Agent of Deterioration: Incorrect Relative Humidity

Stefan Michalski

Table of Contents

- Definition

- Deterioration by incorrect relative humidity, and the collections most vulnerable

- Sources of incorrect relative humidity

- Control of Incorrect Relative Humidity

- Control in terms of overall strategies and target values

- Conclusions

- References

- Glossary

- Vignettes

- Related resources

Definition

Why "incorrect" relative humidity?

Relative humidity, unlike fire, water, pests, etc., cannot be considered an agent of deterioration – we cannot speak of avoiding relative humidity (RH) – but we can avoid "incorrect" relative humidity. From a practical risk assessment perspective, the many forms of incorrect RH can be subdivided into four types:

- Damp, over 75% RH.

- RH above or below a critical value for that object.

- RH above 0%.

- RH fluctuations.

Each of these will be explained in detail under "Deterioration". Different collections have different sensitivities to each of the four types, a few to only one, most to a mixture of two or more. Part of the difficulty in finding a "correct" RH for a collection, or a museum building, is the fact that a perfectly correct RH value may not exist for the collections. The best one can hope for is to find whatever range of RH causes the least amount of damage to the collection. Fortunately, for the majority of mixed museum collections this minimum damage rate is often very low, even zero, and the range of RH that yields this minimum damage is much wider than museums have assumed in the past.

What is relative humidity (RH)?

Relative humidity is a measure of the thing we call "humidity" in everyday speech. It is that quality of the air that ranges between damp and dry. We don't actually perceive RH itself, we perceive the dampness or dryness of our bodies in reaction to ambient RH, or we perceive the effect on objects such as paper or cloth, which become damp or dry in response to the RH. Although we can feel the difference between these two extremes, for all practical purposes we will need to rely on instruments to tell us what the RH is in the museum. (Consult the glossary for the technical definition of RH).

The relation between RH and museum objects

The amount of moisture in organic collection materials such as wood, paper, paint, magnetic tapes, etc., and on the surface of inorganic materials such as stone and metals, can be predicted best by RH. Although engineers that consult on climate control systems may use other humidity parameters such as vapour pressure or dewpoint temperature (Consult the glossary), all the deterioration issues of collections that are linked to humidity, and all the specifications one can provide for consultants about caring for collections in terms of humidity, are best expressed using RH as the parameter.

The relation between RH and temperature

It is sufficient for most purposes here to know that when warm air is cooled, the RH climbs. This leads to problems of damp when warm humid air finds cool spots in a building. The converse is that when cold air is heated, the RH falls. This leads to low indoor RH in winter, and drives the need for humidifiers. A more detailed explanation of this relation can be found in vignette 1.

Deterioration by Incorrect Relative Humidity, and the Collections Most Vulnerable

Damp (over 75% RH)

Damp has been understood since ancient times. It remains a constant battle, especially in the historic buildings that so often house museums. Damp causes several types of deterioration – mould, rapid corrosion, and extreme forms of mechanical damage. Although the practical boundary for damp is given as 75% RH, the deterioration rates all climb rapidly with increasing RH, so any reduction below 100% RH is beneficial.

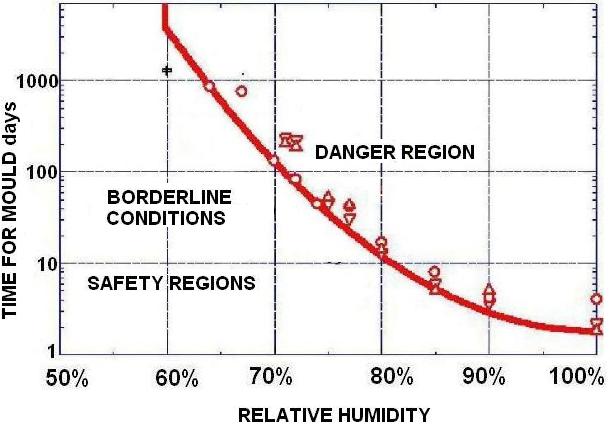

Damp causes mould, which disintegrates or discolours skin, leather (Figure 1), textiles, paper, basketry, and occasionally wood, paint, and glass. Table 1 summarizes the different sensitivities to mould.

Table 1. A summary of all forms of deterioration due to incorrect RH, and the sensitivity of various collections to each one.

| Effects | Low sensitivity | Medium sensitivity | Very high sensitivity | ||

|---|---|---|---|---|---|

| None | Years | ~100 days | ~10 days | ~2 days | |

| Mould | Inorganic artifacts E.g., stone, metals, ceramics. If surface organic layer present such as dirt, may develop mould as listed at right, but effects usually superficial. |

At 60% RH visible mould growth just possible on some surfaces, but a stable RH at this value is rare, any intermittent period at less than 55% will stop growth. | Organic materials with a surface rich in soluble protein, starch, or sugar E.g., leather, skin, parchment. Starched, sized, or dirty textiles and paper. 100 days at 70% RH… 10 days at 80% RH… 2 days at 90% - 100% RH |

||

| Clean plant based organic materials: mould rate typically requires 80% - 85% RH before mould growth likely at all. E.g., clean textiles, clean paper, clean wood. | |||||

| Corrosion of metals | Most precious metals. E.g., gold and platinum. Silver unaffected if no tarnishing pollutants (sulfides) present but if pollutants are present, tarnishing rate will increase with damp. | Coated or plated iron and copper alloys, but any coating flaws move to high sensitivity. E,g. trophies, silverware, costume jewellery, vehicle trim. Metal tools, implements, instruments. | Lead, zinc, bismuth alloys (rate depends on presence of pollutants, such as organic acids). E.g., small Victorian castings, metal parts on many small consumer items, ship model elements. |

Clean iron and copper alloys. E.g. tools, implements, kept bright and clean, but without coatings. Especially rapid if the artifact has mixed metals in contact. |

Salt contaminated iron and copper alloys. Metal pitting and staining of adjacent porous materials takes weeks. E.g bright metals with fingerprints or cleaner deposits, archaeological and marine items, industrial machinery with road dust or salt deposits. |

| Colorants bleed | N/A | N/A | N/A | Dyes bleed. E.g. textile embroidery, watercolours on paper | |

| Special mechanical damage (beyond that considered under RH fluctuations) | N/A | N/A | Glued wooden assemblies reform. E.g. veneer buckles, due to a combination of cross grain veneer expansion and glue softening. When RH drops, the areas of veneer still in contact with the carcass adhere in an expanded state, and a portion of the buckle remains. Speed dependent on thickness of the wood and any coatings. | Gelatin layers cement to adjacent surfaces. E.g., stacked films and photographic prints "block", photographic prints buckle and cement to nearby glass frames. Restrained, tightly woven textiles shrink above 90% RH. E.g. paintings on canvas. Combined with size layer softening, paint layer tents, delaminates. Paper and parchment cockle. |

|

| Effects | Low sensitivity | Medium sensitivity | Very high sensitivity | ||

|---|---|---|---|---|---|

| None | Years | ~100 days | ~10 days | ~2 days | |

| Corrosion of metals | N/A | Disintegration of stable patina on old iron and copper alloys: several critical RH's between 20% RH and 75% RH, depending on metal/contaminant combinations. E.g. maritime and archaeological finds, "bronze disease." | N/A | N/A | |

| Glass crizzling if below ~55% RH Weeping if above ~40% RH |

Stable glass. E.g., most 19th-20th century pressed glass, lead crystal. | Unstable glass: loses luster, crizzles, may fragment. Stains, etches adjacent leather. E.g. some 18th-19th century glass bead work. | N/A | N/A | N/A |

| Minerals crumble, weep | N/A | A small fraction of minerals, such as hydrates and pyrites have specific critical RH above or below which they can crumble and or weep | |||

| Effects | Low sensitivity | Medium sensitivity | Very high sensitivity | ||

|---|---|---|---|---|---|

| None | Years | ||||

| Lifetime @ 50% RH, 20°C to Lifetime @ 10% RH, 20°C |

~300y to ~1500y |

~100y to ~500y |

~30y to ~150y |

~10y to ~50y |

|

| Internal chemical disintegration (by acid hydrolysis, dye instability, or residual chemicals). | N/A | Current best estimate for stable film materials to remain unchanged. E.g., old BW negatives on glass, new BW on polyester film. | Acidic paper and some film become difficult to access. E.g. newsprint and low quality books, papers, post brittle and brown. Acetate film shrinks, image layer cracks. | Typical magnetic media begins to be unplayable. E.g., tapes of video, audio, data; floppy discs. Unstable photograph materials decay. E.g., colour prints fade (in the dark). | Worst samples of magnetic media begin to be unplayable. E.g., tapes of video, audio, data; floppy discs. Some CD's. |

| Effects | Low sensitivity | Medium sensitivity | High sensitivity | Very high sensitivity |

|---|---|---|---|---|

| ±40% RH | None-small damage | Small-severe damage | Severe damage | Severe damage |

| ±20% RH | None-tiny damage | None-small damage | Small-severe damage | Severe damage |

| ±10% RH | No damage | None-tiny damage | None-small damage | Small-severe damage |

| ±5% RH | No damage | No damage | None-tiny damage | None-small damage |

| Flat sheets of paper, film, tape, with an image or data layer may delaminate, fracture, or distort permanently. | Support layer with finely dispersed image/data layers. Laminates with low differences in expansion. E.g. most case-bound books. Most CDs. Commercial signs painted on metal. |

Layered structures with moderate strength, moderate differences in expansion. E.g., most photographs, negatives and film. Most magnetic records. Thin, well adhered inks on parchment, such as deeds. Gouache on paper. Book bindings of vellum and or wood. | Layered structures with poor strength, moderate to high differences in expansion. E.g., Thick images on parchment. Globes. Thick oil-resin images on paper or cloth. Objects listed as medium vulnerability that have weakened substantially due to UV exposure, or aging already causing flaking. | Large reactive (to fluctuations) sheets that are restrained at the periphery. E.g., large paper sheets adhered to stretchers, 19th Century photo-portraits on fabric and stretchers. Large prints adhered at all four corners (usually tear near the point of restraint.) |

| Wood or wood assemblies may crack, split, delaminate, or distort permanently |

Single wood components, or assemblies designed to eliminate stresses, or. E.g., floating panels in furniture or room paneling; tongue and groove planking nailed or bolted on edge only such as wainscotting, wood boxes on farm machinery (unless jammed due to painting, warping), hollowed out totem poles, wooden tool handles. Assemblies with prior damage that allows stress release. |

Wood assemblies with uniformly distributed stresses during fluctuations. Note that fluctuation to higher RH may not always cause visible damage, since many joints, panels are invisibly crushed, but this makes them more likely to split during lower RH. |

Wood assemblies with concentration of stresses during fluctuations. E.g., Veneer over corner joints, such as many wardrobe doors, Victorian secretaries, Art Deco furniture. Fretwork, applied wooden ornaments. Assemblies with bolts, nails, screws that hold both sides of a single plank. Many musical instruments. |

Wood assemblies with attached or inlaid metal, horn, shell, etc. that spans more than 1cm across the wood grain. Attachment or inlays may delaminate or buckle. E.g. West coast masks with abalone, 18th Century-19th Century fine furniture, clocks, with inlays. |

| Paintings or paint layers may crack, delaminate, flake | Acrylic paintings on canvas. E.g., many paintings since . These may move to medium sensitivity if a heavy glue size was used, or if adhesion between layers is poor. | Rigid paint layers on canvas, in moderate to good condition. Oil paint, gilding on narrow spans of wood. E.g. gilt furniture, picture frames. |

Oil paint, gilding, on wide spans of wood, or paint on other organic rigid supports with weak adhesion. E.g., most panel paintings, wide gilded panels. If the seams are flawed, with rigid fills, etc., then may become very high sensitivity. Miniatures on ivory, due to poor adhesion and undulations of some ivories. Heavy modern paintings on smooth side of fiber-board may delaminate due to weak adhesion. |

Paint layers bridging seams or flaws that concentrate stress. E.g. polychromes, painted furniture, painted architectural wood elements. Note that hairline cracks over the joints of doors or painting frames are usually considered "normal" but not those in heavily lacquered furniture. |

| Other organic objects | Woven organic materials without edge restraints. E.g. most basketry. Textiles such as blankets, flags, simple costumes. |

High crimp woven organic materials with edge restraints may tear during fluctuation to high RH. E.g., needlepoint fixed to a stretcher, flat seat. | N/A | N/A |

This page refers only to mechanical damage due to the fluctuation, and assumes a fluctuation long enough for the objects to completely respond. See other incorrect RH on the right page for concurrent additional effects. "Severe" means a high probability of noticeable damage with one fluctuation. "Small" usually needs careful inspection to notice the damage, "tiny" needs magnification. Since fracture can accumulate via fatigue, "severe" damage may be reached by several thousand cycles of "small" or several million cycles of "tiny." "Severe" does not usually mean loss of an archival record, unless it is a record for which dimensions are critical.

The largest fluctuation experienced by the object is the "proofed" fluctuation. Any fluctuation smaller than the proofed will cause much less new damage than indicated in this table or by the fatigue mechanism noted above. Most objects in Canada have experienced at least ±20% RH, many ±40% RH, so unless they have been repaired, their proofed fluctuation is typically at least ±20% RH. These are cautious estimates based on observations of collections, and currently available mechanical models.

Different museums experience very different mould histories, despite similar climate. Figure 4 explains most of these differences. Note how much the time for visible mould shortens in the RH range of 70% RH to 90% RH – from 100 days at 70% RH to two days at 90% RH. Note also that stable RH is not a good thing if it is a stable RH just within the danger zone of Figure 4. Far better for a collection stuck most of the time at 70% RH to have its RH fluctuate down to the safe zone every few days, since it will reset the mould growth clock back to zero.

Temperature plays a role as well in the onset of mould. Figure 4 holds for warm temperatures (~25 °C), so it represents a cautious generalization across all other temperatures. Graphs showing more detail on the role of temperature and RH in onset of mould are available in the key readings noted at the end of this section

Damp causes rapid corrosion of metals. The layer of water molecules that is always present on the surface of metals, grows rapidly above 75% RH. In addition, the ubiquitous contaminant from our hands, salt (NaCl), deliquesces (Glossary) above exactly 75% RH, and forms a very corrosive solution.

RH above or below a specific critical value

Some minerals deliquesce above a certain RH, i.e., they form a salt solution by absorbing moisture from the air. For example, common table salt, sodium chloride (NaCl) deliquesces at 75% RH, and is widely used to melt ice on roads. Calcium chloride (CaCl2) deliquesces at 33% RH, and is used in Canada and the US to control dust on roads, and by farmers as an anti-freeze for the ballast water in tractor tires (thus it can become widespread in agricultural collections.) Magnesium chloride (MgCl2) deliquesces at 35% RH, and is found in sea water, and thus in the aerosols near the sea. If any of these salts have fallen on the surface of a metal object, especially iron and steel, the relatively harmless crystals change into an aggressively corroding salt solution above the critical RH.

In archaeological iron and bronze, a complex sequence of critical RH values, each due to a specific compound in the chain of corrosion, determines the rate of corrosion. In general for metals, the lower the RH the better, above 75% RH all corrosion speeds up a lot. If possible, avoid or remove any contaminating salt from these objects.

Unstable glass (such as the trade beads in Figure 2) "sweat" when the RH is above a critical RH (~55% RH) because fluxing compounds in the glass deliquesce, on the other hand they "crizzle" when the RH is below the critical RH (~40% RH) that causes dehydration of other compounds in the glass. The gap between these two critical RH forms the safe range for these unstable glasses.

A small fraction of minerals, such as hydrates and pyrites have specific critical RH above or below which they can crumble and or weep. For more information consult Waller ().

RH above 0% (when any water vapour is incorrect)

This may seem an odd definition for an incorrect RH, but it applies to all those archival materials such as acidic paper, magnetic tape, acetate and nitrate films, that decay chemically within a few decades – becoming weak, yellow, and brittle, or in some cases sticky (Figure 3). The chemical reaction behind this decay – acid hydrolysis – requires moisture, so the presence of any water vapour, any RH above 0%, permits the reaction to proceed. The rule of thumb is that the rate of decay can be cut by more than half each time the RH is halved. Table 1 summarizes the approximate lifetimes for various classes of objects at various RH (The section Pollutants discusses this process as well, since in this situation water vapour behaves like a pollutant).

RH fluctuations

Finally we come to the type of incorrect RH that has concerned museums more than any other – RH fluctuations. Although the physical phenomena that underlie damage from RH fluctuation are analogous to those discussed under fluctuations in the section on Incorrect temperature, the collections that are vulnerable are not at all the same.

A change in RH causes the moisture content of organic materials such as wood, paper, leather, photographs, negatives, plastics, paints, glues, etc. to change, which in turn causes their size to change. If the material is free to expand and contract as RH goes up and down, then there is no problem, but if the material is constrained by other components of the object, or simply by its own inner bulk during a rapid fluctuation, then expanding parts will be crushed, and shrinking parts may fracture (as with the paint in Figure 3).

A considerable amount of research on this subject has accumulated in the last two decades (Michalski , Erhardt ). Just as important, many conservators and collection managers with long experience of their collections have begun to share informally their observations and conclusions about the damage, or lack of damage, that they have seen over the decades. Taking all this information into account, Table 1 summarises our current best estimate of the likelihood of mechanical damage from various ranges of fluctuation (in the portion labeled "RH fluctuations").

Estimates for the fluctuation damage in Table 1 were derived by starting with what one actually sees in terms of fracture damage in collections that have experienced very low RH. In any cold climate zone, such as Canada, one can assume that heated and unhumidified buildings in the past experienced ~10% RH for sustained periods of time. The fact is, many classes of objects, such as paper bound books, wood handles, traditional wood doors, etc., survived very well, and the only physical damage present is clearly from poor handling. On the other hand, some things did crack, delaminate, or literally fall apart, e.g., barrels and wagon wheels. Some have even cracked audibly in their first winter in a heated museum (wooden folk art) while the collection manager sat quietly at their desk! Together with the current understanding of the science of these phenomena, we can generalize our observations across whole categories of objects. To a very great extent, the most important characteristic is not what specific material is in the object, but how it is assembled, and whether this assembly leads to constraint of some components.

What about many multiple fluctuations? Repetitive stresses can give rise to fatigue cracking Beginning with the "single cycle stress" that causes fracture, engineering data from many materials shows that at about one quarter of this stress for brittle materials (glass, ceramics, old oil paint) and one half of this stress for tough materials (wood, paper, leather) fatigue cracking will occur after about a million cycles. By about one eighth of this stress, fluctuations will be tolerated indefinitely, but since it will take 3,000 years to reach a million daily cycles (!), and since most objects cannot respond fully to cycles faster than this, then we can take the million cycle /one quarter stress combination as a very cautious extrapolation of how much to worry about multiple fluctuations.

The century old, heavily cracked and cupped Krieghoff painting experienced daily and seasonal fluctuations in RH and temperature – 30, 000 daily cycles, and ~100 seasonal cycles. It shows severe cracking, except in the bands over the stretcher bars. The wood of the stretcher bars can moderate the RH in their immediate vicinity for about 30 hours, no more, so they can eliminate the daily fluctuations in the painting layers nearby, but not the seasonal. Since the seasonal fluctuations are about the same, or larger, than the daily fluctuations, we can conclude that 30,000 cycles in RH are very much worse than 100 cycles, as expected.

If one is not convinced by this model of fluctuation damage and its predictions of risk, as in Table 1, one can draw instead upon the concept of a "proofed fluctuation". Any object known to have been at least once at some very low RH, say 10% RH, or at least once at some high RH, say 80% RH, is not susceptible to further mechanical damage from one more event of the same magnitude, since any fractures, delaminations and irreversible compressions will have already taken place (unless it is known to have weakened significantly from other causes in the interim). This is quite distinct from the other forms of incorrect RH, such as damp, or RH above zero, since mould and corrosion and acid hydrolysis do accumulate damage no matter how much has happened before. The fatigue effect does mean that one must modify a simplistic "proofed fluctuation" by noting that risks from a single fluctuation should be predicted in light of the "proofed single fluctuation" and that the risks from repetitive fluctuations should be predicted in light of the "proofed repetitive fluctuations." In other words, any future pattern of fluctuations that is similar to the past pattern of fluctuations cannot be expected to cause significant fluctuation damage. A practical corollary is that even modest improvements on past climate conditions will eliminate the risk of physical damage. It is important, therefore, to be accurate about assessing past climate control, and not to underestimate how bad it was, since the worse one knows the past to have been, the easier it will be to make the future better (the same is shown for temperature fluctuations).

A common question about RH fluctuations in small seasonal museums concerns winter operation: should I heat in the winter if I can't humidify? And if I need to open for occasional winter events, is gradual heating safer for furniture? The answer to both questions is "no." Winter heating causes RH to fall, as noted earlier under "The relation between RH and temperature." In many areas of Canada, by December, this can mean as low as 5% RH indoors when heating to 21°C without humidifying. This creates a high risk of the cracking of furniture (as in Table 1) but there is an important qualification: only if the low RH is maintained long enough for the furniture to fully respond. Most pieces of furniture take many days, even months, to respond fully, so one can reduce the risk from a limited period of low RH by keeping it as brief as possible, even if it necessitates an abrupt change.

Sources of Incorrect Relative Humidity

Sources determined by the local climate

Wet weather obviously leads to problems of damp as illustrated in Figure 5. The converse is not true – a dry climate does not imply low RH, it only implies low precipitation. In dry climates such as the foothills of Alberta, daily average RH rarely falls below 35% RH, and is usually in the range of (40-70)% RH, as it is in most climates most days. Very low RH in Canadian museums only occurs with indoor heating. In summary, high RH problems are exacerbated by wet climates, and low RH problems are exacerbated by cold climates, since people like to heat indoors.

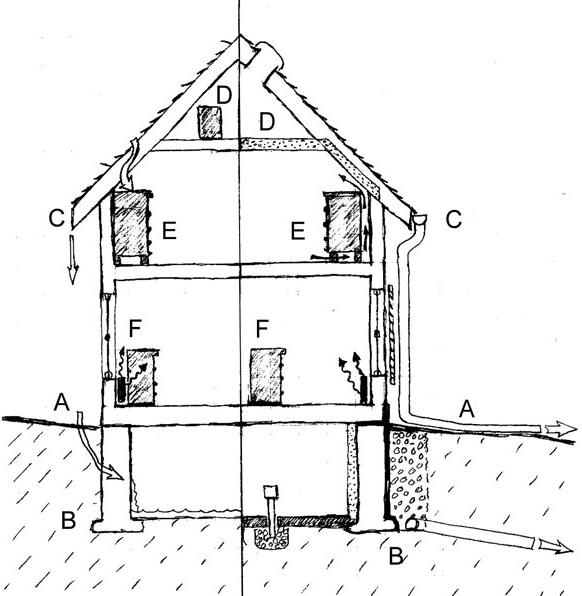

Sources determined by site geography and building micro-climates

- A: surface drainage;

- B: soil drainage;

- C: rainwater;

- D: hot attics;

- E: exterior walls;

- F: heating systems.

Because of space limitations, small museums often consider the basement as an option for collection storage, or even for display. Common experience teaches us that basements, or the ground floor of buildings with no basement, are associated with damp.

Museums also often use attics for museum storage. In poorly ventilated attics, summer sun causes very high temperatures, which in turn causes very low RH.

In rooms other than the basement or the attic, the most common problems occur near sources of heat (causing low RH), such as sunny windows or perimeter heaters, or sources of cold (causing high RH), such as exterior walls.

In all such instances, if one suspects a possible source of incorrect RH, follow the procedures described under "Detect" in the section "Control of Incorrect RH."

Basements: Distinguishing rising damp from condensation on cold surfaces

There are two very distinct sources of damp in basements, with distinct means of control – rising damp, and cold surfaces. To distinguish the two, select a 30 cm square of the damp wall or floor, and wipe it dry. Place a 30 cm square piece of clinging plastic food wrap over the area, using tape or weights to hold the film edges down. Monitor the film until fogging or droplets form (a day or two). If the droplets are underneath the film, the problem is rising damp, and a source of external water needs locating and solving. If the droplets are on top, the problem is warm humid air entering the basement and forming condensation on the wall.

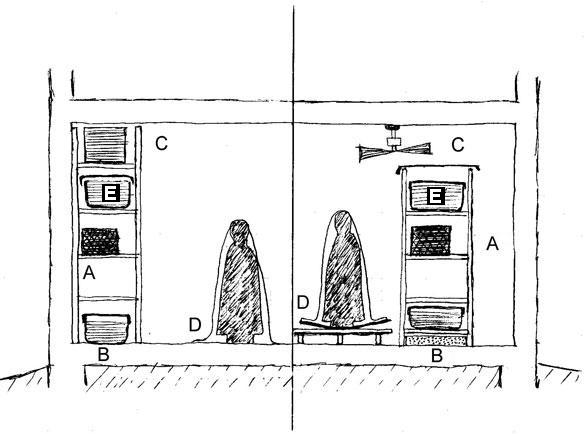

Sources determined by the micro-climates of portable fittings

- A: fittings placed near exterior walls;

- B: fittings placed near cold damp floors;

- C: fittings placed near hot dry ceiling;

- D: dust cover draped over damp floor;

- E: semi-airtight packaging.

Shelving or cabinets placed against exterior walls suffer high RH during cold weather. Objects that are themselves good insulators, such as rolled textiles, costumes, suffer the most. Shelving and cabinets aggravate the problem of high RH near cold floors even more, since cold air sinks. Cabinets placed against south facing windows may protect the objects from sunlight, but the result is a heated, very low RH interior.

If the floor is concrete on ground, or a wooden floor above a dirt crawl space, it may be a source of rising damp. When museums use plastic dust covers over such sources of damp, or if the floor is prone to occasional puddles, then the plastic wrap will trap the damp, and exacerbate the problem. Check the floor for rising damp as noted earlier.

In all such instances, if one suspects a possible source of incorrect RH, follow the procedures described under "Detect" in the section "Control of Incorrect RH."

Sources determined by the micro-climates of packaging

Moisture-proof packaging benefits almost all collections in almost all situations, not only blocking damp and RH fluctuations, but also blocking pollutants, insects, and many physical forces.

Occasionally, however, packages become sources of damp, or aggravate damp from outside. Three problems arise: placing objects that are damp in the package, placing packaged objects in a situation of uneven temperatures, and placing packaged objects in areas that alternate between dry and damp conditions.

Packaging damp objects can happen inadvertently – packaging on a day when the room RH goes unusually high, or shortly after wet cleaning textiles. These objects will remain damp far longer than if they had been left open.

Uneven temperature across a package leads to damp, even condensation, at the end that is consistently colder than most of the package. This occurs whenever an uninsulated package is placed against a cold wall, whether in a room, truck, or airplane. It can occur whenever part of a package is heated by a sunbeam. It also occurs whenever packages are subjected to very sudden and extreme temperature drops, as in low temperature pest control.

In areas where very damp conditions alternate with dry conditions, whether daily, seasonally, or both, packaging will eliminate the daily fluctuations and reduce the seasonal fluctuations. The package RH will follow some slowly shifting average of the room RH. Whether or not the package interior remains in the safe zone (Figure 4) will depend on many factors: the exact vulnerability of the objects materials, the tightness of the bag, the buffering capacity of the object, and the ratio of damp to dry periods. Prediction, even when possible, is impractical and unreliable – one must either control the periods of room damp, or if that is not possible, monitor the package contents.

In summary, if in doubt as to whether the package microclimate enters the danger zone of Figure 4, whatever the cause, and whatever the possible solutions, one must first measure the RH inside the package RH, as described under "Detect" in the next section.

Control of Incorrect Relative Humidity

Identifying incorrect RH values, and specifying correct RH values

Unlike other agents that we recognize easily, and for which we just want "none", the various types of incorrect RH need identification before we can speak sensibly of control. This can be achieved by considering Table 1, and the section on deterioration. On the other hand, by the time we reach the respond stage, which includes building and running all kinds of active and passive climate control systems, the designers of such systems need a "correct" RH. Table 2 provides some examples of correct RH for collections in terms of the two design parameters: "setpoint" and "permissible fluctuation". Five levels of RH fluctuation are specified: AA, A, B, C, D, and the risks to mixed collections summarized. Note that in Table 2 a correct RH for a mixed collection does not reduce all forms of incorrect RH, it is at best a compromise between conflicting issues, and the residual risks are noted in the far right column.

In the long term, especially for small museums, thinking about RH control is best approached from the perspective of risk management that is, being aware of the most damaging kinds of incorrect RH for your collections, and focusing on their reduction (consult "Risk management.").

| Collection Type | Setpoint or Annual Average | Maximum Fluctuations and Gradients in Controlled Spaces | Collection Risks/Benefits | ||

|---|---|---|---|---|---|

| Class of control | Short a fluctuations plus space gradients | Seasonal adjust- ments in system setpoint |

|||

| GENERAL MUSEUMS, ART GALLERIES, LIBRARIES AND ARCHIVES: all reading and retrieval rooms, rooms for storage of chemically stable collections, especially if mechanically medium to high vulnerability. |

50% RH (or historic annual average for permanent collections) T: A value between 15°C and 25°C (Note that rooms intended for loan exhibitions must be capable of the setpoint specified in any loan agreement, typically 50% RH, 21°C, but sometimes 55% RH or 60% RH). |

AA Precision control, no seasonal changes |

±5% RH ±2°C |

RH: no change up 5°C; down 5°C |

No risk of mechanical damage to most objects and paintings. Some metals and minerals may degrade if 50% RH exceeds a critical RH. Chemically unstable objects unusable within decades. |

| A Precision control, some gradients or seasonal changes, not both |

±5% RH ±2°C |

up 10% RH, down 10% RH up 5°C; down 10°C |

Small risk of mechanical damage to high vulnerability objects, no mechanical risk to most objects, paintings, photographs, and books. Chemically unstable objects unusable within decades. |

||

| ±10% RH ±2°C |

RH: no change up 5°C; down 10°C |

||||

| B Precision control, some gradients plus winter temp. setback |

±10% RH ±5°C |

up 10% , down 10% RH up 10°C, but not above 30°C down as low as necessary to maintain RH control |

Moderate risk of mechanical damage to high vulnerability objects, tiny risk to most paintings, most photographs, some objects, some books and no risk to many objects and most books. Chemically unstable objects unusable within decades, less if routinely at 30°C, but cold winter periods will double life. |

||

| C Prevent all high risk extremes. |

Within range 25% RH to 75% RH year-round T rarely over 30°C, usually below 25°C |

High risk of mechanical damage to high vulnerability objects, moderate risk to most paintings, most photographs, some objects, some books and tiny risk to many objects and most books. Chemically unstable objects unusable within decades, less if routinely at 30°C, but cold winter periods will double life. |

|||

| D Prevent damp. |

Reliably below 75% RH | High risk of sudden or cumulative mechanical damage to most objects and paintings due to low humidity fracture, but high humidity delamination and deformations, especially in veneers, paintings, paper and photographs will be avoided. Mould growth and rapid corrosion avoided. Chemically unstable objects unusable within decades, less if routinely at 30°C, but cold winter periods will double life. |

|||

| ARCHIVES LIBRARIES Storage of chemically unstable collections |

Cold Store: -20°C 40% RH |

±10% RH ±2°C |

Chemically unstable objects usable for millennia. RH fluctuations under one month do not affect most properly packaged records at these temperatures. (Time out of storage becomes the lifetime determinant). | ||

| Cool Store: 10°C 30% RH to 50% RH |

(even if achieved only during winter setback, this is a net advantage to such collections, as long as damp is not incurred) | Chemically unstable objects usable for a century or more. Such books and papers tend to low mechanical vulnerability to fluctuations. | |||

| SPECIAL METAL COLLECTIONS | Dry room 0-30% RH | RH not to exceed some critical value, typically 30% RH | N/A | ||

| a Short fluctuations means any fluctuation less than the seasonal adjustment. As noted in the text under "Response times", however, some fluctuations are too short to affect some objects, or enclosed objects. | |||||

Compiled by Michalski, S. Canadian Conservation Institute for use in the ASHRAE handbook, first published , and in a subsequent edition in , (ASHRAE, ).

Avoid

In existing buildings where large changes are not possible, avoid all the sources of incorrect RH outlined in the previous section, such as Figures 5 and 6. In planning new buildings or renovations, avoid the creation of any of such sources in the first place. Note that the forms of incorrect RH illustrated in Figures 5 and 6 are not necessarily incorrect for all collections, e.g., low RH near a heater is not a risk to a metal collections, it may even be beneficial if the metals are contaminated with salts. Only damp can be generalized as something one must almost always avoid in museums.

Block

At all scales – the building, fittings, and packages – a layer of polyethylene film provides an excellent barrier to both water vapour, and air that carries water vapour, at very low cost. Many building materials with a layer of varnish or paint also make effective barriers.

Blocking incorrect RH at the building scale is often the most effective long-term solution for whole collections, but many subtleties emerge in the control of moisture in buildings, and an adequate description of design principles is beyond the scope of this text. Lstiburek and Carmody () provide an excellent text targeted at smaller buildings and the range of climates found in North America. Before entering this technical world, however, museum staff can certainly concentrate on blocking one of the most common sources of damp in small museums, rainwater and groundwater.

Blocking incorrect RH at the scale of storage cabinets, display cases, and packaging, is well within the scope of museum staff. It can be effectively summarized in two statements: block all the holes and cracks that allow air infiltration into an enclosure; and block any adjacent hot or cold surfaces that give rise to incorrect RH via uneven temperatures.

In detail, blocking air infiltration in cases and cabinets means keeping all holes smaller than anything easily visible, and all cracks smaller than the thickness of heavy paper. Blocking air infiltration in soft packaging like polyethylene bags means closing the package well enough that when squeezed slightly one can feel the resistance of the trapped air. Unfortunately, when taking advantage of tight enclosures to block incorrect RH and external pollutants, one must ensure that the enclosure materials themselves are not sources of pollutants (consult Pollutants).

Blocking hot or cold surfaces, i.e., blocking heat transfer, requires insulation. Some of the solutions in Figures 5 and 6 rely on thermal insulation such as foam slabs, but don't forget that the simplest insulation is just an air gap that allows air circulation, 20 cm or more. (One can think of this as avoidance or as blocking).

As with avoid, whenever block is used as a tactic, one must check the results from time to time by monitoring RH, i.e., "detect".

Detect

Although the general pattern of control follows the stages of avoid, block, detect, respond, and recover/treat, in practice one must often begin an assessment of a particular situation at the detect stage. This is particularly true of an agent that is impossible for us to perceive accurately, such as incorrect RH.

There are four points to bear in mind when trying to detect incorrect RH:

- RH measurement always requires some kind of device.

- RH tends to be very local. One must measure at many points in a space to detect all possible areas of incorrect RH.

- RH usually changes over time, and

- Incorrect RH is often a combination of a particular RH and a particular time period (as in mould growth).

Measuring RH precisely and accurately requires an instrument costing on the order of $100 or more, plus the accessories to do routine calibration (time-consuming but feasible by the average user). Low cost hygrometers found in hardware stores, or desktop weather stations, are unreliable. Many regional conservation organizations offer these instruments on loan, already calibrated, or offer advice on purchasing.

Fortunately, we can sense the worst form of incorrect RH, damp, without elaborate instrumentation. If the object or the surroundings feel damp or smell damp (mouldy) they usually are! Simple and accurate confirmation of damp conditions can be made with table salt, since it deliquesces at 75% RH precisely. A few grains of salt attached to clear sticky tape, placed in any suspicious areas, will become droplets after some hours of exposure to damp. Even if the RH returns below 75% and the salt dries before one views the strip, one can see that the crystals have lost their structure.

When monitoring a building or a room, instruments that record RH over time are most useful. Ideally, one uses several recording instruments, placed in locations expected to have different RH (but focused on where the collections sit, or will sit). Most of the types of incorrect RH depend on the pattern over time. If, for example, one measures a room over time and finds zones that hover near 80% RH for periods of ten days or more, then from Figure 4, those zones can be documented as at very high risk for mould.

When monitoring smaller display cases and cabinets, one is typically looking for incorrect RH of various kinds caused by uneven or fluctuating temperatures, or one is looking for the extent to which external RH fluctuations, daily or seasonal, enter the case. For the former situation, an instrument capable of temperature and RH reading is necessary, but the period of monitoring can be brief. For the latter situation, a temperature reading is not essential, but one must anticipate a long period of monitoring, preferably a full year. In this case, a simple dial hygrometer, read daily, may be the most cost-effective method.

When monitoring packages, in addition to the situations described above for cases and cabinets, one is typically looking for signs of damp from various causes. Enclosing a small dial hygrometer, small data logger, or even an RH colour indicator strip, for a period of one day, is sufficient to detect this incorrect RH. If one has concerns about a packaged collection stored in a room with frequent damp periods, then continual monitoring of many, or all bags, is necessary, and the colour indicators strips may be the only reasonable alternative (aside from fixing the room RH).

When monitoring the collection itself for signs of mechanical damage, great care must be taken in interpreting symptoms. Collection caretakers often point at cracked furniture and cite them as proof that they need a new climate control system. There are three possible flaws in this reasoning: the cracks may not imply anything about current RH control, on close inspection many show decades old dirt or even varnish inside; the cause of the incorrect RH could be a single operational error (someone set the thermostat too high during a winter opening); and finally, the object that has cracked cannot crack again if RH control continues to be the same as the past. Using the collection itself to detect subtle effects of incorrect RH over the long term requires excellent photographic records, and routine inspection of the collection against those records.

Respond

Response to the detection of incorrect RH has several forms. Active machinery – humidifiers and dehumidifiers – respond minute by minute via their humidistats. Engineering consultants and technical information are abundant for building wide systems, e.g. ASHRAE (). Special museum systems, such as humidistatically controlled heating, are available (Consult Vignette 3). Portable domestic humidifiers and dehumidifiers are widely understood, and cost-effective for small museums, although one must take care not to create a water risk with these devices.

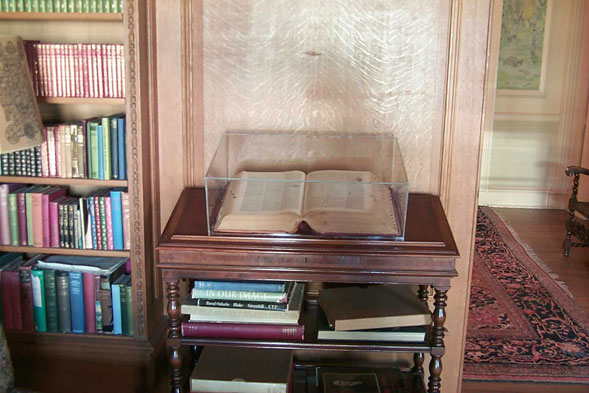

Passive control systems, such as an air-tight display case with the humidity "buffer" silica gel (consult Tétreault and Bégin 2018) depend on the ability of the case contents and the buffer to release or take up moisture when incorrect RH leaks into the case. (This can be thought of as a variation on blocking as well). Articles on silica gel use for museums often do not emphasize enough the role of case air-tightness in the final performance of the system. The book in the case shown in the Vignette 2: Simple display boxes that reduce incorrect RH, needs no extra silica gel, if the acrylic box is visibly air-tight at the base. It will be well protected from all RH fluctuations, i.e., it will "buffer itself." If it is in a leaky box, such as one with a 1mm crack at the top and the bottom seams, then adding one of the recommended ratios of silica gel from the literature will make little difference, and cost much more than just repairing the crack. On the other hand, silica gel is essential when making passive control cases for metal objects requiring very low RH. A case as air-tight as one can manage, and silica gel equal to about 1/10 of the case height, is a good design starting point.

The final form of response to incorrect RH, and the most important, is human. This means the consideration of everything in this section, and informed decision-making by museum staff.

Recover/Treat

One cannot recover from most forms of incorrect RH. Most mould damage remains. Corroded metals lose their original surface. Archive records ageing quickly at high RH must be migrated before the information is lost forever. Only fracture of furniture, paintings, etc. from RH fluctuations can be "reversed," although clearly it is preferable to prevent it, and the repairs are far from perfect.

Control in Terms of Overall Strategies and Target Values

Basic control: No moving parts, no machinery, no energy consumption!

- Ensure reliable walls, roof, windows, doors, with good vapor barriers. In new buildings, explore low energy designs, high thermal mass, high insulation, high airtightness, used by some recent museums and archives.

- Identify and eliminate sources of damp (Figures 5 and 6).

- Use bags, envelopes, or encapsulation on all objects vulnerable to any type of incorrect RH. Transparent polyethylene or polyester is the most reliable, such as food quality bags, e.g. "Zip-Loc" TM.

- Use simple cases on the most sensitive and valuable objects on display. Consult Vignette 2 "Simple display boxes that reduce incorrect RH."

- Use backing boards on all paintings (Consult Daly-Hartin )

Measures such as these that require no moving parts must not be forgotten when jumping to the next level of control, which tends to be more dynamic, interventionist, and thus more vulnerable to errors and accidents. These basic measures will provide control that remains in place even when the power fails, staff change, or the museum cuts its budget.

Optimum control: Different collections, different situations, different control measures

Follow basic control as above, and integrate the following as needed:

- For a mixed historic collection that has remained in an old building for many decades without noticeable change in the last decade, do not "improve" the control systems, e.g. add new components, or change their operation, e.g., heat more in winter than before, without carefully considering exactly what are the current incorrect RH, and what evidence you have to believe they will cause more damage than the "improvements". Begin by ensuring the reliability and long-term maintenance of any current building and systems.

- Use humidistatically controlled heating where feasible. (Consult Vignette 3: A humidistatically controlled storage building.)

- For small quantities of especially sensitive and or valuable objects, use passive microenvironments, such as airtight display cases and storage cabinets, with additional buffers such as silica gel if necessary.

- When considering full scale "building climate control," recognize the building envelope's limitations, especially if it is of historic value itself. Begin with reference to the New Orleans Charter for Joint Preservation of Historic Structures and Artifacts. Assess collection requirements, then select and implement an appropriate ASHRAE control setpoint and fluctuation level. (Table 2).

- When the objective is the display of traveling exhibitions, recognize that some major lending institutions require ASHRAE level A control, or sometimes AA. Purpose built rooms or buildings are usually required. Consider a "room within a room" or cocoon approach, or if available, a dynamic buffering approach.

Conclusions

Thirty years of excellent RH control by mechanical systems at huge expense means little to overall preservation if at some point in those 30 years there was four weeks of exceptionally low RH in an unpackaged furniture collection, or two weeks of very high RH in a photo archive kept in permeable paper packages.

One might argue, after such an experience, if one was lucky, that the collection still looks OK, but that begs the question of why one tried so hard to control the conditions 99% of the time. Or one might argue that if the collections had been in impermeable packaging, the risk would have been successfully blocked. Again, why bother with the elaborate mechanical control?

We tend to assume that RH control means some kind of automatic system, but these systems fail eventually, or they simply never existed due to lack of funding. The most important form of response, in museums both large and small, is human. Staff must learn to recognize the various incorrect RH, and begin to assess the risks to the collections, using Table 1. Often, one will find that only a small and manageable part of the collections is at significant risk from incorrect RH.

Control begins with those items listed above in Basic Control. Most of the time, these make sense even before assessment. With the basics in place, the more complex selection of Optimal Control Strategies begins. If in the initial example, the photographic archive used airtight plastic enclosures, and the furniture was wrapped in heavy gauge polyethylene, then many weeks of very high or very low RH would no longer pose a significant risk: they would be blocked.

A hanging quilt on display on an exterior wall is a different problem: it is not at all at risk from winter dryness, but it is at risk of mildew if the museum is humidified and the wall is cold (unheard of in winters before modern climate control).

Thirty years ago, humidity control for Canadian collections seemed a combination of simple specifications and high, unsustainable costs. We have discovered that for many museums and the heritage buildings that house them, the reverse makes more sense – complex specifications but low, sustainable costs.

References

- Daly Hartin, D. . Backing boards for paintings on canvas. CCI Notes Nº 10/10, (Canadian Conservation Institute: Ottawa).

- Erhardt, D. and M. Mecklenburg. . "Relative Humidity Re-Examined," in Preventive Conservation: Practice, Theory, and Research. Preprints of the Contributions to the Ottawa Congress, -. IIC, (): 32-38.

- Lafontaine, R. H. . "Humidistatically controlled heating: a new approach to relative humidity control in museums closed for the winter season" Journal of the International Institute for Conservation, Canadian Group 7. Issue Number: 1-2. 35-41.

- Lstiburek, J. and J. Carmody. . Moisture Control Handbook: Principles and Practices for Residential and Small Commercial Buildings. (John Wiley & Sons, New York, NY).

- J. Lstiburek is the leading expert in North American on moisture control in buildings, and the role of vapour barriers and air barriers.

- Michalski, S. . "Relative Humidity In Museums, Galleries And Archives: Specification And Control." In Bugs, Mold and Rot II: Moisture Specification and Control in Buildings, edited by W. Rose and A. Tenwolde, National Institute of Building Sciences, Washington, DC, pp. 51-62.

- New Orleans Charter.

- Tétreault, J. and P. Bégin. Silica Gel: Passive Control of Relative Humidity, revised. Technical Bulletin 33. Ottawa, ON: Canadian Conservation Institute, 2018.

- Waller, R. "Temperature and humidity-sensitive mineralogical and petrological specimens" in The care and conservation of geological material: minerals, rocks, meteorites, and lunar finds, ed. Howie, Frank M. (Butterworth-Heinemann Publishers: Guildford) . pp. 25-50

Key Readings

- ASHRAE. . "Museums, Galleries, Archives and Libraries (Chapter 21)", ASHRAE handbook: Heating, Ventilating, and Air-Conditioning Applications, SI edition (American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc. : Atlanta), pp. 21.1-21.16.

- Michalski, S. Guidelines for Humidity and Temperature for Canadian Archives. Technical Bulletin 23. Ottawa, ON: Canadian Conservation Institute, 2000.

Glossary

Absolute humidity

A measure of humidity in terms of the weight of water vapour per unit volume of air. At 20°C, the absolute humidity of 100% RH is 17.3 g/m3.

Deliquesce

The formation of a solution by certain salts that absorb moisture from the air above a critical RH value. E.g., table salt (NaCl) deliquesces at 75% RH and above.

Dewpoint

The temperature to which the air must be cooled to reach 100% RH. The dewpoint for air at 20°C and 50% RH is near 10°C. Often used by engineers to characterize the amount of water vapour in the air.

Hygrometer

Any device that measures RH. Not to be confused with hydrometer, a device to measure the density of a liquid.

Psychrometer

A type of hygrometer, consisting of two thermometers, one with a water soaked sock on its bulb (wet bulb) and one without (dry bulb).

Psychrometric chart

A graph widely used by engineers to plot the relationships between the vapour pressure of water in air, the air temperature, RH, and other parameters such as dewpoint. In the Key Readings identified there are psychrometric charts that include isoperms, i.e., lines of constant chemical lifetime of archival materials.

Relative humidity

The ratio of the partial water vapour pressure to the saturation water vapour pressure at the same temperature. Can also be expressed as the ratio of the concentration of water vapour to the saturation concentration of water vapour at the same temperature. Expressed as a percentage.

Vapour pressure

A measure of humidity in terms of the pressure exerted by the water vapour (which contributes to the overall air pressure). At sea level, 20°C, the contribution to air pressure due to the dry air is 101 Kilopascals (kPa), that due to the water vapour at 100% RH is 2.34 kPa (or 1.2 kPa near 50% RH).

Vignettes

Vignette 1. The relation between RH, temperature, and object moisture content.

The maximum concentration of water vapour in air more or less doubles with each rise in temperature of ~10°C. For example, at ~30°C, the maximum amount of water vapour, i.e. 100% RH, is ~36 grams per cubic meter, whereas at 20°C it is only ~18 grams per cubic meter, at 10°C it is ~9 grams per cubic meter, at 0°C it is ~4 grams per cubic meter, and so on. Thus 50% RH means that the water vapour concentration half the maximum noted, e.g., ~9 grams per cubic meter at 20°C.

The winter heating problem arises because cold outdoor air, e.g., 0°C and 50% RH, contains only ~2gram of water vapour per cubic meter. From the point of view of an object at 0°C, what matters is the 50% RH: the object will contain the same moisture as it does at 50% RH in a room at 20°C. Wood and paper, for example, will contain ~80 grams of moisture per kilogram of material. The problem arises when this outdoor winter air with ~2 grams of moisture per cubic meter is heated inside a building to 20°C. Since this 2 grams is only 1/9 of the maximum value of 18 grams at 20°C, the result is ~11% RH in the heated room (unless humidifiers add more vapour). If outdoors is colder, or the room warmer, the RH drops even more.

The cold damp problem arises with the reverse situation – air that is cooled. Air at 50% RH, if cooled by 10°C, e.g., from 25°C to 15°C, will now be at 100% RH. Further cooling results in condensation on objects. In hot humid weather, outdoor air coming into contact with floors or walls just a few degrees cooler than the air outside will form damp.

Vignette 2. Simple display boxes that reduce incorrect RH

Vignette 3. A humidistatically controlled storage building

The Prince Edward Island Heritage Foundation is responsible for several historic houses, each with storage needs for reserve collections that cannot be met by the houses. Many historic house museums suffer the same problem. When a recently built industrial building went on sale in the area, the group purchased it for collections' storage. Full climate control of the building would not have been possible without extensive modifications to the walls, but it was possible to consider humidistatically controlled heating. In this approach, the building system is switched on and off by a humidistat, rather than the thermostat. Heaters are switched on only if the humidity is above 50% RH. As the air warms up, RH falls, and when it reaches 50% RH, the heating is switched off. Full details are contained in the article by Lafontaine (). Periods of high humidity in summer are controlled by small portable dehumidifiers.

Related resources

Video – Monitoring your environment

Monitoring your environment

This video was created by the Canadian Conservation Institute.

Time-lapse Video of Deterioration: Oil Painting, Incorrect Relative Humidity

Time-lapse Video of Deterioration: Oil Painting, Incorrect Relative Humidity

This video was created by the Canadian Conservation Institute.

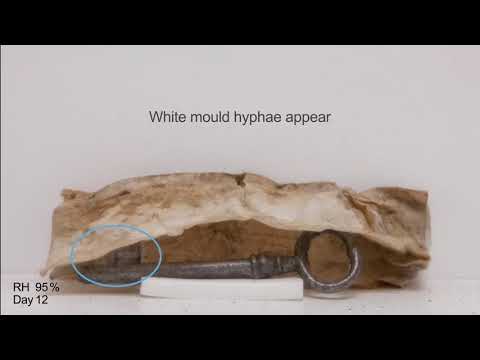

Time-lapse Video of Deterioration: Parchment and Iron Key, Incorrect Relative Humidity

Time-lapse Video of Deterioration: Parchment and Iron Key, Incorrect Relative Humidity

This video was created by the Canadian Conservation Institute.

Time-lapse Video of Deterioration: Two Iron Keys, Incorrect Relative Humidity and Pollutants

Time-lapse Video of Deterioration: Two Iron Keys, Incorrect Relative Humidity and Pollutants

This video was created by the Canadian Conservation Institute.

Transcript | Watch on YouTube

Thanks to the Centro Nacional de Conservación y Restauración in Chile, the Canadian Conservation Institute’s web resource Agents of deterioration, translated into Spanish by CCROM, is now available free of charge. Intended for curators and conservators, the resource identifies 10 primary threats specific to heritage environments.