Products Used in Preventive Conservation – Technical Bulletin 32

Jean Tétreault

CCI Technical Bulletins

Technical Bulletins are published at intervals by the Canadian Conservation Institute (CCI) in Ottawa as a means of disseminating information on current techniques and principles of conservation of use to curators and conservators of Canada’s cultural objects as well as collection care professionals worldwide. The author welcomes comments.

Abstract

This Technical Bulletin provides a critical review of products typically used for the display, storage and transportation of objects by explaining how certain products can affect objects and their preservation, and it proposes guidelines for minimizing damaging effects. Products used to treat objects are not covered here, nor are electronic features such as lighting and security devices.

Author

Jean Tétreault studied at Montréal University where he received a Master’s degree in Analytical Chemistry in 1989. That same year he joined CCI, where he currently works as a conservation scientist in the Preservation Services Division. His main research interests focus on pollutants, products used for display and storage, paper degradation and passive environmental controls in collections. Results of his research have been published in various peer-reviewed journals. He has given more than 100 seminars in Canada and Western Europe on preventive conservation issues such as lighting, environmental guidelines, and exhibit and storage materials. Jean is the author of the book Airborne Pollutants in Museums, Galleries, and Archives: Risk Assessment, Control Strategies, and Preservation Management, published by CCI in 2003. Since 1998, he has also been a board member of the Indoor Air Pollution Working Group, which holds conferences every two years.

Table of contents

- Abbreviations

- Principles for selecting products for preventive conservation

- List of products used in preventive conservation

- Adhesives and tapes

- Boards and panels

- Coatings, laminates and films

- Containers

- Cushioning and padding

- Fabrics

- Films, sheeting, sleeves and envelopes

- Gaskets

- Glazing and glazing films

- Lines, twill tape, strings and wires

- Sealants

- Tubing, tubes and rods

- Where to buy products for preventive conservation purposes

- Tests for products used in preventive conservation

- Examples of preventive conservation practices

- References and further readings

Disclaimer: The information provided here is based on the current understanding of the issues presented. The guidelines given in this Technical Bulletin will not necessarily provide complete protection in all situations or protection against every possible adverse effect caused by the use of products in museum contexts.

Abbreviations

- ABS

- acrylonitrile-butadiene styrene

- CAMEO

- Conservation and Art Material Encyclopedia Online

- CCI

- Canadian Conservation Institute

- cm

- centimetre

- CPVC

- chlorinated poly(vinyl chloride)

- EPDM

- ethylene-propylene-diene monomer

- EPS

- expanded polystyrene

- EVOH

- ethylene vinyl alcohol

- g

- gram

- HDPE

- high-density polyethylene

- HDO

- high-density overlay

- ISO

- International Organization for Standardization

- LDPE

- low-density polyethylene

- LLDPE

- linear low-density polyethylene

- MDO

- medium-density overlay

- mL

- milliliter

- mm

- millimetre

- PC

- polycarbonate

- PE

- polyethylene

- PET

- poly(ethylene terephthalate)

- PETG

- poly(ethylene terephthalate) glycol

- pH

- potential hydrogen

- PMMA

- poly(methyl methacrylate)

- PP

- polypropylene

- PS

- polystyrene

- PTFE

- poly(tetrafluoroethylene)

- PUR

- polyurethane

- PVC

- poly(vinyl chloride)

- PVDC

- poly(vinylidene chloride)

- RH

- relative humidity

- SBR

- styrene-butadiene rubbers

- SDS

- safety data sheet

- SPNHC

- The Society for the Preservation of Natural History Collections

- TVOC

- total volatile organic compounds

- µg

- microgram

- µm

- micrometre

- UV

- ultraviolet

- VOC

- volatile organic compound

- XLPE

- crosslinked polyethylene

- XPS

- extruded polystyrene

Principles for selecting products for preventive conservation

This section describes the principles that guide the selection of products typically used for display, storage and transportation. Safe use of products depends not only on their stability, but also on the context and way in which they are used.

Key terms related to products

Enclosure

A structure or covering that completely surrounds and encloses a limited volume of space and in which one or several museum objects may be contained. Examples include plastic bags, display cases, storage cabinets, boxes and transportation crates. Note that an enclosure is constructed or assembled using one or more products.

Material

A substance that makes up an object or a product, e.g. copper, oak and cotton are materials.

Object

In this context, as opposed to products, an object is an item that is collected by museums, archives or private individuals, because the item is judged by society, or some of its members, to be of historical, artistic, social or scientific importance. Objects can be composed of one or more materials and can be movable (such as archaeological and historic artifacts, paintings, books, archival documents, furniture, costumes, etc.) or immovable (such as architectural interiors, monuments and historic buildings).

Pollutant

In this context, the term “pollutant” is used to describe any compound originating from a product that reacts with objects or becomes strongly bonded to them. Pollutants reach objects as:

- airborne pollutants such as compounds in the form of gases, vapours, aerosols or particles (dust, smoke and spores)

- falling debris (loose material falling on objects)

- compounds transferred by contact (i.e. surface-to-surface transfer)

More general information about pollutants can be found on the CCI website under Agent of deterioration: pollutants.

Product

In this context, the term “product” describes a manufactured or processed substance composed of one or many materials, which can be used alone or assembled with other products into more complex finished items. For example, plywood is a product made of two materials (wood and adhesive) and can be used as is as a platform or can be assembled with other products to make display cases or packing crates.

The ideal product versus reality

Ideally, products used in museums should not contain pollutants and should have long-term chemical and physical stability. Modern glass meets these criteria fairly well but not completely. Metals such as steel plates might also be considered ideal products because of their durability and their absence of off-gassing. However, most uncoated metals will tarnish slowly with oxygen and water vapour in the environment and can eventually stain objects through contact (Figure 1).

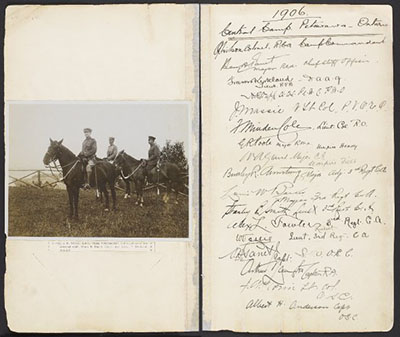

© Government of Canada, Canadian Conservation Institute. CCI 120171-0002

Figure 1. Paper stained by corrosion of a steel paperclip.

Many plastics are far from perfect for museum and archival use. For example, numerous types of plastic sheets or panels are expected to embrittle or weaken to such an extent that within 30 to 50 years they are liable to tear or crack under stress. Some plastic sheets, such as certain types of polyethylene sheeting, become brittle after only five years. Consult Plastics – gifts of the 20th century and challenges of the 21st century.

Although some products have deficiencies, using only ideal products for all applications can be restrictive and expensive. Fortunately, for many applications, products do not need to be chemically and physically perfect, such as when the objects are non-reactive (or slightly reactive) or robust or are not located close to emissive products. Thus, many less-than-ideal products can still be considered because of their other benefits, such as low cost, availability, functionality or sustainability.

Many products can be used in the care of objects in museum collections with a low risk of damage to many types of objects. However, before choosing your materials, a proper risk assessment needs to be made.

Assessing the risks of damage

Understanding the nature of both the objects and the products that will occupy the same environment is important when assessing the risk of any potential interaction between them.

Assessing the vulnerability of the objects

In order to identify risks of damage from products to objects, it is useful to recognize which type of object is most susceptible to various pollutants or to degradation mechanisms and the types of damage that may occur. Tables 1 to 3 detail:

- damage that occurs to objects by airborne pollutants emitted by products (Table 1);

- damage that occurs to objects by direct contact with products (Table 2); and

- damage that occurs to the object by incorrect use of products (Table 3).

Use these tables to determine if your objects could be at risk when sharing the same environment or context with potentially harmful products.

| Objects and types of damageTable 1 note1 | Pollutants | Products that can release the pollutants |

|---|---|---|

|

Acetic acid |

|

|

Adipic acid |

|

|

Ammonia |

|

|

Benzoic acid |

|

|

Formic acid |

|

|

Hydrogen peroxide |

NB: Peroxides can oxidize aldehydes and form carboxylic acids such as acetic and formic acids. |

|

Hydrogen sulfide; Carbonyl sulfide |

|

|

Nitrogen oxides |

|

Table 1 note

- Table 1 note 1

-

Damage reported in ambient conditions, often in airtight enclosures. No accelerated methods were used. High relative humidity (RH) will increase the rate or the extent of damage in most cases

| Types of damage on objectsTable 2 note 1 | Objects at risk, with details of damage | Product and/or compounds within product causing damage |

|---|---|---|

|

|

|

|

|

|

|

|

|

|

|

Products or compounds that risk sticking to objects include:

|

|

Various types of objects, including:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Table 2 note

- Table 2 Footnote 1

-

Damage reported in ambient conditions. No accelerated methods were used.

| Types of physical damage to objects | Causes |

|---|---|

| Breakage or cracks on objects |

|

| Deformation of the object |

|

| Surface abrasion or grooves |

|

| Surface alteration and dust generation |

|

Assessing potential threats from products

In order to evaluate potential risks to objects from specific products, various information about the products should be consulted and assessed, as discussed below.

Chemical composition

Determine the product’s chemical composition and its formation process. This will help identify any potential short- or long-term source of pollutants (consult Tables 1 and 2).

If both the object and the product have a similar composition (e.g. a wooden sculpture on a wooden base), there will usually be no significant damage observed over time.

Physical properties

Determine the product’s physical properties that are useful for its function or can have an impact on the object (e.g. dimension, porosity, strength, flexibility, abrasiveness of the surface). If the product is used to physically support an object, it must provide adequate support and a sufficient area of contact to avoid deformations or stresses due to gravity or handling; the points of contact should not cut, scratch, dent or deform the object’s surface; and the product should be strong enough to support the weight. Consult Table 3 for details on various types of physical damage that can be caused by incorrect use of products.

Rigid, tough products are often padded where they come into contact with an object. For more details on these issues, consult the CCI resource Mount-making for Museum Objects (Barclay et al. 2002).

Changes to properties over time

The long-term qualities or properties of most products vary, especially those composed of organic materials. Because most products are not designed for the preservation of museum collections, their use in some cases can lead to unintended damage. For example, products used inside a new display case can initially emit high levels of pollutants causing corrosion on objects within a few weeks or months. However, these levels usually diminish over time. A change in a product’s properties over time is caused or influenced by four factors:

- the chemical properties of the product;

- the physical properties of the product;

- the environment to which the product is exposed (e.g. RH, temperature, light and oxygen); and

- the context of its use (physical forces exerted on the product, such as tensions, compressions, load-bearing stresses, etc. [consult Table 3]).

Because certain deleterious properties of a product may evolve to become significant or insignificant over time, the product may be used in proximity to objects during the time frame when it does not cause significant adverse effects, while avoiding it otherwise.

Volatile emissions

One property of products that is of concern in preventive conservation is the emission of pollutants over time. Emissions tend to follow typical patterns. Generally, solvent- or water-based products (e.g. paints, varnishes, coatings, adhesives, caulking) release more volatile compounds when fresh (recently applied) than after a few weeks. Depending on a product’s emission rate at different phases of its life cycle, it may be possible to use the product under certain conditions and not others.

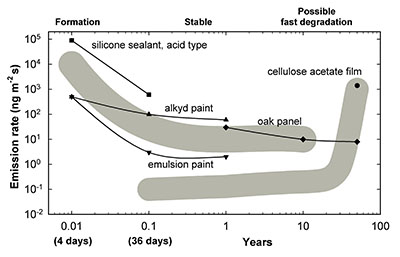

There are two typical phases in a product’s life cycle: a formation phase characterized by high emissions, followed by a stable phase. In addition, there is sometimes a third phase in which rapid degradation after a period of time causes significant emissions. Figure 2 represents these phases based on products emitting acetic acid.

© Government of Canada, Canadian Conservation Institute. CCI 120171-0003

Figure 2. Emission of acetic acid from products over time. For acetoxy cure silicone sealants, alkyd paints and emulsion paints (acrylic, vinyl, vinyl-acrylic, vinyl ethylene, acrylic-styrene), emissions taper off after one month of airing out. Cellulose acetate film is initially stable when made, but after 40 years it starts off-gassing significantly.

Figure 2 – text version

| Years | Alkyd paint | Acetoxy cure silicone sealant | Oak panel | Cellulose acetate film | Emulsion paint | General trend of decreasing emission (grey band) | General trend of increasing emission (grey band) |

|---|---|---|---|---|---|---|---|

0.01 (4 days) |

500 |

90000 |

- | - | 500 |

10000 |

- |

0.1 (36 days) |

100 |

610 |

- | - | 3 |

30 |

0.1 |

1 |

60 |

- | 30 |

- | 2 |

10 |

0.1 |

10 |

- | - | 10 |

- | - | 10 |

1 |

50 |

- | - | 8 |

1400 |

- | - | 1000 |

100 |

- |

- |

- |

- |

- |

- |

- |

During the formation phase, liquid products, such as solvent- or water-based paints and adhesives, can generate significant amounts of volatile compounds when they are being applied and while still fresh. The same is true for products formed by chemical processes, such as room-temperature-vulcanizing (crosslinking) silicone, two-part urethane paints and two-part epoxy paints.

Many types of damage caused by high levels of volatile compounds reported in the conservation literature relate to objects that were stored or displayed in newly made enclosures. Corrosion or efflorescent compounds are usually noticed within the first three months of the object being placed in the inappropriate enclosure. Exposure to high concentrations of volatile compounds may not result in visible damages or mechanical changes in objects in the short term but can initiate chemical alterations that could affect them in the future.

After the initial period of curing or evaporation, typically three to four weeks, many products will enter a stable phase. In this phase, they typically release only a steady, low level of pollutants resulting from the ongoing processes of hydrolysis, oxidation or thermal degradation. Many products in this steady-state phase are generally safe to use in enclosures. Most coated wood and plastic products that release organic acids fall into this category. There are some exceptions to this rule: uncoated oak and cedar are affected by hydrolysis and release high amounts of organic acid vapours well into the stable phase. For example, a 50-year-old piece of oak will still have a noticeable smell of vinegar and can contribute to the corrosion of lead. Another example is the continual release of significant amounts of organic acids by oil-based paints that cure slowly over a long period of time (by oxidative polymerization). Formic acid released by these coatings can affect paper documents over the long term.

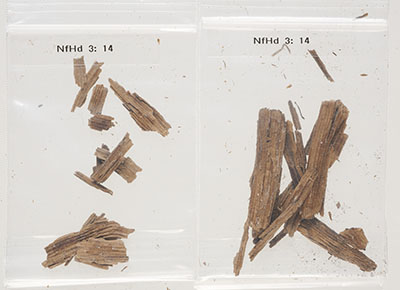

Although some products are not recommended for use during the early phase of their life cycle, it is quite the opposite for others. For example, some products—and objects—deteriorate after a period ranging from a few years to a few decades, and this deterioration causes an increase in the rate at which pollutants are emitted. Cellulose acetate sheets fall into this category as they suffer accelerating deterioration due to acid hydrolysis and release acetic acid. Low-cost polyurethane foam, often used as cushioning in transport packing crates, is also problematic at the end of its life cycle. As the foam degrades by photooxidation and hydrolysis, the foam progressively turns a yellowish-brown colour, which could stain an object by contact and can emit corrosive acids (it will also slowly loose its physical properties, as further discussed below).

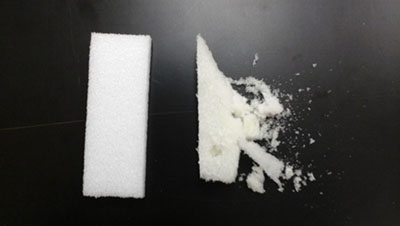

Changes to physical properties

The physical properties of products tend to reflect their specific life-cycle phase. At the formation phase, organic products, such as adhesives and coatings, are typically fluid. At the stable phase, the products tend to maintain their desired properties. This stability is often extended by the use of additives such as antioxidants. However, cumulative chemical deterioration, fatigue or stress will eventually cause the physical properties of products to change. Some products or materials show chemical changes fairly quickly (e.g. within months or a couple of years); they are sometimes called “unstable” because of this. For example, acidic paper noticeably degrades at room temperature within a few decades, becoming yellower and much more brittle and fragile with age. As mentioned above, polyurethane foam will become brittle, no longer maintaining its original cushioning ability after only a few months (if receiving shocks or compressions) up to a few years. A polyurethane gasket is another example of a product with a limited lifespan of about 10–20 years, changing from rubbery to brittle (as shown in Figure 3) and thus losing its gasketing ability.

© Government of Canada, Canadian Conservation Institute. CCI 124703-0081

Figure 3. Some materials have a limited lifetime. For example, a 20-year-old urethane gasket, shown here, that was kept in the dark and in stable environmental conditions is now falling apart.

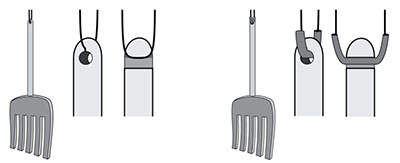

Assessing the context

The probability and extent of damage to an object by a product’s emissions also depends on their context. This context can be identified by three main parameters:

- contact. the proximity between a product and an object and whether or not they touch each other

- enclosure: the surface area of the emissive products in the enclosure compared to the volume within the enclosure and its airtightness

- length of exposure: the length of time a product and an object occupy the same location and can interact with each other

Table 4 summarizes the risks of pollutant damage on collections stored in different contexts: with the product and object in contact or not, and in different enclosure designs (in an enclosed, either partially or fully airtight space, or in an open space, such as a room).

| Enclosure | Non-contact | Contact |

|---|---|---|

| Room or large and well-ventilated space |

|

|

| Small enclosure not fully airtight (1 to 10 air exchanges per day) |

|

|

| Small enclosure fully airtight (leakage rate below 1 air exchange per day) |

|

|

Table 4 note

- Table 4 Footnote 1

-

The risk is high in small enclosures if the product is a freshly applied solvent-based product (e.g. adhesive and paint) or a freshly applied chemically cured product (e.g. some silicone sealants).

Contact

Physical damage can occur at contact points between the object and the product. The product may provide an inadequate contact surface, such as one that is narrow or sharp (resulting in unequal pressure points) or that is abrasive or too hard. A hard surface can damage a softer or weaker one. In the case of a hard or an abrasive surface, vibrations can cause damage if the product and object slide or chatter against each other.

Chemical reactions can also occur at contact points when a product contains harmful compounds that migrate to the surface and transfer to the object or react with it. The transfer of pollutants can be avoided by choosing a different product or by using a good gas barrier interleaf. A list of types of damage to objects caused by contact with a product is listed in Table 2. More information on interleaves can be found in Interleaves – discrete and efficient.

Undesirable transfer also happens when an object is in contact with a sticky product, such as freshly applied paint (less than four weeks old), dark-coloured paint softened because of the nature of colourant added (this can happen in the case of paint up to a few years old), leatherette or old flexible PVC. In time, parts of the object such as fragile coatings, laminations and inlays can become detached and remain stuck to the product. The reverse can also happen where solid compounds from the product can become stuck to the object, as shown in Figure 4.

© Government of Canada, Canadian Conservation Institute. CCI 124703-0082

Figure 4. An object made of acrylic was placed for a few weeks on a surface that had been painted a dark brown colour a year before. When the object was removed, fragments of the paint layer remained strongly adhered to the object.

Compounds can also transfer from objects to products depending on the nature of the object and this is particularly likely with dirty, acidic or fatty/oily objects. Compounds from such objects can stain their mount, their container or even their label, affecting the look of the display and its capacity to be reused, since stained products can stain or damage other objects with which they subsequently come into contact.

Finally, contact between dissimilar metals can cause galvanic corrosion. An electrochemical cell is created where the metals act as anodes and cathodes in the presence of an electrolyte (water with salt). The corrosion affects the anodic metal, i.e. the more reactive or less noble metal. This process is usually negligible in most indoor situations but can be observed in humid environments. For example, if a large copper object is in contact with an iron wire, the wire will corrode at the contact point when exposed to high humidity since iron is less noble than copper. The rust that developed on the iron will then stain the copper object. Metal-to-metal contact also risks causing physical abrasion of surfaces if some vibration occurs.

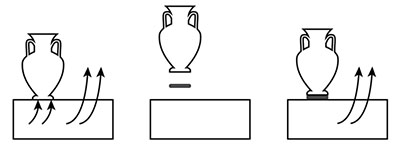

Enclosure

The different physical parameters of the enclosure will have an influence on the concentration of pollutants generated by a product used within it. The concentration of pollutants released by products can be expressed by a simple formula:

C = E A / V N

Where

C: concentration in the enclosure (μg/m3)

E: emission rate of the pollutant from the product (μg/m2h)

A: product surface area (m2)

V: volume of the enclosure (m3)

N: leakage rate of the enclosure (h-1)

From the formula, it can be seen that the most dangerous scenario is when a vulnerable object is placed in a well-sealed enclosure with a large surface area of an emissive product. At the other extreme, the risk of damage will be negligible when either a well-sealed enclosure does not contain emission products or a moderate amount of product-generated pollutants can be easily dissipated from the enclosure. In between, the risk of damage will vary between low and high.

For a more complete formula, one needs to consider extra parameters such as the concentration of pollutants outside the enclosure and the capacity of other products to sorb pollutants. More parameters can be added by considering the contributions of both space and time, such as the concentration gradient through the enclosure and the emission or sorption rate over time (which are also influenced by the RH and temperature).

In general, the use of enclosures such as small boxes and display or transportation cases is the best way to protect objects from outdoor pollutants, with the highest performance achieved when they are well-sealed, but this can expose them to pollutants released by products or other objects inside the enclosures. Table 5 describes in more detail how enclosures at three different levels of airtightness affect objects exposed to pollutants or to other agents of deterioration. Overall, tightly fitted enclosures are an excellent preventive conservation strategy on many fronts, provided that no off-gassing object or product is trapped inside the enclosure.

| Issue | Leaky enclosures (more than 10 air exchanges per day) |

Semi-airtight enclosures (1–10 air exchanges per day) |

Airtight enclosuresTable 5 note 1 (less than 1 air exchange per day) |

|---|---|---|---|

| Pollutants generated in the room or from the outside | Relies on the controls provided in the room. Dust deposition is a problem. |

Provides weak to good protection. | Provides the best protection against outdoor pollutants and pollutants related to human activities in the room. |

| Pollutants generated inside the enclosure from some of the objects or products | The leaks allow pollutant levels inside to remain low. | Levels inside will be low to medium. | Levels inside can reach maximum levels (equilibrium). This is usually a concern mainly for objects sensitive to carbonyls or sulfur compounds. Sorbents may help to reduce levels if the rate of emission is not too high. |

| Relative humidity(RH) | The RH will be the same as in the room. | It runs the risk of high localized RH if there is a cold enclosure wall. Moisture-buffering products will have low to moderate efficiency. |

Generally beneficial but there are risks of high RH or large RH fluctuations if the temperature fluctuates more than 5°C combined with no moisture-buffering surface or no product inside the enclosure to help buffer the RH change. There is a risk of high RH or mould if the stored objects are moist or if there is a cold enclosure wall. |

| Temperature | The temperature will be the same as in the room. | The temperature will be the same as in the room with a delay depending on the thermal insulation of the enclosure walls. Lamps inside enclosures increase the temperature (which will affect the RH). |

The temperature will be the same as in the room with a delay depending on the thermal insulation of the enclosure walls. Lamps inside enclosures increase the temperature (which will affect the RH). Keep the enclosure at least 10 cm (4 in.) away from an exterior (cold) wall or from the floor if the enclosure panel facing the wall or the bottom is not thermally isolated. |

| Insects | No protection from risk of infestation. | Little protection from risk of infestation. | Usually good protection from risk of infestation, although insects can perforate and go through products such as a thin plastic sheet. |

| Water leaks | Provides weak protection (depends on the design). | Provides weak to good protection (depends on the design). | Provides the best protection. |

| Consider leak-proof enclosure tops. Raise enclosures 10 cm (4 in.) above the floor. | |||

| Other agents of deterioration |

|

||

| Design and maintenance | Ventilation inside a leaky enclosure occurs by stack pressure, which allows dust infiltration. This can be counteracted using a dust screen or a positive-pressure filter system. Filters must be replaced periodically. | Can use a positive-pressure filter system. | Must use sealed seams and adequate gaskets. Ensure proper air circulation between objects and moisture and pollutant sorbents. Pollutant sorbents will provide additional long-term protection. Their periodic maintenance is required. Frequent need for access may limit airtightness. |

Table note

- Table 5 note 1

-

These require special attention to the assembly, in particular good-quality, carefully designed gaskets and sealants.

Length of exposure

It is not always possible to display or transport objects in pollutant-free enclosures. Sometimes enclosures may be made with potentially problematic products for different reasons such as design, the recycling of existing enclosures or simply due to financial and time constraints. A balance between optimum preservation and visitor access must be considered. For temporary use, some small imperfections in the set-up may be acceptable. However, for storage or permanent display, it is best to investigate the most appropriate products.

Instead of displaying an object in an exhibition case lacking an adequate long-term set-up, the object could be displayed for a limited time before being returned to better storage conditions. The same approach is used for exposure to light: an object can follow display–storage cycles where it is displayed only a few months per year and spends most of its time stored in an airtight archival box while other objects are displayed.

Risk management knowledge helps decision makers understand that they have some flexibility in selecting products for their specific contexts and needs. Some low-cost or easily accessible products that have a limited lifetime, such as 10 years or less, can still be used temporarily in some cases; for example, polyurethane foam can be used as inside padding within shipping crates for short-term loan programs. This flexibility can be useful for assigning priorities when resources are limited. However, there is a risk that a product suitable for a well-defined short-term purpose might be used beyond the planned time frame or is reused for another purpose without an assessment of the new context, leading to the possibility of the product causing damage to an object.

If the risks of using a product in a specific context cannot be assessed with confidence, it is best to err on the side of safety.

Monitoring

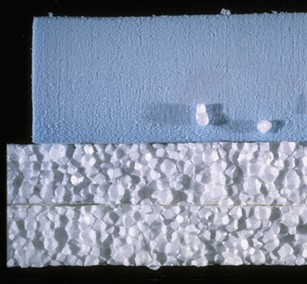

As in any management project, it is a wise practice to monitor whether products are being properly used to fulfil their initial purposes. Manufacturers do change the formulation and manufacturing processes of products over time, usually for the best. Unfortunately, from time to time, the change may affect properties that are a concern for museums; for example, the adhesive is more acidic or the lifetime of a product is shorter. A significant problem occurred in the 1990s when polyethylene foams degraded and crumbled after only a few years, as shown in Figure 5. No products are exempt from failures. This is true of foam as well as any other kind of product.

© Government of Canada, Canadian Conservation Institute. CCI 120171-0005

Figure 5. In the 1990s, one company made polyethylene foam board with a different process or formulation, which caused the dramatic degradation of the foam after a few years. Faulty foams (on the right) had an acrid smell. Some museums encountered this problem and had to replace all of the defective foam. The company has since fixed the problem (on the left), but a museum professional still has to wonder if it can happen again.

List of products used in preventive conservation

This section provides advice about choosing the right product from the wide range available and about avoiding situations that present significant risks of damage to objects. The products are grouped alphabetically according to function and material. A better understanding of products is just one part of the overall decision-making process when choosing products for preventive conservation—one must also consider the nature of the object and its context (placement, environment and intended use). Some products that are recommended for general use may present risks under certain conditions. For example, a product that could be used safely in an open space where ventilation is adequate may release unsuitably high levels of pollutants in an enclosure. Caution and critical assessment are always needed.

Disclaimer: The information provided in this Bulletin is based on the current understanding of the issues presented. The guidelines will not necessarily provide complete protection in all situations or protection against every adverse effect possibly caused by the use of products in museum contexts.

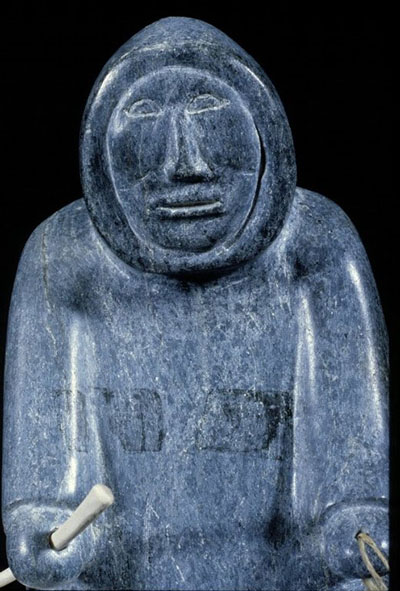

Adhesives and tapes

Applying adhesives or tapes directly to objects is unsafe and not recommended. Over time, adhesive on an object can become brittle or viscous, suffer bond failure and cause staining (Figure 6) that can be difficult to remove. Adhesives should be used only for assembling storage and display fittings, such as mounts, backings, boxes, sleeves and cases, and should not be applied directly to objects for the purpose of mounting or labelling. It can be assumed that all tapes will fail to adhere one day; it is just a question of time. In storage, it is not uncommon to find examples of old misguided practices; for example, labels that were applied directly onto objects now becoming completely dissociated (unglued). This not only causes stains but also puts very important information concerning the object (e.g. the accession number) at high risk of being lost. Similarly in displays, when objects have been glued to the wall, this has not only caused stains but also high risk of physical damage, because adhesive failure often occurs over time and results in the objects crashing to the floor.

© Government of Canada, Canadian Conservation Institute. CCI 120279-0005

Figure 6. Adhesive tape has left a residue on the soapstone sculpture.

Starch paste and methyl cellulose are examples of adhesives acceptable for use on paper artwork because they are removable if necessary (by a trained conservator) and do not stain. Even so, its use for preservation purposes is confined to attaching supportive hinges, and it is best applied under conservation supervision.

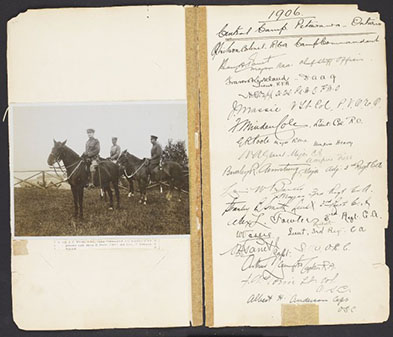

© Government of Canada, Canadian Conservation Institute. CCI 120078-0083

© Government of Canada, Canadian Conservation Institute. CCI 120078-0223

Figures 7a and 7b. Stains on a historic scrapbook caused by tape adhesive: before treatment (left) and after treatment (right). The stains are greatly reduced, and areas of damage are reinforced.

Unless the tape adhesive is part of the artist’s intent, all tape on objects that can be safely removed from objects should be done sooner rather than later. Tape adhered onto fragile substrates such as paper and photographs typically requires the expertise of a conservator (Figures 7a and 7b). If any doubt arises regarding the safety of the removal process, a conservator should be consulted. With archival documents, all sticky notes (e.g. Post-it) should be removed from direct contact but kept and preserved properly. The same applies for all staples and paperclips (Figure 1).

Adhesives used in an open space do not present a significant off-gassing problem. However, adhesives used in an enclosure should be allowed to off-gas or dry out (cure or set) for three to four weeks, especially if there is a large surface area to be glued, before sensitive objects are placed in the enclosure.

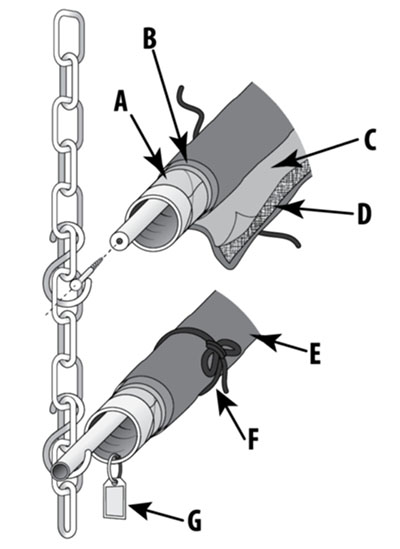

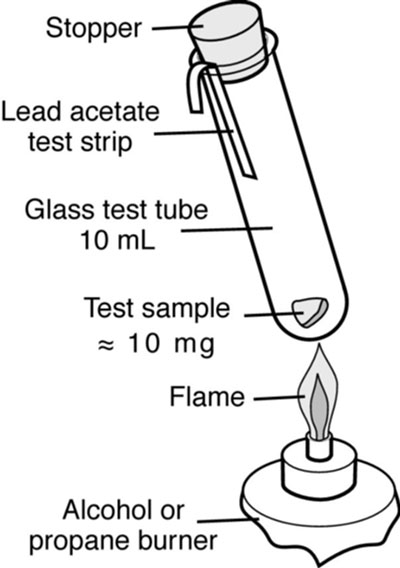

One way to avoid the constraint of drying time is to use hot-melt glue (hot glue sticks). This type of thermoplastic adhesive can be made up of a large variety of raw materials such as ethylene vinyl acetate, polyethylene and polyurethanes. Colourless hot-melt glues are preferable because they do not contain rosin or sulfur-based compounds. Rosin, a natural resin containing sulfur, yellows within a short period of time, while sulfur compounds tend to tarnish silver and discolour many organic objects (consult Test #1: Lead acetate test for detecting sulfur compounds for instructions on how to detect sulfur compounds in materials).

Sealants such as silicone and latex acrylic caulking are sometimes used as adhesives, e.g. when assembling cases, etc. More information on these products appears under Sealants.

Modelling clays, putties, waxes or clear gels (such as museum gel) are sometimes used to stabilize small objects against small shocks and vibrations. They are applied underneath the object, then the object is pressed down to the horizontal surface. This unobtrusive method can be a short- to medium-term solution for waterproof and smooth surfaces such as glass, metal or coated metal. However, it is not suitable for many types of porous objects such as wood, fabrics, unglazed ceramics, stone or historic glass (which can be porous) because the clay or gel contains organic or silicone oil which will leave stains or residues at the contact point. Some of these materials also contain sulfur compounds. The oil may be removable on non-porous surfaces but not on a porous object. Also, as the gel ages, it will lose its adherence properties. Risk analysis would be required to determine whether these products provide more benefit than risk, such as the possibility of failure and stains on the objects. Otherwise, the alternative would be the use of padded mechanical fasteners.

Alternatives to adhesives used for assembling storage and display fittings include mechanical fasteners such as nails, screws and hook-and-loop fasteners, such as Velcro, TouchTape, Aplix and Dura-Grip. Velcro products that contain an adhesive are not recommended because failure of the adhesive is likely an issue in the future. This is why it is preferable to use the type of Velcro that can be mechanically fixed (i.e. by sewing). For more information on mechanical fasteners, consult CCI’s resource Mount-making for Museum Objects (Barclay et al. 2002).

Boards and panels

Boards and panels are used extensively in a museum context to build structures such as shelving, display cases and shipping crates and to make storage trays, boxes and other enclosures, as well as backing boards, mounts and supports. The most common types of boards and panels are those that are plastic-based, wood and wood-based products (such as plywood) and paper-based products (such as matboard). Other types include metal panels, which are ideal for applications requiring strength and durability, and composite panels, which are ideal when looking for lightweight panels that remain rigid without bowing, even when used in extra-large dimensions. These are described in more detail below.

Plastic boards and panels

Note that transparent glazing materials for display cases and framing are discussed in their own section, Glazing and glazing films.

Poly(methyl methacrylate) (PMMA and acrylic)

Known as Plexiglas, Perspex, ACRYLITE or simply acrylic, this transparent sheet is popular for making display mounts (Figure 8) as well as cases (consult Glazing and glazing films for more information on display cases). The extruded type of acrylic sheet, which offers superior forming capabilities as compared to the cell cast type, is recommended for mount making since bending, forming and finishing are usually required. (In contrast, cell cast acrylic is recommended for framing and display cases because of its superior optical clarity.) Acrylic sheets in general can be joined using methylene chloride (solvent-dissolving acrylic) or with acetoxy cure silicone sealants or an epoxy. The resulting joints are strong but not strong enough to be load-bearing for medium to heavy weights; bending the acrylic, rather than joining pieces at an angle, is a stronger and less time-consuming alternative. Note that coloured translucent and opaque acrylic sheets are also available, as well as those with a mirrored look. Scratch-resistant types are also sold.

© Government of Canada, Canadian Conservation Institute. CCI 69345-0023

Figure 8. Acrylic sheet is widely used to make custom mounts for the display of museum objects.

Polycarbonate

Known as Lexan or Makrolon (formerly Tuffak), polycarbonate resists shattering, which gives it a security advantage as an impact-proof material. Some polycarbonates are slightly less crystal clear than acrylic. Polycarbonate is not as easy to glue due to its resistance to solvents, and the resulting joints are not as strong as joints in acrylic. Unlike acrylics, sharp bends in thin sheets (up to 3 mm or 1/8 in.) can be done cold by hand. Scratch-resistant varieties are also available.

Poly(ethylene terephthalate) glycol (PETG)

PETG, or copolyester sheets (a common brand name is Vivak), is especially useful for lightweight applications when transparency and ease of forming are required.

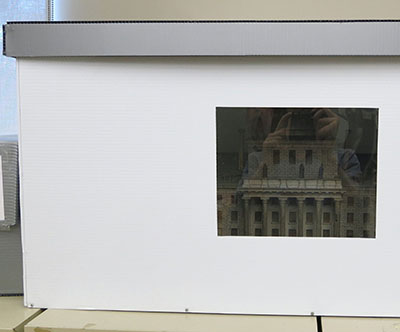

Corrugated sheets

Corrugated polymer sheets, such as fluted plastic sheet, polyflute, Coroplast, Cor-X, Correx, Hi-Core, Corru-Lite (Corulite) and Diversi-Plast, are made of polypropylene and polyethylene, or both as a copolymer. They are commonly used in conservation as flat bases or platforms or to make backing boards, folders, trays (Figure 9) and boxes. The corrugated sheets are available in different thicknesses and many colours. Factors such as the thickness of the walls composing the flutes, the stress of folding, exposure to UV radiation and extent of handling can limit the lifetime of corrugated sheets to a few decades. Panels having polypropylene may have a longer lifetime than those made only of polyethylene. Some corrugated plastics are specially made to be biodegradable, such as the Hi-Core Oxo-Biodegradable. If used in institutions, they must always be well-identified and used only for short-term purposes. Ideally, biodegradable products should not be used for conservation to avoid unwanted results. Recycled corrugated sheets should also be used for short and medium terms only because a portion of the polymer has probably been partly broken down and oxidized in its previous life. Consult the section on Containers to see how corrugated sheets are used to make boxes.

Some large panels made of polycarbonate (such as Verolite) and acrylic are available and are used for building structures (twinwall or multiwall) such as greenhouses. In museums, they can be used to support large-sized flat objects.

© Government of Canada, Canadian Conservation Institute. CCI 120171-0006

Figure 9. Objects stored in a custom-made corrugated plastic tray, with cotton twill tape securing objects to the tray.

High-density polyethylene (HDPE)

High-density polyethylene hard boards or panels are popular choices when strength and rigidity are needed, e.g. to make display case bases. The product can be cut into various intricate shapes, can be used to make replicas and comes in a variety of colours. Marine and outdoor quality boards (e.g. Marine Board, StarBoard, Seaboard) typically have better chemical stability (e.g. addition of UV stabilizers). This could be beneficial if enclosures made of this product are exposed to direct sunlight.

Poly(methyl methacrylate) and polycarbonate (PC)

Coloured translucent and opaque acrylic and polycarbonate sheets are available, as well as those with a mirrored look. Consult Plastic boards and panels for further information on these materials.

Foam boards

For polyethylene (PE) foam board and polystyrene (PS) insulation foam board, consult Foam planks, thick (>13 mm or 1/2 in.).

Poly(vinyl chloride) (PVC)

Some hard foam boards are made of rigid PVC foams. Gatorcel, Komacel and Sintra are common trade names for these boards. Rigid PVC foam boards are not recommended for use in contact with objects or in a fairly airtight enclosure for long-term purposes. This constraint is to minimize the impact of the possible release of low levels of hydrochloric acid during the slow degradation of the PVC.

Wood and wood products

Both solid wood or wood product panels are commonly used. Wood products or wood-based boards are composites made chiefly of wood and glue. They include plywood, waferboard (oriented strand board and flakeboard), particleboard (chipboard) and fibreboard (low, medium and high density). The usual adhesives used for wood products are urea formaldehyde and phenol formaldehyde. The main problem with wood and wood products is the acidic emission of the wood components and their capacity to stain during contact (Figures 10a and 10b). A non-porous interleaf (e.g. Melinex) between the wood and the object will avoid the problem of staining (consult Interleaves – discrete and efficient for details on using an interleaf).

© Government of Canada, Canadian Conservation Institute. CCI 120171-0007

© Government of Canada, Canadian Conservation Institute. CCI 120171-0008

Figures 10a and 10b. An example of a stain caused by contact with a knot in a piece of wood. The brownish stain on the paper (left) was caused by contact with the back wooden panel, which has a large knot (as seen on the right).

Lead, copper alloys and paper are commonly known to be among the most susceptible types of objects to acidic vapours and thus, if possible, should not be exposed to emissions from wood and wood products, especially within enclosure settings where the emissions can accumulate.

When choosing wood and wood products for museum uses, the species can matter. Oak and cedar are the most acidic wood species, and in general, they should not be used to make enclosures. Rather, choose a wood species that has a pH higher than 5. It should be well-aged and conditioned to the temperature and humidity of the room. Elm, maple, poplar, ash and aspen are some of the Canadian species that usually have a pH above 5. An extended list of wood species with their respective pH values and how it can be measured can be found in CCI Technical Bulletin 21 Coatings for Display and Storage in Museums (Tétreault 1999). The pH of wood products may be hard to predict because they are composite materials. The use of pH strips saturated in a glycerol and water solution can be used to estimate the level of acidity generated by a product or by an enclosure. Consult Test #2: pH test using glycerol to measure the acidity of volatile compounds for a description of this test.

The adhesive used in wood products is usually not the main issue. Wood products may have a smell of adhesive when new, but the main concern should be focused on the acid emission from the wood itself. It is important to realize that no wood can be referred to as being of “museum-quality.” Formaldehyde-free wood products are beneficial in terms of human health but not usually for objects.

In terms of sustainability, it is best to use local wood and wood products, if possible, and from a well-managed forest. In Canada and the United States, the Forest Stewardship Council can certify that the wood meets sustainability criteria.

Also, some wood products, such as medium density fibreboard, can be made of post-consumer recycled content which is good from a sustainability point of view. In terms of conservation, these materials should be dealt with in the same way as new wood products.

Be aware that wood products can be treated with fire-retardant compounds. Some of these compounds make wood products more corrosive. As a precautionary approach, avoid these types of specially treated wood products for use within airtight enclosures.

A common method to reduce emissions from wood and wood products is to seal them with a coating or to buy them already laminated (for information about Formica and melamine laminates and medium- and high-density overlaid plywood [MDO and HDO], consult Coatings, laminates and films). In general, when ambient RH is well-controlled, adequately coated wood and wood products should be acceptable for enclosing most objects, except those containing lead. A coating on wood products will protect them and limit the generation of airborne wood particles.

Paperboards

For simplicity, as the name states, paperboards include all boards made of wood pulp that are thicker than a single sheet of paper. The most common are matboards and corrugated cardboards, but many other types of paper-based boards are possible. These products are lightweight and generally used in conservation to make boxes, trays, window mats, mounts, folders, backing boards, etc.

The best practice recommends the use of buffered (acid-free) wood pulp-based products including paperboards for the storage and display of photographs and paper documents. The alkaline reserve from the calcium carbonate in the board will extend the lifetime of the mount or box itself compared to a regular acidic product. Although it is not conclusively proven that buffered boards can slow down the degradation of papers, at least they will not further contribute to their degradation.

© Government of Canada, Canadian Conservation Institute. CCI 124703-0054

Figure 11. Paper artwork stained by an acidic mat after many years of contact.

In practice, books and paper documents are sometimes stored in acidic boxes. This situation is tolerated if the content is acidic, such as papers made of wood-pulp fibres. Although acidic boxes are not ideal, at least the papers will be protected against outdoor gases and dust deposition and light. In terms of chemistry, the main cause of deterioration of acidic paper is the amount of water in the paper (acid-catalyzed hydrolysis). To reduce this deterioration, strategies can aim at preventing the paper from becoming more fragile and yellowing by limiting periods of high temperature and high RH.

Boards in contact with photographic documents should also pass the photographic activity test (ISO Standard 14523:1999).

Matboards

Matboard is a paperboard typically used by the picture framing field as well as in conservation for mounting and storing works of art on paper and photographs (folders, window mats) and, in glazed frames, for increasing the gap between the mounted artwork and the glass. Acidic matboards are known to damage paper artwork, as shown in Figure 11. Matboard recommended for conservation purposes, described by the manufacturers as “100% rag fibre,” is available either buffered (pH 7.5–8.5) or unbuffered (pH 7). Matboard made from highly purified wood pulp buffered to pH 8.5 is an acceptable, more economical alternative. Matboard that is buffered (i.e. has a pH slightly above 7.0) to protect paper from acidity is appropriate for most works on paper. Generally, the use of white or buffered four-ply matboard is recommended (Figure 12). If using coloured matboard, ensure that the dye is fast (consult Test #3: Testing for colourfastness).

© Government of Canada, Canadian Conservation Institute. CCI 85428-0012

Figure 12. Aquatint on paper depicting a large boat on water, in window mat. Entitled Commencement of the Action Between His Majesty’s Ship Shannon and the United States Frigate Chesapeake, this work of art belongs to the Art Gallery of Nova Scotia, accession number 2003.397.

Corrugated paperboards

The common corrugated cardboards used everywhere commercially for storage and packing of manufactured goods are acidic, but acid-free and buffered varieties are produced and marketed for the museum and archival field. Corrugated boards are available in a few different thicknesses (e.g. single or double corrugated layer). They are useful as lightweight platforms and trays or to make storage boxes and containers (Figures 13a and 13b).

© Government of Canada, Canadian Conservation Institute. CCI 126389-0039

© Government of Canada, Canadian Conservation Institute. CCI 126389-0037

Figures 13a and 13b. A twined basket with a silk lining, stored within a custom-made box constructed of acid-free corrugated paperboard. The basket rests on a cloth-covered, foam-padded movable base inside the box (left). The basket within its box with the lid on (right).

Metals

Metal sheets such as aluminum, steel or galvanized steel are also used for building display cases or storage cabinets. In indoor environments, many metals tend to slowly tarnish and may stain objects that they are in contact with. Contact between metallic objects and metallic products may cause galvanic corrosion in a highly humid environment (described under Contact). For this reason, the use of coated metallic units is recommended if contact with objects is expected in both the short and long term. In particular, powder-coated metal shelving is often used in museums, as it is sturdy, does not contain solvents nor corrode and eliminates the risk of staining. More details about the selection and use of coatings can be found under Coatings, laminates and films.

Composite panels

Composite panels are typically lightweight and usually quite rigid. They include foam core panels, honeycomb panels and metallic composites.

Foam core boards

Boards with foam centres (foam core boards or laminated foam boards such as Gatorplast, Gator board or Gatorfoam, Fome-Cor) are chiefly made of polystyrene foam laminated on each side with thin sheets usually made of plastic (e.g. a hard polystyrene sheet or a sheet of resin-impregnated paper). Foam boards are light and somewhat fragile. Those made of a thin layer of polystyrene adhered to the foam core can be used safely in terms of minimal risk of off-gassing. As for the resin-impregnated paper types, the most common products are acidic but some made for the museum and archival field are acid-free. The nature of the adhesive gluing the laminated layers is not critical since it is covered by the vapour-proof outer layers of plastic or buffered paper. No problems related to emissions or contact are expected with them. However, foam boards with a laminate made of acidic paper, thin cardboard or wood veneer, or PVC rigid board may need evaluation to ensure their compatibility with the objects that they may be in contact with. Products made of hard foam cores covered with metal sheets are discussed further below.

Honeycomb panels

Honeycomb panels are a very light and versatile alternative to other kinds of heavy sheet products such as wood panels. They can be made of paper and cardboard, aluminum, polyethylene, polycarbonate or other plastics. Their top surfaces are often laminated with paper, wood products, aluminum or plastic film. They can be used for flat mounts or for backing boards used in framing, as well as flat supports for paintings and textiles. They are less readily available in local hardware stores and tend to be expensive. Note that some honeycomb panels are finished with potentially problematic materials such as acidic paper, cardboard or wood veneer. Some honeycomb panels fall in the category of metallic composite panels, described below.

Metallic composite panels

Composite laminated panels with rigid metal skins on rigid or foam plastic cores, such as the aluminum composite products made by Dibond, Reynobond or Alucobond, are being successfully used to provide a metallic look when building display cases. They can also be called by the generic name of “foam sandwich panels.”

Sometimes, metal sheets are used on their own to build the structure of the display cases.

Coatings, laminates and films

Coatings are often applied on wood, metal and concrete surfaces for aesthetic purposes but also to protect the substrates and to block potentially harmful compounds that can be released by wood products. However, sometimes, there may be more harmful volatile compounds released by coatings than by the wood itself. It is important to follow guidelines for the selection of coatings and to adhere to their drying periods in order to avoid unsafe conditions. Where time is limited, consider using laminated wood products that prevent emissions, instead of other coatings that may need several weeks of airing out to off-gas naturally.

Coatings

Coatings such as paints, varnishes and stains are used for aesthetic purposes and to provide vapour barriers. Coatings formed by oxidative polymerization, such as oil-based paints, oil-based urethanes, alkyds, melamine and epoxy esters (one-component or one-part systems), should be avoided in museums because they release acids and peroxides that can harm objects, especially papers, metal objects (lead, copper and their alloys) and black and white photographs. Fortunately, with new volatile organic compound (VOC) regulations in Canada and the United States, these coatings are becoming less and less available. The coatings that are generally acceptable in archival and museum contexts are acrylic or acrylic-urethane emulsion paints (latex) and, for special applications, two-part epoxy and two-part urethane paints.

Drying period

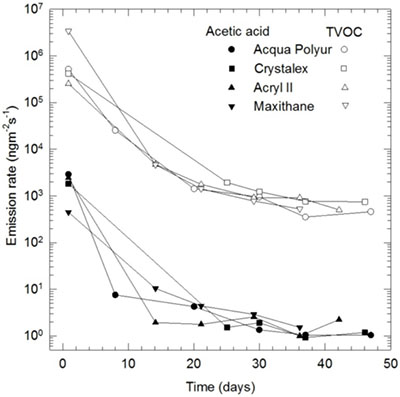

Even with recommended coatings, there is an important factor to consider: the drying period. As shown in Figure 14, many volatile compounds are released when the coating is still relatively fresh; the emissions decrease as the paint dries or cures. As the figure shows, the emission rate tapers off (the curve flattens) after 20 to 30 days. This is why a drying period of four weeks is recommended. Planning this drying period ahead of time when schedules and timelines are being developed is important. However, there may be situations where a balance is required between reaching a low level of volatile compounds in the freshly painted enclosure (and consequently reaching a low risk of damage) and the need to install the object in that enclosure with only a short delay. For example, there may be a delay in one or more preceding steps during an exhibition project with a fixed deadline which can lead to pressure to cut down the drying period. Research done in 1997 at CCI did not conclude that low volatile organic compound paints can be safely used with a shorter drying time. Today, most paints that are on the market emit fewer volatile compounds than 10–20 years ago; unfortunately, no research had been done to support a reduction of the drying period while keeping the risk of damage low. A rough estimate of the acidity generated by painted enclosures can be done with pH strips saturated with a glycerol and water solution (consult Test #2: pH test using glycerol for measuring the acidity of volatile compounds).

The drying period for a painted surface in a room is less critical since normal room ventilation will prevent high levels of pollutants from accumulating. Volatile compounds released by the painted walls, floors or shelves should dissipate easily.

© Government of Canada, Canadian Conservation Institute. CCI 120171-0009

Figure 14. Emission of volatile compounds over time for four brands of acrylic and urethane varnishes. The emission rate of different emulsion varnishes reduces exponentially over time. The curves show that the volatile emission after two weeks is about 10 times less than after one week. After four weeks of off-gassing, the curves flatten off, so there is not much to be gained by airing out the painted surfaces further. (TVOC: total volatile organic compounds)

Figure 14 – text version

| Acqua Polyur | Crystalex | Acryl II | Maxithane | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Time (days) | Acetic acid (AA) | Total volatile organic compounds (TVOC) | Time (days) | AA | TVOC | Time (days) | AA | TVOC | Time (days) | AA | TVOC |

0.833 |

2912.112 |

519105.6 |

0.833 |

1820.592 |

419559.8 |

0.833 |

2452.32 |

254931.8 |

0.833 |

447.552 |

3413318 |

7.98 |

7.55 |

25555.6 |

25.06 |

1.525 |

1932.6 |

14.119 |

1.938 |

4750 |

14.119 |

10.39 |

4666.6 |

19.999 |

4.255 |

1425 |

29.96 |

1.91 |

1232.9 |

21.07 |

1.775 |

1767.45 |

21.07 |

4.39 |

1416.487 |

29.96 |

1.35 |

946.2 |

36.995 |

0.92 |

765.4 |

29.12 |

2.56 |

921.86 |

29.12 |

2.893 |

774.19 |

36.995 |

1.05 |

353 |

46.06 |

1.19 |

748.5 |

36.12 |

1 |

913.58 |

36.12 |

1.5186 |

525.92 |

46.97 |

1.04 |

458.47 |

- | - | - | 42.119 |

2.235 |

502.92 |

- | - | - |

A drying period of four days has been recommended for a painted surface in a room. In practice, if removing all objects from the room being painted is not feasible, an option may be to move the collection to one side of the room and paint the walls on the other side, while protecting the collection with plastic sheeting and providing as much ventilation as possible. In the context of a large enclosure such as a room, if a delay of four days for off-gassing is impossible to commit to, it is safer to avoid painting the room if acid-sensitive objects are present, such as lead, colour photographs, and paper, unless localized means of protection are provided such as tightly sealed boxes or display cases.

Selection of coatings based on substrate and purpose

Different types of coatings for different substrates and purposes are summarized below:

- Inside wooden enclosures: The common choice is a latex acrylic paint (emulsion). Two-part epoxy paint can be chosen if there is a requirement for good chemical resistance, and two-part urethane is recommended for good abrasion resistance. Allow a four-week drying period before inserting objects.

- Walls, ceilings, open wooden shelves and any exterior wooden surfaces of enclosures: Same recommendation for coatings as for inside wooden enclosures. Allow a four-day drying period.

- Wooden and concrete floors: Two-part epoxy paint can be chosen if there is a requirement for good chemical resistance, and two-part urethane is recommended for good abrasion resistance. Latex acrylic-urethane paint is also an option if a moderate abrasive-resistant coating is needed. Allow a four-day drying period.

- Metallic enclosures: Powder coatings are a good popular choice. Baked alkyd paints should be avoided due to the potential for off-gassing problems from incompletely baked paint. Small aluminum parts can be anodized and dyed. For both powder-coated and anodized metals, no drying time is needed.

- Metallic fixtures outside of enclosures: Powder coatings, anodized coatings and baked alkyd paint can be used in a large-sized well-ventilated room since the first two release no emissions and emissions are fairly low for the third. Even regular (unbaked) alkyd paint, which has higher emissions, can be used if the surface to be painted is very small compared to the dimensions of the room (emissions will become quickly diluted). No drying time is needed in either context. (Do not use these products inside an enclosure without making a proper risk assessment.)

- Coated surfaces in contact with objects: To avoid tackiness, choose a paint based on the type of substrate mentioned above. Allow a four-week drying period before contact between a white (or pale-coloured) painted surface and an object. Coloured paint, especially dark colours, will need a longer drying period (Figure 4). If the stated drying periods are hard to fulfill, the best option is to use an interleaf between the surface and the object. Consult Interleaves – discrete and efficient for more on the use of interleaves. As a precaution, it is recommended to always use an interleaf between objects and any painted surfaces. Surfaces with a coating cured by radiation, anodized or covered with powder coatings do not need a drying period prior to contact with an object.

For more information on coatings, consult “Sustainable Use of Coatings in Museums and Archives – Some Critical Observations” (Tétreault 2011).

Laminates

One way to avoid dealing with the prolonged airing-out period needed when using wet coatings is to use wooden panels already covered by a stable vapour barrier or laminate, or to apply a laminating film on the wood product that will seal in any off-gassing emissions. These options are described below.

Formaldehyde-based laminates

Panels surface-finished with a high-pressure laminate are an alternative (e.g. Formica, Arborite). They are often made of formaldehyde-based resins such as phenol formaldehyde and/or melamine formaldehyde, and they are not problematic (emissive or corrosive). High-pressure laminates are good vapour barriers and are available in different colours or patterns. Most of the time, these laminates are applied on particleboard, which have limited load capacity, but the laminates can also be applied on more robust types of wood products such as plywood.

Plywood panels can also be laminated with an overlay such as a high-density overlay (HDO) and a medium-density overlay (MDO). The laminate in this case is a kraft paper impregnated with phenol formaldehyde of high or medium density. These laminated surfaces are good gas and vapour barriers. These products are commercially available with the laminate surface on one or both sides. The high-density overlay surface has a slick or waxy surface and cannot be painted (in case this is necessary for display aesthetics), while the medium-density overlay can accept paint. The side with the overlay surface is placed towards the interior of packing crates. They can also be used for the base of display cases where the interior surface of the panels is not visible to visitors. Their core being plywood panels, these products can be cut and assembled easily and are quite sturdy. They can be found in regular hardware stores.

Films

Plastic-laminated aluminum foil

Another option for sealing wooden panels is to apply a plastic-laminated aluminum foil such as Marvelseal 360 or Valsem S27 (in France), as shown in Figure 15. This excellent vapour barrier has a shiny metallic appearance due to its aluminum foil core. It can be covered with fabric or coloured matboard to mask this appearance, as necessary. An in-house version of the film can be made with domestic aluminum foil and polyethylene sheets (consult CCI Note 1/9 Low-Cost Plastic/Aluminum Barrier Foil for details on this application). The aluminum can also be used to seal and block the transfer of potentially harmful products from different materials, such as papier-mâché, to objects, as shown in Figure 16.

© Government of Canada, Canadian Conservation Institute. CCI 69345-0024

Figure 15. A hot iron is applied to plastic-laminated aluminum foil to melt the polyethylene side of the foil onto the plywood panel. The plastic on the other side of the foil is nylon, which has a higher melting point. Use an interlayer when applying heat to avoid any risks of the foil sticking to the iron or hot spatula. In this case, the iron was covered with a sheet of beige-coloured Teflon, but just a sheet of paper would do.

© Government of Canada, Canadian Conservation Institute. CCI 120171-0011

Figure 16. Mannequins made of papier-mâché and covered with plastic-laminated aluminum foil.

Containers

Small enclosures such as containers are extremely useful for storing museum objects because they can provide very good protection against physical forces and, depending on how they are made, can also protect against external agents such as pests, pollutants and large RH fluctuations in the room.

The ideal storage containers should be:

- airtight (protection against external pollutants and insects and to some degree against large RH fluctuations);

- waterproof (if not stored in a waterproof cabinet or not covered by a plastic sheet);

- made of non-emissive products;

- stable for many decades;

- strong enough to support the weight of objects they contain when lifted, plus other possible loads (such as the weight of one or two other boxes potentially placed on top);

- labelled to allow ease of identification during retrieval; and

- easy to handle (provided with sturdy handles and not too heavy).

Containers could also be insulated if they are located in an area where the temperature fluctuates. For example, if the box is placed near cold walls, it is at high risk of becoming cool and damp inside. Ideally though, the temperature should be controlled on a larger scale via the room and building features (adding more insulation in the walls or within enclosed cabinets). For more details, consult the CCI webpage Agent of deterioration: incorrect relative humidity.

It may even be good to have fire-resistant containers, although the products used to make them should not be impregnated by flame retardants since not all of the compounds that make up flame retardants are safe for objects and some could cause alterations to objects in a closed environment. It is better to have a good system of fire detection and suppression as a first line of defence.

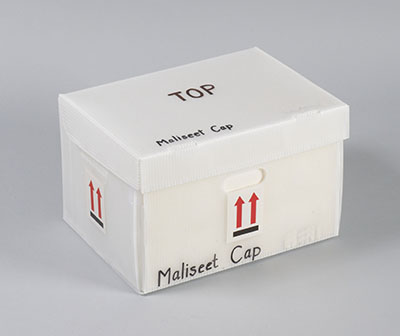

It is also wise to avoid stacking many boxes on top of each other, as shown in Figure 17. Typically avoid stacking more than three boxes, and use shelving with sufficient shelves to store the objects both safely and in a compact, space-saving manner (Figure 18).

© ICCROM

Figure 17. Many containers are not designed to be excessively piled.

© Government of Canada, Canadian Conservation Institute. CCI 126753-0005

Figure 18. Example of paperboard boxes used in storage. Notice that shelves were adjusted so that no more than two or three boxes are stacked.

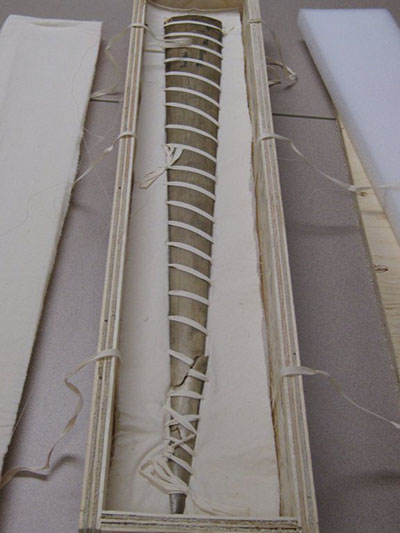

Boxes and small containers can be made using a wide variety of products. If they are custom-made, most commonly the raw materials or products for their walls (including top and base) consist of plastic or paper-based panels. Sturdier options are also possible, such as wood or wood products, or metal; these are discussed under Boards and panels. A wide variety of fastening devices and techniques can be used to connect the walls together to make the box. As well, other products discussed within this Technical Bulletin are usually integrated within the design, such as light board separators, foam padding, interleaf sheeting or fabric liners, cotton twill tape and paper or plastic labels. Choosing which product is most appropriate to make containers will depend on the characteristics (size, weight, fragility, etc.) of the object(s) being contained as well as on the context, environment and intended use.

Although making boxes out of boards and panels is usually more economical and offers more possibilities in terms of materials and designs (consult Boards and panels), there are many types of pre-made containers that are commercially available in many standard sizes and that can be used in a museum setting, as discussed below.

Clear small containers

Acrylic, polystyrene (Figure 19), polypropylene, polyethylene (e.g. many types of Tupperware containers, Lock & Lock food containers) and poly(ethylene terephthalate) (PET) are the most commonly used materials for small clear plastic boxes. Polyethylene containers, which are usually milky rather than fully transparent, may turn slightly yellow with time. Transparent plastics offer the advantage of allowing objects to be viewed without handling (note though that the wrapping or padding which usually covers the object, at least partially, is usually not transparent). Plastic containers will not be able to maintain an RH very different from the RH in the room over the long term: the water vapour in the air can slowly infiltrate the container by leakage at the lid joint or through the plastic walls (permeability).

© Government of Canada, Canadian Conservation Institute. CCI 124703-0030

Figure 19. Examples of small clear boxes made of polystyrene plastic.

Plastic bins with lids

Plastic storage bins are usually made of polyethylene and available at a good price. These containers are supplied in a range of colours, or they can be slightly opaque. Colours in plastic containers are not a problem as the colour does not transfer. Plastic boxes, such as Tupperware and Rubbermaid boxes (Figure 20), are usually supplied with fairly tight lids. High-density polyethylene should have a longer working life than low-density polyethylene. Look for a company that offers a 10-year warranty for its products.

© Government of Canada, Canadian Conservation Institute. CCI 125773-0010

Figure 20. Polyethylene bins can be very useful for storing and handling objects.

Corrugated plastic containers

Custom-making a box from corrugated (or fluted) plastic sheets allows for the box to be tailor fitted to the object’s size and needs and also makes it possible for the box to be fully opened flat to allow easy retrieval of fragile objects (Figure 21).

Pre-made corrugated plastic die-cut boxes are available, sold either flat-packed or assembled (Figure 22). The boxes are made of polypropylene and polyethylene or both as a copolymer. The weakest point of the boxes is the stress at bent edges. A good option to relieve this stress, which is observed as a whitening of the plastic, is to gently warm the bends with a blowtorch. Information on making boxes and trays with corrugated plastic can be found in CCI Technical Bulletin 14 Working with Polyethylene Foam and Fluted Plastic Sheet (Schlichting 1994).

© Government of Canada, Canadian Conservation Institute. CCI 100548-0024

Figure 21. A collapsible, custom-fitted box made of a plastic corrugated sheet for a fragile ivory casket. The box opens up fully to allow easy retrieval of the object. The box is padded with foam lined with a non-woven fabric.

© Government of Canada, Canadian Conservation Institute. CCI 99201-0030

Figure 22. Die-cut assembled corrugated plastic box.

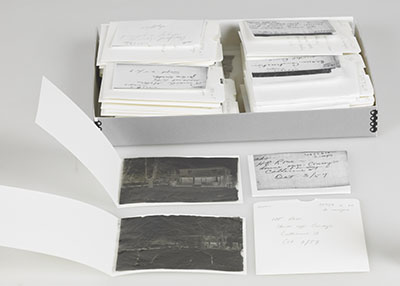

Paperboard containers

Pre-made acid-free laminated paperboard or corrugated cardboard boxes are available for the museum and archival field in several standard sizes (Figures 23 and 24). Some types of laminated board boxes are reinforced with metal edges for added strength and durability. The common and ubiquitous corrugated cardboard box is acidic and so has limited use in a museum setting (as discussed under Boards and panels).

© Government of Canada, Canadian Conservation Institute. CCI 124901-0001

Figure 23. Example of a die-cut acid-free corrugated cardboard box.

© Government of Canada, Canadian Conservation Institute. CCI 124840-0001

Figure 24. Example of a store-made laminated paperboard box with reinforced metal edges.

Cushioning and padding

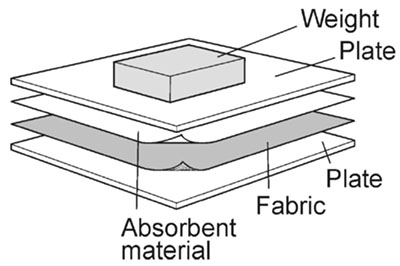

Cushioning and padding materials include foams of different densities, battings, felts and cushioned wraps used to support or pad out objects, or to wrap objects. They are often used in a combination of layers of increasing densities (e.g. as a first layer of shock-absorbent material), to fill up the extra space inside a hard container such as a shipping crate or to bulk out the inside of objects with a soft cushioning material generally added to more fully pad and protect areas of the object that are in contact with the container (example in Figures 20 and 21). Ensure that the cushioning is adequate for the expected shocks and vibration. Information on how to use cushioning material within shipping crates can be found on the CCI website: Step 5: Use Cushioning Material Effectively in Six Steps to Safe Shipping.

Bubble wrap (air bubble packing)

Bubble wrap (air bubble pack) is a generic name given to a range of clear cellular cushioning sheets made of low-density polyethylene. The air cells can be as small as 6 mm (1/4 in.) in diameter to as large as 26 mm (1 in.). Bubble wraps are recommended mainly for wrapping fragile or lightweight objects for short periods of time because the cells tend to rupture and deflate with time. When bubble wrap is placed in direct contact with objects or held taut against surfaces for long periods, there is a risk that stains in the shape of the air cells can become imprinted on objects (Figure 25). This undesirable pattern can be quite noticeable, affecting the appearance of the object. In general, the recommended practice is to avoid direct contact between bubble wrap and objects. Because of these drawbacks, overall polyethylene foam sheeting is a preferable option. Otherwise, the use of an interleaf between the bubble wrap and the object is recommended to avoid potential staining.

© Government of Canada, Canadian Conservation Institute. CCI 120260-0334

Figure 25. A silver-plated brass bowl became tarnished on areas in direct contact with bubble wrap.

Foams