:2014, Imaging Materials – Magnetic Hard Drives Used for Image Storage – Care and Handling. Geneva, Switzerland: International Organization for Standardization, 2014.

Iraci, J. Remedies for Deteriorated or Damaged Modern Information Carriers. Technical Bulletin 27. Ottawa, ON: Canadian Conservation Institute, 2005.

Iraci, J. Longevity of Recordable CDs, DVDs and Blu-rays, revised. CCI Notes 19/1. Ottawa, ON: Canadian Conservation Institute, 2020.

Library of Congress. Care, Handling, and Storage of Audio Visual Materials, n.d.

St-Laurent, G. “The Care of Grooved Recordings.” In Audiovisual Archives: A Practical Reader (PDF format). Paris, France: United Nations Educational, Scientific and Cultural Organization, 1995.

St-Laurent, G. The Care and Handling of Recorded Sound Materials. Ottawa, ON: National Library of Canada, 1996.

Audio digitization

Association for Recorded Sound Collections. ARSC Technical Committee Preservation of Archival Sound Recordings (PDF format), 2009.

Association for Recorded Sound Collections. Essential Resources for Audio Preservation (PDF format), 2009.

Bradley, K., ed. Guidelines on the Production and Preservation of Digital Audio Objects. 2nd ed. N.p.: IASA Technical Committee, 2009.

CDP Audio Digital Working Group. Digital Audio Best Practices, N.p.: n.p., 2006.

E-MELD. E-MELD School of Best Practices in Digital Language Documentation: Digitization of Audio Files, 2005.

Henriksson, J., and N. Wallaszkovits. Audio Tape Digitisation Workflow. N.p.: TAPE (Training for Audiovisual Preservation in Europe), n.d.

Hess, R., J. Iraci and K. Flak. The Digitization of Audiotapes, revised. Technical Bulletin 30. Ottawa, ON: Canadian Conservation Institute, 2020.

National Initiative for a Networked Cultural Heritage (NINCH). The NINCH Guide to Good Practice in the Digital Representation and Management of Cultural Heritage Materials, (PDF format) 2002-2003.

Sound Directions. Sound Directions: Best Practices for Audio Preservation, 2008.

Video digitization

E-MELD. E-MELD School of Best Practices in Digital Language Documentation: Digitization of Video Files, 2006.

Fleischhauer, C., and K. Bradley, eds. IASA-TC 06 Guidelines for the Preservation of Video Recordings. London, UK: International Association of Sound and Audiovisual Archives, 2018.

Iraci, J. The Digitization of VHS Videotapes. Technical Bulletin 31. Ottawa, ON: Canadian Conservation Institute, 2017.

VideoPreservation Website. Digital Migration Tools and Techniques, 2007.

© Government of Canada, Canadian Conservation Institute, 2020

Published by:

Canadian Conservation Institute

Department of Canadian Heritage

1030 Innes Road

Ottawa, ON K1B 4S7

Canada

Cat. No.: CH57-4/6-2-2020E-PDF

ISBN 978-0-660-35113-1