Caring for vehicles

George Prytulak

Caring for vehicles is part of CCI’s Preventive conservation guidelines for collections online resource. This section presents key aspects of managing the care of vehicles in heritage collections within a protected indoor environment based on the principles of preventive conservation and risk management.

Table of contents

Understanding vehicles and how they are damaged

Vehicles comprise a very wide and diverse assortment of objects, which can include vehicles of transport, agriculture, maintenance, exploration and leisure. Although diverse in their nature, methods of construction and use, all vehicles share common elements. They are in some ways similar to instruments and small machines: they are functional, they have moving parts and they are composed of a wide range of materials with an equally wide range of finishes. Accordingly, they also share many of the same deterioration problems, such as corrosion, wear and physical damage, but on a larger scale.

Characteristics of vehicles

Metals, oils and lubricants

Most vehicles are predominantly made of metal and metal parts, with oils and lubricants present to allow mechanical movement.

Metal is subject to corrosion. It can also be physically damaged, e.g. by abrasion, causing scratches, and by physical forces, causing dents. Oils and lubricants age with time due to oxidation, hydrolysis and other processes, thus losing their ability to perform as originally intended. Metal containers may rust or fail, causing the oils and lubricants to leak or produce staining.

Finish and decorative striping

Many vehicles also feature decorative striping (Figure 1a), decals or lettering on their bodywork. These elements often incorporate fragile layers of gold leaf and are invariably coated with a clear protective varnish. The decorative details greatly enhance the visual appeal of a vehicle and, in turn, might have encouraged its former owner or user to maintain and care for the vehicle.

Fine automobile finishes are very prone to scratching. Abrasive dust is generated from bare concrete floors and walls; it also results from maintenance work in storage and display areas. Dust accumulates mainly on horizontal surfaces (Figure 1b). Careless removal of abrasive dust may result in deep scratching of finishes (Figure 1c). Accumulation of dust should be avoided as it accelerates corrosion processes (Figure 1c).

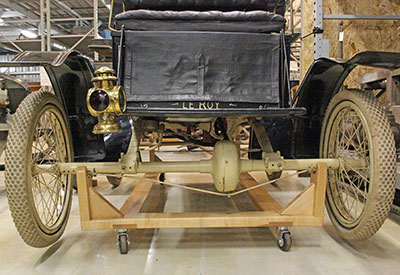

Courtesy Waterloo Region Museum

Figure 1a. A Le Roy automobile with a black paint finish and some decorative striping. The vehicle was made by the Le Roy Manufacturing Co. of Berlin (now Kitchener), Ontario, a company founded around 1902 by Nelson and Milton Good that produced no more than 20 Le Roys before going out of business in 1904.

Courtesy Waterloo Region Museum

Figure 1b. Accumulated dust on one of the fenders of the Le Roy automobile. Improper cleaning or sliding contact with a dust cover will permanently scratch the finish.

Courtesy Waterloo Region Museum

Figure 1c. Detail of scratches and of a few spots of localized corrosion on a Gray & Davis brand brass headlamp on the Le Roy automobile.

Interior furnishings

Unlike smaller machines and instruments, vehicles are designed to move people, freight or heavy implements. In most cases, they have designated areas for operators and, very often, passengers. In order to provide some degree of human comfort and visual appeal, these areas are usually furnished with upholstered seats, armrests and headrests, sun visors and other amenities such as carpeting, curtains and door or wall panelling (Figure 2).

© Canada Science and Technology Museum

Figure 2. A view of the interior furnishings of an early 20th-century four-wheeled horse-drawn carriage (a brougham).

Other organic or plastic materials

The composition of most vehicles introduces a host of conservation problems in the form of vulnerable organic components, including such materials as leather, textiles, foam rubber, plastics, wood veneer, rattan, wicker, paper products (pasteboard, cardboard, etc.) and even decorative animal-based materials such as ivory, horn, tortoiseshell and mother-of-pearl. To compound the problem, many of these materials are secured in place with organic adhesives. For information on the care of these individual materials, consult the relevant resources under Care of objects and collections.

Moving parts and control mechanisms

The operator and passenger areas are also likely to have moving parts and control mechanisms. These devices invite physical interaction. They include steering wheels, shift levers, foot pedals, door handles, window cranks, locks, electric pushbuttons, knobs and dials, ashtray covers, heater controls and hinged storage compartments (e.g. glove compartment). These components add further vulnerable materials and small moving parts to the list of concerns for vehicle preservation.

Propulsion fuel or device

Vehicles are created to move from one point to another. Every form of propulsion poses risks to the materials and operators. Examples of these risks include flammable fuels, electricity, high-speed moving parts, combustion exhaust products and excessive heat. In addition, when a vehicle is set in motion, there is a risk of serious damage or complete destruction if the vehicle crashes, sinks or burns. Each vehicle must be surveyed methodically for potential hazards. The most important concern in displaying and housing vehicles is public and staff safety.

Wheels and tires

Courtesy Waterloo Region Museum

Figure 3. A wheel on a historic automobile, showing cracks in the degrading rubber tire.

One recurring problem with road vehicles is the long-term effect of the weight of the vehicle on the wheels and tires. In use, the wheels of a vehicle will never stop in the same place, so stresses due to gravity are distributed around the entire circumference of the wheel. In static display or storage, the wheels are rarely moved, so stresses due to gravity are concentrated. This results in distortion in wooden wheels and in both compression and distortion in rubber tires. Early rubbers are a particular preservation issue because of their rapid deterioration (Figure 3), especially under adverse conditions. For more information on the care of rubber, consult CCI Note 15/7 Rubber Components in Industrial Collections and Caring for plastics and rubbers.

Causes of damage to vehicles and preventive conservation strategies

Under proper museum display and storage conditions indoors, vehicles can survive for generations. The control strategies which apply most specifically to vehicles indoors focus on countering the force of gravity, minimizing handling and unauthorized access, and controlling the environment—in particular, dust, temperature and relative humidity (RH). Other preventive conservation strategies that apply to a mixed collection will also provide benefits.

Control strategies specific to vehicles

Countering gravity

Gravity is a physical force constantly acting on each of a vehicle's components and especially on the axle and other joints of its assembled parts. For large weighty objects such as vehicles, the effects of gravity can be substantial, and countering them (i.e. supporting loads, especially at joints or weak points to avoid stresses and possible fractures) is essential.

Recommendations

- Insert supports under axles and other load-bearing members of vehicles with wooden wheels or rubber tires. Wheels should be just slightly off the ground (Figures 4a, 4b, 5 and 6).

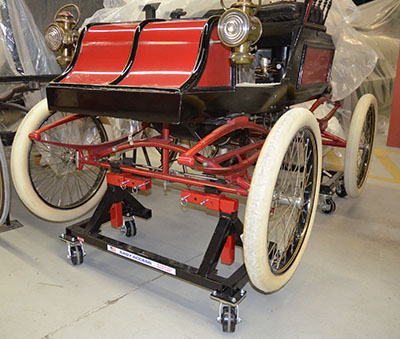

Courtesy Waterloo Region Museum

Figure 4a. Back view of a support dolly inserted under the axles of the Le Roy car shown in Figure 1. This takes the load off the car's wheels, yet still allows the vehicle to be moved when necessary.

Courtesy Waterloo Region Museum

Figure 4b. Front view of the support dolly (shown in Figure 4a) under the car.

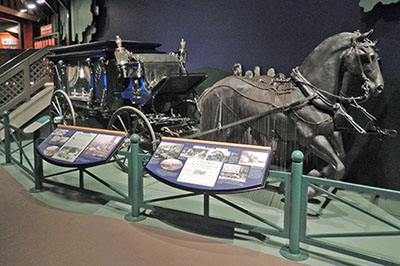

© Canada Science and Technology Museum

Figure 5. Another type of wheeled support inserted under the axles of a car.

© Canada Science and Technology Museum

Figure 6. Axle supports for a wooden carriage.

- Raise vehicles and rotate wheels regularly if no axle stands are present.

- Store vehicles on a firm and flat surface, such as a level concrete floor. Use rubber mats to prevent abrasion between the wheels and the floor.

- Custom build supports for unstable or fragile objects (Figure 7).

© Canada Science and Technology Museum

Figure 7. A sturdy, custom-made metal stand for an 1886 high-wheeler bicycle.

For more preservation strategies to deal with physical forces, consult Agent of deterioration: physical forces.

Security and unauthorized handling

Visitors are often charmed by historic vehicles, which can lead to inadvertent damage. The desire to touch, feel and handle the vehicle can result in damage such as wear marks and abrasion as well as harmful deposits of salts, oils and dirt transferred from fingerprints. Movable parts intended originally for control of the vehicle always attract attention and often end up being mishandled or forced; they are at high risk of becoming broken. Theft of small parts can occur as unscrupulous visitors may be tempted to take them as souvenirs.

Recommendations

- Prevent harm due to unauthorized access with temporary pedestrian barriers that cannot be moved easily. Several kinds are available, e.g. braided or velvet ropes or retractable belts on metal stanchions. Permanent barriers such as metal railings or floor edging resist being moved by the public but are also more expensive and less versatile (Figures 8a and 8b).

© Government of Canada, Canadian Conservation Institute. CCI 128209-0012

© Government of Canada, Canadian Conservation Institute. CCI 128209-0008

Figures 8a and 8b. Effective pedestrian barriers can be integrated into a display, as shown in these two examples from the Remington Carriage Museum. Left: Hearse carriage manufactured circa 1900. Right: Menard Auto Buggy manufactured circa 1908.

- Install a psychological barrier, such as a raised curb or wooden strip along the edge of the walkway to alert visitors to the inviolability of the space beyond (Figure 9).

© Government of Canada, Canadian Conservation Institute. CCI 128209-0010

Figure 9. These two sleighs are exhibited on a raised platform which functions both as a psychological barrier and as a display aid suggesting snow.

- Install signs instructing visitors not to touch the objects (Figure 10).

© Government of Canada, Canadian Conservation Institute. CCI 128209-0009

Figure 10. The sign on the sleigh states: "These vehicles are 100 years old. Thank you for not touching."

- Assess small movable or easily breakable parts (glass dials, etc.) in terms of their vulnerability to theft and vandalism, and implement a means of protection, if warranted. Several levels of deterrence are possible. For example, install temporary protective barriers such as a Plexiglas screen. Using security screws (requiring special tools or procedures for removal) is another option. Before altering any original parts, consult a conservator for guidance.

- Prevent the deposition of corrosive fingerprints on bare metal surfaces with barriers and other deterrents (see above).

- Treat bare metal surfaces with transparent, non-tacky rust-preventive coatings or microcrystalline wax.

- Use proximity alarms with loud sounds to deter visitors from approaching items.

- Install a remote security system, including motion detectors, silent alarms and video surveillance, as required. These measures are most useful during closing hours and only helpful during opening hours if there is vigilance and immediate staff response.

- Full-time security guards or guides who accompany visitors may prove more effective than an alarm system.

For more preservation strategies on these topics, consult CCI Note 15/4 Indoor Display of Industrial Collections. Consult also Agent of deterioration: thieves and vandals and Caring for metal objects.

Dust

Because dust is a high abrasion risk to finishes and decorative striping and because it can accelerate corrosion of metal parts (pitting), strategies to prevent dust deposition on vehicles are quite beneficial.

© Canada Science and Technology Museum

Figure 11. Historic automobiles protected with polyethylene non-woven (Tyvek) dust covers in storage.

Recommendations

- Dust properly and regularly to prevent abrasive scratching of polished or painted surfaces (Figure 1c). This must be done by trained, conscientious staff.

- Once the surfaces have been dusted, use dust covers to protect vehicles in storage (Figure 11).

- Eliminate sources of dust, e.g. by installing carpets at the entrance of the building, by paving entrances and by sealing concrete floors and walls.

- Consider applying protective coatings such as microcrystalline wax to protect bare metal surfaces, as further discussed in CCI Note 15/4 Indoor Display of Industrial Collections.

For more preservation strategies to prevent dust deposition, consult Agent of deterioration: pollutants (under the "Fine particles" subsection).

Managing temperature and relative humidity

Temperature

Cooler temperatures will reduce corrosion rates and chemical degradation rates for sensitive materials such as rubber and plastic. In fact, lowering the temperature by a mere 5 °C cuts their degradation rate by half. On the other hand, reduced heating can lead to increased RH if there are no dehumidification controls in place, and high RH increases the metal corrosion rate. Overall, the best strategy is to keep temperatures as low as possible, but only to the extent that it is also possible to keep the RH below 70%.

For more preservation strategies related to managing temperature, consult Agent of deterioration: incorrect temperature.

Relative humidity

Preservation strategies for controlling the RH that are tailored to vehicles usually involve finding the best compromise solution between the needs of the vehicle's metal parts and those of the organic components (wood, upholstery, rubber, plastic).

Recommendations

- Keep RH below 70% to prevent rapid corrosion and to prevent the swelling of wooden joints such as wheel spokes, which loosen upon return to moderate RH. Among the risks associated with incorrect RH, damp is the most important to vehicle collections.

- If vehicles contain complex wooden items and assemblies, or restrained leather such as canopies, keep RH above 30%, especially if they have never been in heated buildings before. (This 30–70% RH range is Level C in the ASHRAE nomenclature (the American Society of Heating, Refrigerating and Air-Conditioning Engineers); consult Climate Guidelines)

- Note that if the entire collection has already been exposed to very low RH many times over the years (e.g. during winter in a heated building, the RH can become very low) and there has not been any remedial treatment (no repairs of cracks and tears or refinishing of old coatings), then the risk of new fractures from low RH is reduced. These periods of low RH can prove beneficial, since dry air slows down the process of corrosion.

- Metal surfaces that may have been exposed to calcium chloride salts (used to control dust on gravel roads or as an antifreeze in the water added to agricultural tractor tires as a ballast) should be cleaned since these dusts and contaminants accelerate corrosion at any RH above 33% (worse than the salt used for melting snow, which accelerates corrosion when RH is above 75%). Contact a conservator for advice on cleaning delicate surfaces.

- Protect bare metal surfaces with transparent, non-tacky rust-preventive coatings (e.g. microcrystalline wax). It is especially important to protect bright surfaces of base metals (iron, steel, copper, bronze, brass), particularly if they were either sliding surfaces or kept polished during original use. Even at moderate RH, these uncoated surfaces will corrode (tarnish) in a few years, especially if they are exposed to the ambient air rather than protected by a tarp or dust cover, or in an enclosure. If left to accumulate, dust and lint will aggravate corrosion problems.

- Consider humidistatically controlled heating for large vehicle storage buildings, especially in central Canadian climates. Consult Agent of deterioration: incorrect relative humidity – Vignette 3 for an example of such storage climate management.

For more preservation strategies related to managing RH, consult Agent of deterioration: incorrect relative humidity, Caring for metal objects and Furniture and objects made of wood.

Types of damage caused by each agent of deterioration

The following table provides an overview of the risks related to each of the 10 agents of deterioration that can affect vehicles or individual parts of vehicles.

| Agent of deterioration | Risks to vehicle |

|---|---|

Physical forces |

|

Thieves and vandals |

|

Dissociation |

|

Fire |

|

Water |

|

Pests |

|

Pollutants |

|

Light and ultraviolet (UV) |

|

Incorrect temperature |

|

Incorrect RH |

|

© Canada Science and Technology Museum

Figure 12: This sleigh's upholstery was extensively damaged by insects.

© Government of Canada, Canadian Conservation Institute. CCI 128209-0015

© Government of Canada, Canadian Conservation Institute. CCI 128209-0014

Figures 13a and 13b. This velvet upholstery fabric has been permanently damaged by excessive exposure to sunlight. Left: Seat cushions appear greyish-mauve in colour. Right: One of the cushions is lifted, revealing the original blue colour on the underside

For general preservation strategies for each of these agents, consult Agents of deterioration.

For more details on how specific materials associated with vehicles are affected by the agents of deterioration, consult Caring for metal objects, Caring for plastics and rubbers, Caring for leather, skin and fur and Caring for textiles and costumes.

Bibliography

Industrial collections

Canadian Conservation Institute. Lubrication for Industrial Collections. CCI Notes15/5. Ottawa, ON: Canadian Conservation Institute, 2002.

Canadian Conservation Institute. Trade Literature for Industrial Collections. CCI Notes 15/6. Ottawa, ON: Canadian Conservation Institute, 2002.

National Park Service. Preparing Historic Motorized Vehicles for Storage or Exhibit (PDF format). Conserv O Gram 10/3. Washington, D.C.: National Park Service, 1999.

Prytulak, G. Indoor Display of Industrial Collections. CCI Notes 15/4. Ottawa, ON: Canadian Conservation Institute, 1998.

Rubber

Canadian Conservation Institute. Rubber Components in Industrial Collections. CCI Notes 15/7. Ottawa, ON: Canadian Conservation Institute, 2002.

Williams, S. Care of Objects Made from Rubber and Plastic. CCI Notes 15/1. Ottawa, ON: Canadian Conservation Institute, 1997.

Metals

Barclay, R. Care of Objects Made of Zinc, revised. CCI Notes 9/9. Ottawa, ON: Canadian Conservation Institute, 2007.

Barclay, R, and C. Hett. The Cleaning, Polishing and Protective Waxing of Brass and Copper, revised. CCI Notes 9/3. Ottawa, ON: Canadian Conservation Institute, 2007.

Logan, J. and L. Selwyn. Recognizing Active Corrosion, revised. CCI Notes 9/1. Ottawa, ON: Canadian Conservation Institute, 2007.

Logan, J. and L. Selwyn. Storage of Metals, revised. CCI Notes 9/2. Ottawa, ON: Canadian Conservation Institute, 2007.

Logan, J. and L. Selwyn. Care and Cleaning of Iron, revised. CCI Notes 9/6. Ottawa, ON: Canadian Conservation Institute, 2007.

Logan, J., L. Selwyn, C. Cook and T. Grant. Tannic Acid Coating for Rusted Iron Artifacts, formerly published under the title Tannic Acid Treatment, revised. CCI Notes 9/5. Ottawa, ON: Canadian Conservation Institute, 2013.

Prytulak, G. Mechanical Removal of Rust from Machined Ferrous Surfaces, revised. CCI Notes 9/8. Ottawa, ON: Canadian Conservation Institute, 2007.

© Government of Canada, Canadian Conservation Institute, 2018

Published by:

Canadian Conservation Institute

Department of Canadian Heritage

1030 Innes Road

Ottawa, ON K1B 4S7

Canada

Cat. No.: CH57-4/6-16-2018E-PDF

ISBN 978-0-660-28035-6