Module 2 - Guide to employee education on Musculoskeletal Injuries (MSI)

Introduction

Many hazards in the work place can lead to employee injuries. Part XIX of the Canada Occupational Health and Safety Regulations outlines a hazard prevention program for employers under federal jurisdiction. In December 2007, Part XIX (commonly known as the Hazard Prevention Program Regulations) was amended to include ergonomics-related hazards, which can cause musculoskeletal injuries.

A musculoskeletal injury (MSI) is an injury or disorder of the musculoskeletal system. The musculoskeletal system includes muscles, tendons, blood vessels, ligaments, nerves, joints, spinal discs and related soft tissue.

Other common terms used for musculoskeletal injuries are:

- Musculoskeletal disorder (MSD);

- Cumulative trauma disorder (CTD);

- Repetitive strain injury (RSI);

- Occupational overuse syndrome;

- Sprain and strain.

This guide does not cover musculoskeletal injuries that result directly from:

- Falling, slipping or tripping;

- Being struck by an object or knocked against something;

- Being caught in or on something; or

- Being in a vehicle accident.

The hazards that can cause MSIs are usually associated with the physical demands of work activities. For example, employees may injure themselves by:

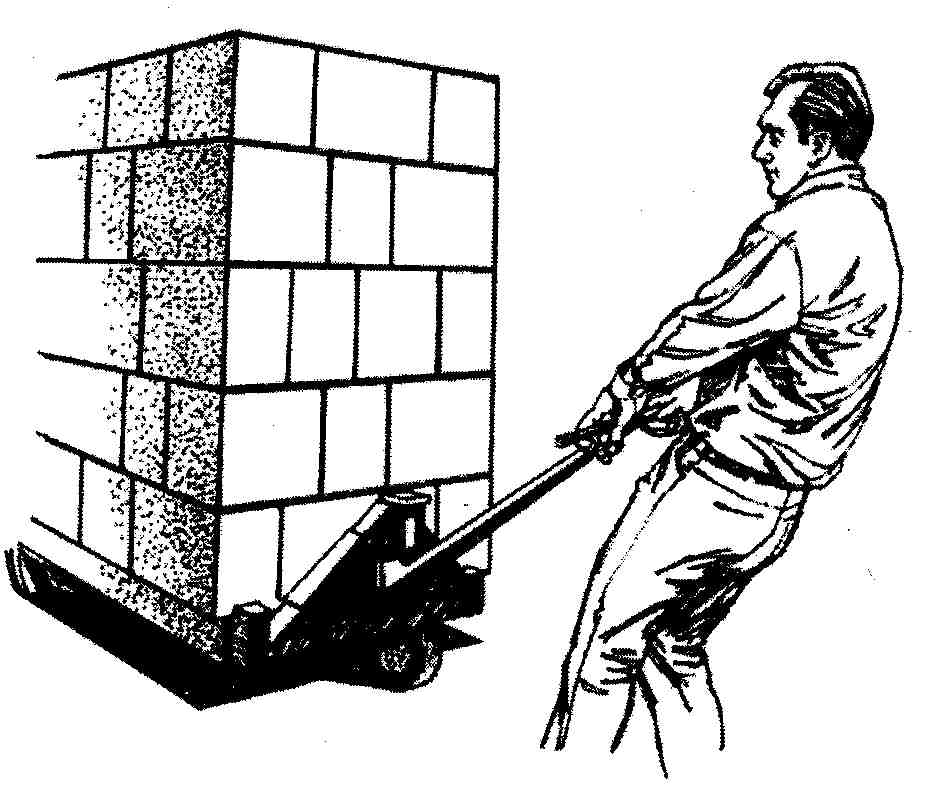

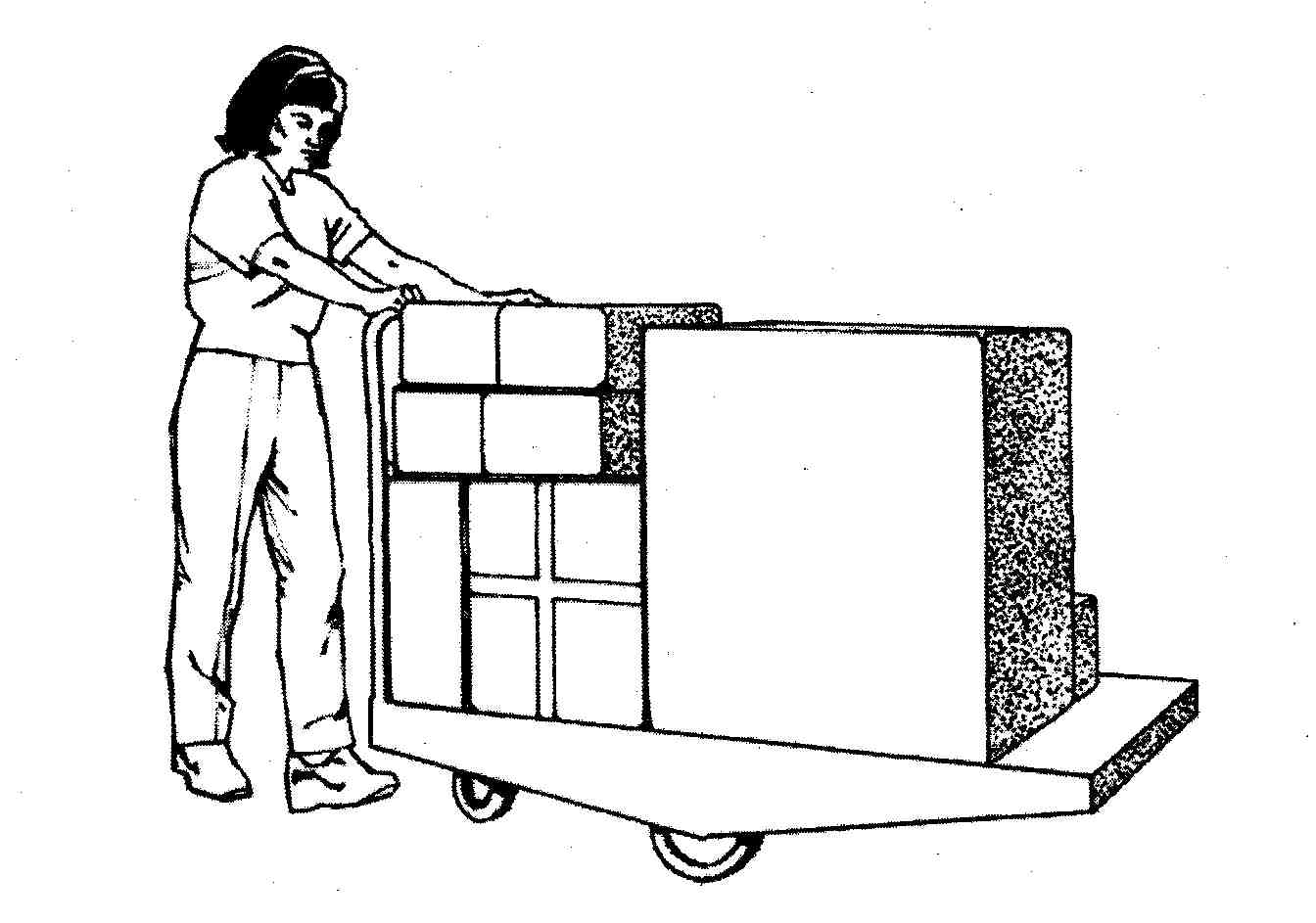

- Lifting or pushing loads that are too heavy;

- Reaching or bending in an awkward posture;

- Holding the same position for a long time; or

- Repeating the same movements over and over with little chance for rest or recovery.

Through ergonomics, the risk of injury posed by such hazards can be eliminated or reduced.

Ergonomics is the scientific study of the relationship between people and their working environment with a view to improving safety, ease of action and efficiency.

Purpose of the Guide to Employee Education on Musculoskeletal Injuries

As part of the hazard prevention program (HPP) employers are required to provide health and safety education to their employees. Under the amendments to the Regulations, this includes teaching them about ergonomics. The purpose of this Guide is to assist employers with employee education. The Guide outlines:

- The regulatory requirements specific to ergonomics-related hazards;

- The program approach to MSI prevention;

- The components of the MSI prevention program;

- Common ergonomics-related hazards in the work place; and

- The employees' duty to report ergonomics-related hazards.

The Guide highlights only those aspects of the hazard prevention program that are specific to ergonomics-related hazards. It does not cover aspects (such as periodic review of the employee education program) which apply to all hazards.

MSI prevention and employee education

In order to prevent musculoskeletal injuries, employers must have a hazard prevention program that covers ergonomics-related hazards. This HPP is to be developed in consultation with and with the participation of the policy committee (or the work place committee or the health and safety representative).

Under the Regulations, a HPP must include the following components:

- Implementation plan;

- Hazard identification and assessment methodology;

- Hazard identification and assessment;

- Preventive measures;

- Employee education; and

- Program evaluation

Employee education is thus one of the components. Employees need to know about all the parts of the program and how it will be implemented.

The Guide on the Prevention of Musculoskeletal Injuries (MSIs) outlines the general process for implementing an MSI prevention program as part of the overall HPP. However, it is up to the employer, in cooperation with the policy committee, to select and implement the MSI prevention program best suited to that particular work place.

Employees must be educated on each component of the employer's chosen program. When it comes to MSI prevention, this includes telling them about:

- Ergonomics-related hazards in the work place;

- Their duty to report things that are likely to be a risk to themselves or others;

- The process for reporting ergonomics-related accidents or other occurrences in the work place.

Employee education - Implementation plan

Employees must be educated on how the HPP is to be implemented to deal with ergonomics-related hazards. This includes the process and the time frames for implementing each part of the program.

Employee education - Hazard identification and assessment methodology

An important source of information for this part of the HPP is employee reports.

Employees have a duty to report:

- Anything or circumstance in the work place that is likely to be hazardous to the health or safety of themselves, other employees or authorized visitors to the work place; and

- Accidents or other occurrences arising in the course of or in connection with their work that has caused injury to them or to anyone else.

To fulfill this duty, employees need to understand the signs and symptoms of MSIs, as well as the factors that can pose ergonomics-related hazards.

Signs and symptoms of MSIs

A sign is something that can be observed, such as redness, swelling or difficulty moving a particular body part. A symptom may be felt but cannot be observed. Examples include pain, numbness or a tingling sensation. It is important to be able to recognize the early signs and symptoms of MSIs. This will help in getting treatment as soon as possible, before the condition worsens. Signs and symptoms may appear gradually over a period of time, or may appear suddenly, as a result of a specific incident.

Ergonomics-related factors

A number of ergonomics-related factors can pose a hazard to employees. Some of the common factors are force, fixed or awkward postures, repetition, contact stress, vibration and extremes of temperature. There may be other site-specific ergonomics-related factors that must be evaluated in assessing the risk to employees.

Force:

Force is the effort exerted by the employee to do the work. All work requires some level of force and in most cases the work can be done without harmful effects. However, if the force exerted (for example, when lifting an extremely heavy object) is more than the musculoskeletal system can handle it can lead to injury.

The risk of injury increases if a fairly high level of force is exerted repeatedly over a long period. There is even more risk of injury if the work is also done in an awkward posture (for example, lifting objects repeatedly with a twisting motion).

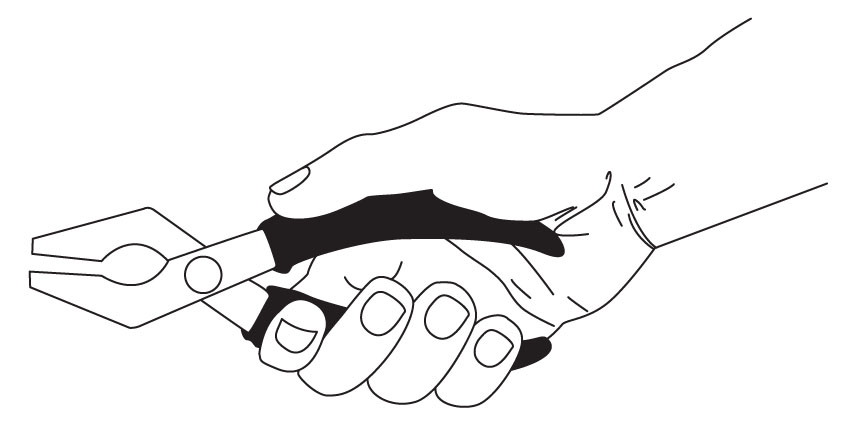

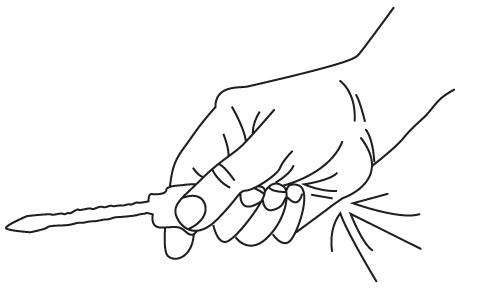

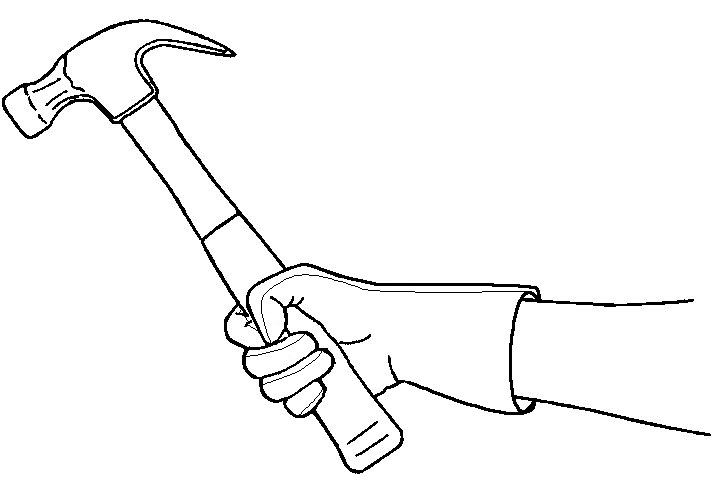

In addition to lifting, other common types of work associated with forceful exertion are pushing, pulling and gripping.

Holding things may be more difficult when the hands are cold or the object being manipulated is heavy. In addition, extra effort may be needed because of the nature of the task to be performed (for example, holding a knife to cut through a dense object).

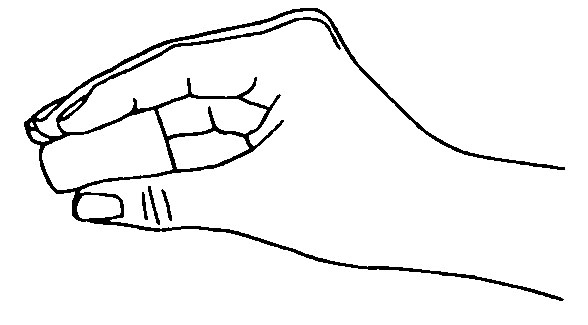

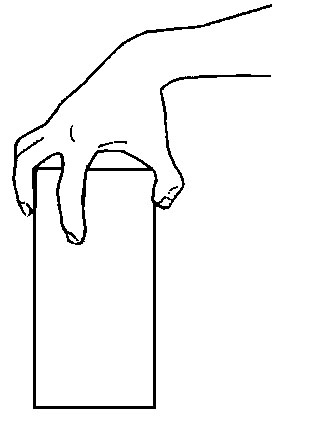

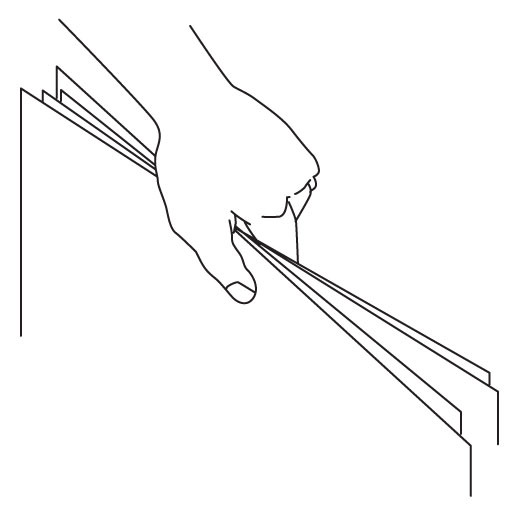

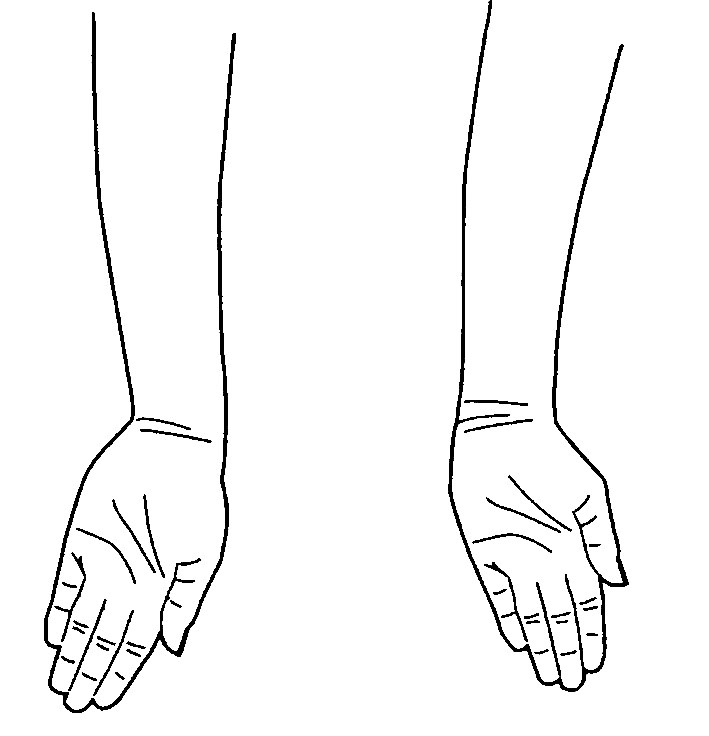

Here are some examples of tasks requiring increased grip force:

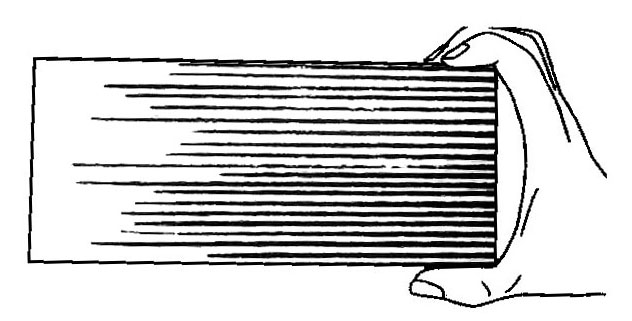

- Holding a slippery object;

- Gripping a small tool or holding an object for precision work;

-

Holding an object that is too large for a comfortable grip (i.e. fingers do not slightly overlap);

-

Handling something using the fingers and the thumb (a pinch grip) instead of the whole hand (a power grip);

-

Grasping an odd-shaped object that is difficult to hold;

- Holding vibrating tools or objects.

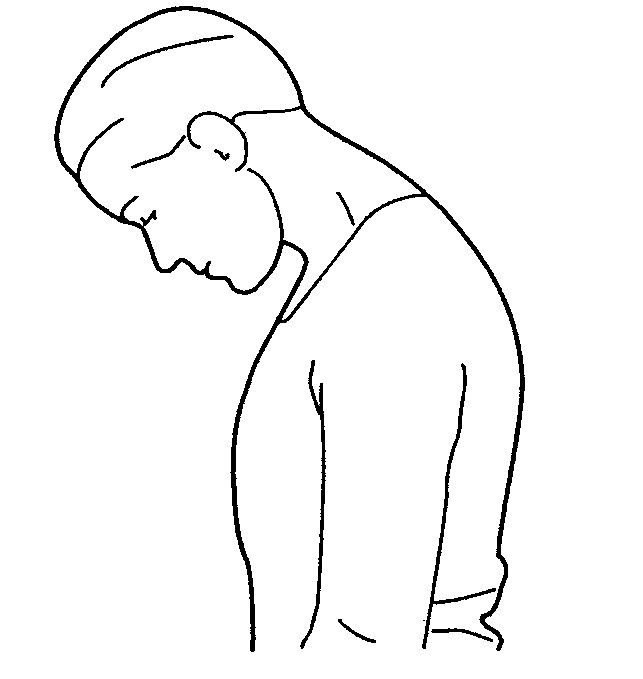

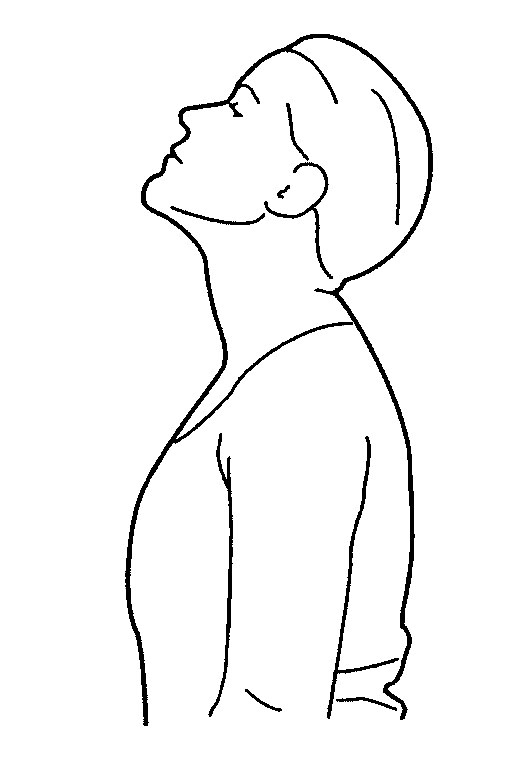

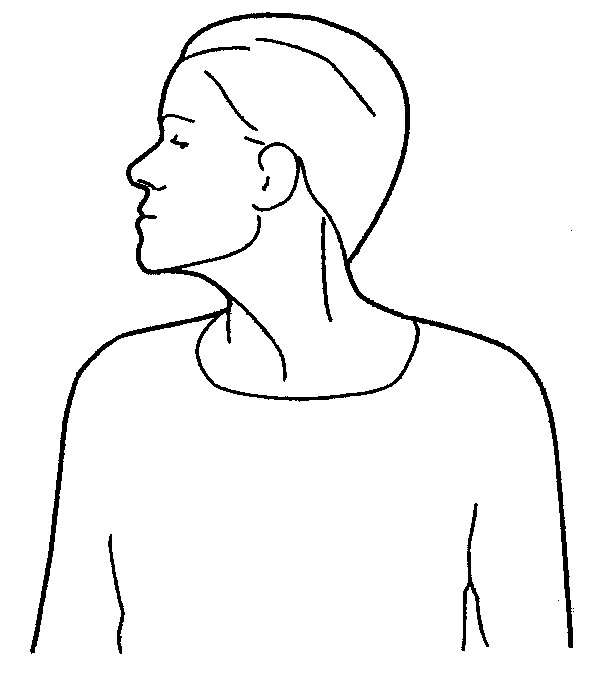

Static (fixed) or awkward postures:

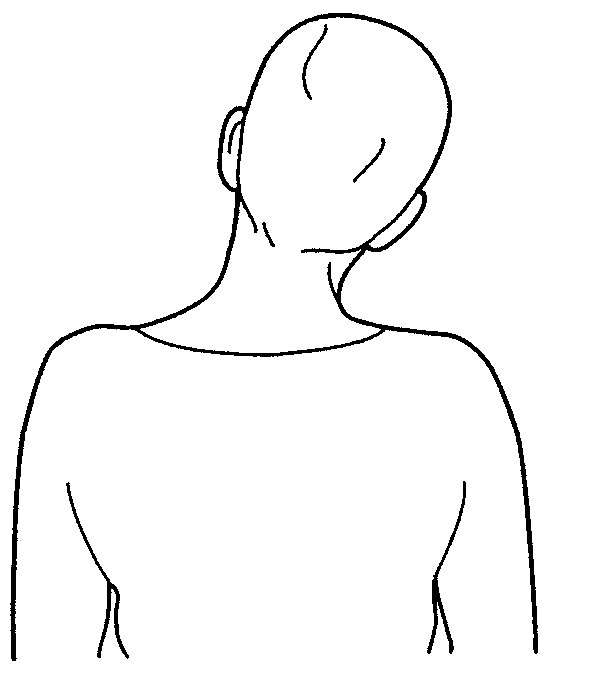

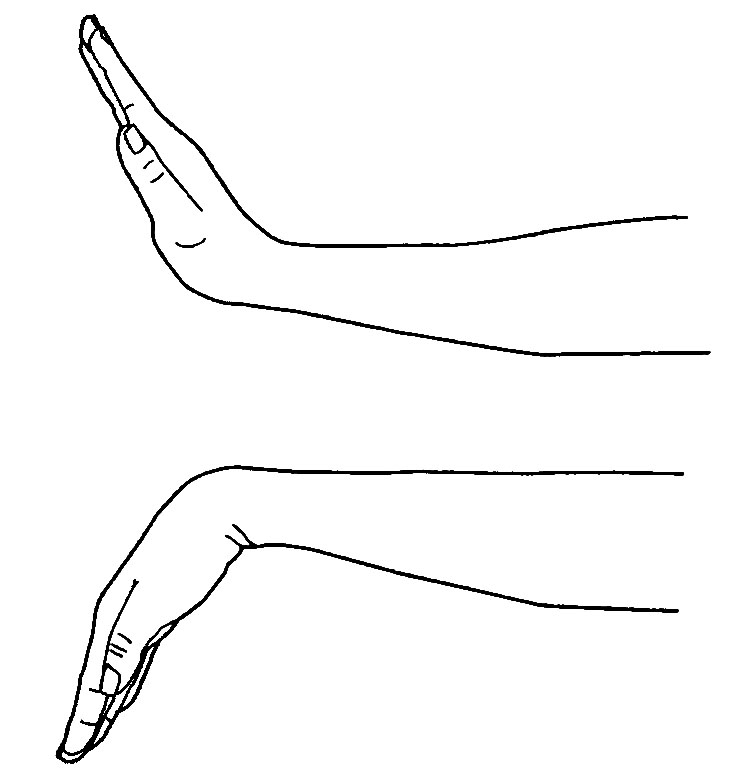

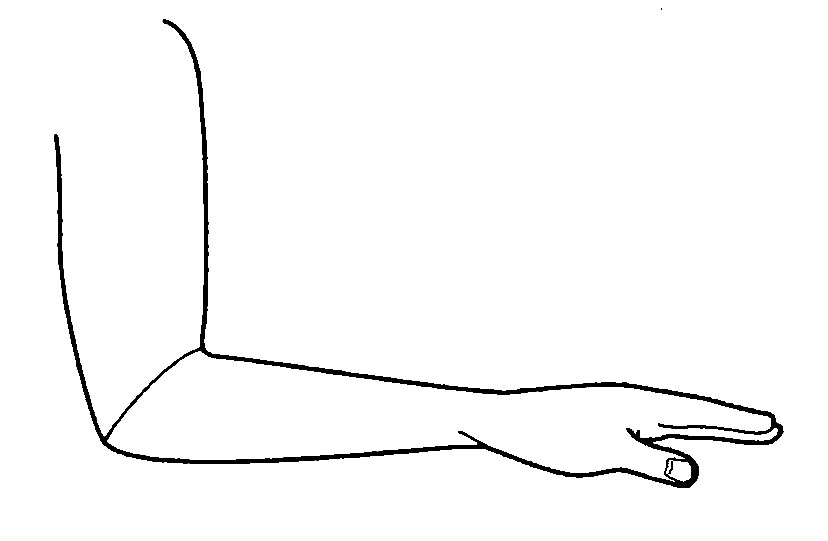

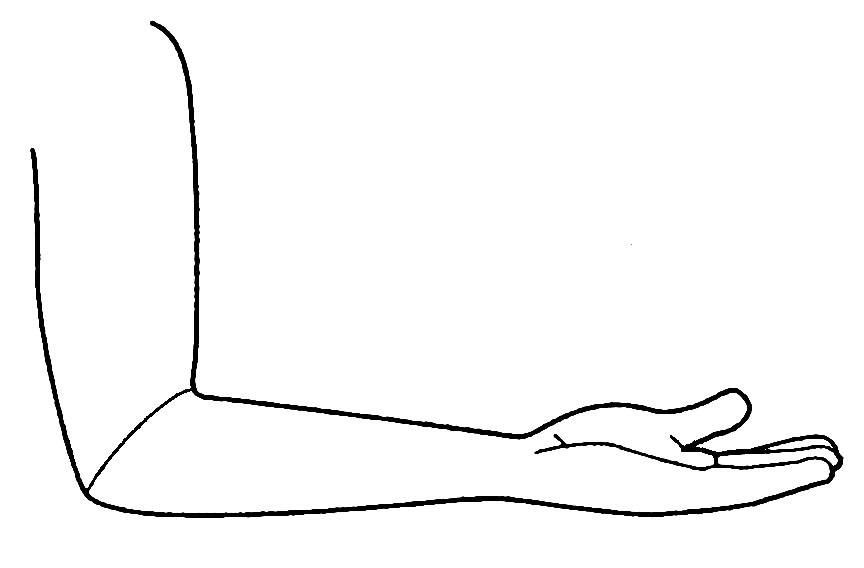

Posture refers to the position of a body part, in relation to nearby body parts, during an activity. Awkward posture results when a joint in the body bends or twists excessively, outside the comfortable range shown in the diagram below.

Joint position inside the comfortable range of motion is known as the neutral position. The farther a joint moves away from the neutral position, the greater the effort required by the supporting soft tissues.

If a posture is held fixed, or static, for a long time, the muscles get tired because the lack of movement stops them from getting enough blood flow to keep them supplied with energy. This results in aches and pains.

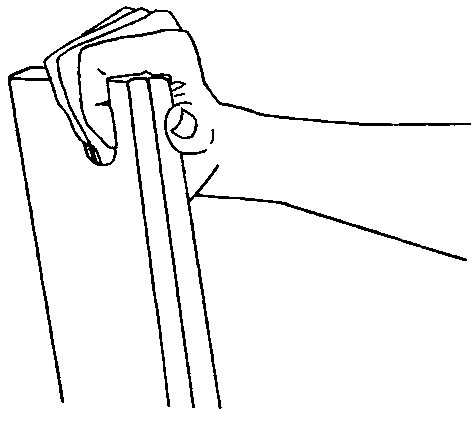

Some common awkward postures are illustrated below:

Here are some examples of office tasks that can result in awkward postures:

Awkward shoulder posture

- Reaching overhead to get books or files on a high shelf;

- Reaching across the desk to use a telephone placed on the far side.

Awkward neck posture

- Twisting the neck to talk to someone seated to the side while using a keyboard directly in front;

- Bending the neck down to do detailed drawings on paper laid flat on the desk;

- Looking up frequently at a security screen high on the wall to monitor access points to the building, while working on a desktop computer.

Awkward back posture

- Leaning sideways to reach into a low drawer while sitting;

- Bending down and sorting documents on the floor.

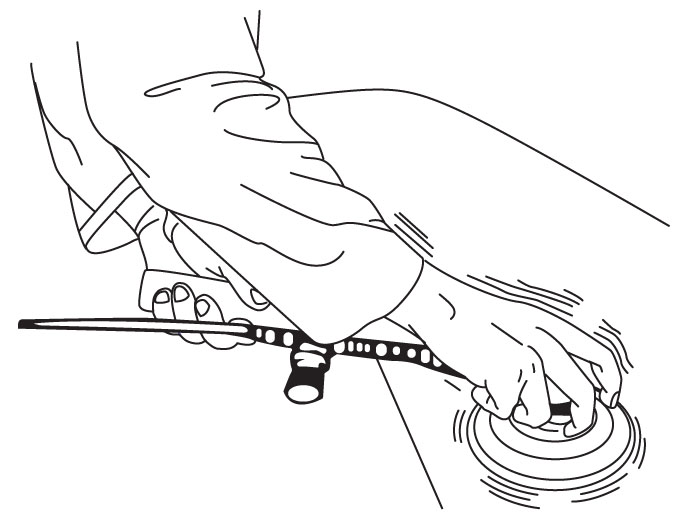

Contact stress:

Contact stress occurs when a hard or sharp object comes in contact with the skin. Here are some things that can lead to contact stress:

Using body parts to strike hard surfaces

- Using the hand to knock metal parts into place while assembling machinery;

- Kicking the carpet-stretcher with the part of the leg right above the knee when installing carpet.

Kneeling on hard surfaces

- Kneeling on cement while setting floor tiles;

- Kneeling on a metal surface while stacking baggage inside the hold of a small aircraft;

- Kneeling on wood flooring while putting together a piece of furniture.

Having the sharp edge of a desk dig into the forearm or wrist while typing

Having ridges on a tool handle dig into the hand when the tool is held tightly

Repetition:

Using the same muscles, tendons and other soft tissues repeatedly with little chance for rest or recovery can lead to musculoskeletal injury when the muscles get tired. Repetition increases the risk of injury when other factors such as forceful exertion and awkward posture are also present.

Hand-arm vibration (HAV):

Small hand tools such as drills and sanders produce vibrations that are transferred to the hands of the employee holding them. This also happens with larger tools such as chain saws and pneumatic chippers and drills. Exposing cold hands to vibration (for example, using a chain saw outside in the winter) raises the risk of hand-arm vibration syndrome.

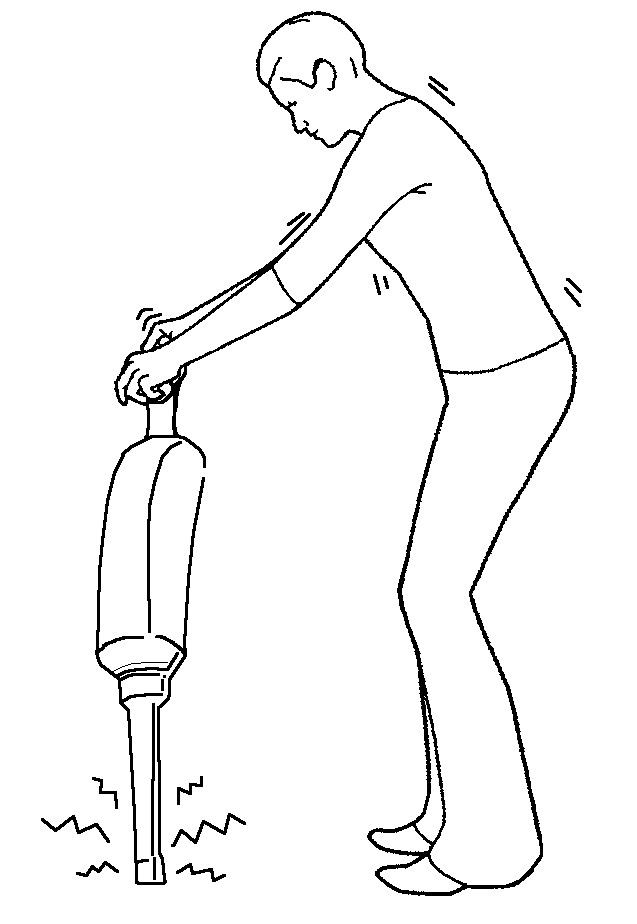

Whole-body vibration:

When a worker is sitting or standing on a vibrating surface, such as a surface directly attached to a large diesel engine, the vibration can be transmitted to his whole body. The same thing occurs when driving vehicles over rough surfaces.

Depending on the level, frequency and duration of exposure, whole-body vibration can contribute to back pain and performance problems.

Extremes of temperature:

When exposed to cold, muscles and tendons become less flexible and do not work as efficiently. The blood circulation in the hands and arms is reduced and the worker will lose some of the feeling in his hands and fingers. As a result, the worker will have to use more grip force to grasp objects.

Here are some examples where cold is a factor:

- Handling tools that are stored outside during the winter;

- Handling frozen or refrigerated food;

- Working outside during the winter;

- Having cold air from the exhaust of a pneumatic drill blow over the hands and fingers.

Working in a hot or humid environment also imposes strain on the body. It increases the body temperature and causes dehydration, leading to muscle tiredness. People working in commercial kitchens or working outside during the summer are exposed to hot, humid work environments.

Employee Education - Hazard Identification and Assessment

Hazard identification and assessment involves looking at ergonomics-related factors and assessing the level, duration and frequency of exposure to determine how much of a hazard they represent.

The level is the quantity or magnitude of the ergonomics-related factor:

- How much force is being applied by the employee?

- How severe is the awkward posture?

- How hard is the strapping digging into the skin when lifting the box?

- How fast is the employee repeating the same movements?

The duration is the length of time the employee is exposed to the factor:

- How long is the employee exerting the force?

- How long is the employee in the awkward posture?

- How long is the employee carrying the heavy box by its strapping?

- How long does the employee perform the repetitious task?

The frequency refers to how often the employee is exposed to that factor:

- How often is the employee exerting the force?

- How often is the employee in the awkward posture?

- How often is the employee carrying the heavy box by its strapping?

- How often does the employee perform the repetitious task?

Some of the methods and tools for hazard assessment are complex, and the people using them must have the necessary training.

Employee Education - Preventive Measures

The Regulations specify the order of priority for the types of preventive measures, or risk controls, that must be used to deal with ergonomics-related hazards.

(a) Elimination of the hazard:

It may be possible to eliminate the hazard by means of engineering controls. Common examples include:

- Having an adjustable work surface to eliminate awkward posture;

- Using a mechanical hoist to eliminate manual lifting;

- Using automation to eliminate repetitive manual tasks.

When preventive measures such as equipment modifications are implemented, the physical attributes of the employee(s) using that equipment must be taken into account. For example, modifying a work station to suit a very tall employee who is on the day shift may introduce new ergonomics-related hazards for a shorter employee on the night shift. Making sure that adjustability is built into the preventive measure can help overcome such challenges.

(b) Reduction of the hazard

Ergonomics-related hazards can be reduced by making changes in the work place (for example, so the employee does not need to reach as far or bend down as often to get materials).

A hazard can be reduced by lowering the level (magnitude/quantity), the duration of exposure or the frequency of exposure, or through any combination of these three methods.

(c) Personal protective equipment

Personal protective equipment includes things such as knee pads for kneeling on hard surfaces and vibration dampening gloves for using hand tools that vibrate.

There is a very limited range of personal equipment for protection against ergonomics-related hazards. This equipment is best used in combination with other preventive measures, such as administrative procedures.

For example, to reduce the risk to an employee assigned to set tiles on a large floor area, the employer may include different tasks in the employee's work day so he does not have to spend too long kneeling on a hard surface. However, during the time the employee does spend kneeling, using knee pads will improve his safety.

(d) Administrative procedures

A good example of an administrative control is having the employee monitor himself in order to change tasks when physical tiredness sets in while he is performing a physically demanding task.

Another example is having two or more employees alternate between a physically demanding task and less demanding tasks, to give them a chance to recover. Yet another possibility is for the employee to spread the physically demanding portion of the daily work over the entire shift rather than do it all at once.

The Regulations also say that when planning changes to the work environment or to work duties, equipment, practices or processes, the employer must be proactive in identifying and addressing potential ergonomics-related hazards.

As with hazard identification and assessment, the employer must ensure that anyone assigned to implement ergonomics-related preventive measures has the necessary training.

Employee Education - Program Evaluation

As with other hazards addressed under the HPP Regulations, the effectiveness of the ergonomics-related components must be evaluated. Records and statistics regarding ergonomics-related first aid and injuries are important considerations in conducting this evaluation.

The effectiveness of the ergonomics-related components can be evaluated when evaluating the hazard prevention program as a whole, and the findings can be recorded as part of the HPP evaluation report.