Draft guidance on sampling and mitigation measures for controlling corrosion: Guidance for public consultation

On this page

Introduction and background

Corrosion is a common issue in Canadian drinking water supplies. Corrosion is the deterioration of a material, usually a metal, which results from a reaction with its environment. In drinking water distribution systems, materials that could be affected by (internal) corrosion and release increased amounts of contaminants include metal pipes (e.g., lead service lines) and fittings. Corrosion tends to increase the concentrations of many metals in tap water (i.e., corrosion by‑products) at the consumers’ tap. Corrosion deposits in pipes also provide a major reservoir for a broad variety of elements, some of which are a health concern.

The term corrosion is also commonly applied to the dissolution and carbonation (i.e., precipitation of CaCO3) reactions of cement-based materials. An increase in pH often occurs as a result of this reaction, which can be detrimental to disinfection and the aesthetic quality of the water, as well as reducing the effectiveness of corrosion control chemicals. In some cases, the chemical attack on the pipe by the water may cause a reduction of structural integrity and subsequent failure.

Corrosion in drinking water distribution systems can be caused by several factors, including the type of materials used, the age of the piping and fittings, the stagnation time of the water and the water quality in the system, including its pH. The most influential properties of drinking water when it comes to the corrosion and leaching of distribution system materials are pH and alkalinity. Other drinking water quality parameters of interest are temperature, calcium, free chlorine residual, chloramines, chloride, sulphate and natural organic matter (NOM). Any change to the drinking water treatment process or to water quality (including from blending) may impact corrosion in the distribution system and in household plumbing.

In this document, “corrosion control” refers to the action of controlling or mitigating the release of metals, specifically lead, that results from the corrosion of materials in drinking water distribution systems. Although corrosion itself cannot readily be measured by any single, reliable method, the levels of lead at a consumer’s tap can be used as an indication of corrosion. Monitoring of lead levels at the tap can help identify sources of lead and aid in the selection of strategies to effectively control corrosion and reduce lead levels at the tap.

There are no direct health effects linked to corrosion in distribution systems. However, corrosion may cause the release of contaminants at levels that would be a concern for the health of Canadians. The main contaminant of concern is lead, which is used as the trigger to initiate corrosion control programs, including mitigation measures. The current drinking water guideline for lead, based on health effects in children, is a maximum acceptable concentration (MAC) of 0.005 mg/L. Corrosion control treatment can effectively minimize lead concentrations at the point of consumption. However, when water is supplied through a lead service line, treatment alone may not be sufficient to reduce lead to concentrations below the MAC. As such, the removal of the full lead service line is likely the most effective and most permanent solution.

Other contaminants that can be released as a consequence of corrosion in drinking water distribution systems include copper and iron. The guideline for copper is 2.0 mg/L. The guideline for iron is an aesthetic objective of ≤ 0.3 mg/L in drinking water. This guidance is meant to complement the information on sampling and mitigation measures provided in the Guidelines for Canadian Drinking Water Quality for lead. Microbiologically influenced corrosion is beyond the scope of this document.

Although the protocols described in this document represent the best approach to address corrosion in drinking water distribution systems, based on available science and monitoring data, they may not be practical or feasible in all systems. In such cases, a different or scaled- down version of this approach may provide some improvement in health protection and water quality (see section on considerations for small systems).

In this document, the term “distribution system” will be used broadly to include both the system of conduits by which a public water supply is distributed to its consumers as well as the pipes, fittings and other apparatus adjacent to and within a building or dwelling for bringing in the water supply.

Corrosion control programs and protocols

Any size of drinking water distribution system can be subject to corrosion; therefore, it is important for responsible authorities to conduct a monitoring program to assess if and to what degree corrosion may be occurring in a system and to take appropriate corrective measures. A corrosion control program for a drinking water system should be based on the levels of specific contaminants at the consumer’s tap. Although corrosion will affect the release of several contaminants, the primary focus should be lead, since it is the contaminant whose presence is most likely to result in adverse health effects at concentrations typically seen in residences and distributions systems. The Framework for residential corrosion control program shows activities and steps to undertake to achieve a holistic approach to corrosion control and corrosion control treatment (i.e., chemical). This framework outlines the interconnection between the various elements of the System Corrosion Control Plan (SCCP) with those of the monitoring protocols. An example of some of the elements to include in the SCCP for lead can be found in Figure 1. The SCCP is beyond the scope of this document.

Figure 1. Example of elements to include in an SCCP

System Corrosion Control Plan for lead (Pb)

- Lead risk assessment

- Types, locations of lead sources

- Lead Service Line (LSL) inventory & timeline for initial and updated inventory

- Lead sampling and water quality parameter monitoring

- Potential disturbances (planned or urgent road work or distribution system [DS] repairs/upgrades, etc.)

- Mitigation measures

- LSL replacement plan

- Notification prior to repair work

- Point-of-use (POU) filter/bottled water for use after disturbances

- Flushing (temporary measure) after disturbances

- Construction, distribution system/site repair

- Partial LSL replacement

- Corrosion Control Treatment (CCT)

- Assessment of constraints on lead optimization

- Plant optimization studies for simultaneous compliance

- Treatment plant water quality targets (set operational ranges)

- Set ranges and limits for important water quality goals in DS (inhibitor and disinfectant residual, pH, etc.)

- DS characterization and operation in relation to Pb (or Cu) release

- Mitigation of sediment/deposition/biofilm/discolouration (i.e., cleaning) prior to implementation of CCT or optimization

- Repair and recommissioning of lines as supplementary Pb CCT measure

Corrosion control protocols

One of the first steps in implementing a corrosion control program is to conduct monitoring of lead levels at consumers’ taps as well as water quality characterization. This provides responsible authorities with information on the corrosiveness of the water towards lead. The major source of metals in drinking water is related to corrosion in distribution and plumbing systems, so measuring the contaminant at the tap is the best tool to assess corrosion and reflect population exposure. A monitoring program provides the information needed to determine the corrective measures that should be undertaken when lead concentrations above the MAC are observed in the system. It also provides information on the level of monitoring that should be conducted in the future. Water quality monitoring for parameters such as pH and alkalinity are essential to assess both corrosion issues and help determine the effectiveness of a corrosion control program. Sampling protocols will differ depending on the desired objective (see Table 1). As monitoring of lead at the tap can be done using different sampling protocols, it is important that the protocol selected be appropriate to meet the desired objective and type of dwelling.

| Objective | Sampling type | Protocol | |||

|---|---|---|---|---|---|

Regulatory compliance for lead |

First draw (US EPA) | 6+ h stagnation Collect 1 L |

|||

| RDT (U.K./EU) | Random sample collection without prior flushing Captures variable stagnation Collect 1 L |

||||

| 30 MS (Ontario) | 2 to 5 min flush 30 min stagnation Collect first two litres |

||||

Determination of lead sources (plumbing/lead service line)

-length related to location of Pb source |

Profile (or sequential)a sampling –traditional | Defined stagnation time 10 to 20 sequential samples of a defined volume (125 mL, 250 mL, 1 L, etc.) |

|||

| Profile sampling that stimulates particle release | Traditional profile sampling at increasingly higher water flow rate (low, medium and high) | ||||

| Fully flushed sampling | 5 min flush Collect 1 L and compare to validated threshold for presence of LSL |

||||

| 3Ts for schools and childcare facilities: revised manual, U.S. EPA | Overnight stagnation Collect first 250 mL from all taps and fountains Sample results from each facility should be compared to prioritize follow-up sampling and remediation (in consultation with State drinking water authority) |

The objective of the sampling protocols in this document is to characterize whether distributed water is corrosive to the materials found in the distribution system and household plumbing and to determine if corrosion control measures are effective.

If monitoring done as part of a corrosion control program shows lead concentrations in excess of the MAC of 0.005 mg/L, then any or several of the suggested corrective measures should be undertaken, after which the effectiveness of the corrective measures should be determined by appropriate monitoring. This is important to ensure that the corrosion control program is optimized to minimize lead concentrations and reduce exposure to lead and other related contaminants.

Building types

When monitoring for lead as part of a corrosion control program, 2 different situations need to be addressed:

- residential dwellings (up to 6 residences)

- non-residential and residential buildings, which include schools, multi-dwelling buildings and large buildings

In a residential setting, which includes residential dwellings such as single-family homes and multiple-family dwellings (up to 6 residences), monitoring will seek to assess lead concentrations across the system and to identify sources of lead in both the distribution system and the residential plumbing. The purpose of residential monitoring programs is generally to identify and diagnose systems in which corrosion is an issue and to determine the best corrective measures to take when needed. Subsequent monitoring should be done to assess the effectiveness of a system-wide corrosion control program and determine if corrosion control has been optimized.

Due to the complex nature of buildings, monitoring for schools, multi-dwelling (i.e., more than 6 residences) buildings and large buildings will focus primarily on the source of lead within the building’s plumbing system. The purpose of the monitoring program for non‑residential and residential buildings is to locate specific lead problems and identify where and how to proceed with remedial actions. Given that the goal of the sampling protocols for residential dwellings and for non-residential and residential buildings are different, the number of samples and sampling frequency (and corrective measures) will differ for these 2 types of settings.

Corrosion control treatment

The implementation of corrosion control treatment is intended to minimize leaching from distribution system materials to protect consumers’ health. Additional benefits include extended pipe life, reduced leakage and decreased plumbing repairs and replacements. It is generally expected that the costs of implementing corrosion control would both protect human health and extend the life of distribution system materials.

Utilities should ensure that changes made to treatment processes or a change in supply do not make the water corrosive towards lead. Managing water quality by controlling inputs of sources (e.g., blending) and other contaminants (e.g., Fe, Mn) is crucial for effective corrosion control treatment. Although it is recognized that a utility’s responsibility does not generally include residential plumbing systems, most of the guideline values (MAC) established are intended to apply at the consumer’s tap. As such, corrosion control programs need to ensure that the delivered water is not aggressive for all components of the distribution system and the plumbing system.

For the purposes of this document, the distribution system includes the supply pipe that connects the water main to the dwelling and/or building and the plumbing system. Corrosion control programs will vary depending on the responsible authority. They can range from extensive system-wide programs implemented by the water supplier to localized programs implemented by a building owner to ensure a safe and healthy environment for the occupants of residential and non‑residential buildings.

Sampling at the tap

Considering that lead levels at the consumer’s tap may be significantly higher than levels at the treatment plant or in the water mains, strategies to reduce exposure to lead will need to focus on controlling corrosion within the distribution system and on removing lead-containing components, such as lead service lines, from these systems. Although it is recognized that a utility’s responsibility does not generally include residential plumbing systems, most of the MACs are intended to apply at the consumer’s tap. Compliance sampling is undertaken by collecting samples representative of the population served in a discretely supplied area (zonal sampling). All zones should be sampled such that the entire distribution system is assessed and, therefore, all problem zones identified across the entire system.

Lead service line inventory

A lead service line inventory is an important tool in selecting both compliance and sentinel sites when implementing corrosion control. Additionally, the inventory will be critical in managing lead service lines as well as developing and implementing plans for their removal. Sentinel sites are typically used to reflect potential lead issues in the community and to assess the efficacy of corrosion control programs. Sentinel sites should focus on areas confirmed to have lead service lines and include zones supplied by potentially corrosive water (e.g., dead ends in a chloraminated system) and consecutive systems (i.e., public water systems whose drinking water supply is from another public water system). A sampling-based framework (e.g., using profile or flushed samples) for determining the presence of lead service lines can be a helpful tool in developing a lead service line inventory.

Corrective measures

An exceedance of the MAC should be investigated and followed by the appropriate corrective actions. These actions include, but are not limited to, resampling, removal of lead service lines, public education, temporary filter installation at the point-of-use and/or corrosion control treatment measures. Although corrosion control treatment can effectively minimize lead concentrations at the point of consumption, treatment alone may not be sufficient when water is supplied through a lead service line. For this reason, the removal of the full lead service line is likely the most effective and most permanent solution.

Some of these corrective measures could also include distribution system maintenance such as removing iron, manganese and aluminum, which interfere with corrosion control treatment and can also contribute to lead release. It should be kept in mind that flushing the cold water tap has not been found to sufficiently reduce lead exposure in schools, multi-dwelling residences and large buildings in a consistent fashion. These actions should be based on an assessment of the cause of the exceedance using appropriate protocols.

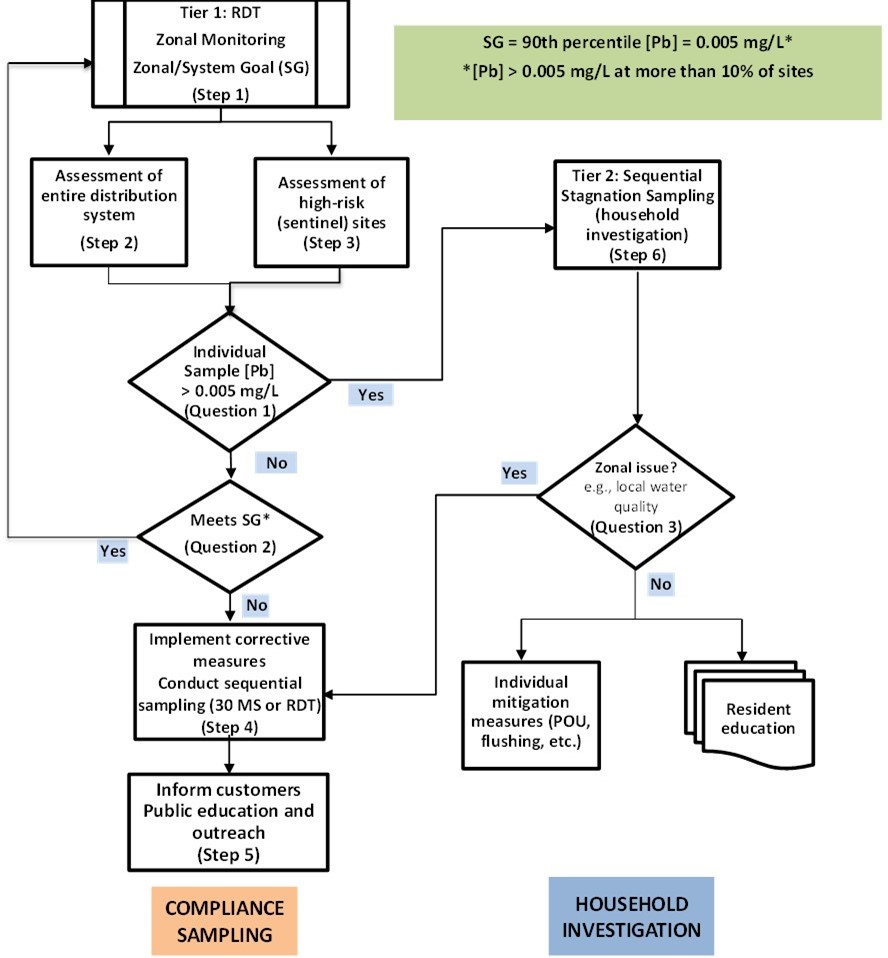

Monitoring protocol for residential dwellings: option 1 – RDT + stagnation (two‑tier)

Sampling at residential sites is a 2-tier approach for assessing corrosion of a variety of lead materials in residential distribution systems. This protocol is based on random daytime (RDT) sampling. The first-tier sampling provides an indication of lead concentrations throughout the system and the need to take action to control corrosion and reduce exposure to lead. A subset of sentinel sites is included in the Tier 1 sampling to characterize zones/areas of highest concern and to assess the effectiveness of planned corrosion control measures. Once a corrosion control program has been put in place, it also provides the appropriate data to assess if corrective measures have been effective in reducing corrosion of different types of lead-containing material throughout the system. When more than 10% of sitesFootnote 1 exceed a lead concentration of 0.005 mg/L (system/zonal goal -SG), then Tier 2 sampling should be conducted.

Tier 2 sampling is conducted at a reduced number of sites from Tier 1 and will provide more detailed information on the concentrations of lead contributed from different lead‑containing materials in the distribution system (lead profile). This will enable responsible authorities to determine the likely source(s) and potentially the largest contributor(s) of lead so that the suitable corrective measures can be selected and corrosion control can be optimized. Analysis of other metals (e.g., Cu, Cd, Fe, Mn) in the collected samples can help in identifying source of lead (e.g., brass, galvanized steel) or reveal interferences that impair corrosion control treatment (i.e., orthophosphate) that should be addressed.

In some cases, the responsible authority may wish to collect samples for both tiers during the same site visit. This step eliminates the need to return to the residence if the system goal (SG)Footnote 2 for Tier 1 is not met but it may not be feasible for some situations (e.g., 6 h stagnation sampling). The analyses for the second tier are then done only on the appropriate samples, based on the results of the Tier 1 samples.

Tier 1 sampling protocol (RDT)

Random daytime sampling captures typical exposures for a population, including potential exposure to particulate lead. It identifies priority areas for actions to reduce lead concentrations and assesses compliance system-wide.

A first-draw 1 L sample is taken at the consumer’s cold drinking water tap (without removing the aerator or screen) randomly during the day in each of the residences. There is no stagnation period prescribed and no flushing should occur directly prior to collecting the sample, to better reflect actual consumer use. If less than 10% of sites have lead concentrations above 0.005 mg/L, utilities should provide consumers in dwellings with lead concentrations above 0.005 mg/L with information on methods to reduce their exposure to lead (such as those listed in measure 1 below). It is also recommended that utilities conduct follow-up sampling for these sites to assess the effectiveness of the corrective measures undertaken by consumers.

When more than 10% of the sitesFootnote 1 have a lead concentration greater than 0.005 mg/L (system/zonal goal -SG), it is recommended that utilities take the following measures:

- Communicate the results of the testing to the consumers and inform them of the appropriate measures that they can take to reduce their exposure to lead, particularly for children and formula-fed infants. Corrective measures that consumers can take may include any or a combination of the following:

- flushing the system after any extended period of stagnation

- using certified drinking water treatment devices until the lead sources can be replaced

- replacing their portion of the lead service line (ideally, in coordination with the replacement of the utility’s portion)

- replacing brass fittings or in-line devices and/or

- replacing galvanized piping or copper piping that have lead solder

- Initiate a public education program to encourage consumers to flush the water after a period of stagnation while appropriate corrective measures are being assessed or undertaken. Flushing should be conducted so that any water that has been in contact with lead present in faucets, fittings and the associated solders as well as the lead service line following a period of stagnation is removed. Consider supplying or recommending the use of drinking water treatment filters certified for the removal of lead.

- Conduct additional sampling (as outlined in the Tier 2 sampling protocol) at 10% of the sites sampled in Tier 1 at which the highest lead concentrations (above 0.005 mg/L) were observed.

- Implement appropriate corrective measures to control corrosion community-wide. Results of the Tier 2 sampling should be used to help determine the corrective measures for the system, which may include any or a combination of the following:

- replacing lead service lines (as well as pigtails and gooseneck, if present);

- adjusting the pH and alkalinity

- adjusting the pH (if needed) and adding corrosion inhibitors and/or

- replacing brass fittings, in-line devices and/or galvanized piping

- Encourage homeowners to periodically clean debris from the screens or aerators of drinking water outlets. If a substantial amount of debris is removed from the aerator or screen, authorities may want to retest the water from these outlets following the same protocol. If results of the retesting show lead concentrations below 0.005 mg/L, utilities should investigate whether particulate lead may be contributing significantly to elevated lead levels and whether regular cleaning of the aerator or screen is an appropriate corrective measure.

Tier 2 profile sampling protocols

This sampling protocol is an investigating tool that can help identify the source of the lead. It provides a profile of lead contributions from the faucet, plumbing (lead in solder, brass and bronze fittings, brass water meters, etc.) and any contribution from the lead service line. Tier 2 profile sampling is required only when the Tier 1 sampling identified more than 10% of sites with lead concentrations above 0.005 mg/L. Profile sampling is conducted at 10% of the sites sampled in Tier 1, specifically the sites at which the highest lead concentrations were measured. For smaller systems (i.e., serving 500 or fewer people), a minimum of 2 sites should be sampled to provide sufficient lead profile data for the system.

Four consecutive 1 L samples are taken at the consumer’s cold drinking water tap (without removing the aerator or screen) after the water has been stagnant for a defined period of a) 30 min -30 MS or b) 6 h minimum. Selection of the stagnation time is based on practical considerations and the desire to generate higher lead concentrations and thus make it easier to evaluate any changes.

Each 1 L sample is analyzed individually for total lead to obtain a profile of lead contributions from the faucet, plumbing (lead in solder, brass and bronze fittings, brass water meters, etc.) and any contribution from the lead service line. Note: It may be of benefit to collect smaller cumulative volumes for each 1 L sample to more precisely identify the source of lead. Since four consecutive 1 L samples may not identify the lead service line contribution in larger plumbing systems, the collection of additional 1 L samples can be beneficial in this regard.

Tier 2 a) 30 MS profile sampling

This sampling protocol measures the concentration of lead in water that has been in contact for a transitory and short period of time (30 min) with the lead service line as well as with the interior plumbing (e.g., lead solder, lead brass fittings). Four consecutive 1 L samples are taken at the consumer’s cold drinking water tap (without removing the aerator or screen) after the water has been fully flushed for 5 min and then left to stagnate for 30 min. Each 1 L sample is analyzed individually to obtain a profile of lead contributions from the faucet, plumbing and a portion or all of the lead service line. Utilities may choose to collect four 1 L samples during the site visits for Tier 1 sampling and proceed with analysis of these samples once the analysis of the first Tier 1 sample identifies the appropriate residences (i.e., those with the highest lead concentrations).

Tier 2 b) 6 h (minimum) profile sampling

Four consecutive 1 L samples are taken at the consumer’s cold drinking water tap (without removing the aerator or screen) after the water has been stagnant for a minimum of 6 h. Each 1 L sample is analyzed individually to obtain a profile of lead contributions from the faucet, plumbing (lead in solder, brass and bronze fittings, brass water meters, etc.) and the lead service line.

Profile sampling results

Results from either of the profile sampling options above will inform the selection of mitigation measures that utilities can implement or recommend to the consumer. Examples include:

- Communicate the results of the testing to the consumers and inform them of the appropriate measures that they can take to reduce their exposure to lead, particularly for children and formula-fed infants. Corrective measures that consumers can take may include any or a combination of the following:

- flushing the system after any extended period of stagnation

- using certified drinking water treatment devices (i.e., certified for lead removal) until the lead sources can be replaced

- replacing their portion of the lead service line (ideally, in coordination with the replacement of the utility’s portion)

- replacing brass fittings or in-line devices and/or

- replacing galvanized piping or copper piping that has lead solder

- Initiate a public education program to encourage consumers to flush the water after a period of water stagnation while appropriate corrective measures are being assessed or undertaken. Flushing should be conducted so that any water that has been in contact with lead present in faucets, fittings and the associated solders as well as the lead service line following a period of stagnation is removed.

- Consider supplying or recommending the use of drinking water treatment filters certified for the removal of lead.

- Implement appropriate corrective measures to control corrosion community-wide. Analysis of individual Tier 2 samples will help provide information on the source of lead in the system. However, if the source of the lead problem cannot be identified by the lead profile in the 4 1-L samples, further investigation may be required. Depending on the source of lead and the number of residences affected, corrective measures may include any or a combination of the following:

- replacing lead service lines (as well as pigtails and goosenecks, if present)

- adjusting the pH and alkalinity

- adjusting the pH (if needed) and adding corrosion inhibitors and/or

- replacing brass fittings, in-line devices and/or galvanized piping

- Encourage homeowners to periodically clean debris from the screens or aerators of drinking water outlets. If a substantial amount of debris is removed from the aerator or screen, authorities may want to retest the water from these outlets following the same protocol. If results from retesting show lead concentrations below 0.005 mg/L, utilities should investigate whether particulate lead may be contributing significantly to elevated lead levels and whether regular cleaning of the aerator or screen is an appropriate corrective measure.

Figure 1 - Text description

The flow chart has steps and decision points with yes or no questions for option one for monitoring of residential dwellings, which is RDT and stagnation (two-tier). Tier 1 provides information on compliance sampling for the System Goal. Tier 2 provides information on household investigation sampling. The following information is presented in a box: the system goal (SG) is that the 90th percentile lead concentration be equal to 0.005 mg/L, which means the lead concentration is greater than 0.005 mg/L at more than 10% of sites.

Step 1: Tier 1: RDT, Zonal monitoring, zonal/system goal (SG).

- Steps 2 and 3 are conducted simultaneously after step 1.

Step 2: Assessment of entire distribution system.

Step 3: Assessment of high-risk (sentinel) sites.

Question 1: Is the individual sample lead concentration greater than 0.005 mg/L?

- If your answer is “Yes”, go to step 6

- If your answer is “No”, go to question 2

Question 2: Do the system samples taken meet the system goal?

- If your answer is “Yes”, go to step 1

- If your answer is “No”, go to step 4

Step 4: Implement corrective measures. Conduct sequential sampling (30 MS or RDT).

Step 5: Inform customers. Conduct public education and outreach.

Step 6: Tier 2: Sequential sampling (household investigation)

Question 3: Is it a zonal issue, for example, local water quality?

- If your answer is “Yes”, go to step 4

- If your answer is “No”, undertake:

- Individual mitigation measures (POU, flushing, etc.)

- Resident education

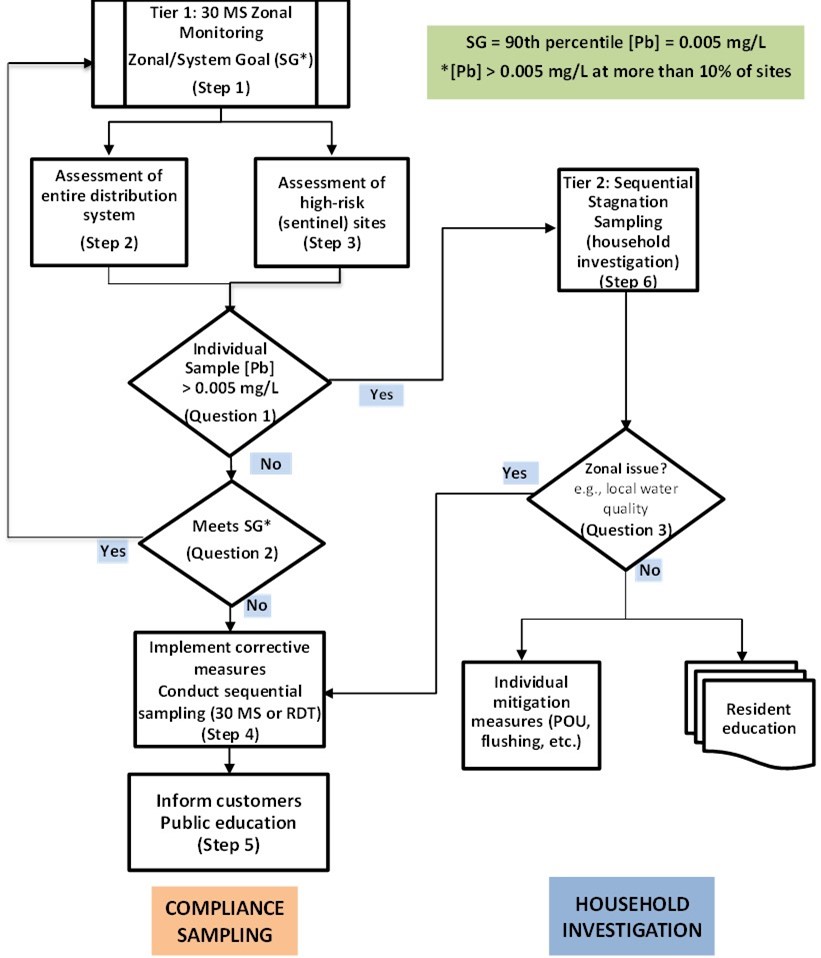

Monitoring protocol for residential dwellings: option 2 – 30 MS + stagnation (two-tier)

Sampling at residential sites is a two-tier approach for assessing corrosion of a variety of lead materials in residential distribution systems. This protocol is based on 30-min stagnation (30 MS) sampling. Since flushing occurs prior to the stagnation time, it likely will not capture particulate lead release.

The first-tier sampling provides an indication of lead concentrations throughout the system and the need to take action to control corrosion and reduce exposure to lead. A subset of sentinel sites is included in the Tier 1 sampling to characterize zones/areas of highest concern and to assess the effectiveness of planned corrosion control measures. Once a corrosion control program has been put in place, it also provides the appropriate data to assess if corrective measures have been effective in reducing corrosion of different types of lead-containing material throughout the system. When more than 10% of sitesFootnote 1 exceed a lead concentration of 0.005 mg/L (SG), then Tier 2 sampling should be conducted.

Tier 2 sampling is conducted at a reduced number of sites from Tier 1 and will provide more detailed information on the concentrations of lead contributed from different lead-containing materials in the distribution system (lead profile). This will enable responsible authorities to determine the source and potentially highest levels of lead so that the corrective measures can be selected and corrosion control can be optimized.

In some cases, the responsible authority may wish to collect samples for both tiers during the same site visit. This step eliminates the need to return to the residence if the system goal for Tier 1 is not met but is not feasible in some situations. The analyses for the second tier are then done only on the appropriate samples, based on the results of the Tier 1 samples.

Tier 1 sampling protocol (30 MS)

This sampling protocol measures the concentration of lead in water that has been in contact for a transitory and short period of time (30 min) with the lead service line as well as with the interior plumbing (e.g., lead solder, lead brass fittings). A 1 L sample is taken at the consumer’s cold drinking water tap (without removing the aerator or screen) after the water has been fully flushed for 5 min and then left to stagnate for 30 min. If fewer than 10% of sites have lead concentrations above 0.005 mg/L, utilities should provide consumers in residences with lead concentrations above 0.005 mg/L with information on methods to reduce their exposure to lead (such as those listed in measure #1 below). It is also recommended that utilities conduct follow-up sampling for these sites to assess the effectiveness of the corrective measures undertaken by consumers.

When more than 10% of the sitesFootnote 1 have a lead concentration greater than 0.005 mg/L (SG), it is recommended that utilities take the following measures:

- Communicate the results of the testing to the consumers and inform them of the appropriate measures that they can take to reduce their exposure to lead. Corrective measures that consumers can take may include any or a combination of the following:

- flushing the system after any extended period of stagnation

- using certified drinking water treatment devices (i.e., certified for lead removal) until the lead sources can be replaced

- replacing their portion of the lead service line (ideally, in coordination with the replacement of the utility’s portion)

- replacing brass fittings or in-line devices and/or

- replacing galvanized piping or copper piping with lead solder

- Initiate a public education program to encourage consumers to flush the water after a period of stagnation while appropriate corrective measures are being assessed or undertaken. Flushing should be conducted so that any water that has been in contact with lead present in faucets, fittings and the associated solders as well as the lead service line following a period of stagnation is removed. Consider supplying or recommending the use of certified drinking water treatment filters for the removal of lead.

- Conduct additional sampling (as outlined in the Tier 2 sampling protocol) at 10% of the sites sampled in Tier 1 at which the highest lead concentrations (above 0.005 mg/L) were observed.

- Implement appropriate corrective measures to control corrosion in the system. Results of the Tier 2 sampling should be used to help determine the best corrective measures for the system, which may include any or a combination of the following:

- replacing lead service lines (as well as pigtails and goosenecks, if present)

- adjusting the pH and alkalinity

- adjusting the pH (if needed) and adding corrosion inhibitors and/or

- replacing brass fittings, in-line devices and/or galvanized piping

- Encourage homeowners to periodically clean debris from the screens or aerators of drinking water outlets. If a substantial amount of debris is removed from the aerator or screen, authorities may want to retest the water from these outlets following the same protocol. If results of the retesting show lead concentrations below 0.005 mg/L, utilities should investigate whether particulate lead may be contributing significantly to elevated lead levels and whether regular cleaning of the aerator or screen is an appropriate corrective measure.

Tier 2 profile sampling protocol

Tier 2 profile sampling is required only when the Tier 1 sampling identified more than 10% of sites with lead concentrations above 0.005 mg/L.

Four consecutive 1 L samples are taken at the consumer’s cold drinking water tap (without removing the aerator or screen) after the water has been stagnant for a defined period (30 min [30 MS] or a minimum of 6 h). Selection of the stagnation time is based on practical considerations and the desire to generate higher lead concentrations and thus make it easier to evaluate any changes.

Each 1 L sample is analyzed individually to obtain a profile of lead contributions from the faucet, plumbing (lead in solder, brass and bronze fittings, brass water meters, etc.) and any contribution from the lead service line. Utilities may choose to collect 4 1-L samples during the site visits for Tier 1 sampling, but it may not be feasible for some situations (e.g., 6 h stagnation sampling). The analyses for the second tier are then done only on the appropriate samples, based on the results of the Tier 1 samples (i.e., residences with the highest lead concentrations). Note: It may be of benefit to collect smaller cumulative volumes for each 1 L sample to more precisely identify the source of lead. Collecting more than 4 consecutive 1 L samples is also beneficial in some cases to identify if a lead service line is present.

Tier 2 a) 30 MS profile sampling

This sampling protocol measures the concentration of lead in water that has been in contact for a transitory and short period of time (30 min) with the lead service line as well as with the interior plumbing (e.g., lead solder, lead brass fittings). Four consecutive 1 L samples are taken at the consumer’s cold drinking water tap (without removing the aerator or screen) after the water has been fully flushed for 5 min and then left to stagnate for 30 min. Each 1 L sample is analyzed individually to obtain a profile of lead contributions from the faucet, plumbing and a portion or all of the lead service line. Utilities may choose to collect 4 1-L samples during the site visits for Tier 1 sampling and proceed with analysis of these samples once the analysis of the first Tier 1 sample identifies the appropriate residences (i.e., those with the highest lead concentrations).

Tier 2 b) 6 h (minimum) profile sampling

Tier 2 sampling is required only when the Tier 1 sampling identified more than 10% of sites with lead concentrations above 0.005 mg/L. Sampling is conducted at 10% of the sites sampled in Tier 1, specifically the sites in which the highest lead concentrations were measured. Four consecutive 1 L samples are taken at the consumer’s cold drinking water tap (without removing the aerator or screen) after the water has been stagnant for a minimum of 6 h. Each 1 L sample is analyzed individually to obtain a profile of lead contributions from the faucet, plumbing (lead in solder, brass and bronze fittings, brass water meters, etc.) and the lead service line.

Results from either of the profile sampling options above will inform the mitigation measures that utilities take or recommend. Examples include:

- Communicate the results of the testing to the consumers and inform them of the appropriate measures that they can take to reduce their exposure to lead. Corrective measures that consumers can take may include any or a combination of the following:

- flushing the system after any extended period of stagnation

- using certified drinking water treatment devices (i.e., certified for lead removal) until the lead sources can be replaced

- replacing their portion of the lead service line (ideally, in coordination with the replacement of the utility’s portion)

- replacing brass fittings or in-line devices and/or

- replacing galvanized piping or copper piping that have lead solder

- Initiate a public education program to encourage consumers to flush the water after a period of water stagnation while appropriate corrective measures are being assessed or undertaken. Flushing should be conducted so that any water that has been in contact with lead present in faucets, fittings and the associated solders as well as the lead service line following a period of stagnation is removed.

- Consider supplying or recommending the use of certified drinking water treatment filters for the removal of lead.

- Implement appropriate corrective measures to control corrosion in the system. Analysis of individual 1 L samples will help provide information on the source of lead in the system. However, if the source of the lead problem cannot be identified by the lead profile in the 4 1-L samples, further investigation may be required. Depending on the source of the lead problem and on the number of residences affected, corrective measures may include any or a combination of the following:

- replacing lead service lines (as well as pigtails and goosenecks, if present)

- adjusting the pH and alkalinity

- adjusting the pH (if needed) and adding corrosion inhibitors and/or

- replacing brass fittings, in-line devices and/or galvanized piping

- Encourage homeowners to periodically clean debris from the screens or aerators of drinking water outlets. If a substantial amount of debris is removed from the aerator or screen, authorities may want to retest the water from these outlets following the same protocol. If results of the retesting show lead concentrations below 0.005 mg/L, utilities should investigate whether particulate lead may be contributing significantly to elevated lead levels and whether regular cleaning of the aerator or screen is an appropriate corrective measure.

Figure 2 - Text description

The flow chart has steps and decision points with yes or no questions for option two for monitoring of residential dwellings, which is 30 MS and stagnation. Tier 1 provides information on compliance sampling for the System Goal. Tier 2 provides information on household investigation sampling. The following information is presented in a box: the system goal (SG) is that the 90th percentile lead concentration be equal to 0.005 mg/L which means the lead concentration is greater than 0.005 mg/L at more than 10% of sites.

Step 1: Tier 1: 30-minute stagnation zonal monitoring zonal/system goal.

- Steps 2 and 3 are conducted simultaneously after step 1.

Step 2: Assessment of entire distribution system.

Step 3: Assessment of high-risk (sentinel) sites

Question 1: Is individual sample lead concentration greater than 0.005 mg/L?

- If your answer is “Yes”: go to step 6.

- If your answer is “No”: go to question 2

Question 2: Do the system samples taken meet the system goal?

- If your answer is “Yes”: go to step 1.

- If your answer is “No”: go to step 4

Step 4: Implement corrective measures. Conduct sequential sampling (30 MS or RDT).

Step 5: Inform customers. Public education.

Step 6: Tier 2: Sequential stagnation sampling (household investigation)

Question 3: Is it a zonal issue? For example, local water quality.

- If your answer is “Yes”, go to step 4

- If your answer is “No”, undertake:

- Individual mitigation measures (POU, flushing, etc.)

- Resident education

Follow-up sampling (demonstrating CCT optimization)

Monitoring data collected over time can be used by utilities to assess the effectiveness of corrosion control and optimize their programs. The frequency and duration of follow-up sampling will depend on the type of corrosion control measures selected. General guidance for the frequency and duration of monitoring for different corrective measures can be found in the following section on frequency of sampling for residential monitoring. Follow‑up sampling that is intended to demonstrate that lead concentrations throughout the system have been adequately reduced and that corrosion control treatment has been optimized should be conducted until a minimum of 2 consecutive sampling rounds have demonstrated that compliance has been achieved. Depending on the most significant source of lead in a system, utilities may need to supplement follow-up Tier 1 sampling with Tier 2 sampling to assess whether corrosion control has been optimized.

Comparison of the highest lead levels at the sentinel sites and in the system before and after corrosion control is implemented is the best approach for accurately quantifying the effects of corrosion control treatment on reducing lead levels and for demonstrating optimization. Once it has been determined that corrosion control is optimized, annual monitoring can be resumed.

Frequency of sampling for residential monitoring

For compliance purposes, lead levels should be monitored at the tap at least once a year to assess whether corrosion is occurring in a water distribution system. When a corrosion control program is being implemented, monitoring needs to be more frequent than once per year, the frequency depending on the control measures selected; this increased monitoring frequency must be maintained until the control measures are optimized. Because lead corrosion and lead levels are easily influenced by small changes in the quality of the distributed water, annual sampling for lead should continue even when corrosion control has been optimized. More frequent monitoring is recommended when changes in the water quality in the distribution system (e.g., nitrification) are noted or when there are changes made to the treatment process (including changes in the disinfectant, oxidant or coagulant) or source that would alter water quality parameters affecting corrosion, such as pH and alkalinity. Under certain circumstances, additional sampling may be required when localized changes are made in the distribution and/or plumbing systems.

When pH and alkalinity adjustments or pH adjustment (if needed) and corrosion inhibitors are used as system-wide corrosion control methods, the water quality should be monitored at least weekly at the entry point to the distribution system and monthly within the distribution system, including at the tap. When implementing a corrosion control program, it must be done so as to capture conditions that are representative of the variations in the water quality (e.g., temperature, pH, alkalinity). If corrosion control is carried out over a period of less than a year, then it would be necessary to demonstrate that seasonality issues (e.g., temperature, colour, pH, alkalinity) have been taken into account in analyzing the effectiveness of corrosion control measures. Online, real time monitoring of all process control parameters should be considered for capturing water quality variability.

Water quality parameters such as pH, alkalinity, lead concentration and corrosion inhibitor residuals (where applicable) should be monitored for at least 6 months when pH and alkalinity adjustments are used and for 18 months when corrosion inhibitors are used. Best practices dictate that parameters affecting corrosion control or those that measure its effectiveness should continue to be monitored. During the implementation stage, copper, iron, disinfectant residuals and microbial indicators should also be monitored within the distribution system.

Generally, utilities should strive to achieve a full replacement of the lead service line to minimize the consumer’s exposure to lead. However, it is recognized that mitigation measures may include partial or full replacement of the lead service line, depending on a number of factors. When lead service lines are replaced, extensive flushing of the cold water by the consumer should be encouraged, and weekly or biweekly sampling at the tap should be conducted until lead levels stabilize. This is especially important when only partial lead service line replacement can be achieved. Once it has been determined that corrosion control is optimized, annual monitoring can be resumed.

Routine annual (compliance) sampling should be conducted during the same period every year, since lead leaching as well as the leaching of other materials within the distribution system are influenced by changes in temperature as well as seasonal variations. The warmer season from May to October is chosen both for practical purposes in Canada and because levels of lead are expected to be highest in those months.

Number and selection of sites for residential monitoring

The number of residences to be monitored is determined based on the size of the drinking water system, as outlined in Table 2. The suggested number of monitoring sites is considered to be the minimum required to characterize the distribution of lead levels in a system. A minimum of 20 samples per year is required in a water supply zone (a geographical area within which the quality of drinking water is considered approximately uniform), regardless of sampling methodology. Generally, 20 to 60 samples from a water supply zone are needed (per year) to be statistically robust. However, for small water systems, fewer samples may be appropriate, depending on local circumstances.

RDT sampling is used system-wide and 30 MS sampling is typically used at sentinel sites. Due to its random nature, RDT sampling requires 2 to 5 times more samples than 30 MS to be statistically robust. Whereas RDT sampling is relatively inexpensive, more practical to implement and generally more acceptable to the consumer than 30 MS sampling, the 30 MS sampling protocol can also be used for investigating the cause of exceedances and identifying appropriate mitigation measures.

High-risk residences should be chosen as sentinel sites to reflect potential lead problems in the community and to adequately reduce population exposure to lead. Sentinel sites are also used for assessing the effectiveness of corrosion control. Generally, a minimum of 6 sentinel sites is recommended and weekly sampling is recommended when assessing corrosion control. The establishment of a lead service line inventory will help identify water supply zones or residences that are more likely to have high lead concentrations. Monitoring sites should be determined based on the selected sampling protocol.

Monitoring programs for RDT sampling are conducted within defined water supply zones, which can vary in size but generally should not exceed 50,000 residents each. Increased sample size can be achieved by either increasing the number of samples or by aggregating several years’ worth of data. In these cases, sampling of properties using other approaches (e.g., sentinel sites) will provide a more reliable method of estimating public exposure and the effectiveness of corrosion control measures and optimization. Determining water use (low volumes, long periods of no use, etc.) at sampling sites may also be helpful in determining the potential impact on lead levels and corrosion control treatment effectiveness.

Regardless of the protocol used, all samples should be collected in wide-mouth sample bottles, and without removing the aerator. The samples need to be acidified using a 2% nitric acid solution (by volume) and held for a minimum of 16 h after preservation with nitric acid before analysis. Each sample should be thoroughly mixed prior to analysis using an appropriate method.

| Supply zone size (number of people served) | Number of sites per supply zonea (annual monitoring) | Minimum number of sites per supply zoneb (corrosion control monitoring) |

|---|---|---|

| 5,000 to 100,000 | 8 | 20 |

| 100 to 5,000 | 4 | 20 |

| < 100 | 1 | < 20 |

a Adapted from European Union (2015) |

||

It must be noted that further investigation may be required to identify the lead problem in some cases. This additional investigation could include the collection of several 1 L (or smaller cumulative volumes, e.g., 4 x 250 mL, 2 x 500 mL, depending on plumbing configuration) sequential samples to more accurately identify the lead profile of a residence.

It is important that responsible authorities develop an inventory of monitoring sites where lead materials are likely to be present. Historical records, such as plumbing codes, building permits and water meter records, may provide utilities with useful information on the materials used during certain periods or in certain areas of the distribution system, which can be used to identify potential monitoring sites. It is recognized that historical information may be limited and/or incorrect, and utilities may need to assess the sampling results to determine if additional monitoring sites are needed to ensure that the system has been adequately assessed. A sampling-based framework for determining the presence of lead service lines can be a helpful tool in developing a lead service line inventory. It is also recognized that where contaminant concentrations are highly variable, as with lead it is impossible to design a selective monitoring protocol that will reflect with complete confidence the concentrations throughout the entire system.

Table 2 provides the suggested number of reduced monitoring sites that should continue to be monitored annually once the corrosion control program has been optimized. For smaller systems, a reduced number of monitoring sites is not possible, since a minimum number of sites is required to adequately characterize lead concentrations in the system. If at any time a system does not meet the system goal outlined in option 1 or option 2 of the monitoring protocols for residential dwellings in a reduced annual monitoring program, corrective measures should be re-evaluated and the appropriate action should be taken. Subsequent sampling should be conducted at the number of sites used for annual monitoring until a minimum of two monitoring events demonstrates that corrosion control has been effective.

In cases where utilities have already been conducting lead sampling or implementing corrosion control measures, the option of a reduced number of sites should be undertaken only when the criteria for the protocol are met for a minimum of two consecutive periods of testing, based on the results of the sampling protocol. The establishment of a lead service line inventory will help identify water supply zones (geographical areas within which the quality of drinking water is considered approximately uniform) that are more likely to have high lead concentrations. Monitoring programs are conducted within defined water supply zones, which can vary in size but generally should not exceed 50,000 residents each. It is recommended that total lead be monitored, at least once per year, at the tap of a minimum of 20 randomly selected residences in each water supply zone.

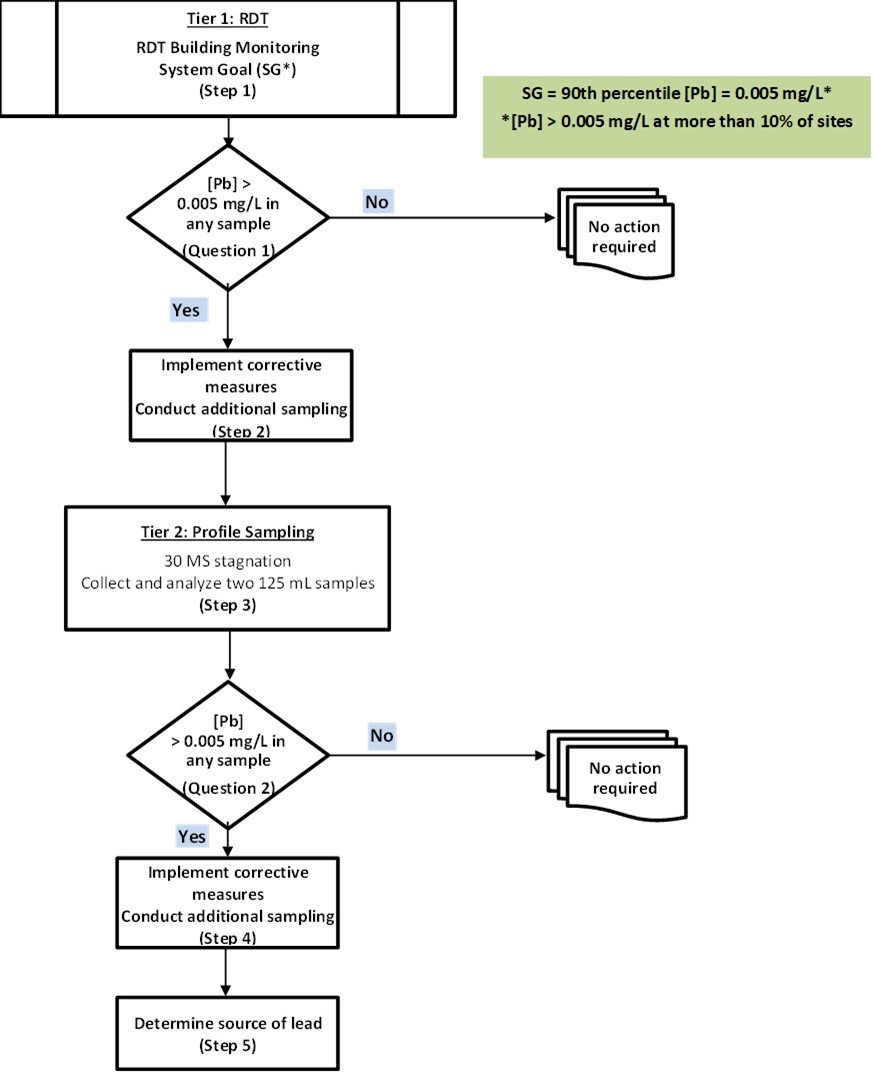

Monitoring protocol for non-residential/residential buildings (two-tier)

The objectives of the sampling protocols and SG for non-residential buildings, such as child care centres and schools, as well as residential (greater than six dwellings) and larger buildings, are to locate specific lead problems within the buildings and identify where and how to proceed with remedial actions. The intention is to minimize lead concentrations at the cold drinking water outlets (i.e., fittings/fixtures such as faucets and fountains) used for drinking and cooking and therefore protect occupants’ health from exposure to lead. The sampling protocols are based on an understanding of the variations in lead concentrations observed at outlets in these buildings resulting from sources of lead within the plumbing and water use patterns.

A sampling plan should be developed to take into consideration the type of building being sampled and to target priority sites for sampling. It is recommended that a plumbing profile of the building be developed to identify potential sources of lead and areas of stagnation and to assess the potential for lead contamination at each drinking water fountain, cold drinking water outlet or cooking outlet.

Stagnation periods will be influenced by such things as the frequency of use of the outlet, whether bottled water is distributed in the building, whether the building is occupied 24 or 8 h per day and the number of occupants. As such, establishing the source of the problem within a specific building becomes a critical tool in assessing which measures to take to reduce lead exposure. The locations of specific lead problems are determined by measuring lead levels at water fountains and cold drinking water outlets. When elevated concentrations of lead occur at an outlet, they can be from lead-containing material within the outlet itself (e.g., faucet, bubbler, water cooler), from the plumbing upstream of the outlet or from the water entering the building. A two‑tier sampling approach is used to identify the source of the elevated lead concentration.

Since elevated concentrations of lead can be found in drinking water as a result of leaching from plumbing materials, including fittings and fixtures, within a building, this protocol should be followed by responsible authorities, such as building owners or managers, school boards and employers, as part of the overall management of the health and safety of the occupants of schools, child care centres and other non-residential buildings. This protocol may also be followed by utilities that want to include non-residential or residential buildings such as schools and multi-dwelling buildings in their corrosion control monitoring programs. The extent of sampling conducted by an individual responsible authority within a building may vary depending on the objective of the sampling and the authority conducting the sampling.

Sampling with fixed stagnation is difficult to implement, especially in multiple-unit dwellings and large buildings. Larger buildings present particularly difficult sampling challenges for the following reasons: the complexity of use patterns, the variability in age of the plumbing, the variability in plumbing configuration between rooms and the lack of a detailed inventory of the plumbing products installed in the buildings. Maintaining stagnation in larger buildings can be very difficult. To this end, an RDT sampling protocol is recommended in this context. The stagnation protocol modelled on the U.S. EPA 3Ts monitoring can be found in Part F. Samples should be collected, preferably in wide-mouth sample bottles, at a medium to high flow rate without removing the aerator or screen.

Tier 1 sampling protocol

The objective of Tier 1 sampling is to identify specific cold drinking water outlets that have elevated levels of lead using the RDT. This sampling protocol captures typical exposures, including potential exposure to particulate lead. It identifies priority areas for actions to reduce lead concentrations and exposure to lead.

Collection of a smaller sample volume helps to pinpoint whether the source of lead is from the specific outlet and to direct the appropriate corrective measures. Tier 1 sampling should be conducted at the locations of the cold drinking water outlets identified in the sampling plan for the non-residential/residential building. In addition, a sample that is representative of the water that is entering the building (water main sample) should be collected at each monitoring event. Water main samples should be collected from a drinking water faucet in close proximity to the service line following a period of approximately 5 min of flushing (longer flushing may be necessary to ensure that the sample is representative of water that has been flowing in the main). All other samples in the building should be collected using the protocol described below.

A first-draw 250 mL sample is taken randomly at the cold drinking water outlets identified in the sampling plan (without removing the aerator or screen, where applicable) during the day in each of the residences. There is no stagnation period prescribed and no flushing should occur directly prior to collecting the sample, to better reflect actual consumer use. To ensure that representative samples are collected, the aerator or screen on the outlet should not be removed prior to sampling when present. It is recommended that samples be separated into smaller volumes (preferably 2 x 125 mL). This is a form of profile sampling that helps in the investigative phase if the analysis of the sample(s) indicates that lead is present. These smaller samples represent the water from the fitting (fountain or faucet) and a smaller section of plumbing and has the added benefit of being more effective at identifying the source of lead at an outlet. Collecting the Tier 2 samples provide the benefit of not having to return to the location to resample to identify the source of lead.

The use of wide-mouth sample bottles allows the sampler to fill the bottle at a medium to high (i.e., typical) flow rate, which provides a more accurate result. Sample bottles with a smaller opening will be difficult to fill at a typical flow rate and provide inaccurate results with respect to potential exposure and for investigative/remediation purposes. Where two 125 mL volumes are collected, the concentration of lead is determined by averaging the results from both samples.

If the lead concentration exceeds 0.005 mg/L (MAC) at any of the monitoring locations, it is recommended that the following measures be undertaken:

- Educate the occupants (e.g., teachers, day care providers, students) of the building and other interested parties (e.g., parents, occupational health and safety committees) on the sampling results and the interim measures that are being undertaken, as well as the plans for additional sampling.

- Conduct additional sampling at the outlets with lead concentrations that exceed 0.005 mg/L to determine the source of lead, as outlined in the Tier 2 protocol.

- Implement interim corrective measures immediately to reduce the occupants’ exposure to lead in first-draw water. These measures may include any or a combination of the following:

- taking the outlet out of service

- cleaning debris from the screens or aerators of the outlet

- flushing the plumbing system following periods of stagnation

- installing certified drinking water treatment devices (i.e., certified for lead removal) until the lead sources can be replaced and/or

- providing an alternate water supply

- Where a substantial amount of debris was removed from the aerator or screen, authorities may want to retest the water from these outlets following the same protocol. If results of the retesting show lead concentrations below 0.005 mg/L, authorities should investigate whether particulate lead may be contributing significantly to elevated lead levels and whether regular cleaning of the aerator or screen should be implemented as part of the maintenance or a rigorous (cold water) flushing program.

Tier 2 sampling protocol

Tier 2 sampling is used in combination with Tier 1 sampling results to determine the source of the lead in the plumbing within the building. Sampling in sequential volumes will help determine the concentration of lead in the water that has been stagnant in the plumbing upstream of the outlet. This sampling protocol measures the concentration of lead in water that has been in contact for a short period of time (30 min) with the interior plumbing (e.g., lead solder, lead brass fittings). This is a form of profile sampling that helps in the investigative phase if the analysis of the sample(s) indicates that lead is present. These smaller samples represent the water from the fitting (fountain or faucet) and a smaller section of plumbing and has the added benefit of being more effective at identifying the source of lead at an outlet.

At those cold drinking water outlets (without removing the aerator or screen) with lead concentrations that exceeded 0.005 mg/L for Tier 1, a minimum of 2 consecutive 125 mL samples are taken after the water has been fully flushed for 5 min and then left to stagnate for 30 min. Each 125 mL sample is analyzed individually to obtain a profile of lead contributions from the faucet and plumbing. Utilities may choose to collect a larger number of samples of varying volumes during the site visit to better characterize the source of lead.

When the lead concentration in any of these second samples exceeds 0.005 mg/L, any or a combination of the following corrective measures should be undertaken immediately until a permanent solution can be implemented:

- routine flushing of the outlet before the facility opens (a minimum of 5 min to obtain cold water from the water main)

- removing the outlet from service

- using certified drinking water treatment devices (i.e., certified for lead removal) until the lead sources can be replaced or

- providing an alternate water supply

In addition, depending on the results of the Tier 1 and 2 sampling, one or a combination of the following corrosion control measures should be initiated:

- Educate the occupants of the building (e.g., teachers, day care providers, students) and other interested parties (e.g., parents, occupational health and safety committees) on the sampling results and the interim and long-term corrective measures that are being undertaken.

- Compare the Tier 1 and Tier 2 sampling results to determine whether the source of the lead contamination is the fitting, fixture or internal plumbing. If the results of the Tier 1 and Tier 2 sampling both indicate lead contamination, conduct additional sampling from the interior plumbing within the building to further determine the sources of lead contamination.

- Flush the outlets.

- Install certified drinking water treatment devices (i.e., certified for lead removal) until the lead sources can be replaced.

- Replace the outlets, fountains or pipes.

- Remove the outlets from service.

- Replace lead brass fittings or in-line components.

- Work collaboratively with the water supplier to ensure that the water delivered to the building is not aggressive.

- Distribute an alternate water supply.

Selection of monitoring sites and monitoring frequency

The number of sites sampled in a building may vary depending on the objective of the sampling, the responsible authority conducting the sampling and the type of occupants within the building. Where schools, day care facilities and other non-residential/residential buildings fall under the responsibility of utilities, the priority for sampling should be schools and child care facilities.

Other authorities that are responsible for maintaining and monitoring water quality within non-residential buildings will need to do more extensive sampling at individual outlets based on the sampling plan developed for the buildings. The sampling plan should prioritize drinking water fountains and cold water outlets used for drinking or cooking based on information obtained in the plumbing profile, including areas with lead solder or brass fittings containing lead, areas of stagnation, areas serviced by lead pipe and areas that provide water to high-risk populations, such as infants, children and pregnant people.

Utilities, building owners and other responsible authorities (e.g., school boards) should work collaboratively to ensure that sampling programs are designed to be protective of the health of the occupants, including high-risk populations such as young children and pregnant people. It must be noted that large variations in lead concentrations can be expected to be found between individual outlets in a building and that sampling programs should be carefully designed and implemented so that outlets with potentially elevated levels of lead are correctly identified.

When outlets with elevated lead concentrations have been identified, corrective measures should be implemented. Depending on the type of corrective measure selected (e.g., replacement of outlets, routine flushing), additional sampling should be conducted to ensure that the lead levels have been effectively reduced. When routine flushing programs are implemented as a corrective measure, sampling should be conducted so that it can be demonstrated that flushing is effective at reducing lead concentrations throughout the period of the day when the building is occupied. Similarly, when outlets are replaced, sampling should be conducted up to 3 months following replacement to ensure that lead levels have been adequately lowered.

Once appropriate corrective measures are in place, subsequent sampling should be conducted at the sites used for initial monitoring, until a minimum of 2 monitoring events demonstrates that the corrosion control program is effective. Once sampling has been completed at all sites identified in the sampling plan of a non-residential building and a corrosion control program has been implemented effectively, only priority (high-risk) sites need to be monitored annually. Localized changes in the distribution system, such as changes in the piping, faucets or fittings used as a result of repairs or new construction as well as changes in water use patterns, should also trigger additional monitoring.

It is also recommended that at each monitoring event, samples be taken from an outlet close to the point where the water enters the non-residential building to determine the level of lead in the water contributed by either the service line or the main water distribution system (water main). Ideally, samples should be collected after an appropriate period of flushing so that they are representative of water from the service line and from the water main. The volume of water to flush will depend on the characteristics of the building plumbing system (e.g., the distance between the service line and the water main).

Schools and child care facilities

The sampling plan for public schools, private schools and child care centres/providers should take into consideration that the types of occupants in these buildings are among the most susceptible to adverse health effects from lead. Consequently, sampling plans for these facilities should prioritize every drinking water fountain and cold water outlet used for drinking or food preparation over infrequently used outlets. Total lead should be monitored at least once per year. It is recommended that sampling be conducted in either June or October for schools and, when the buildings are fully occupied and functional, between the months of June and October for other building types. Jurisdictions may choose to reduce monitoring once they have established that the lead issues have been identified and addressed.

Other sampling sites, such as outlets in classrooms that are used infrequently for drinking or first-aid rooms that are not identified as priority sites, could then be sampled in subsequent years so that ultimately all sites identified in the sampling plan have been tested within a 5-year period.

Other non-residential/residential buildings

In other building types, sampling plans should also target drinking water fountains and cold water outlets used for drinking or food preparation, but with the number of sites sampled based on the size and population of the building. Every priority site identified in the sampling plan should be sampled in the first year. The remaining sites in the plan should then be sampled in subsequent years so that ultimately all sites identified in the sampling plan have been tested within a 5-year period.

In multi-dwelling (i.e., more than 6 residences) buildings or large buildings, it is recommended that total lead be monitored in a manner such that each of the drinking water fountains and a proportion of cold water taps where water is used for drinking or food preparation is sampled within a specified period. When sampling multi-dwelling buildings, priority should be given to sites suspected or known to have full or partial lead service lines.

Figure 3 - Text description

The flow chart has steps and decision points with yes or no questions for monitoring of non-residential/residential buildings (two-tier). The following information is presented in a box: the system goal (SG) is that the 90th percentile lead concentration be equal to 0.005 mg/L which means the lead concentration is greater than 0.005 mg/L at more than 10% of sites.

Step 1: Tier 1: RDT, RDT building monitoring system (SG*)

Question 1: Is lead concentration greater than 0.005 mg/L in any sample?

- If your answer is “Yes”, go to step 2

- If your answer is “No”, no action required

Step 2: Implement corrective measures. Conduct additional sampling.

Step 3: Tier 2: Profile sampling. 30 MS. Collect and analyze two 125 mL samples.

Question 2: Is lead concentration greater than 0.005 mg/L in any sample?

- If your answer is “Yes”, go to step 4

- If your answer is “No”, no action required

Step 4: Implement corrective measures. Conduct additional sampling.

Step 5: Determine source of lead.Considerations for small systems

Although the measures described in this document represent the best approach to address corrosion in drinking water distribution systems, they may not be practical or feasible in small systems. In such cases, a different approach may be needed to provide improvement in health protection and water quality. For example, it may be more reasonable for small systems to consider materials replacement rather than corrosion control treatment (CCT). The implementation of CCT requires studies and monitoring of water quality and lead that may be more resource intensive and complex than a system’s capability or budget. The need for pipe loop, coupon and desktop studies may result in a long-term commitment when a similar output of resources in a shorter time frame may provide an equally effective result by removing the sources of lead (e.g., LSLs).

Alternatively, there are a number of options available to the operator to implement some CCT that could provide relief with some operational complexities and chemical handling and occupational challenges. For example, the use of sodium silicates necessitates adherence to occupational health and safety protocols that are more demanding than the use of a combination of aeration and limestone contactors, which can achieve the same result. The use of software such as WaterPro can also help simplify CCT in systems that have relatively straightforward water quality. Some of the small system challenges, basics and strategies for CCT are listed below:

- Challenges

- Fewer resources to address issues

- may require a consultant

- Footprint of treatment plant may limit

- Available strategies that can be implemented

- Operator availability, level/training may limit:

- Treatment chemicals that can be used

- Adjustments to water quality that can be implemented

- Sampling capacity

- Basics (need to know)

- Characterization of water quality is critical

- pH *

- alkalinity

- cations (e.g., calcium, magnesium)

- anions (e.g., chloride, sulphate)

- Fe

- Mn

*Measure pH on-site for accuracy

- Water quality

- Provides information on possible issues

- Can inform best strategies for mitigating lead (& copper)

- Know your system materials

- Are LSLs present?

- Newer home (< 10 years) with copper plumbing?

- Galvanic connections?

- Strategies

- Removing manganese and iron has many benefits

- Makes pH adjustment easier

- Minimizes accumulation and release of metals in DS

- Can reduce oxidant/ disinfectant demand

- Can minimize interference with corrosion control treatment

- Chloride to sulphate mass ratio (CSMR) can help predict galvanic corrosion

- Need to know chloride and sulphate anion concentrations

- Detection of LSLs can be done with simpler sampling methods

- Sequential sampling is ideal but flushed sampling is good tool

- Must determine screening threshold for lead

Sampling protocols for lead

References

- Footnote 1

-

Based on the 90th-percentile value of the highest lead concentrations of tap samples collected during the monitoring period

- Footnote 2

-

SG = 90th percentile [Pb] = 0.005 mg/L ([Pb] > 0.005 mg/L at more than 10% of sites)