Guidance on improving indoor air quality in office buildings

Download in PDF format

(1.5 MB, 70 pages)

Organization: Health Canada

Published: 2025-09-19

Cat. : H144-141/2025E-PDF

ISBN : 978-0-660-78983-5

Pub. : 250228

Table of contents

- Acknowledgements

- Introduction

- Background

- Indoor air quality in office buildings

- Ventilation

- Building stewardship

- Roles and responsibilities

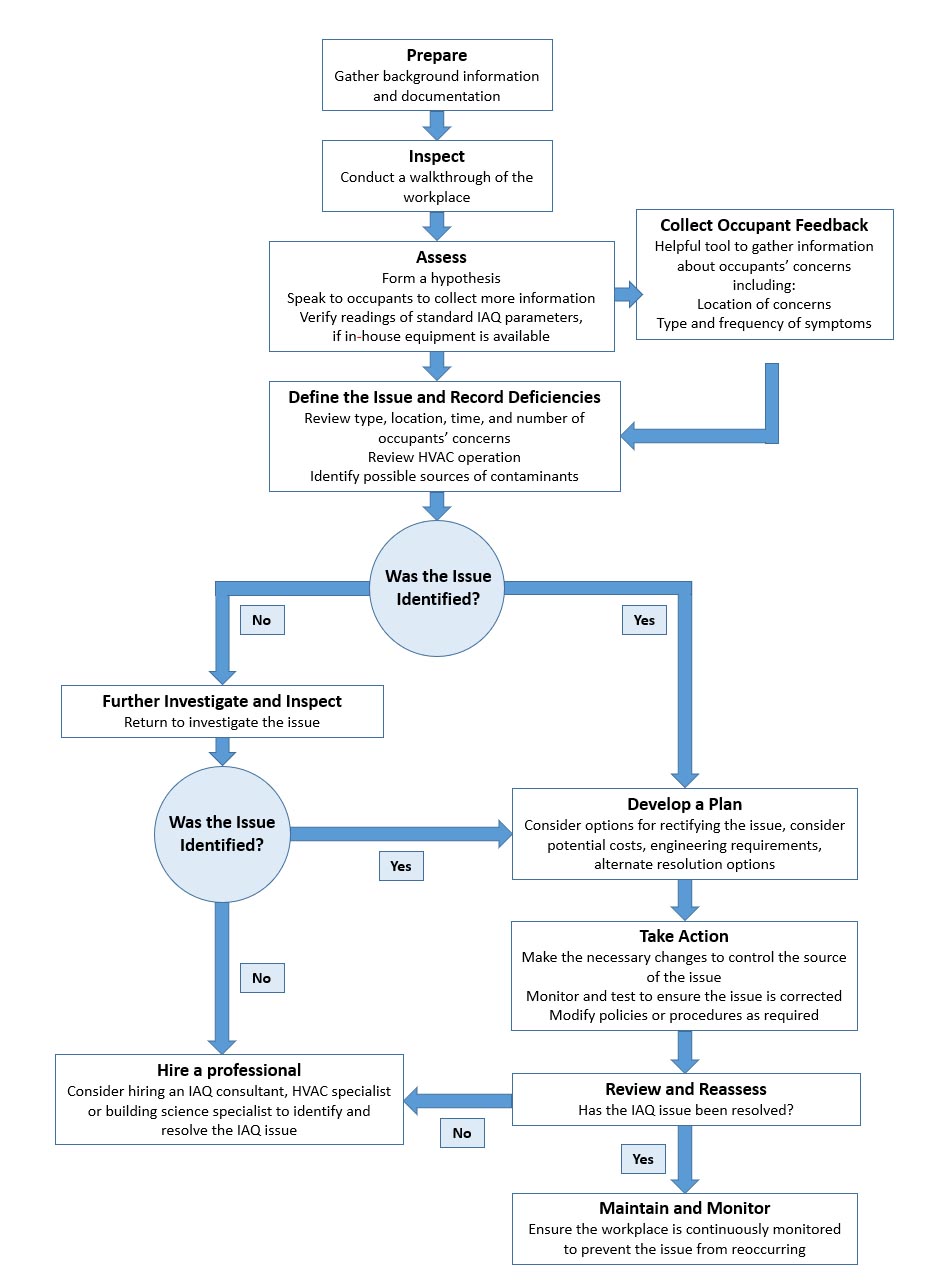

- Guidance for developing an indoor air quality resolution process

- When and how to hire a professional

- Summary

- References

- Appendix A: Glossary

- Appendix B: Sample HVAC overview checklist

- Appendix C: Sample HVAC inspection checklist

- Appendix D: Sample indoor air quality assessment form

- Appendix E: Indoor air quality health effects reporting form

- Appendix F: Sample summary assessment notes

Acknowledgements

This product was developed by Health Canada. Additional consultations and contributions from National Research Council Canada, Public Service and Procurement Canada, and the Public Health Agency of Canada further supported the development of this document.

With acknowledgement of the Canadian Centre for Occupational Health and Safety and the Canadian Committee on Indoor Air Quality in Buildings for the development of supporting background material.

Introduction

The purpose of this guidance is to summarize ways to evaluate, improve and maintain indoor air quality in office buildings. This guidance provides practical recommendations to address and respond to potential indoor air quality problems, including:

- guidance for reducing contaminant sources and properly operating ventilation systems

- sample checklists for evaluating building systems

- considerations when hiring a professional to remediate indoor air quality issues

This guidance is intended for employers, building operators, maintenance staff, urban planners, as well as environmental public health professionals.

The quality of the air in an office building is the result of the complex interactions between the ventilation system (if present), the building (that is, age, condition, component materials, structure, and envelope), the climate, the quality of the outdoor air, the furnishings and products present, the work processes, and the occupants and their activities. Some factors that contribute to poor indoor air quality may be related to building stewardship activities such as maintenance and housekeeping; inadequate ventilation system design or maintenance; and selection and use of equipment, furnishings, building materials, office supplies and cleaning chemicals.

This guide addresses issues relating to indoor air quality that are common in an office building setting, and promotes best practices. It provides guidance for maintaining good indoor air quality and managing and resolving issues promptly, while encouraging consistency and transparency throughout the assessment, investigation, and resolution process. Good operational practices can prevent many indoor air quality issues. However, when issues do arise, they can be addressed by implementing corrective actions after identifying the potential cause(s). When taking actions to improve indoor air quality, it is important to find appropriate solution(s) that prevent the issue from re-occurring, ensuring that one issue is not being traded for another, or creating new problems.

This guide applies to any size office building in Canada. It applies to non-industrial and non-residential workplace settings which may include buildings with meeting rooms, lunchrooms, and small kitchens.

While this guide provides advice for employers and building operators to help resolve indoor air quality issues, there may be situations that will require the services of a qualified professional, such as a heating, ventilation, and air conditioning (HVAC) professional or an occupational hygienist.

Preventing issues before they arise and addressing issues as soon as they are identified is the best strategy to maintain appropriate indoor air quality. Good practices to maintain indoor air quality include the following:

- Eliminate or reduce sources of contaminants. Sources of contamination may be present indoors (for example, combustion, cleaning products, furnishings, moisture, or odours from occupants or activities) or outdoors (for example, smoking areas, vehicle idling, wildfire smoke).

- Maintain protocols to reduce viral and bacterial transmission between building occupants.

- Ensure effective ventilation system design and operation. Ventilation can improve air quality by replacing the indoor air with filtered and conditioned outdoor air, thereby removing and diluting contaminants. Verify ventilation flow rates to match them with any changes in occupant levels, duration of occupancy, renovations, redesigns, and how the space is utilized.

- Develop and implement a preventive maintenance program for the ventilation system. Remove contaminants through appropriate air cleaners or filters.

- Install efficient filtration units or filters as part of the ventilation system and ensure adequate outdoor air ventilation based on applicable standards and outdoor conditions. Select the correct filter efficiency for the contaminants present and the ventilation system. When possible, choose MERV 13 filters or higher.

- Use proactive housekeeping practices, including choosing cleaning products with low volatile organic compounds (VOCs) and using a vacuuming system with a high-efficiency particulate air (HEPA) filter.

- Control moisture and humidity levels and ensure early intervention if mould is suspected. Remediate moisture and damage from flooding, clean mould appropriately, and prevent reoccurrence by determining the source of the moisture and addressing the issue.

- Implement workplace procedures to consider indoor air quality issues throughout procurement and renovations in new and existing buildings. Assess any potential mismatches of the intended space and occupant activities. Where these do not align, the design of the space may affect ventilation distribution and air exchanges.

- Ensure occupants are following workplace policies and procedures, such as the use of scents and cleaning products.

- Conduct indoor air quality training and education for building operators, employers and occupants. Training should be relevant to the audience and can include how to identify a potential indoor air quality issue and how to report concerns. Occupants should also be made aware of issues unrelated to indoor air, such as ergonomic and psychosocial risk factors (for example, relationships with co-workers, control over workload), as they can affect perceptions of indoor air quality.

In addition to the guidance on indoor air quality in office buildings provided in this document, indoor air quality professionals seeking technical guidance on the health effects of specific air contaminants and on air sampling and monitoring are also referred to Health Canada's Guidance for Indoor Air Quality Professionals (Health Canada 2025).

Background

Indoor air quality is considered an environmental determinant of health. A healthy indoor environment is one that contributes to productivity and comfort, and protects the health and well-being of occupants. As such, it is an important health and safety consideration for workplaces such as office buildings. Exposure to several contaminants commonly found in indoor air has been associated with adverse health effects. Occupants who work in buildings with adequate ventilation have reported better air quality and health as compared to those working in poorly ventilated spaces (Allen et al., 2015). Higher ventilation flow rates in indoor environments are associated with a reduced prevalence of adverse health effects (Sundell et al., 2010).

Many of the recommended control mechanisms that aim to improve and maintain good indoor air quality also apply to reducing the risk of infectious disease transmission. These mechanisms are often the responsibility of employers, building operators, and maintenance staff. However, other activities undertaken by the building's occupants—such as using printing and photocopying equipment, wearing perfumes and fragrances, blocking vents or improperly using equipment—can generate odours and contaminants that also affect indoor air quality. It is important to recognize that factors that impact indoor air quality can vary over time, and that competing factors can impact air quality goals (for example, balancing increased ventilation with energy conservation). Management of indoor air quality requires balancing multiple factors to ensure that improvements in one area do not result in significantly reduced efficiency in other areas. Through awareness and education, building operators and occupants can help prevent many indoor air quality issues from developing.

This guidance replaces Health Canada's (1995) Indoor Air Quality in Office Buildings: A Technical Guide.

Indoor air quality in office buildings

What is indoor air quality?

Indoor air quality refers to the quality of air in an indoor environment, such as inside a building, particularly as it relates to the health and comfort of occupants. Indoor air quality results from the constantly changing complex interactions among building systems, the environment outside the building, activities and items in the building, and occupants that affect the types and levels of contaminants in indoor environments (Canadian Committee on Indoor Air Quality [CCIAQ] 2013a).

Factors affecting indoor air quality

Indoor air quality results from the interactions between the ventilation system (if present), the building, the climate, the quality of outdoor air, indoor sources of air contaminants, work processes, and occupants.

Elements that impact indoor air include:

- improperly or inadequately designed, maintained or installed heating and ventilation systems, including systems not properly modified after renovations

- improperly or inadequately designed, maintained or installed building envelope or structure (for example, water leaks through the roof, windows, walls, penetrations, and flashings as well as air leakages, which can lead to condensation, drafts, rodent or pest infestations, and sanitation issues)

- uses or activities that do not match the original or renovated design of the building or ventilation system (for example, there are more occupants than planned for in the ventilation system design)

- insufficient intake of outdoor air (such as resulting from an effort to improve energy efficiency) that may allow for a build-up of air contaminants indoors if there is an insufficient exchange rate of the indoor air (for example, how frequently indoor air is exhausted outdoors and replaced with fresh outdoor air)

- poor quality of outdoor air drawn indoors

- characteristics of the building or room (for example, age, design, renovations, dimensions)

- presence of problematic building materials (for example, asbestos-containing materials, lead, composite wood)

- types of office equipment and furnishings present (for example, emissions from photocopiers, off-gassing from furnishings, composite wood products containing formaldehyde)

- permeation of contaminants into the building from the ground, such as radon, soil gases or environmental contamination

- high humidity levels leading to increased odours, stuffiness, and potential for mould growth;

- increased number of building occupants and time spent indoors

- occupant activities that impact air quality or circulation (for example, placement of furnishings, renovations, blocking grilles or vents, cleaning spills, housekeeping, smoking, vaping) or items brought into the building (for example, food, scented products)

Sources of indoor air contaminants

Contaminants found in the indoor air of a building can originate from within the buildings, be affected by occupant-related factors, and also be brought in from outdoors. Sources of indoor air contaminants include:

- exhaled air of occupants leading to increased carbon dioxide (CO2) levels, odours, and stale air;

- dampness and increased moisture leading to mould growth

- smoking or vaping

- heating systems and occupant activities (for example, cooking and reheating food), which can produce combustion-related contaminants s (for example, carbon monoxide [CO], nitrogen dioxide [NO2]), particulates and odours

- attached garages and parking facilities as a source of automotive and fuel-related contaminants (for example, particulate matter [PM], CO, CO2, VOCs, and semi-volatile organic compounds [SVOCs])

- building materials and renovations (for example, release of VOCs, SVOCs, dusts or fibres from building materials, adhesives, cleaning products, furniture, paints)

- cleaning products, disinfectants, and biocides

- individuals with airborne infectious diseases, typically spread by infectious respiratory particles

- perfumes, fragrances, and air fresheners

Contaminants may also enter the office through the outdoor air intakes of the ventilation system and open windows and doors, and by infiltration through cracks and openings in the building envelope. Air contaminants that may originate from outdoor sources include:

- vehicle exhaust and other traffic-related pollution (for example, CO, NO2, PM), including from vehicles idling near air intakes

- nearby industrial contaminants

- microbial contaminants (for example, bacteria, mould, fungi, viruses, pollen)

- moisture and humidity leading to condensation and mould growth

- radon gas

- soil or ground gases (for example, methane, hydrogen sulfide, alcohols, alkanes, aromatic hydrocarbons)

- wildfire smoke

- pollutants arising from emergency events (for example, fires, chemical spills)

In some situations, contaminants may also originate from ventilation systems which are shared with other businesses (for example, in a common building or strip mall).

Occupant comfort and indoor air quality perception

In addition to factors that directly impact the types and concentrations of indoor contaminants, building occupants can be affected by a number of environmental and personal factors, which can affect how they perceive indoor air quality. Some factors affect both the levels of contaminants and perceptions of air quality.

The way in which occupants perceive indoor air quality may also influence their overall comfort, well-being, and productivity. Occupant perceptions are influenced by factors such as air temperature, relative humidity, air movement, and odour as well as non-indoor air quality factors such as noise, lighting, and ergonomics. Employers and building operators should consider both indoor and non-indoor air quality factors when investigating complaints.

Air temperature and relative humidity

Air temperature and relative humidity are the two main factors that determine thermal comfort and are major environmental factors contributing to heat-related illnesses from thermal stress.

Thermal comfort

Thermal comfort refers to conditions of feeling neither too hot nor too cold when wearing office-appropriate clothing. Occupants find conditions within a space most comfortable when the air temperature is uniform and the relative humidity between 30% and 50%. Maintaining relative humidity below 50% also prevents mould growth indoors (Health Canada 2016).

Generally, when relative humidity is below 30%, complaints of dry skin, eyes, sinuses, mouth, and throat increase (Jones et al., 2022). When relative humidity is above 50%, complaints of excessive humidity or heat increase. High humidity levels may contribute to condensation, moisture, and mould or fungi growth (Health Canada 2023a).

Personal preferences for temperature may vary greatly. When a space is too warm, occupants may feel lethargic or tire quickly. On the other hand, when a space is too cold, occupants may feel restless or easily distracted. Desired temperatures may vary with the season, clothing worn, and/or activity.

When considering temperature and humidity:

- maintain the building indoor temperature between 20 degrees Celsius and 23.5 degrees Celsius in the winter and between 23 degrees Celsius and 26 degrees Celsius in the summer (CSA Standard Z412), striving to ensure a thermal environment that a substantial majority (over 80%) of the occupants find acceptable (American Society of Heating, Refrigerating and Air-Conditioning Engineers [ASHRAE] Standard 55)

- maintain the relative humidity of indoor spaces between 30% and 50% (Health Canada 2016), depending on the maximum tolerances of the building envelope, to avoid condensation on interior surfaces

- perform regular maintenance on the HVAC equipment including economizers, air flow control equipment and fan systems (such as air flow valves, flow control stations, automated pressure control systems)

- confirm airflows meet current applicable ventilation standards (ASHRAE Standard 62.1) and that the HVAC equipment and thermostats are functioning properly, including humidity control

- correctly operate and maintain water systems associated with ventilation systems, such as cooling towers, steam systems, and humidifiers

- adjust ventilation to closely match the persons, activities and equipment in the building;

- confirm that grilles, vents and other ventilation components are not restricted or blocked

- use portable humidifiers with caution, as they may become a source of mould and bacteria if not maintained

- use space heaters with caution, as they are not connected to the building-wide ventilation system

Thermal stress

A further concern with temperatures that should be considered in office buildings is heat-related illnesses. Extreme heat is a serious health risk. Older adults, low-income earners, people experiencing homelessness, and people living with certain underlying medical conditions are among those at greater risk to heat-related illnesses (Health Canada 2024). Vulnerability to heat-related illnesses may also differ between population groups and individuals due to factors such as acclimatization, fitness, and sleep quality (Bergeron et al., 2011; McGarr et al., 2020).

Occupants may be at greater risk of adverse health effects from heat in office buildings when temperatures and humidity levels exceed those recommended in the thermal comfort guidelines described above; however, some occupants that are more susceptible to heat might experience health effects even at temperatures that are within the thermal comfort guidelines. Employers and building operators should seek guidance from local health authorities during extreme heat events.

Odours

Odours (smells) can be indicative of elevated levels of certain contaminants in indoor air, which may lead to potential health risks. Of note, health effects of some indoor contaminants are recognized to occur at levels below the odour threshold. Odours are associated with a perception of poor air quality, regardless of whether or not the source of the odour is a nuisance concern (for example, food odours) or has the potential to result in direct health effects (for example, vehicle exhaust). Odours are caused by organic or inorganic gases and vapours that stimulate the olfactory organs. Individual responses can vary with age, experience, time of exposure, and other factors.

Odours may be the result of:

- vehicle exhaust or other traffic pollution infiltrating into the occupied spaces of the building from outdoors or from parking garages

- body and food odours

- mould growth

- moisture (for example, wet concrete, dampness)

- chemicals and related vapours

- sewer gases

- pest infestation (for example, rodents, bedbugs, cockroaches)

Identification and control of the odour's source will help improve indoor air quality. Note that some individuals may have medical conditions, or there may be personal or occupational factors that contribute to odours that are not within their control. For response to environmental sensitivities and medical conditions, see Roles and responsibilities of employers.

Ventilation and comfort

Indoor air contains a mixture of contaminants from both outdoor and indoor sources. A building's ventilation system, when designed and operated properly, exchanges indoor air by replacing or diluting it with outdoor air. This exchange is designed to keep the concentration of biological and chemical contaminants at low enough levels to not cause discomfort for most occupants.

When the rate of replacement of indoor air by outdoor air is too low, the indoor air concentrations of contaminants primarily produced indoors rise, and occupant complaints may become more common. Those complaints typically include exposure-related perceptions (for example, smells/odours, "stale air", "stuffiness") and potential health effects (for example, eye, nose, sinus and throat irritation, headaches, fatigue).

It is important to note that the addition of outdoor air into the system may also introduce contaminants into the indoor environment. Outdoor sources of contamination may include smoke, smog, traffic pollution, pollen, and industrial contaminants.

Air velocity and drafts

Air velocity (or speed) refers to the rate of air movement. Lower air velocities may make a space feel "stuffy", while higher air velocities increase skin evaporation and may result in occupants finding the air too cool or "chilly". Air velocity should conform to applicable standards (ASHRAE Standard 55). In most buildings, an air velocity below 0.20 meters per second (40 feet per minute) would be expected.

When there is an issue with the air velocity or leakiness in the building envelope, occupants may report drafts, experienced as an unwanted cooling of the body from air movement. Occupants notice drafts when the air cools the body unevenly, such as at the head, neck or shoulders, or at the foot, ankle or lower leg. Drafts can be related to the air being "thermally stratified", which means there are layers of different air temperatures. Causes often include cold air entering through windows or walls, ventilation that directs cold air towards occupants or floors that are colder than the air. The difference between floor and ceiling temperatures should not be more than 4 degrees Celsius to avoid thermal discomfort (ASHRAE Standard 55).

Non-indoor air quality factors

Concerns about indoor air quality may occur even if all indicators are within acceptable limits. How occupants perceive the general quality of air may depend on organizational and individual factors unrelated to actual air characteristics. For example, noise, lighting, workplace layout, privacy, and workstation design may contribute to how occupants perceive air quality.

Health effects of poor indoor air quality

In many cases, the presence of indoor air contaminants, including in situations with poor temperature or humidity control, is known to cause or worsen health effects. Exposure to indoor air contaminants may result in:

- dryness and irritation of the eyes, nose, and throat

- respiratory symptoms such as wheezing, coughing, and shortness of breath

- headache, fatigue, dizziness, nausea, and flu-like symptoms

- worsening of lung and heart conditions such as asthma, chronic obstructive pulmonary disease, and heart disease

Recognizing health effects caused or exacerbated by exposure to poor indoor air can be difficult, as many of the symptoms can also be produced by illnesses or exposures unrelated to the air quality indoors. For example, exposure to poor indoor air has been associated with symptoms often experienced by individuals with allergies, the common cold or the flu (influenza), making it difficult to determine the role of indoor air in causing or worsening these symptoms (CCIAQ 2013b). As well, occupants with a respiratory illness may experience symptoms similar to those seen following exposure to other indoor air contaminants, or may find that their symptoms are exacerbated when entering a building. A qualified health professional may be able to help determine whether an individual's symptom is associated with poor indoor air quality.

Poor indoor air quality does not affect everyone in the same way. Certain individuals are generally susceptible to health effects associated with exposure to indoor air contaminants, including children, the elderly, people who are pregnant, and those with pre-existing health conditions such as asthma and cardiovascular diseases. Susceptible individuals may experience a variety of adverse health symptoms resulting from exposure to environmental contaminants, even at very low concentrations.

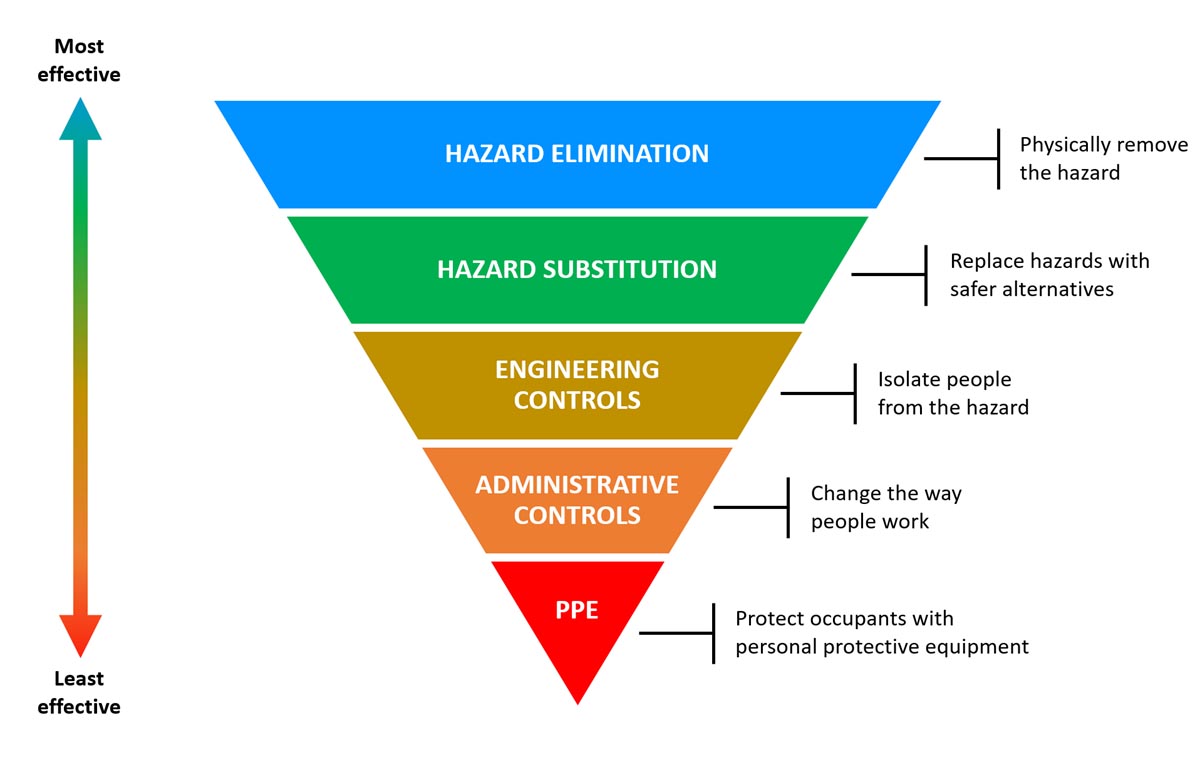

Key strategies for improving air quality in office buildings

Indoor air quality in an office building is the result of complex and constantly changing interactions, and as such, many interacting factors need to be considered when addressing indoor air quality issues. The following are key strategies to address some of these factors, and to maintain and improve indoor air quality:

-

Reducing or eliminating the sources of air contaminants. The source(s) of the air contaminants may exist inside and outside the building. Detailed information on specific indoor air contaminants can be found in Guidance for Indoor Air Quality Professionals (Health Canada 2025) and in Sources of indoor air contaminants.

For indoor sources, contaminants can be eliminated or reduced by practicing good building stewardship, which includes adequate space design, choosing lower emitting products and furnishings, regular housekeeping, and preventive building maintenance as well as open communication between building operators, employers, and building occupants (for example, education of building staff and employees on indoor air quality).

The employer or building operator may have little control over contaminant sources outside the building. However, awareness of outdoor air quality conditions, knowledge of the ventilation system, and good operation practices can help prevent or reduce the infiltration of contaminants that may enter the building from outdoors. Infiltration of contaminants can also be reduced or eliminated through activities such as sealing cracks in the building envelope and foundation, and operating remediation systems where required.

-

Ventilating can improve air quality by removing and diluting contaminants and by replacing indoor air with filtered air from outdoors. Maintaining the building ventilation system and replacing filters as per the manufacturer's recommendations will help reduce contaminants drawn into the building. Detailed information can be found in Ventilation.

In Canada, the national, provincial and territorial building codes require that ventilation flow rates respect, at a minimum, current applicable ventilation standards (ASHRAE Standard 62.1 and 62.2). Beyond that, higher ventilation flow rates have been suggested to help mitigate the risk of airborne infectious disease transmission and to contribute to an improvement of overall indoor air quality (ASHRAE 2023; Centers for Disease Control and Prevention [CDC] 2023; Lancet 2022; Ontario Society of Professional Engineers [OSPE] 2022). While improving indoor air quality, increased ventilation flow rates come at an additional energy cost.

-

Filtering the indoor air can reduce some indoor air contaminants and some viral and bacterial respiratory pathogens, depending on the contaminants and filtration equipment used. Although filtering the indoor air may help to improve indoor air quality, it should be combined with reducing contaminants at the source whenever possible and improving ventilation effectiveness. Detailed information can be found in Air filtering.

Indoor contaminants such as dust, fine particles, viruses, bacteria and spores can be removed effectively using indoor air filters. These filters are generally not as effective for gaseous contaminants (for example, VOCs, CO, CO2, NO2). In-duct or portable filtration devices using high efficiency filters can help reduce the levels of airborne particulates.

A combination of ventilation and filtering can be more cost-effective for reducing particulate levels, including infectious respiratory particles, than increased ventilation alone.

Ventilation

Building operators and those responsible for indoor air quality should be knowledgeable about the ventilation system design and operation, which include the outdoor air supply, outdoor air quality, filters and filtration efficiency, space planning (occupant density and activity, as well as duration of occupancy), equipment maintenance, control of other contaminant pathways such as unintended infiltration of pollutants, and when to consult an HVAC professional.

To be effective, a ventilation system must bring in outdoor air and exhaust indoor air—simple air movements (for example, recirculation) or filtration is not enough. Efficient ventilation helps improve indoor air quality, as it reduces contaminant and moisture levels that may directly or indirectly result in poor occupant comfort or negative health effects (Health Canada 2018).

Outdoor air ventilation may occur naturally or mechanically:

- Natural ventilation describes air flows caused by pressure differences between the inside and the outside of a building, which are primarily driven by weather, wind direction, and pressure and temperature differentials through intentional openings in the building envelope. Occupants generally have little control over natural ventilation, aside from opening and closing external windows and doors. Ventilation that relies only on window opening can lead to excessive energy costs, particularly due to heat loss in the winter or loss of conditioned air in the summer. Window opening can also challenge the management of relative humidity, infiltration of allergens, infiltration of ambient pollution, unintended pressure differences, and entry of pests in the absence of window screens.

- Mechanical ventilation refers to air flows intentionally created through the use of fans, ducting, and designed openings in the building envelope. This includes the operation of a localized, single-path exhaust fan (for example, bathroom exhausts, range hood fans). In the case of a small building or office, mechanical ventilation will typically be delivered through a central make-up air unit located on the rooftop of the building. In most large office buildings, a central air handling unit will typically be responsible for mechanically ventilating the building.

Outdoor air ventilation versus infiltration

It is important to be aware of the distinction between outdoor air ventilation and infiltration (Persily 2021). Outdoor air ventilation is intentional and refers to outdoor airflow into a building through intentional openings such as intakes, vents, and open windows. Infiltration refers to uncontrolled and unintentional airflow from the outdoors into the building interior (that is, entry of air into buildings), and a corresponding exfiltration of air from the building interior to the outdoors (that is, exit of air from the building). Depending on indoor-outdoor pressure differences, uncontrolled entry and a corresponding exit of air through the building envelope can occur. These pressure differences can be due to weather (for example, wind and temperature) and the operation of building systems (for example, exhaust fans and vented combustion equipment). It is important to note that infiltration rates are not controlled, nor is the distribution of infiltrated air within a building. Infiltration can have significant negative impacts on indoor air quality due to transit through spaces with poorer air quality such as wall cavities and basements. In addition, it can lead to condensation by creating cold surfaces where it enters and inside wall cavities where it exits, leading to issues with indoor moisture management. Proper air sealing and insulating are important strategies for reducing infiltration and associated condensation issues. Ventilation systems, natural or mechanical, that are well designed, installed, operated, and maintained are preferable to infiltration for meeting building ventilation requirements since they can provide the desired ventilation flow rate of higher quality air where it is needed, avoiding both under- and over-ventilation. Ventilation systems also provide opportunities to reduce energy impacts by recovering heat or moisture from the outgoing air. They allow for better humidity control, which has health benefits and can reduce potential for mould issues.

HVAC systems

Heating, ventilating, and air conditioning systems have a significant impact on how air contaminants move through a space, how outdoor air is brought in and indoor air exhausted, and how contaminants are removed from the air. An HVAC system is designed to:

- bring outdoor air into the building

- clean and filter the air

- heat or cool the air

- humidify or dehumidify the air

- distribute the air throughout the building

- remove stale air from the occupied space

- control the portion of the indoor air recycled vs exhausted outdoors

The HVAC system typically has many interconnected parts throughout a building, such as intakes, filters, ducts, and fans, that work together to move air into, around, and out of rooms. A well-designed and properly functioning HVAC system will deliver the appropriate amount of air to each zone (for example, a room or space) to achieve outdoor air ventilation requirements, thermal comfort, proper moisture levels and contaminant control.

Understanding HVAC systems

When functioning properly, an HVAC system will balance the different zones and maintain the desired pressures throughout the occupied space(s). Blocking supply air vents or return air grilles or interrupting air flow with furniture or boxes may unbalance the HVAC system, which may negatively affect the ventilation in other areas of the office or building space.

These systems use filters which can remove PM, including dust, pollen, mould, bacteria and viruses, from the air. Filters must be the appropriate dimensions and rated to match the HVAC system, as improperly sized or rated filters will not function properly. As filter efficiency increases (filter rating), so does the amount of pressure required to move air through the filter. The manufacturer's instructions or an HVAC specialist should be consulted when installing or upgrading filters (increasing the filter rating) to make sure that the mechanical system can handle the increased pressure drop across the filters. Additional information can be found in.

HVAC systems may also be the source of air contamination if the supply air grilles or air filters are dirty, if there is stagnant water in drip pans, or if there is moisture in air ducts that may promote the growth of moulds or other microbial agents.

Components of HVAC systems

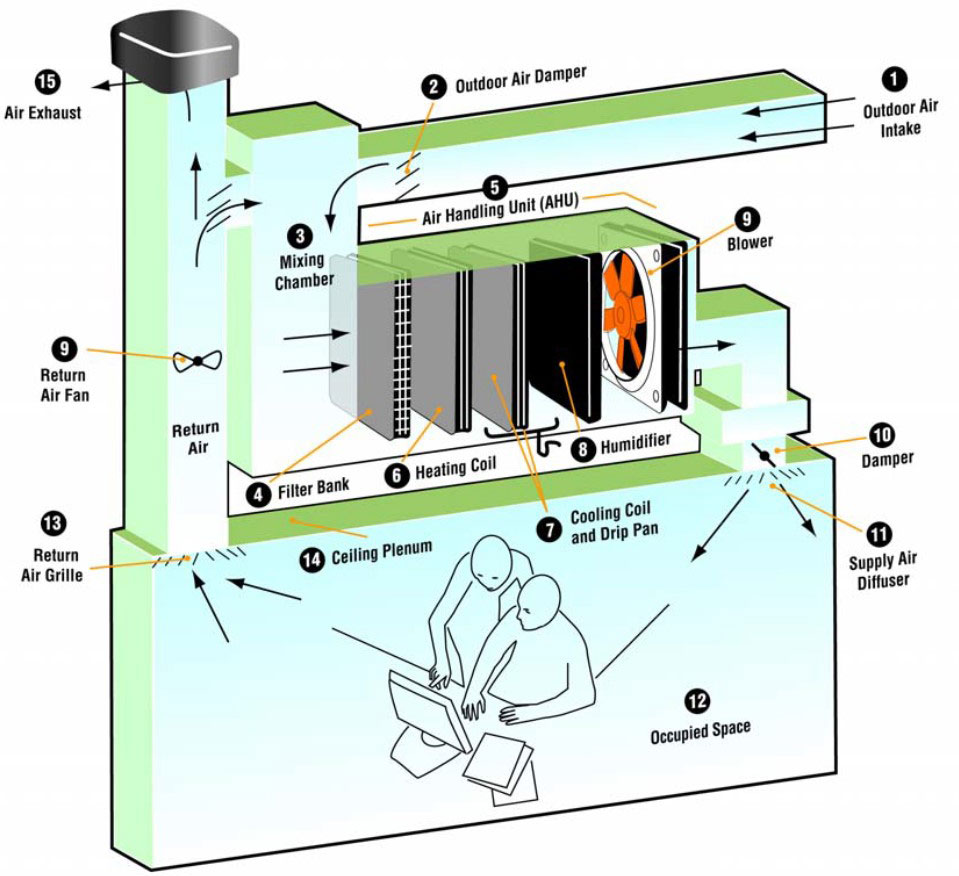

HVAC systems used in office or commercial buildings vary considerably in their size and complexity. These may range from simple make-up air units to large systems that are integrated into the building. Independent of their complexity and size, HVAC systems have the basic components described below (Figure 1). It is important that all components be inspected, cleaned, and maintained to ensure proper function of the equipment and delivery of quality air to the indoor environment. The following figure and associated numbers highlight the major components and functions of an HVAC system.

Figure 1 - Text description

- Outdoor air intake: Where outdoor air enters the building.

- Outdoor air damper: Adjustable barrier that limits the amount of air being brought into the building.

- Mixing chamber: Area where outdoor air is mixed with air returned from the indoor occupied space and recirculated.

- Filter bank: May consist of a pre-filter to remove large dust particles, bugs, feathers, and leaves from air before passing through the primary filter. Following filtration, the air is distributed to the occupied spaces.

- Air handling unit: Includes the blower or fan, heating and/or cooling coils, and related equipment such as controls, condensate drip pans, and air filters.

- Heating coil: Heats the air if needed.

- Cooling coil and drip pan: Cools the air if needed; drip pan catches water that is produced during the air-cooling process and drains into the wastewater system.

- Humidifier or dehumidifier: Adds or removes moisture to and from the air as required to adjust the relative humidity of the building air.

- Blower or fan: Pushes (supply) or pulls (exhaust) air through the system; controls flow to various parts of the building.

- Damper: Adjustable barrier that limits air flowing into or out of a space.

- Supply air diffuser: Distributes the ventilation air into the occupied space.

- Occupied space: Where people are normally present.

- Return air grille: The grille through which air exits the occupied space, being drawn by the return air fan to be returned to the HVAC system for exhausting or recirculation.

- Ceiling plenum: Space above the suspended ceiling that may be used as a part of the air return system.

Heat or energy recovery ventilators

A heat or energy recovery ventilation (HRV/ERV) system (also called economizer) may be used. This equipment is designed to mechanically ventilate the building by replacing indoor air with outdoor air while recovering the heat and/or moisture from the air stream to reduce energy costs. These systems include a sensible or latent heat exchanger core, which both the outdoor and exhaust air streams pass through to recover a percentage of the energy from the conditioned exhaust air within the building. HRVs/ERVs can be grouped into three categories: flat plate, rotary, or regenerative. In office buildings, the most commonly employed HRV/ERV is the rotary type (heat/energy wheel).

Single room HRV/ERVs are also available, which are mounted on an external wall, independent of the ductwork of the HVAC or other mechanical system. This equipment allows for ventilation of a single room, while transferring the energy from the exhausted air to the incoming air stream, thus reducing the heating and air conditioning load. Installation and operation of single-room HRV/ERVs should be done in consultation with a qualified HVAC technician.

System inspection and maintenance

When inspecting the HVAC system of a building, confirm each of the following items and determine if further action is required:

- No potential sources of contaminants (for example, garages, loading areas, roadways) are near outdoor air intake

- Outdoor air dampers are open and functioning, noting that these should be open to at least their minimum position during the coldest and hottest outdoor temperature conditions

- Air supply and exhaust fans are in operable condition

- Proper fan belts and blades are in operable condition

- Fan blades are installed properly (correct orientation)

- Ductwork or intakes are free of dust and mould

- Ducts are dry, clean, intact and well maintained

- Air handling units (fans, coil units, induction units) are in good repair

- Air filters with appropriate filtration efficiency ratings are dry, clean, properly sized and well maintained

- Condensate pans are free of dirty water, slime, rust or mould

- Drip pans are free of dirty water, slime, rust or mould

- Humidifier reservoirs are free of dirty water, slime, foam or mould

- HRV/ERV equipment is maintained as per manufacturer's recommendations (for example, filter cleaning and replacement, core and cabinet cleaning)

This list is provided as a customizable checklist in Appendix B. Any other information that is pertinent to the specific HVAC unit being inspected can be added. It is always relevant to consult the operator's manual or a qualified HVAC professional for assistance.

A preventive ventilation system maintenance program should be developed and implemented to ensure that the mechanical system is operating correctly, and filters are replaced on a set schedule. This helps reduce contaminants and maintain temperature and moisture levels. All HVAC systems should be inspected and maintained by a qualified professional as per manufacturer's recommendations. If none are available, ASHRAE Standard 62.1 proposes a recommended activity table, along with an inspection frequency, that building operators and employers can reference. As a last resort, a sample checklist (Appendix C) may be used to help inspect and maintain the HVAC system regularly. It is good practice to document and record each inspection and, in some instances, this documentation may be a legal requirement (for example, if the employer is targeted by the Canada Occupational Health and Safety Regulations). It is highly recommended to have the building operator/engineer or an HVAC specialist participate in this inspection.

Ventilation operating practices

As an HVAC system is critical to the overall quality of the indoor air, building operators and those responsible for indoor air quality should follow good operating practices. A well-implemented preventive maintenance program improves the operation of the mechanical systems and can save money over the long term by preventing critical breakdowns.

Good operating practices will:

- reduce indoor sources of contaminants

- limit outdoor contaminants from entering the space

- maintain the HVAC system to ensure it is operating correctly

- provide adequate outdoor air to occupants

- control temperature, velocity, and relative humidity in the building

- dilute, capture, and remove contaminants though ventilation, filtration, and air cleaning

The following sections address good operating practices.

Outdoor air intake considerations

When considering outdoor air:

- take steps to ensure that the outdoor air intake is free from exterior contaminant sources, including:

- traffic exhaust (for example, roadways, parking lots, idling vehicles)

- birds and other animals, and their droppings

- contaminants from other sources (for example, other businesses, garbage bins, industries)

- use an air intake screen with sieve openings smaller than 13 mm to help trap debris and prevent it from entering

- keep the building under a slightly positive pressure, if possible (that is, drawing slightly more outdoor air into the building than air that escapes or exhausts), as positive pressure limits air infiltration of cold air during heating colder seasons, hot air during warmer seasons, or intake of contaminants

- ensure that sufficient outdoor air (expressed as airflow rates of outdoor air) is flowing into the space, with the help of available guidelines and formulas. Airflow rates of outdoor air consider the number of occupants, the area/size, and the activities performed in that space

Outdoor air captured for indoor use should be of good quality. Depending on the jurisdiction, some buildings may require conformity with national standards and guidelines.

The following minimum distances should separate air intakes from sources of contamination:

| Object | Distance (m) |

|---|---|

| Cooling tower exhaust | 7.5 |

| Driveway, street or parking place | 1.5 |

| Garage entry, automobile loading area, or drive-in queue | 5 |

| Garage storage/pick-up area, dumpsters | 5 |

| Plumbing vents | 1 |

| Truck loading area or dock, bus parking or idling area | 7.5 |

| Thoroughfare with high traffic volume | 7.5 |

Operating schedules

Reduced operating schedules can help conserve energy during off-peak hours when the building is at a reduced occupancy overnight and on weekends. It is important to make sure that enough air changes occur before regular work hours to remove indoor air contaminants that may have accumulated overnight, and that temperature and humidity are brought to a desired level. The number of air changes depends on the duration of the shutdown period and other factors. These parameters can be determined through consultation with an HVAC specialist. In situations where respiratory infectious diseases are circulating in the community, it is recommended to run the system for two hours at maximum outdoor airflow before and after the building is occupied (Public Health Agency of Canada [PHAC] 2021).

Additionally, adjusting the ventilation system to not operate during the morning rush hour can significantly reduce traffic-related air pollutants within buildings located near major roads (MacNeill et al., 2016). This entails conducting the morning flush-out before morning rush hour, stopping during rush hour, and reactivating once rush hour has passed. This approach allows buildings to be ventilated with cleaner air than if the morning flush-out period was done during morning rush hour. Another important measure that can help reduce the intake of outdoor pollutants into the indoor environment is ensuring that outdoor air intakes are located as far away from traffic and idling vehicles as possible.

Ventilation flow rates

The ventilation flow rate can be expressed as an absolute ventilation flow rate (in litres per second, cubic metres per second, cubic feet per minute) or as an air change rate relative to the volume of the space. Non-residential ventilation flow rates are based on number of occupants and room dimensions or are calculated based on the intended dilution of known contaminants (ASHRAE Standard 62.1).

Replacing all the air in a room is called an air change. The number of air changes per hour (that is, the air change rate) is determined by dividing the amount of air that moves through a room in one hour by the volume of the room (CDC 2023). When there is inadequate mechanical ventilation with minimal infiltration and/or natural ventilation, the air change rate is low and indoor air contaminant levels can increase, resulting in more complaints from occupants.

Canadian building codes reference ASHRAE Standard 62.1 which provides minimal ventilation rates. However, the ventilation flow rates should be determined according to the requirements of the applicable jurisdiction and consider the various zones in a building. Once the appropriate rates are determined, any setting or adjustment of ventilation flow rates and air balancing of the building should be conducted by a qualified HVAC professional.

Building ventilation flow rates should be measured and brought in line with current applicable ventilation standards (ASHRAE Standard 62.1 and 62.2).

Increased air exchange, combined with other measures, has been suggested to help mitigate the risk of airborne infectious disease transmission and to contribute to an improvement of overall indoor air quality (ASHRAE 2023; CDC 2023; Lancet 2022; OSPE 2022). Improved filtration can also be used. These options come at an additional energy cost related to increased energy requirements of HVAC systems due to longer operation, requirements to overcome greater pressure drops across filters and/or the need to condition greater amounts of fresh outdoor air.

Responsive ventilation

Different procedures such as renovation, maintenance and changes in occupancy may result in localized higher concentrations of indoor air contaminants, and it may be necessary to manually control or schedule the mechanical system during these times to provide additional ventilation. At other times, it may be necessary to reduce the amount of ventilation if the outdoor conditions are deemed to be poor (for example, wildfire smoke, spills), or if work being done in the building requires containment to reduce dissemination of contaminants throughout the building.

Determining when to manually increase or decrease ventilation, and for how long, is the responsibility of the building operator. During wildfire smoke or other air quality events, pay attention to the Air Quality Health Index (AQHI), InfoSmog (Quebec), and air quality warnings (Health Canada 2023b).

Air filtering

Filtration of indoor air is an important part of reducing exposure to small particles including aerosolized virus particles. Air can be filtered by the HVAC or other mechanical systems through the building filtration system. This helps protect the indoor air from contaminants that originate in the outdoor supply air as well as in the building return air. It is recommended to use a filter with a minimum efficiency reporting value (MERV) rating of 13 or higher in buildings with return air, where feasible, in order to reduce viral transmission indoors (Unites States Environmental Protection Agency [US EPA] 2024b; Health Canada 2020a). Indoor air can also be filtered using HEPA-based portable air cleaners (PACs), which can help capture some contaminants (for example, pollen, dust, viruses) regardless of whether they are produced indoors or outdoors (Health Canada 2022a). Note that filters can help remove particulates but will not be effective against gases, such as CO or CO2.

Filtration system considerations

Increasing the efficiency of filters decreases the chance of particulate material and infectious respiratory particles being spread through the air distribution system. However, even if higher filtration is more effective, it may not be practical because of diminishing returns in improvement of particulate removal and increasing static pressure and cost. For example, while an increase from MERV 13 to MERV 14 enhances the efficacy of capturing particles between 1 and 3 µm from 85% to at least 90%, this improvement may be outweighed by the increased pressure requirements to move air through the filter, which the system may not be able to provide (ASHRAE 2023). Although a filter with a rating of MERV 13 or higher is ideal, the appropriate filtration for a system will depend on the system's capabilities and the manufacturer's recommendations.

Filters must be of appropriate dimensions for installation in the HVAC system, as improperly sized filters will not function as designed. When considering using a higher efficiency filter in an HVAC system, it is important to adjust for the additional air resistance of the higher rated filter.

The gold standard for interior air filtration is a HEPA filter. A HEPA filter is a type of pleated media air filter that is often required for sterile, controlled environments such as hospital operating rooms, laboratories, and micro-electronics manufacturing facilities. HEPA filters remove at least 99.97% of particles at or above 0.3 mm such as dust, pollen, mould, bacteria, viruses and other airborne particles. However, due to the higher pressure drop from HEPA filters, building systems where this rigorous filtering is not required may not be able to accommodate them.

It is important to consult an HVAC or filtration specialist when selecting the type of filters, the MERV rating, and pressure drop of the system.

Portable air cleaners

Portable air cleaners (PAC), also known as air purifiers, can also help improve indoor air quality by reducing levels of airborne particulates. This equipment can provide high-efficiency filtration when used alongside building ventilation systems but is not a substitute for whole-building ventilation. However, when mechanical ventilation is not available, PACs can be effective in reducing indoor particulate levels.

Many commercially available PACs are designed to filter the air in a single area or room using HEPA filters. It is important to select a PAC appropriately sized for the space it is used in. The following should be considered when purchasing and installing a PAC (Health Canada 2022a):

- Use a certified PAC with a HEPA filter to help remove particles from the indoor air.

- A PAC is designed to remove particles from the air in a single room. It is not designed to remove particles from an entire building.

- The most reliable way to select a PAC is by looking at the suggested room size and the clean air delivery rate (CADR). The CADR describes how well the machine reduces particles with sizes equivalent to those of tobacco smoke (the smallest particles), dust, and pollen.

- For an overall reduction in fine particles, consider choosing a PAC with the highest tobacco smoke CADR that is properly sized to fit the room in which it will be operated. The higher the number, the more fine particles the PAC can remove.

- Calculate the minimum CADR required for a room: as a general guideline, the CADR of a PAC should be equal to at least two-thirds of the room's area.

- Follow the manufacturer's instructions for placement and operation to ensure good airflow. Generally, higher fan speeds and longer run times will increase the amount of air filtered. Be aware that some PACs can be noisier than others.

- Clean or replace filters as recommended by the manufacturer. Consider increasing the frequency of filter cleaning or replacement depending on use and conditions.

In general, a PAC will work best when operating at the highest fan speed setting; however, noise may become an issue. The CADR reflects the effectiveness of a PAC and assumes that the PAC is operated at full speed.

Devices that use ions, such as photocatalytic oxidizers, ion generators, electrostatic precipitators, and others, to purify air may produce ozone. If selecting these devices, they should have an Underwriters Laboratory (UL) 2998 (zero ozone emissions) certificate (UL 2022b). If the device is not certified, it should be avoided, as ozone can impact human health. The California Air Regulatory Board lists units that have passed testing for ozone emissions (Health Canada 2022a).

Stand-alone filtration units

In addition to portable filtration units, larger filtration systems are available that can be affixed to walls and ceilings to allow air cleaning in defined areas. Where available, building operators should seek equipment with independent stages of filtration that can be replaced at different times. Filtration systems may contain at least the following three layers:

- A pre-filter to trap larger particles in the air

- A layer of carbon filtration to capture odours

- A HEPA filter to capture fine particles, smoke, bacteria, viruses, etc

These systems will allow for the replacement of individual filters at different times and of the pre-filter on a regular basis to prolong the useful life of the expensive HEPA filter.

Do-it-yourself air cleaners

If a ventilation system or certified portable air cleaner is not available, an option to consider is to use a do-it-yourself (DIY) air cleaner (Health Canada 2023b; National Collaborating Centre for Environmental Health [NCCEH] 2023). There is some evidence that DIY air cleaners can be an effective option in short-term emergency situations, such as during a wildfire smoke event. It is important to understand the limitations and safety risks associated with DIY air cleaners. If choosing to use DIY air cleaners, remember to use a clean, recent (2012 or later) box fan with a safety fuse and ideally certified to UL 507 (UL 2022a). Never leave the fan running unattended and keep it away from walls, furniture and curtains. Do not use an extension cord, do not use a damaged or malfunctioning fan, and be sure to change the filters regularly during smoke events as clogged filters are ineffective and may cause the fan to overheat and lead to fires.

Carbon dioxide as an indicator of ventilation

The primary source of CO2in indoor air is occupant respiration, with lesser sources such as improperly vented combustion appliances and cigarette smoke also potentially contributing to indoor CO2levels (Health Canada 2021b). Common situations leading to elevated CO2concentrations indoors include excess building occupancy (overcrowding), or when occupants are spending prolonged periods of time indoors. As such, CO2can serve as a proxy for occupant-emitted contaminants and pathogens and as a means to assess the ventilation rate (Morawska et al. 2024). With increased public awareness of the importance of ventilation, alongside commercially-available inexpensive CO2monitors, there is a renewed interest in using CO2monitoring as a method for quantifying ventilation efficiency.

Indoor CO2concentrations have long been used to control outdoor air intake rates of building HVAC systems, using demand-controlled ventilation. This control strategy reduces the energy use associated with overventilation during periods of low occupancy and helps to ensure that spaces are adequately ventilated based on their actual occupancy (ASHRAE 2022). When CO2monitors are integrated into an HVAC system, it is important for those investigating indoor air quality to confirm that the system has been properly maintained, calibrated, and monitored; that false readings are not common; and that system reports are available for review (National Education Association 2022).

Guidance provided by ASHRAE (2022) acknowledges that indoor CO2concentrations can be a useful tool in indoor air quality assessments if users understand its limitations. Sensor accuracy, location, frequency of monitoring, and calibration, as well as building occupancy, among other issues, are all critical for drawing meaningful inferences from measured indoor CO2 concentrations. See Guidance for Indoor Air Quality Professionals (Health Canada 2025) for more information.

The importance of ventilation as a method for reducing transmission of the SARS-CoV-2 virus was highlighted during the COVID-19 pandemic (PHAC 2021). However, indoor CO2levels should not be interpreted as a proxy for risk of infection from airborne infectious diseases, as transmission depends on multiple factors, of which ventilation is only one (US EPA 2024a; NCCEH 2021). There are numerous scenarios in which reliance on indoor CO2levels may cause occupants to under- or over-estimate the risk of transmission.

Thermostats and monitors

Thermostats must be functioning, calibrated, correctly located, and not obstructed or enclosed in a way that limits air flow to them. To be correctly located, a thermostat should be placed on an interior wall that is in the centre of the room and away from direct sunlight or other heat sources. Placing a thermostat in the path of direct sunlight can have implications on the operation of the HVAC system and an associated energy penalty (Berquist and O'Brien 2018). In addition, personal heaters or humidifiers can disrupt or interfere with thermostats and humidity sensors, and may lead to inaccurate adjustments of the temperature or humidity in an area.

If CO2or any other indoor air quality monitoring is part of the ventilation system design, an HVAC professional should be consulted to determine proper locations for mounting any sensors or monitors.

Special areas

Special areas include photocopy rooms, bathrooms, kitchens, parking garages, loading docks, print shops, janitorial closets, and some storage areas (for example, for paint, cleaning chemicals or other hazardous products). These areas require additional consideration for exhausting air and may require increased ventilation flow rates, as there may be higher contaminant levels present. Section 8 (Exposure controls/Personal protection) of the safety data sheet for any hazardous products provides additional guidance for exposure controls and personal protection. To avoid recirculating contaminants into the main air supply, these areas should be designed to exhaust air directly outdoors if they contain hazardous products.

Balanced systems

A balanced ventilation system introduces outdoor air and exhausts inside air to achieve the target pressure balance (Health Canada 2018). Outdoor air is conditioned prior to being supplied to offices and meeting rooms where occupants spend most of their time, and air is specifically exhausted from areas where there may be extra moisture and contaminants, such as in lunchrooms and washrooms. A portion of the return air may also be exhausted depending on system design and operation. Office areas and meeting rooms have supply air diffusers and return air grilles to ensure proper air movement. Installation, calibration, and inspection of a balanced system will be the responsibility of an HVAC professional or other appropriately trained individual.

Blocking air supply diffusers or return air grilles may cause the system to overcompensate, leading to balancing issues. The correct volume of air should be delivered to all locations in a building to provide adequate air quality. It may be beneficial in the HVAC system design and operation to use zone controls to help manage changing temperature and humidity needs. For example, a south-facing sunny location may need more cool air while a north-facing location may need more heated air. Induction heating or cooling units on the building perimeter can be used for this purpose.

Reducing airborne infectious aerosol exposure

Many of the control mechanisms recommended to improve and maintain good indoor air quality also reduce the risk of airborne infectious diseases. Ensuring proper ventilation by introducing outdoor air can reduce the concentration of contaminants—including virus- and bacteria-laden particles—in indoor air through dilution or exhausting to the outdoors. Use of localized ventilation (for example, exhaust fans typically found in bathrooms, kitchenettes) can also help reduce the transmission of infectious diseases. Proper ventilation can reduce surface contamination by removing some virus- and/or bacteria-laden particles before they can deposit on surfaces.

In addition to increasing outdoor air ventilation as a mechanism for reducing infectious disease transmission, ASHRAE Standard 241 provides guidance on using filtration and disinfection to deliver equivalent clean air. Equivalent clean air is calculated by considering dilution ventilation using outdoor air and the impact of different kinds of air cleaners, filters, and ultraviolet (UV) germicidal irradiation disinfection systems. A filter or air disinfection unit can be added to the ventilation system instead of increasing outdoor air intake above the minimum outdoor air ventilation requirements, thus providing energy savings and flexibility in how a building delivers clean air.

In Canada, UV radiation-emitting devices designed to kill or control human pathogens on surfaces and in air are regulated under the Pest Control Products Act and must be registered prior to use and installation (Health Canada 2022c). Selection, installation, and maintenance of UV disinfection equipment should be done by a trained professional in accordance with the manufacturer's instructions to prevent unintended exposure of room occupants to UV energy. These devices are not permitted to produce ozone or other harmful substances.

When used alongside other personal protective measures (for example, staying home when ill, wearing a well-fitting respirator or mask, practicing hand hygiene, covering coughs and sneezes, and cleaning and disinfecting high-touch surfaces and objects), improving ventilation and air filtration can be part of a plan to reduce the spread of infectious diseases indoors (PHAC 2021, 2022a, 2023a, 2023b, 2023c). For additional information on controlling exposure to infectious diseases, consult PHAC.

Other air cleaning technologies

Beyond removal of fine particulate material from the indoor air by mechanically trapping them on filter material, additive air cleaning or alternative methodologies exist that are meant to clean or disinfect the air. ASHRAE (2021a) recommends to "only use air cleaners for which evidence of effectiveness and safety is clear". Also, these technologies have the potential to degrade the quality of the air through the generation of ozone and other harmful secondary by-products.

ASHRAE Standard 241 provides a procedure for testing the effectiveness and safety of air cleaning systems. This guidance establishes testing methods and reporting requirements for in-room and in-duct air cleaning system effectiveness against microorganisms and sets limits for the release of UV radiation and degradation by-products.

Poor outdoor air quality events

As outdoor air pollution can be an important determinant of indoor air quality, strategies to prevent infiltration of outdoor air pollutants are essential to maintain and improve indoor air. General recommendations for maintaining and protecting indoor air when outdoor air quality is poor include (Health Canada 2020b):

- Reducing infiltration of outdoor air pollutants

- Installing the highest quality filter that the ventilation system will allow in accordance with the manufacturer's instructions to filter incoming air. Additional information can be found in Air filtering

- Switching off any HRV/ERV to limit the intake of outdoor air

- Properly sealing windows and doors and keep them closed

- Using a PAC with a HEPA filter to help remove fine particles from the indoor air

Wildfire smoke

Communities across Canada regularly experience wildfire smoke events, with wildfire season typically running from early April to late October. The indoor air quality in office buildings may be impacted by such pollution events. As wildfires burn, they produce dense smoke and a variety of air pollutants that can have an impact on human health.

Proactive planning by building managers will allow procedures to be initiated during wildfire events to help protect office building occupants. Planning frameworks developed by ASHRAE (2021b, 2024) and the US EPA (US EPA 2025) focus on reducing exposure to PM2.5. These frameworks provide recommendations and processes for developing a Smoke Readiness Plan for commercial buildings and similar building types that can be implemented when smoke is forecasted and during smoky days. The advice closely aligns with guidance developed for community-based cleaner air spaces for use during wildfire events (Health Canada 2020a).

The framework emphasises that a Smoke Readiness Plan needs to be specific to a building. According to ASHRAE's Smoke Readiness Plan (2021b, 2024), building managers should consider the following:

- Purchase smoke preparation supplies prior to the wildfire season to ensure that enough extra filters and PACs are available for use, as supplies may be limited during a smoke event.

- Upgrade HVAC system recirculation filters to MERV 13 after ensuring that the system has been deemed capable of handling the upgraded filters. Note that high efficiency filters will likely require more frequent changes than usual due to their greater particulate retention and the increased outdoor smoke levels.

- Repair broken dampers, actuators, and HVAC controls prior to wildfire season and ensure they will allow the reduction in outdoor air flow, if required.

- Optimize airflows such that they are protective of human health while controlling odour, temperature, and indoor contaminant levels and maintaining a positive building pressure consistent with the building and HVAC system design.

- Add air intake filtration during a smoke event, where possible. Installing MERV 13 filters on air intakes will capture a large fraction of PM5prior to entering the HVAC system.

- Routinely monitor filter conditions and add a pressure gauge to measure the pressure drop on air handling units. This will help determine when to replace filters.

- Limit smoke intrusion by weatherizing the building envelope to reduce infiltration—seal and caulk cracks, and keep doors and windows closed.

- Monitor indoor PM5by obtaining one or more air monitors equipped with a PM2.5sensor. Even low-cost monitors can provide important information to building operators on the PM2.5levels in the building. Level trends can indicate if interventions are needed and if existing practices are effectively reducing indoor PM2.5. For example, an upward trend can indicate that doors are open, air filters are degrading, or HEPA PACs should be turned on.

- Determine how to create temporary cleaner air spaces within the building prior to fire season. Select and operate properly-sized HEPA portable air cleaners. It may be helpful to use an air monitor to determine whether the air is being cleaned and to verify that the air is in fact cleaner than other spaces in the building.

- Anticipate other sources of PM5in the building such as cooking, vacuum cleaning, use of printers or copiers, and smoking. Awareness of potential sources can assist in reduction of these sources during wildfire events and beyond.

Ventilation standards

Standards

Standards are produced by non-profit organizations, such as the CSA Group, the American National Standards Institute, ASHRAE, and the International Organization for Standardization. Specific standards are often incorporated into building codes, regulations, and certifications. Examples of standards relevant to indoor air quality include the following:

- American Conference of Governmental and Industrial Hygienists: Threshold Limit Values

- ASHRAE 55: Thermal Environmental Conditions for Human Occupancy

- ASHRAE 62.1: Ventilation and Acceptable Indoor Air Quality

- ASHRAE 62.2: Ventilation and Acceptable Indoor Air Quality in Residential Buildings

- ASHRAE 170: Ventilation of Health Care Facilities

- ASHRAE 180: Standard Practice for Inspection and Maintenance of Commercial Building HVAC Systems

- ASHRAE 241: Control of Infectious Aerosols

- CAN/CSA-F326-M91: Residential Mechanical Ventilation Systems

- CAN/CSA-Z317.2: Special Requirements for Heating, Ventilation, and Air-Conditioning (HVAC) Systems in Health Care Facilities

- Canada Labour Code: Canada Occupational Health and Safety Regulations

- MD 15000: Mechanical Environmental Standard for Federal Office Buildings – Public Works and Government Services Canada

- MD 15161: Control of Legionella in Mechanical Systems – Public Works and Government Services Canada

Building codes

Building codes outline the requirements for air exchanges, thermal comfort, and occupancy limits in a building, structure or facility. Heating, ventilation, storage facilities, renovations, CO alarms, smoke alarms, and maintenance are typically covered and are enforced by the provinces, territories, and municipalities. Certain premises are under federal jurisdiction. Always refer to the building code(s) that apply to your building.

Their objectives are to ensure that:

- the building is structurally adequate for its intended use

- the structure and materials can withstand temperature extremes, wind, seismic activity, and ice and snow loads

- the building design meets the fire code, electrical safety code, ventilation requirements, and other regulatory requirements

- the building is suitable for the planned occupancy

HVAC safeguarding

Building operators should consider the possibility of deliberate attempts to tamper with or damage HVAC systems and/or introduce chemical, biological or radiological contaminants into the building through outdoor air intakes or from within the building, and plan accordingly. Additionally, depending on the HVAC system, cybersecurity incidents such as malware and ransomware attacks on the controls could disable and damage system components. Prevention of tampering or damage requires an assessment of the access points, operating conditions, and controls of the HVAC system.

Conducting a risk assessment of the building's mechanical ventilation system is an important component of protecting the building and its occupants. Using up-to-date drawings (for example, mechanical, electrical) and the written operational procedures for the existing HVAC system, building operators should consider the following:

- Determine the location of outdoor air intakes and outdoor mechanical components. Design or modify the location of air intakes and mechanical components so they are not readily accessible and are less noticeable. If this is not possible, incorporate barriers such as fences and locked gates and/or surveillance and monitoring to limit access as much as possible.

- Determine the location of the filtration and distribution systems as well as the ventilation system controls. Secure areas where equipment is located, restrict access to these areas to authorized personnel, and screen and supervise personnel and contractors that have access to these systems.

- Establish a procedure for rapidly and safely shutting down the system should it be required. Ensure staff are trained and available.

- Determine if the system has the capacity to zone off, isolate or independently control ventilation of specific sections of the building. If so and if the HVAC system is damaged, operators can continue to provide ventilation to unaffected parts of the building while damaged sections are undergoing repairs. If contaminants are deliberately introduced into the system (from inside or outside), this capability combined with the operators' quick response can prevent or limit the exposure of occupants. This capability can also aid in evacuation planning.

- Determine the location and types of filters used in the system to aid operators with regular maintenance and help inform whether filters can mitigate the entrance of certain contaminants.

- Assess whether the system has adequate cybersecurity protection. Software used to automate and/or control these systems can be subject to cyber-attacks disabling or harming system components, which can in turn cause issues with indoor air quality, heating, and cooling. This can impact business operations through disruption of occupant activities and cause damage to equipment or materials stored in the building. Additionally, if the system controls are not adequately protected from intrusion, they can provide a gateway to access other networks and information, including financial and personal data.

The above list includes a few examples of the many mitigation measures that may be implemented to protect the HVAC system and the indoor air quality of an office building. A building-specific risk assessment is necessary to determine specific risks and help identify additional mitigation measures that may be implemented.

Undertaking a comprehensive risk assessment and implementing changes to help protect the HVAC system will help reduce but not necessarily prevent intentional disruption of the building operations. Monitoring and surveillance, comprehensive operational procedures for which staff are adequately trained, and communication with building occupants are all necessary to lessen the adverse impact to the mechanical ventilation system, the indoor air quality, and the health of the building occupants should an incident occur.

For additional information, refer to Protecting HVAC Systems from Cybersecurity Threats (ASHRAE 2021c) and Guidance for Protecting Building Environments from Airborne Chemical, Biological or Radiological Attacks (National Institute for Occupational Safety and Health 2002). All design, maintenance, and risk assessment activities should be conducted with the assistance of an HVAC professional.

Building stewardship

Good indoor air quality management includes building stewardship and communication.

Stewardship refers to the oversight of and responsibility for the care and maintenance of property. Building operators and employers are often able to directly and positively impact indoor air quality through building stewardship. By understanding indoor air and the interactions between products, furnishings, occupants, processes, and air quality, building managers and employers can develop policies and procedures or implement changes with air quality in mind.

Stewardship includes the day-to-day proactive upkeep and maintenance of the building and building envelope. By promptly identifying and addressing issues, operators or employers will be able to eliminate or reduce the causes of poor air quality, ideally before the issue becomes serious. Building stewardship includes building maintenance, space design and renovations, procurement, and housekeeping. Building operators should develop and maintain good communication with occupants, and educate employers, custodians, maintenance staff, and occupants about the importance of air quality and good practices to follow. Good communication between building operators and occupants can be facilitated through the development of a formal reporting process. A standardized procedure will ensure that communication regarding building issues is handled consistently over time.

Building maintenance

Similar to good maintenance practices required for ventilation systems, measures should be taken to upkeep a building's indoor air quality or address potential causes of poor air quality before they become a problem. It is important to schedule routine cleaning and maintenance and to conduct regular inspections of the building.

Maintenance personnel or the health and safety committee should carry out regular inspections and monitor the building systems as required to look for indicators of moisture issues and to ensure that contaminants are not introduced into the building.

During inspection of the building and building envelope, particular attention should be given to:

- decay, leaks or damage in exterior walls, masonry work, roofs, eaves, soffits, foundations (for example, cracks, openings, missing shingles, deteriorated caulking, separating flashings, missing eavestroughs, etc.)

- erosion, cracks or damage between doors or windows and the building itself that may let air or water enter the building

- the soil grading around the building (that is, the ground surface should slope downward to divert water away from the building)

- damage from plants, trees or shrubs, and their roots (for example, roots lifting and cracking concrete, roots accumulating in drainage pipes)

- water or sewage leaks from plumbing (for example, safety showers, emergency eyewash stations, fire suppression sprinkler systems, washrooms, drinking fountains, kitchens, roof drains)

- damage or discolouration in ceiling tiles, floors, and walls