Corrosion detection in ships Sandbox

Halifax, NS

25 Apr - 20 May 2022

9 Companies

6 Corrosion test stations

2 Royal Canadian Navy Ships

16 Technical and DND end-user experts

17 Organizations receiving the results

How might we detect and assess corrosion behind surface coatings?

The Innovation for Defence Excellence and Security (IDEaS) Corrosion Detection in Ships Sandbox, called for Canadian innovators to test and demonstrate to Department of National Defence and the Canadian Armed Forces (DND/CAF) their technology to detect and assess corrosion on CAF vessels without reliance on human visual inspection or removal of equipment.

What IDEaS Provided

A cost-sharing chance to test and demonstrate solutions in front of military experts and end users, putting innovator technology in the spotlight. Innovators received observational feedback from DND, CAF experts and potential users. Detailed instructions on how innovators apply and to those subsequently selected, as well as selection criteria and test plans specific to the individual Sandbox.

What Innovators Brought

Solutions that demonstrated their corrosion detection and assessment technology to help the CAF reduce corrosion’s operational impact onboard vessels and improve the effectiveness of scheduled and unscheduled maintenance.

Sandbox Overview

Background

The COVID-19 pandemic provided its share of delays in conducting this Sandbox. Thankfully, the storm passed and IDEaS was once again able to get the propellers turning on this long awaited event. After a two year wait, the program kicked off its Corrosion Detection on Ships (CDIS) Sandbox on April 25, 2022 at the Center for Ocean Ventures and Entrepreneurship (COVE) in Dartmouth, Nova Scotia. During the delay, no time was spared in making the best out of a challenging situation. Adjustments were made to this Sandbox call to provide clarity to address the ever evolving nature of the Department of National Defence and Canadian Armed Forces (DND/CAF) needs.

A total of nine teams of avid innovators were enthusiastically welcomed by our Sandbox team, where they tested and demonstrated their medium to high Technology Readiness Level technologies. The test sites and resources readily available to these participants were nothing short of extraordinary! Over a period of 3 to 5 days, teams set off to test their technology on a total of six different test panels in dry and submerged scenarios. These installations were carefully replicated in order to simulate areas of Maritime Coastal Defence Vessel (MCDV) where corrosion could be hidden. Furthermore, participants had a designated team of DND science experts and data collectors on hand to accompany them in their journey through the various test stations. Once completed, all teams were then invited onboard a MCDV to demonstrate their corrosion detection solutions in a realistic environment.

The Testing Method

The goal of the Sandbox was to challenge the participants through a succession of static trial scenarios, starting with the simplest challenges and moving to more complex challenges. Such was the case for the Corrosion Detection Sandbox, where six corrosion detection stations presented all nine teams with the opportunity to push their technology to new heights.

Before the evaluation began, participants were invited to calibrate their solutions for each scenario using calibration panels, knowing full well where the corrosion defects were located. This allowed participants to make the necessary changes to their solutions before tackling the various test panels. Each test panel provided at the Sandbox hid a corrosion defect, concealed under various coatings, and ranging in difficulty (easy to complex). Much thought went into building these scenarios as they used the same material used on board the Royal Canadian Navy’s ships. While the teams of observers (defence scientists and industry subject matter experts) knew where the defects were hiding, the participants did not.

During the evaluation, participants provided a testing plan to the evaluators, in which they identified which scenario was preferred to test their solution. This allowed participants to experiment on adapted scenarios while also having the option to explore more complex layouts. Observers were allocated to each team in order to communicate the solution’s successes and failures without revealing the hidden defects in the test panels. Upon completing their work on the test panels, participants were then escorted on board the HMCS Goose Bay to continue their testing in a real life scenario on a RCN serving vessel, recently returned from a tour of duty. This testing method demonstrated the agility of the technology while also translating any successes or failures in the detection of the corrosion from test panels to the ship. The criteria on which the technology was evaluated included:

- Technical functions of the system;

- Assembly requirements (installation, wiring, software, configuration, personnel, etc.);

- Physical requirements (power, cabling, shelter, etc.);

- Training requirements to operate the system;

- Operational requirements and limitations;

- The analysis process;

- Detecting general corrosion, pitting corrosion, crevice corrosion and corrosion under coatings;

- Possible interferences (ex. welding seams, surface roughness, etc.); and

- Speed and accuracy of the solution.

What Was Provided?

The corrosion detection provided an enriched environment in which innovators were able to test their solutions in a wide range of simulated and real life scenarios. Each team was given up to five days of testing time, during which they received daily one-on-one consultation and briefing time with corrosion specialists. Science and military observers also dedicated their time and corrosion expertise to each team in order to provide direct feedback from an end-user perspective. On location, the IDEaS program was mindful of public health measures in order to keep all attendees safe. As such, the outdoor tented test areas provided suitable boundaries for everyone to circulate and work safely. Furthermore, bearing in mind the costs for conducting tests and demonstrations, IDEaS offered funding for up to 50 percent of identified eligible expenses (up to $12,000) for each innovator participating to this Sandbox, on a cost sharing basis. Claimable expenses were limited to travel, accommodation and living expenses, as well as shipping and transportation costs of equipment to/from the Sandbox environment.

At no cost to the innovator, DND provided the Sandbox. Meanwhile, the CAF facility and staff supported participants by providing:

- Science and military observers with corrosion experience;

- Storage space for the participants’ equipment;

- A test area of suitable boundaries;

- Various corroded test panels manufactured according to NETE specifications and representative of those encountered on a ship;

- Photography/video services to record appropriate visual aspects of the solutions and the Sandbox;

- TEEMS data collectors;

- Hard accommodations and tented testing sites;

- Lunches and refreshments;

- Some pre-existing inventory such as tables, chairs at COVE; and

- HMCS Goose Bay for final testing.

Visitor Day

The IDEaS program is committed to giving various organizations the opportunity to witness participants’ technology through a live action demonstration. During the CDIS Visitor Day, stakeholders were given a chance to understand the IDEaS program, how a Sandbox is conducted, and how corrosion can be detected by walking through the test site and interacting with participants as they demonstrated their proposed solutions. For this Sandbox, while being mindful and vigilant of COVID-19 restrictions, the IDEaS program welcomed a total of 13 visitors in small groups, from other Canadian federal organizations (i.e. Coast Guard), and DND/CAF’s domestic and international defence and security partners (i.e. Five-Eyes, NATO, NORAD). Additionally, a Media Day and a Stakeholder Day gave local media outlets and other organizations a chance to share this unique experience more broadly.

Innovators, Experts & End-Users

A successful Sandbox occurs when you gather innovators with subject matter experts and end-users. In this case, 9 companies and 16 carefully picked specialists from DRDC, and DND/CAF.

| Participating Innovators | Country | Detector Technology |

|---|---|---|

| Allied Scientific Pro | Canada | Electromagnetics |

| Avestec Technologies | Canada | Intelligent Robotic Inspection |

| CMQ Centre de Métallurgie | Canada | Electro-chemical & ultrasound |

| Crawford Technologies | USA | Kinetic hammer taps |

| Eddyfi Technologies #3, Floormap X | Canada | Magnetic flux technology |

| InpecTerra Inc | Canada | Magnetic |

| MLVX Technologies Inc | Canada | Hyperspectral |

| Qii.AI | Canada | AI-Enabled Corrosion Detection from Dron-Acquired Visual and Thermal Data |

| Visiooimage Inc | Canada | Infrared Thermography |

| DND/CAF Subject Matter Experts and End-Users |

|---|

| Assistant Deputy Minister (Materiel) |

| Defence Research and Development Canada |

| Quality Engineering Test Establishment (QETE) |

| Royal Canadian Navy |

What We Achieved

The CDIS Sandbox:

- demonstrated current technologies and their limitations in both simulated conditions (test panels with machined thinning) and under “real world” conditions (onboard HMCS GOOSE BAY & HMCS GLACE BAY);

- displayed the corrosion challenges in a marine environment. Most of the companies have their technologies developed for the oil and gas industry (mainly pipeline inspections), therefore representing the reality of a marine environment exposed different challenges;

- acquired knowledge of the applicability and versatility demonstrated by participants’ technologies, including the limitations of their technology, and the impact of the real ship conditions versus a controlled/lab environment;

- allowed the innovators to test and improve their technologies in realistic scenarios and receive feedback from military personnel and defence scientists. Full written reports are also provided to each innovator.

Test Plans

The IDEaS CDIS Sandbox offered participants a variety of test scenarios in order to demonstrate their CDIS capability. Test panels were manufactured to simulate different parts of a navy ship and induced general, pitting, and crevice corrosion which was then covered with various materials to visually obscure the corrosion. The Photo Gallery has images of the test panels.

Participants were able to demonstrate the ability of their solution to detect the corrosion, for the following scenarios.

- Baseline Pipe. Used for system calibration. An 8” Schedule 16 Steel pipe diameter with varying wall thickness. Estimated Test Time: 120 mins

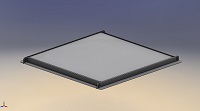

- Baseline Hull Plate – 7mm. Used for system calibration. One plate that is 3’ x 3’ with thickness of 7 mm. Estimated Test Time 120 mins.

- Baseline Hull Plate – 9mm. Used for system calibration. One plate that is 3’ x 3’ with thickness of 9 mm. Estimated Test Time 120 mins.

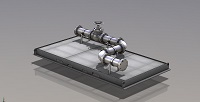

- Copper Pipe. Pipe made of 90/10 Copper Nickel Dimensions: 219.1mm OD, 3.84mm wall thickness with welded flanges, rubber gaskets, and various valves made of Bronze. Estimated Test Time 120 mins.

- Steel Pipe. One test pipe made of seamless steel 8” Gr. B Schedule 40 with flanges, rubber gaskets, and steel valves. Estimated Test Time 120 mins.

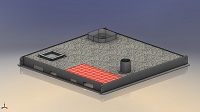

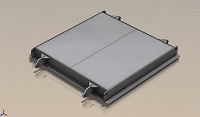

- Unrestricted Deck. One steel plate with a thickness of 9 mm. A hatch, welds, induced pitting and general corrosion on the plate. Quarry tiles, non-skid, or other coatings will be used to create a liftoff. Estimated Test Time 120 mins.

- Restricted Deck. One steel plate with a thickness of 9 mm. Insulation will be used to cover the plate. Estimated Test Time: 180 mins

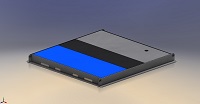

- Hull Dry. One 8’ x 8’ steel plate with a thickness of 7 mm-9 mm. Hull paint, Boot Top, and antifouling will cover the surface. The test plate will be on dry land. Estimated Test Time 240 mins.

- Hull Wet - Simulated. One 8’ x 8’ steel plate with a thickness of 7 mm-9 mm partially submerged into sea water (Note: Only the outer surface of the steel plate will be in contact with water, the inner surface will be dry). Hull paint, Boot Top, and antifouling will cover the surface. Estimated Test Time: 240 mins

- Hull Wet – Real. A A marine vessel for a full in-water hull survey. The hull will be steel, have hull paint covering defects and corrosion. Details and availability of this scenario are subject to confirmation. Estimated Test Time: 360 mins

- Ship Structure. One 8’ x 8’ steel plate with a thickness of 7 mm-9 mm. Stiffener beams will be welded to the plate and covered with insulation. Estimated Test Time: 120 mins

- Equipment Mounts. One 6’ x 6’ steel plate with a thickness of 7mm – 9mm. An equipment mount held with four fasteners. Crevice corrosion will be induced under the plate and on fasteners. Estimated Test Time: 120 mins

- Penetration Points. One 6’ x 6’ steel plate with a thickness of 7mm -9mm. One kick pipe penetrating the plate. Estimated Test Time: 120 mins

Funds

- DND/CAF provided the test environment at no cost to Participants.

- On a cost sharing basis, IDEaS funded 50 percent of identified eligible expenses as outlined below provided the Participant also paid 50%, up to a maximum combined 100% amount identified as the Cost Sharing Ceiling for that Sandbox. The Participant is 100% responsible for all costs above the ceiling amount, as well as all costs not covered as described below. The cost ceiling for this Sandbox was $24,000 and the maximum share provided by DND/CAF to Participants is $12,000 or 50% of eligible expenses, whichever is less.

- Eligible Costs. All costs claimed must be directly attributable to attending the Sandbox itself and are inclusive of delivered duty paid and applicable taxes. The types of claimable expenses under this cost-sharing arrangement are limited to:

- Travel, accommodation, and living expenses. The National Joint Council Travel Directive will apply for any travel, accommodation and living expenses.

- Shipping and transportation expenses of equipment to/from the Sandbox environment.

- Consumables used during the demonstrations themselves, such as munitions or fuel, which must be pre-approved by DND/CAF in order to be eligible. This does not include the damage or loss of equipment.

- Each Participant submitted a forecast of such reasonable expenses prior to the Sandbox which was subject to approval by Canada.

- Upon conclusion of the Sandbox, applicable processes for submitting actual expenses and payments were administered.

Example Application of the Cost Sharing Model

- The published cost ceiling for eligible expenses is $24,000 CAD. The Participant submitted receipts for $30,000 for travel and shipping of their equipment to/from the Sandbox, and $2,000 of travel they made prior to the Sandbox to develop their prototype.

- The $2,000 CAD for their internal sandbox preparations is not an eligible expense.

- The $30,000 CAD for the travel and shipping to the Sandbox is eligible; however, only the amount of $24,000 CAD is eligible within the ceiling limit.

- The IDEaS 50% share of that eligible amount and amount paid to the Participant would be $12,000 CAD. The Participant is responsible for all other costs.

The Challenge

Challenge statement and outcome

“How might we detect and assess corrosion behind surface coatings (such as paint, insulation, tiles, seamless decking …) onboard Royal Canadian Navy (RCN) platforms in order to reduce corrosion’s operational impact and improve the effectiveness of scheduled and unscheduled maintenance?”

- The end-state outcome of this challenge was to implement a functional solution for rapidly and easily detecting and informing the operators and engineers of all corrosion in a vessel while it is in operational use in a non-destructive manner that does not rely on human visual inspection or the removal of equipment. The information could be used for unscheduled but required repairs, and planning for major work.

Background and context

- Corrosion prevention, detection, and repair on RCN platforms is an essential component throughout their service life. This includes the aspects of:

- unscheduled maintenance when a corrosion problem is discovered while the ship is operational and requires immediate repair;

- scheduled maintenance to repair corrosion during major overhauls or other maintenance opportunities;

- the provision of corrosion data into the broader question of a vessel’s seaworthiness and risk assessments for current operational use as well as estimates of the fatigue and overall life expectancy of that vessel; and

- with consideration of the above, the prioritization of what maintenance on which ship is performed when in order to create an effective and efficient maintenance program in total for the RCN with the requisite operational availability.

- While corrosion prevention and repair remain crucial aspects of this overall topic, this particular Sandbox is focusing on the corrosion detection aspect of this problem space.

- The current approach to the corrosion detection has often been removing insulation, deck covering and interference items in order to see the steel plating and be able to perform an assessment of the required repairs. The removal of interference items can be very difficult and intrusive in itself, and is frequently not viable while the ship is operational. Consequently, the corrosion detection and repair planning is mostly done once the ship has started her major overhaul after the insulation, deck covering and interference items have been removed. Only then can the repair surveys can be completed to define work repair scope. This leads to new unplanned work that will need to be completed as work arising, which leads to significant schedule delays and cost increases.

- Alternatively, to be effective and efficient the detection of corrosion and the consequential maintenance planning would ideally be done well in advance of such major overhauls while the ship is still operational and without the removal of surface coatings (such as paint, insulation, tiles, seamless decking, etc).

- In summary, currently, the RCN relies mostly on:

- Visual or limited technologies for detection of corrosion via inspection as noticed, or during scheduled inspection cycles and/or based on historical experience and trends, including corrosion by-products or thinning of steel; and

- Experienced hull surveyors to determine if tile or seamless decking has delaminated from the steel deck;

- These current methods are inadequate in their ability to:

- assess steel condition under the tile or seamless decking;

- detect corrosion in difficult to assess area such as under/behind large pieces of equipment; and

- ability to “see” through insulation to assess steel plating.

Operational Scenarios for this Sandbox

While there are many scenarios where corrosion can appear, for the purposes of this sandbox application, evaluation, and selection process the following scenarios for detecting corrosion were examined:

- Detecting corrosion on the hull out of the water. The hull is made from steel plate, is painted, has Boot Top, and antifouling. Scanning the entire hull external surface above the waterline or full hull while in dry-dock and detecting all corrosion.

- Detecting corrosion on the hull in the water. The hull is made from steel plate partially submerged into sea water. The hull is painted, has Boot Top, and antifouling. Scanning of the hull that is below the waterline is done while the ship is in the water. A manual solution such as a diver using a hand-held scanner is not considered applicable to this scenario, as something more advanced is required.

- Detecting corrosion on the deck. The deck is made from steel plate and may include hatches, welds, and surface coverings such as quarry tiles and non-skid coatings. There may be assorted pipes or other items protruding through the deck, as well as assorted equipment mounted to it.

- Detecting corrosion on/in pipes. A ship includes many pipes of assorted diameters and wall thicknesses, often in difficult to reach locations, encased in insulation, with welded flanges, rubber gaskets, and various valves made of Bronze, with both internal and external corrosion. Detectors need to be small in size, or effective from a standoff distance, or be used internally on the pipe. Disassembly of the pipes for inspection is time consuming and not desirable.

- Detecting corrosion on/in structure. The structure is generally made of steel plate with stiffener beams welded to the plate and covered with insulation. Plates will be painted and may be horizontally or vertically mounted with welds, protrusions, and hatchways.

- Detecting corrosion in tanks. Tanks come in many sizes for assorted fluids (fuel, water, oil, etc), are difficult to access, and may have internal baffles. Detectors need to be maneuverable in such confined spaces. Note that “tanks” will not be included at the actual Sandbox test environment.

Transcript

IDEaS Sandbox – Corrosion detection in ships

The Challenge: Detect and assess corrosion on Royal Canadian Navy vessels in order to reduce its impact on operations.

Because rust never sleeps

Spring 2022

Halifax, Nova Scotia

The IDEaS Sandbox Corrosion detection in ships

COVE Facility, Halifax, Nova Scotia

For more information http://Canada.ca/Defence-Ideas

Apply Now

Multimedia

Photo Gallery

Social media posts

Videos

May 10, 2022

High-tech gear to protect Canada's naval ship from rust (en anglais seulement)