Management of Pesticide Spray Drift

Preface

A pesticide may only be sold or used in Canada if it has been registered or otherwise authorized by Health Canada. Health Canada's primary role in regulating pesticides is to protect human health and the environment. To accomplish this, Health Canada conducts a rigorous science-based risk assessment to ensure that the product meets health and environmental standards before a pesticide is registered. To ensure that registered pesticides continue to meet modern standards, Health Canada re-assesses pesticides at least every 15 years. When potential risks are identified, Health Canada implements measures to help minimize those risks.

One potential risk to the environment is the off-target movement of agricultural pesticides into areas where impacts on wildlife and their habitat may occur. A potential route of this exposure is through spray drift that occurs during or shortly after pesticide spraying. Part of the strategy in fulfilling the responsibility to protect the environment is to provide the necessary management tools for reducing pesticide loss resulting from spray drift under agricultural situations. Specifically, the guidance document, Management of Pesticide Spray Drift was developed that examines the airborne movement of spray droplets and their potential deposition onto non-target areas such as aquatic and terrestrial habitats. This document does not address the other routes of unintentional pesticide movement such as surface run-off (erosion), vapour drift (volatility) or wind-swept soil.

The development of Management of Pesticide Spray Drift was the result of integrating the existing scientific information on the factors influencing spray drift and the methods and strategies used to reduce it, and the advice and recommendations provided by the expertise within provincial government departments.

This document is, therefore, chiefly intended for pesticide applicators, growers and stakeholders, including Federal, Provincial and Territorial departments, other pesticide regulatory authorities, the industry sector and technical working groups. More specifically, the document is designed to encourage pesticide applicators develop spray drift management strategies for the particular circumstances of their spraying operation. Additionally, this document serves as a useful tool in establishing regulatory policy and development of educational training programs.

It should be recognized that this document does not exempt regulatory requirements that are reflected as mandatory measures or precautions on pesticide product labels. Finally, there will be periodic updates to the document as more information becomes available.

Introduction

A successful agricultural pesticide spray program requires a uniform application of pesticide spray to a target area with a minimal loss outside of the target area. Lost spray is spray that will not control pests. Pesticide loss at the time of application can occur due to spray drift, vapour drift and run-off. This document focuses on spray drift.

Unintentional off-target pesticide deposits from spray drift can cause damage to nearby sensitive habitats and the organisms that reside in them. It is therefore essential that applicators become familiar with the principles and practices of spray drift management and adopt strategies to minimize pesticide loss.

Applicators can minimize pesticide spray drift loss by considering weather conditions, timing of application, adjusting or modifying spray equipment and adopting spray buffer zones for sensitive habitats.

This guide outlines the following principles and strategies for a spray drift management program:

- The properties of spray drift

- Best management practices relating to

- spray planning

- weather conditions

- application technology

- Spray buffer zones on product labels

- Application of buffer zone modifiers to reduce the size of the spray buffer zones

What is Spray Drift?

Spray drift is the airborne movement of droplets or particles outside the intended target area. Some level of spray drift will always occur, either during or shortly after an application. However, by understanding what can influence spray drift, it can be minimized.

Factors that influence spray drift

Generally, spray drift depends more on the method of application and local conditions at the time of application than on the chemical being applied. Factors that influence spray drift include weather conditions, application technology and application parameters.

The most critical considerations are:

- Wind speed – High winds increase potential for drift.

Atmospheric turbulence – There is a high likelihood of thermal inversions during late evening, night, and early-morning hours making spray droplets more prone to drift. - Atmospheric turbulence – There is a high likelihood of thermal inversions during late evening, night, and early-morning hours making spray droplets more prone to drift.

- Temperature and humidity – High temperature and low relative humidity will increase evaporation, which can result in smaller droplets that are more prone to drift.

- Nozzle distance – The greater the distance between a spray nozzle and the target (crop or ground), the greater the opportunity for droplets to evaporate and/or be blown off target by wind. Lowering horizontal booms on field sprayers, using protective shields or shrouds over the boom or using ducted conveyors (such as towers) on airblast sprayers will minimize this factor.

- Nozzle selection – Smaller nozzle orifices and greater spray pressure can result in smaller droplets, including those with diameters less than 150 µm that are most prone to drift. Poorly maintained nozzles can produce erratic spray patterns with unintended droplet sizes. Modern air-induction and other low-drift nozzles reduce small droplets, even at higher pressures.

- Operating speeds – Higher travelling speeds can create turbulence and wind shear which can move spray droplets off target. Using a slower operating speed improves coverage and canopy penetration, which improves efficacy and reduces drift.

- Spray volume – Low-volume application rates usually require the use of small droplets, which increase spray drift.

- Crop canopy – The density of the crop canopy affects spray interception. In orchard airblast applications, too much air during early-season applications can lead to unnecessary spray drift. However, low-speed, high-volume air is required for proper canopy penetration later in the season and reduces spray drift considerably.

All things being equal, as the droplet size decreases, the amount of spray drift increases and droplets with diameters less than 150 micrometres (µm) are most prone to spray drift. (Note: 100 µm = thickness of human hair.) These drifting spray droplets may eventually deposit onto non-target areas, which may include sensitive aquatic and terrestrial habitats.

The smaller the droplet size, the greater the spray drift

Weather Conditions

Applicators should be aware of how weather contributes to spray drift. They should apply pesticides only during favourable conditions.

- Temperature and Relative Humidity – These factors determine the amount of evaporation for liquid tank mixes. For example, hot and dry conditions may increase spray drift due to rapid evaporation to smaller spray droplets. In general, avoid spraying when relative humidity is less than 40 per cent and air temperature is above 25°C.

- Wind Direction – Sensitive habitats on the downwind side of a sprayed field require protection from spray drift. Applicators must monitor wind direction just prior to and during an application. If possible, spray with a crosswind. Be sure that wind direction has stabilized.

- Wind Speed – Wind speed affects the distance that spray drift travels before being deposited. Higher wind speeds lead to greater spray drift. Dead calm conditions, which often occur in the early morning or late evening, can also result in greater spray drift due to temperature inversions. Therefore, spraying in dead calm conditions is prohibited. Spraying is best done when there is a light wind (greater than 1-2 km/h).

- Temperature Inversions – Inversions are atmospheric conditions in which warm air above traps cooler air near the earth's surface. Inversions are often accompanied by calm conditions. During this time, spray dispersion is suppressed and a concentrated cloud of small pesticide droplets is formed above the ground. As the wind increases, the cloud moves and is eventually carried long distances downwind.

Do not spray in dead calm conditions

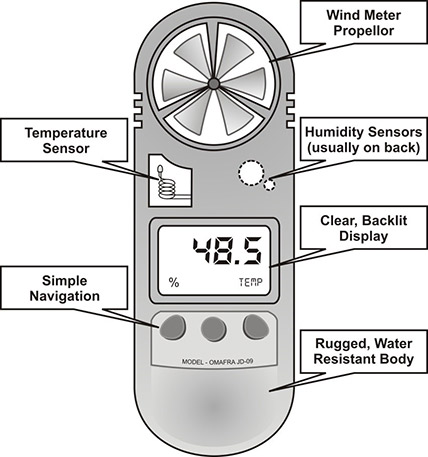

Weather conditions can be measured with a handheld weather sensor.

- For field applications (ground and aerial), wind speed should be measured at a height of 1.5 m above ground or the height of the spray boom, whichever is greater.

- For airblast spraying in orchards or vineyards, wind speed should be measured towards the top of the canopy, upwind of the orchard (in other words, from outside, not within, the planting). A wind vane will provide greatest accuracy in measuring wind direction, but applicators can also use simple tools such as ribbons and a compass to assess wind direction.

Prior to spraying, monitor winds over a two- to three-minute span, recording the maximum sustained wind speed and average wind direction during that period. If conditions become too adverse, or contradict label directions during spraying, stop spraying until they improve.

(Image courtesy of Ontario Ministry of Agriculture and Food, 2013)

Figure 1 - Text description

Schematic drawing of a water-resistant hand-held weather sensor showing: a wind meter propeller, humidity sensors, temperature sensor, a clear backlit display window and three navigation buttons.

Figure 2 - Text description

Photograph of a 3-metre high pole with a top-mounted anemometer for measuring wind speed and direction at the edge of a barley field.

Spray Droplets

Spray Quality

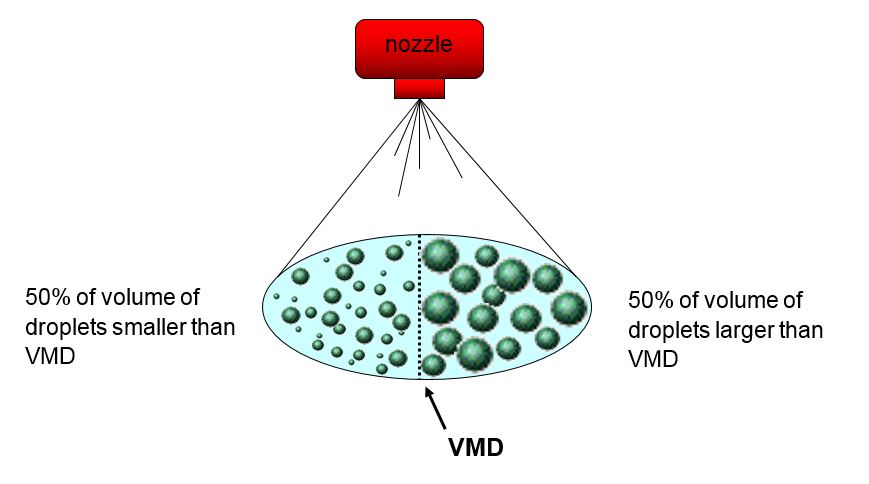

In every volume of spray, there is a range of droplet sizes. This is called "spray quality." Spray quality is often described by the volume median diameter (VMD) and is one of the most important considerations when choosing an appropriate spray nozzle. If you were to arrange all the droplets in a spray cloud according to their size, the VMD is the droplet diameter (measured in µm; 1/1,000 mm) at which 50% of the spray volume is made up of droplets less than the median droplet size and 50% is made up of droplets greater than the median droplet size.

Figure 3 - Text description

Schematic diagram describing the volume median diameter (VMD) in which a nozzle delivers a spray where 50% of the spray volume is made up of droplets with diameters less than the VMD and 50% is made up of droplets with diameters greater than the VMD.

The amount of spray with droplet diameters less than 150 µm is an indicator of the drift potential for that spray quality. For example, a spray quality of "very fine" has droplets that can drift 20-30 times farther downwind than droplets from a "very coarse" spray. This is because the very fine spray has a higher proportion of droplets that are less than 150 µm than the very coarse spray.

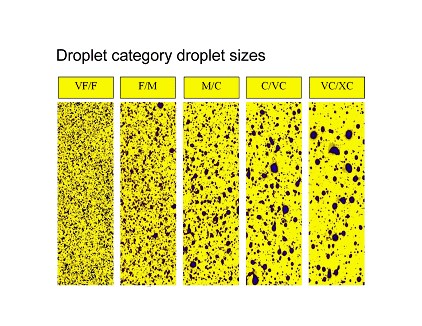

The required minimum spray quality for specific pesticide applications can be found on the product label as either ASAE S572.1 Fine or Medium or Coarse. Spray quality categories were developed by the American Society of Agricultural Engineers (now renamed the ASABE) in the S572.1 standard (ANSI/ASAE S572.1 MAR2009). Each category is based on an approximate VMD range and has an associated colour code as listed in the table below. The colour codes of spray quality however, are not associated with the colours of nozzle tips. Spray quality colour codes are used in nozzle catalogues to help applicators select nozzles. For an example of how spray quality categories are used in nozzle selection, see Spray Nozzles below.

| Spray Quality | Colour Code | Approximate Volume Mean Diameter (μm) |

|---|---|---|

| Very Fine (VF) | Red | 50-150 |

| Fine (F) | Orange | 150-240 |

| Medium (M) | Yellow | 240-350 |

| Coarse (C) | Blue | 350-400 |

| Very Coarse (VC) | Green | 400-500 |

| Extremely Coarse (XC) | White | 500-660 |

| (adapted from ANSI/ASAE S572.1 MAR2009) | ||

(Image courtesy of Agriculture and Agri-Food Canada)

Figure 4 - Text description

Photograph of water sensitive cards showing the coverage of spray droplets from different droplet size categories, ranging from Very Fine/Fine to Very Coarse/Extremely Coarse: the finer the droplet size the greater and more evenly distributed the coverage on the card.

Reducing the proportion of small droplets reduces the amount of spray drift

Spray Nozzles

Spray nozzles are classified by their spray patterns, spray rates or spray quality. The PMRA specifies only the spray quality on pesticide labels. Applicators are responsible for modifying spray parameters such as nozzle type, flow rate, spray pressure and tractor speed to ensure that the labelled spray quality is met during applications.

Nozzle manufacturers produce nozzle selection guides and many have online tools to help applicators determine the spray quality under defined conditions. Manufacturers may use the spray quality colour codes shown in the table above in their guides. Note however, that nozzles are also colour coded by manufacturers based on their flow rate according to the ISO 10625 reference standard, and nozzle colour doesn't reflect spray quality colour. In addition, the colours of one nozzle type may not correspond to the same colour of another nozzle type (for example, an orange flat fan nozzle does not have the same operating conditions as an orange hollow cone nozzle).

The colour codes for spray quality should not be mistaken with the colour of the nozzle

The chart below is an example of a manufacturer's nozzle selection guide. If the pesticide label specifies that an ASAE S572.1 Medium spray quality must be used, the applicator would only be able to use the 015, 02, 025, 03, 04 and 05 nozzles because these nozzles can deliver medium droplet sizes (yellow section of the chart). If the applicator wants to apply at a spray rate of about 1.00 L/min, the 03 nozzle at 2.0 bar or the 025 nozzle at 3.0 bar could be used.

| Spray pressure (bar) | 1.5 | 2.0 | 2.5 | 3.0 | 4.0 | 5.0 |

|---|---|---|---|---|---|---|

| Nozzle | Spray rate (L/min) | |||||

| 0075-Pink | 0.21 F | 0.24 F | 0.27 F | 0.30 F | 0.35 F | 0.39 F |

| 01-Orange | 0.28 F | 0.33 F | 0.37 F | 0.40 F | 0.46 F | 0.52 F |

| 015-Green | 0.42 M | 0.49 F | 0.55 F | 0.60 F | 0.69 F | 0.77 F |

| 02-Yellow | 0.57 M | 0.65 M | 0.73 F | 0.80 F | 0.92 F | 1.03 F |

| 025-Lilac | 0.71 M | 0.82 M | 0.91 M | 1.00 M | 1.15 F | 1.29 F |

| 03-Blue | 0.85 M | 0.98 M | 1.10 M | 1.20 M | 1.39 M | 1.55 M |

| 04-Red | 1.13 M | 1.31 M | 1.46 M | 1.60 M | 1.85 M | 2.07 M |

| 05-Brown | 1.41 C | 1.63 C | 1.83 M | 2.00 M | 2.31 M | 2.58 M |

| 06-Grey | 1.70 C | 1.96 C | 2.19 C | 2.40 C | 2.77 C | 3.10 C |

| 08-White | 2.26 VC | 2.61 C | 2.92 C | 3.20 C | 3.70 C | 4.13 C |

| 10-Light blue | 2.83 VC | 3.27 VC | 3.65 VC | 4.00 VC | 4.62 C | 5.16 C |

F – Fine, M – Medium, C – Coarse, VC – Very Coarse (adapted from Hardi ISO Nozzles – Nozzle Product Guide, 2011, p. 7) |

||||||

Each manufacturer has a slightly different range of droplet sizes for each spray quality. However, the use of standard reference nozzles used in the tests to define the ASAE S572.1 standard spray quality categories adjusts for these differences, and therefore the spray qualities are comparable across all manufacturers.

Droplet Size Management

Smaller droplets result from:

- increasing the spray pressure

- using smaller nozzle orifices

- increasing the nozzle angle into the air stream (for airblast sprayers and aircraft)

- increasing the distance from the nozzle to the area being sprayed (for example, boom height)

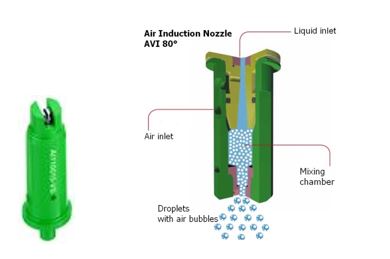

Droplets under 150 µm are particularly prone to drift but offer better coverage. With conventional nozzles, droplets over 300 µm resist drift, but depending on the leaf surface or the spray mix characteristics, may bounce or run off upon impact, thus providing poorer coverage. Droplets in the 100 – 300 µm range are a good compromise between minimizing spray drift and maximising biological effectiveness (coverage and retention). The exception may be air-induction (AI, sometimes referred to as Venturi) nozzles, which produce coarser droplets that contain air bubbles. Manufacturers and independent studies indicate that AI nozzles are a reasonably good choice for ground applications. The droplets arrive at the target intact and shatter upon impact, increasing coverage while greatly minimizing spray drift.

The most effective way to reduce spray drift potential is to apply coarser sprays that minimize the number of droplets less than 150 µm. Droplet size can be varied through nozzle and spray pressure selection.

- Pressure: For any nozzle, lower pressures result in coarser sprays. Nozzle catalogues often state the pressure range at which a specific nozzle can be used. The lowest recommended pressure will minimize spray drift, but applicators should always operate towards the middle of the nozzles' recommended pressure range.

- Nozzle Type: Low-drift nozzles are designed to produce larger spray droplets that drift less. The droplets are produced in pressure-reducing chambers inside the nozzle and in certain nozzles, incorporate air into the spray droplets. Spray drift can potentially be reduced by 50% to 95% compared to conventional nozzles. Low-drift nozzles are sometimes not recommended for use with contact-type pesticides (see label for any restrictions). Many of these nozzles require higher pressures to obtain the correct spray pattern.

- Nozzle Spray Angle and Orientation: With most nozzle types, narrower fan angles produce larger droplets. Droplet size decreases as nozzles are oriented more directly into the air stream, especially on fast moving aircraft. A flat fan nozzle (for example, 110°) produces a wider fan angle and allows the operator to lower a field sprayer boom, reducing the opportunity for spray drift.

- Low-Drift Adjuvants: Low-drift adjuvants increase droplet size for most applications, but some products or product rates may alter deposit patterns, especially in low-drift nozzles. Therefore, it is best to consult with the product manufacturer before using.

Sprayer Performance

Equipment operation, maintenance and calibration, including sprayer set up is under the direct control of the applicator. Applicators should minimize pesticide spray drift by using good management practices that include the proper use of appropriate application technology. The most important application technology factors that affect spray drift are spray quality (droplet size), boom height, air-assist settings and nozzle placement/orientation.

Equipment Calibration

The proper calibration of equipment can minimize off-target spray drift. Equipment calibration should be verified as part of normal sprayer setup and use, and adjustments made to ensure compliance with application requirements. An example for calibrating field sprayers can be found on the Ontario Ministry of Agriculture, Food and Rural Affairs website under "OMAFRA Sprayer Calibration Calculator".

- Clean spray equipment after use.

- Operate sprayers according to manufacturer instructions, and calibrate them for proper performance (minimum of twice per growing season).

- Check spray equipment regularly for wear, damage and leaks. Worn or damaged nozzles should be replaced to prevent over or under application of pesticide and changes in the spray discharge patterns and spray quality.

| Nozzle Damage | Result | Possible Causes | Potential Impact |

|---|---|---|---|

| Worm nozzle | Over application Uneven application |

Regular use (particularly with wettable powders) | Higher product cost Phytotoxicity (particularly on heat or moisture-stressed plants) Unacceptable residue level |

| Plugged nozzle | Over application Uneven application |

Debris Dirty carrier water Product build-up |

Inadequate protection Increased risk of pest resistance Increased risk of resistance |

| Distorted nozzle | Uneven application | Regular use Improper cleaning |

All of the above |

Water-sensitive paper can be used to check spray quality, coverage and drift. When placed in a crop or adjacent sensitive area the paper will change from yellow to blue where contacted by a spray droplet or moisture. Information on using water sensitive paper to verify the spray pattern of your nozzles and off-site drift can be found at Sprayers101.com under "Confirm coverage with water-sensitive paper".

Refer to Figure 4 - Droplet category droplet sizes

Periodically test and calibrate equipment to optimize application

Sprayer Configuration

Aerial Sprayers

Boom Length

The forces that provide lift and flight to the aircraft also produce wake and vortex effects in the air into which spray droplets are released. Vortex strength increases with slower flight speed or greater aircraft weight. Vortex strength also changes in response to flight characteristics. If droplets become trapped in the wing-tip vortices, their trajectory can change dramatically. Reducing the boom length reduces the probability of smaller droplets being caught up in the wing tip vortices and increases deposition on the crop. To reduce the effect of wing-tip vortices on smaller droplets, boom length should not exceed 65% of the wingspan or rotor diameter.

Figure 5 - Text description

Photograph of a fixed-wing aircraft with a spray boom measuring 65% of the aircraft's wingspan spraying pink-coloured dye over a barley field.

Air Shear

The production of small droplets that are more prone to spray drift can be reduced by minimizing air shear at the nozzle tip where the liquid meets the air blast from the aircraft motion. Reducing flight speed (for example, using slower helicopters rather than higher-speed fixed-wing aircraft) can reduce this shear, but may affect productivity rates and optimal operation. Reducing the nozzle angle is an effective way to reduce air shear. With deflector nozzles, the nozzle angle and the deflector angle can be reduced to provide minimal air shear conditions. Lowest air shear occurs for nozzle angles that are 0 degrees straight back.

Pressure

The relative velocity of the air and liquid is important in affecting droplet size. For most nozzles, lowering the pressure within the optimal operating range produces coarser sprays. However, with very narrow angle sprays such as those from solid stream and narrow angle flat fan nozzles pointed straight back, higher pressure generally produces coarser sprays.

Consult nozzle manufacturer information for specific recommendations on pressure range settings for optimal droplet size and application criteria.

Rotary Atomisers

With rotary atomisers, droplet size increases with lower rotation rate, which can reduce the potential for drift. Windmill-blade-driven atomisers allow you to choose the rotation rate by changing the blade angle. With rotary atomisers, droplet size tends to increase with higher flow rates because the drag on the atomiser reduces the rotation rate and flooding of the screens changes the atomisation mode. Some rotary atomiser manufacturers provide models for predicting droplet size with their equipment based on operational parameters such as rotation rate, flight speed and liquid flow rate for specific product types.

Figure 6 - Text description

Close-up photograph of a single rotary atomiser spray nozzle mounted on the wing boom of a fixed-wing aircraft

Figure 7 - Text description

Photograph of the same fixed-wing aircraft showing positions of all ten rotary atomisers mounted along the entire wing boom

Special Equipment

Some spray equipment allows in-flight optimisation of application conditions. For example, booms can sometimes be lowered after take-off, allowing spray release height to be reduced with lower spray drift potential.

Adjust your flight parameters and spray boom to reduce the potential for spray drift.

Field Sprayers (Ground Boom Sprayers)

Spray drift from field applications increases with smaller droplet size and greater boom height. You should take special care when applying at high speed as boom bounce can significantly increase the height of the end of the boom, which increases spray drift potential.

Pressure

For most hydraulic nozzles used within the prescribed operating range, lower liquid pressures produce coarser sprays. Electrostatic and some twin fluid spraying systems may be the exception.

Pulse-flow modulation systems and variable-orifice nozzles have recently been made commercially available for boom sprayers. These systems maintain the desired rate and spray quality independent of pressure and forward speed (within certain limitations).

Consult nozzle manufacturer information for recommendations on pressure range settings for optimal droplet size and flow criteria.

Release Height

Wind will have less effect if the boom is lowered to its minimum recommended setting: 45 cm above the target (for example, crop or bare ground) for field sprays with 80° fan angles and 35 cm for 110° fan angles. By orienting the spray forward or backward, you can further reduce boom height as long as the nozzle-to-target distance in the direction of spray travel is maintained at the minimum recommended. Low-drift nozzle spray pattern angles vary among manufacturers, therefore boom height should be adjusted to ensure a 100% overlap of spray patterns at target height (in other words, the width of the spray pattern should be twice the nozzle spacing).

Stabilizing boom height when driving over uneven ground can reduce spray drift by avoiding conditions of greater release height at the ends of the boom. Avoid high application speeds to help reduce boom bounce, air shear and wakes that can favour spray drift potential. Automatic boom height controllers are available; these can maintain the boom at a certain height in changing terrain.

High release height

Figure 8 - Text description

Photograph of a field sprayer with a high spray release height, where the boom is greater than one metre above the top of the crop, resulting in substantial drift travelling upward and away from the target area.

Low release height

Figure 9 - Text description

Photograph of a field sprayer with a low spray release height, where the boom is close to the top of the crop, resulting in no visible drift from the target area.

Low-Drift Nozzles

Several types of low-drift nozzles are available, including the following:

- Low-pressure (extended-range nozzles) – provide a uniform spray pattern at spray pressures down to 15 psi, reducing the number of driftable droplets compared to operating with spray pressures of 30-40 psi. Available in 80° and 110° flat fan. At higher pressures, spray becomes too fine, especially with the 110°, and more prone to drift.

- Pre-orifice – nozzles use a pre-orifice at the entrance side of the nozzle to reduce the exit pressure, which reduces the number of driftable droplets in the spray pattern. Spray pressures should be slightly elevated to between 40-50 psi to maintain spray pattern. Higher spray pressures will result in more drift, but not as much drift as with conventional nozzles.

- Low-pressure air-induction – a pre-orifice nozzle with a venturi hole in the nozzle body which draws air into the spray producing large droplets even at high spray pressures. Optimum pressure is 50-70 psi. Usually produces Coarse and Very Coarse sprays.

- High-pressure air-induction – similar to low-pressure air-induction, except designed for even higher pressures. Optimum pressure is 60 to 80 psi. Produces Very Coarse and Extremely Coarse sprays. With pressures higher than 100 psi, drift increases, but not nearly as great as with conventional nozzles.

(courtesy of TeeJet, Albuz)

Figure 10 - Text description

Photograph of a standard flat-fan nozzle showing its cylindrical base of about 2 cm in diameter with a grooved top housing the spray outlet

(courtesy of TeeJet, Albuz)

Figure 11 - Text description

Photograph of a low-drift air induction nozzle that is about 4 cm long and 1 cm in diameter with an air inlet port on the nozzle body and a grooved apex housing the spray outlet. Schematic showing the cross-section of a low-drift air induction nozzle with its liquid inlet, air inlet, mixing chamber and resulting spray droplets containing air bubbles

Figure 12 - Text description

Photograph of a field sprayer from the side, showing substantial spray drift from a boom fitted with standard flat-fan nozzles

Figure 13 - Text description

Photograph of the same field sprayer, showing little to no visible spray drift from a boom fitted with low-drift nozzles

(Images 12 and 13 courtesy of Agriculture and Agri-Food Canada)

Special/Modified Equipment

Wiper applicators can be used to apply herbicides to weeds without atomization into spray droplets which pose a spray drift exposure risk.

Shielded and hooded sprayers can significantly reduce spray drift by reducing the effect of wind. Shrouds surrounding the whole boom can reduce spray drift by 65% to 85%, while protective cones around individual nozzles can reduce drift by 30% to 50%. Shrouds and cones are usually only used on tractor-drawn sprayers with low boom heights and travel speeds less than 12 km/h, while air curtains are more often found on larger, powered field sprayers.

(image courtesy of Agriculture and Agri-Food Canada, 2006)

Figure 14 - Text description

Photograph of field sprayer with spray drift-reducing shrouds fitted along the entire length its spray boom

Figure 15 - Text description

Close-up photograph of a spray drift-reducing cone fitted over a nozzle on the boom of a field sprayer

Air-assisted boom systems use an air curtain to shield the spray from the wind and improve canopy penetration. Manufacturers claim that spray drift can be reduced by forcing the spray down into the canopy. However, the crop canopy should be sufficient to capture the spray, as high air flow rates applied to ground with little or no vegetative cover can result in higher drift.

(courtesy of Hardi International)

Figure 16 - Text description

Photograph of a tractor-mounted air-assisted field sprayer with an inflated air sleeve enveloping the entire spray boom. The air sleeve forces a curtain of air to carry the spray droplets down into the crop canopy.

For application of herbicides in orchards, small low boom sprayers fitted with shrouds or shields protect against crop damage by minimizing drift.

(Spraydome 3049, courtesy of Micron Group, 2013)

Figure 17 - Text description

Photograph of a low-boom shielded sprayer (Spraydome 3049) in an orchard consisting of dome-shaped shields spanning the length of the boom. The shields are approximately 20 cm above the ground and surrounded by flexible curtains reaching the ground that prevent spray drift from leaving the sprayer.

Airblast Sprayers

These types of commercial sprayers are designed primarily for orchards and vineyards, but may also be used in other crops such as berries or ornamentals. Airblast sprayers use forced air to deliver the pesticide liquid to the target. Nozzles deliver spray droplets into the high-speed airstream which are then shattered into smaller (fine) droplets which allow them to penetrate crop canopies. There are four discrete sprayer configurations:

- Axial fan sprayer – generates a radial airblast near ground level and discharges the spray up towards the canopy; very high volume and very high spray drift potential. Sprayers can be either single- or dual fan types.

Figure 18. Axial-fan airblast sprayer

Figure 18 - Text description

Photo of an axial-fan sprayer generating a radial airblast of spray to fruit vines that are on either side of the sprayer. The uppermost nozzles are turned off to avoid spraying above the tops of the vines.

- Cross-flow/tower sprayer – generates a horizontal spray from a vertically oriented spray tower; minimizes losses over the top of the canopy.

Figure 19. Airblast tower sprayer

Figure 19 - Text description

Photo of an airblast tower sprayer showing two vertical wings, each about three metres high housing nozzles along its length, spraying dwarf apple trees that are on either side of the sprayer. The spray is being directed horizontally into the tree canopy along the entire height of the tree.

- Top-down sprayer – vertically directed spray used in orchards and vineyards; decreases downwind losses.

Figure 20. Top-down airblast sprayer

Figure 20 - Text description

Photo of a top-down airblast sprayer in a dwarf apple orchard showing a V-shaped wing that is about three metres high housing nozzles on both sides for spraying at a downward angle.

- Tunnel Sprayer – over-the-row tunnels with spray recovering shrouds; used in low-medium height orchard crops (grapes, raspberries) and ornamentals. Significant spray drift reduction compared to conventional airblast.

Figure 21. Tunnel sprayer mounted on a high-clearance tractor

(courtesy of Ontario Ministry of Agriculture and Food, 2013)Figure 21 - Text description

Photo of a tunnel sprayer showing two tunnels (each approximately 3 metres high by two metres wide) mounted on a high-clearance tractor enveloping orchard trees for spraying. The spray is mostly captured within the tunnels.

Airblast applications differ from other sprayers in that an airstream delivers the spray cloud to the canopy by directing the droplets upwards and outwards, rather than downwards as from field sprayers. Spray from this type of equipment can be very prone to drift if the discharge direction and volume is not well matched to the canopy height or condition. Drift of smaller droplets becomes more of an issue when these droplets are deflected over the top of the canopy, where they can be carried by the above-canopy wind to significant distances.

Air Settings:

Adjusting air settings to match weather and canopy conditions is critical in ensuring proper spray coverage.

Air settings are a combination of air direction, air speed and air volume.

Air direction can be adjusted using towers, deflectors or repositioning air outlets to direct air into, not under or over, the target canopy.

Deflectors can also counteract the spin associated with radial fan sprayers, where the turn of the fan directs air upward on one side and downward on the other.

Air speed is measured in metres per second, and has less impact on canopy penetration than air volume (or airflow rate), which is measured in cubic metres per second.

When spraying orchards, applicators should keep air speed low and air volume high to form openings in the canopy, expose the lower surface of leaves and only just move the leaves in the next row.

In vineyards, studies have shown that excessively high air volumes reduce spray-side deposition by blowing spray through the target in a process known as "slip-streaming."

This principle would apply to cane, shrub and berry bush spraying as well.

The ideal settings are situation specific, depending on the ambient wind, the size and density of the canopy being sprayed and the capabilities of the airblast sprayer.

More air does not imply better coverage. Too much airflow tends to carry droplets over or through the canopy, increasing the potential for off-target deposition and reducing coverage.

Research in vineyards has shown that reducing the average airblast fan speed by 25% can potentially eliminate 75% of spray drift without compromising coverage.

Air settings can be adjusted by:

- Using a lower power-take-off (PTO) speed and adjusting nozzle rates to compensate for any reduced pressure or travel speed. The technique called Gear Up – Throttle Down (GUTD) may be effective for reducing air speed in some airblast sprayer types.

- Adjusting the blade pitch, if possible.

- Changing the fan speed using a gear box, if present.

- Installing a hydraulic motor to control fan speed.

- Using an air intake limiting device such as the Cornel "doughnut."

- Slowing travel speed to give spray-laden air an opportunity to displace the air in the canopy. Reduced travel speeds improve spray penetration.

Further information on airblast sprayer calibration can also be found at Sprayers101.com.

Nozzle Orientation

During calibration, ensure nozzles not directed at the target are turned off.

For dual-fan orchard sprayers, the nozzle orientation plays a larger role in mitigating spray drift than fan location. This means:

- closing or redirecting nozzles that are off target

- adjusting angles into the carrier air

- ensuring the desired flow and spray pattern is established

For fan-driven airblast sprayers, the counter-clockwise turn of the fan carries spray up and over the canopy on the right-hand side and downward on the left. The best spray pattern occurs when nozzles are angled to counteract the spin: the right-hand nozzles are set to horizontal with the top two set 20° downward, and the left-hand nozzles are aimed 45° upward. Spin may not be as pronounced on dual-fan or turbine-driven sprayers.

Spray should only be directed towards the crop when spraying an outside row. Turn off outward pointing nozzles at row ends and outer rows.

Forward Speed (Working Rate)

Timing is very important; it incorporates pest growth stage, pest pressure, weather conditions and working rate. Given the limited timeframe, it is tempting to speed through an application, but as the canopy fills, it is increasingly important to give the spray time to penetrate.

For example, in apple orchards high air volume/low air speed used at low forward speed results in a large increase of air volume penetrating trees. Forward speed adds to the wind effect, so travelling at 5.5 km/hr can potentially add 5.5 km/hr to the wind speed at the nozzle and result in smaller droplets and increased spray drift. Ways to save time include:

- investing in faster filling systems

- using an over-the-row sprayer

- using moderately lower carrier volumes or refill vehicles

- reducing row spacing and adjusting hedging/pruning practices

Figure 22 - Text description

Photo of an axial fan airblast sprayer without proper nozzle calibration producing a large drift cloud as it sprays orchard trees

Figure 23 - Text description

Photo of the same axial fan airblast sprayer with proper nozzle calibration showing minimal drift as it sprays orchard trees

Special Equipment

Sensors

More growers are using automated canopy sensing systems that reduce waste by closing individual nozzles when there are gaps in the canopy. Traditional practice in airblast orchard spraying is to close nozzles that spray over or under the canopy and to choose nozzles with progressively smaller outputs further from the centre position of the boom. This is sound advice, providing that the top of the tree receives sufficient coverage.

Chemigation

Chemigation drift management requires consideration of the sprinkler type, the release height of the spray and the meteorological conditions at the time of application. The use of a high-pressure end gun can increase spray drift if the spray is projected upwards as fine droplets. Any increase in spray release height increases spray drift potential.

Figure 24 - Text description

Photo of a high-clearance irrigation sprinkler spanning a length of approximately 200 m. Water is being sprayed onto the field from drop-tubes approximately two metres above the crop.

Spray Buffer Zones

A spray buffer zone is the downwind distance between the point of direct pesticide application, usually the end of the spray swath, and the nearest boundary of a sensitive habitat.

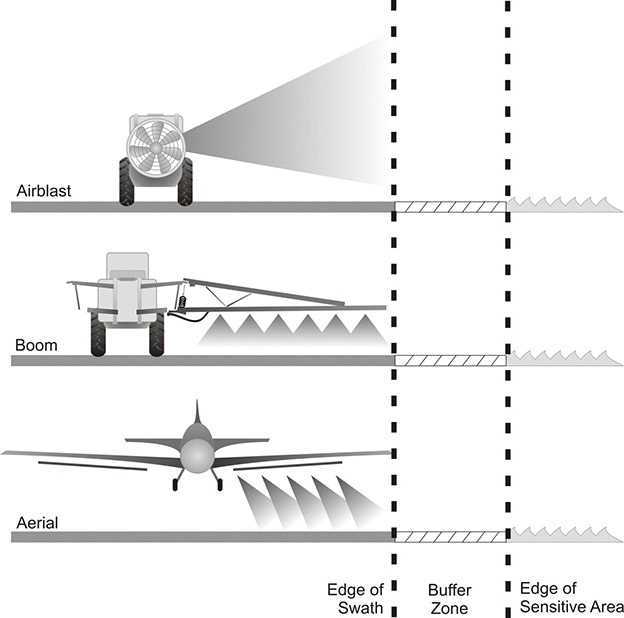

(Figure courtesy of Ontario Ministry of Agriculture and Food)

Figure 25 - Text description

Illustration of pesticide spraying with an airblast sprayer, field boom sprayer and aircraft showing the spray buffer zone (no-spray zone) that is between the edge of the spray swath and the edge of the sensitive habitat.

Applicators can reduce the downwind off-target deposition of a pesticide to a level that is no longer a risk by observing a spray buffer zone between the edge of the swath and the edge of a sensitive habitat.

The size of the spray buffer zone depends on several factors, including the method and conditions of application (for example, field sprayer, airblast, aerial), the nature of the product being applied and the type and sensitivity of the habitat requiring protection (for example, riparian zone, open water). The spray buffer zone specified on the product label usually reflects the conditions that are expected to produce the highest level of spray drift. These labelled spray buffer zones can be reduced without compromising adjacent habitats to reflect conditions at the time of spraying. Applicators wishing to modify their spray buffer zones can use the online PMRA Spray Buffer Zone Calculator tool.

Check the product label. Spray buffer zones may be needed to protect sensitive habitats downwind from your spraying area.

Sensitive Habitats

This document focuses primarily on minimizing spray drift for the protection of sensitive environmental habitats, as opposed to non-target crops. Sensitive environmental habitats are areas that contain species that can be adversely affected by a pesticide.

A sensitive habitat may be aquatic (including permanent and seasonal water bodies), terrestrial (for example, shelterbelts and woodlots), or a combination of both (for example, wetlands, riparian zones, wet meadows, marshes, swamps, fens, and bogs).

A sensitive habitat requires protection from spray drift if it is downwind from the treatment area. An area that is upwind or crosswind to the treated area, does not require further protection from spray drift but may still require protection from other types of off-target deposition such as run-off.

Sensitive Aquatic Habitats

A sensitive aquatic habitat is defined as an area adjacent to or within a spray area that consists of any form of water, such as lakes, rivers, sloughs, ponds, prairie potholes, creeks, marshes, streams, reservoirs and wetlands and estuarine/marine habitats.

Figure 26 - Text description

Photo of farmland with riparian vegetation at the end of the field that borders a river in western Quebec.

For the purposes of applying spray buffer zones, aquatic habitats are classified under two general categories. Permanent water bodies, such as lakes, are present throughout the season. Seasonal water bodies such as sloughs, may hold water for only part of the season, and may not have water present at the time of application. If they are dry, they do not need to be protected by the application of spray buffer zones or other means.

NOTE: Temporary bodies of water resulting from flooding of, or drainage to low-lying areas are not considered sensitive aquatic habitats and thus do not need to be buffered.

The depth of the water body is the most important characteristic for determining the appropriate spray buffer zone size. With increasing depth, the aquatic habitat is able to receive a higher deposit of the pesticide but maintain a lower average pesticide concentration that will not pose a risk to sensitive species. In practice, the depth of the water body will be visually estimated by the applicator based on the deepest part and recorded on the application record.

To account for the variations in water depth of permanent and seasonal habitats, the pesticide label indicates the spray buffer zone for water bodies less than 1 m deep and greater than 1 m deep.

Sensitive Terrestrial Habitats

Terrestrial habitats vary widely in their characteristics—they can include grasslands, forested areas, shelter belts, woodlots, hedgerows, riparian areas and shrublands. Wetlands and riparian zones (the area between a distinctly aquatic and terrestrial habitat) possess characteristics of both aquatic and terrestrial habitats and may support both aquatic and terrestrial species. In the interim, the spray buffer zones on product labels apply to all sensitive terrestrial habitats. Further modification of labelled spray buffer zones for terrestrial habitats is possible based on application techniques and weather conditions at the time of the application.

Figure 27 - Text description

Photo taken in British Columbia of potato plants in several rows bordered by a terrestrial habitat consisting of shrubs and trees.

Spray Buffer Zone Modifiers

Spray buffer zone modifiers are used to refine the labelled product-specific spray buffer zones based on local weather conditions and sprayer configuration at the time of pesticide application.

Applicators that use the spray buffer zone modifiers must fill out an application record to document the weather conditions, sprayer configuration, and modified spray buffer zone distance as part of the documentation for labelled spray buffer zone reduction. Records must be retained for at least one year following application.

Applicators can easily calculate modifications of labelled spray buffer zones using the PMRA Health Canada online Buffer Zone Calculator, an interactive tool that calculates the spray buffer zone reduction.

The calculator incorporates the elements of spray drift reduction such as wind speed, wind direction, sprayer configuration and weather conditions. The factors that affect the modified spray buffer zones differ among application methods and are reflected in the following table:

Factors that affect modified spray buffer zones

Column one lists the factors that affect spray buffer zones; other columns list the application method and whether or not the factor in that row affects the size of the buffer zone required.

| Factor | Field sprayer | Chemigation | Airblast | Aerial |

|---|---|---|---|---|

| Wind speed | Yes | Yes | Yes | Yes |

| Spray quality | Yes | Yes | No | Yes |

| Boom height | Yes | No | No | No |

| Sprayer type | No | Yes | Yes | No |

| Shrouds and cones on booms |

Yes | No | No | No |

| Temperature and humidity |

No | No | No | Yes |

| Low-drift nozzle | Yes | No | Yes | No |

| NOTE: Modified spray buffer zones cannot be less than 1 m. | ||||

Hold on to your Spray Buffer Zone Modifier Record for at least one year from time of spraying

Spray Planning

When agricultural operations are planned, it is important to carefully consider spray strategies to avoid spray drift. Applicators who use buffer zone reductions in response to on-site spray conditions must maintain their application records in order to justify the reduced buffers.

Pre-spray Planning

The following are some suggestions for preparing your spray management plan:

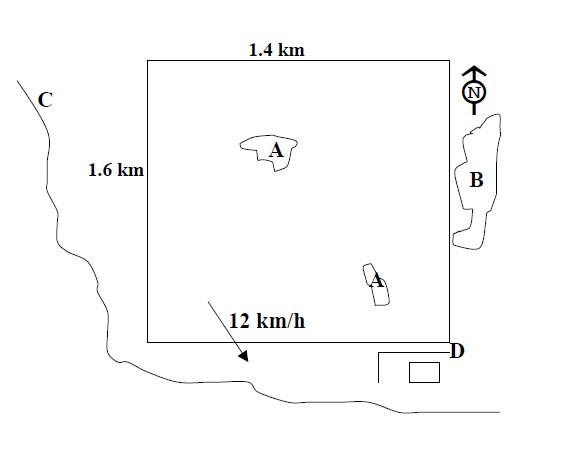

- Sketch the spray area with field sizes clearly marked. Ensure that field orientation to north is identified. A hand-held GPS unit is a useful tool to accurately survey the spray area boundaries by recording the block boundaries in UTM coordinates.

- Sketch sensitive habitats relative to the spray area. Identify sensitive habitat type (water bodies, terrestrial, riparian). For sensitive habitats outside the spray area, note closest distance from the field boundary. Following is an example of a field map and notes:

Figure 28 - Text description

Sketch of a spray management plan indicating the field size and shape, adjacent aquatic habitats (stream and ponds), terrestrial habitat (shelterbelt) and wind direction.

Notes:

- Pond Depth less than 1 m

- Pond Depth 1-3 m

- Stream Depth 1-3 m

- Shelterbelt

- Estimate water depth associated with each permanent water body and note on sketch map. Applicators should identify temporary water bodies (sloughs, creeks) and note changes in water depth (if applicable) or boundaries at the time of spray. Once completed, this map can serve as the basis for future spray operations.

- Ensure nozzle spray quality conforms to that recommended on the product label.

- Check nozzles for wear and replace as necessary.

- Calibrate sprayer output for application speed.

- Check spray pattern to ensure deposit uniformity.

- Enter sprayer configuration data on application record.

- Enter product application data on application record.

- Categorize water body depths and calculate reduced buffer zones on the day prior to the spray. Record and note on sketch.

Spray-day Planning

- Record time, wind speed, direction, temperature and humidity at downwind edge of field prior to spraying.

- Sensitive habitats that are upwind need no buffering. For instance, with a north-west wind (in other words, a wind component from the north and west), sensitive habitats along the north and west sides of the spray area would require zero spray buffers. Sensitive habitats within the spray block (shown as A on the example field map) would require a buffer along the north and west edge but not along the south and east edge. Sensitive habitats outside the spray area and along the south and east boundaries (B, C, D on the example field map) would require buffers.

- Calculate modified buffer zones for aquatic and terrestrial habitats using the Health Canada Spray Buffer Zone Calculator. Record on sketch map and application record.

- Use sketch map as reference during spray operation.

- Areas that are not sprayed because they were within the buffer zone can be sprayed when the wind direction changes and they become upwind.

- When spraying is complete, record time and meteorological conditions.

- Maintain application record for future reference.

Definitions

- Ditch:

- A depression or trench, either natural or constructed, that conveys drainage water away from a property area. Ditches are characterized by not having any headwaters, may be permanently or intermittently wet and do not form part of the natural waterways that drain a watershed. They often undergo mechanical or chemical maintenance and may or may not contain aquatic life.

- Forest:

- A wooded area that is larger than 500 hectares.

- Grassland:

- An area with herbaceous plants dominated by grasses rather than large shrubs or tress. Grasslands may include hay lands, pastures and prairies.

- Hedgerows:

- Lines or groups of trees, shrubs, perennial forbs, and grasses planted along field edges or other unused areas.

- Non-permanent water body:

- An area holding water for only part of the year. These bodies can be seasonal or temporary.

- Permanent water body:

- An aquatic area holding water all year round. Most lakes, ponds, rivers and the oceans are examples of this kind of aquatic habitat.

- Seasonal water body:

- An area covered with water only part of the year and for which flooding occurs in subsequent years on a regular basis, depending on climatic conditions and patterns. An example is an aquatic area with water in the spring and summer but which dries out in the fall and winter.

- Sensitive habitat:

- Any area containing or comprised of organisms that can be adversely affected by the pesticide product being applied. A sensitive habitat may be aquatic (such as a lake, pond, stream, river, creek, slough, canal, prairie pothole, marsh, reservoir, or wetland), terrestrial (such as a forest, woodlot, shelterbelt, meadow, or hedgerow) or a combination of both (such as riparian zones, wet meadows, swamps, fens, and bogs).

- Shelterbelt:

- A barrier consisting of one to several rows of trees or shrubs on agricultural fields whose purpose is to reduce soil erosion by wind, increase moisture for crop growth due to snow trapping and reduced moisture loss through evaporation, reduce wind damage to crops and provide wildlife habitat and shelter.

- Shrubland:

- An area covered by shrubs, defined as perennial woody plants usually less than 10 m tall with branches near ground level but with no distinct trunk. Shrubs may be deciduous (for example, hawthorn) or evergreen (for example, holly).

- Spray buffer zone:

- The distance between the point of direct pesticide application at the downwind end of the swath and the nearest downwind boundary of a sensitive habitat, unless otherwise specified on a product label. It mitigates non-target deposition of spray.

- Spray drift:

- The wind-induced movement of spray particles (droplets) away from the spray swath during application. This definition does not include vapour drift or other mechanisms of off-target deposition such as run-off. In this document, 'spray drift' refers only to particle drift.

- Temporary water body:

- An area covered with water only some of the time where the water-holding period is not regular or seasonal. An example is a lower part of a field flooded after a heavy rain or run-off.

- Wetlands and riparian zones:

- Wetlands and riparian zones (the area between a defined aquatic and terrestrial habitat) possess characteristics of both aquatic and terrestrial habitats. These types of habitats include wet meadows, marshes, swamps, fens, and bogs. The primary characteristic of these areas is water covering at, or near, the surface of the soil for part or all of the year. Wetlands and riparian habitats may support both aquatic and terrestrial species.

- Woodland (Woodlot):

- A wooded area between 4 and 500 hectares. Examples of woodlots include Christmas tree plantations, regenerating tree stands and tree areas such as parklands and private woodlots.