Module 3 - General guide for identifying ergonomics-related hazards

Purpose of the guide

This General Guide for Identifying Ergonomics-Related Hazards is designed to provide you with a relatively quick and easy way to more formally assess the risk associated with exposures to some common ergonomics-related hazards. This check-list will tell you, for the ergonomics-related hazards included on the checklist, if the workers performing the task have an increased risk of developing a Musculoskeletal Injury (MSI).

Note:

This checklist identifies tasks that have at least a moderate level of risk, where research suggests that the number of MSI claims begin to increase when job demands are at or above the levels provided on this checklist. Generally, the more demands exceed levels on the checklist, the greater the MSI risk.

Important - Please read before using the checklist

This checklist can be used as part of an in-depth risk assessment process, as described in the Hazard Prevention Program, Part XIX of the Canada Occupational Health and Safety Regulations . If this checklist indicates that workers are exposed to ergonomics-related hazards at or above the levels provided, then the work place should consider if controls to reduce the workers' exposure to ergonomics-related hazards are required and the priority level for any required controls

The levels given on this checklist are not designed or intended to represent maximum acceptable or legal limits and should not be interpreted as such.

A job or task that does not expose workers to ergonomics-related hazards at or above the levels on the checklist is not necessarily free from significant risk of ergonomics-related hazards. If workers are reporting MSIs, pain or discomfort, it may be necessary to use a different, more specific in-depth risk assessment method, or to review job and task demands to identify other work-related factors that may be contributing to the MSIs, pain or discomfort.

It is recommended that this method NOT be used for:

- Return to work assessment and evaluations

- Job placement and worker selection

- Assessing the work relatedness of an injury or disorder

- Identifying MSI hazards when handling people or animals

Instructions

- Document the job title or task, date and name of person(s) completing the worksheet.

- Observe a sample of workers performing regular work activities.

- Read the risk level criteria listed for each hazard.

- For lift/lower and push/pull tasks consider if the job is always performed by male workers only, males and females, or females only.

- Check the box if workers are exposed to hazards that meet or exceed the risk levels. Ask workers about specific items on the risk assessment checklist if you are unsure.

- Write notes when the risk levels are met or exceeded to clarify the task or duty where the increased risk is present.

Note:

The risks associated with some ergonomics-related hazards, (e.g. hot and cold temperatures, handling of people or animals, contact stress, whole body vibration, lighting, and aspects of work organization) are not addressed in this checklist. If these or other ergonomics-related hazards exist, make note of them and use other risk assessment methods to determine if they contribute to the risk of ergonomics-related hazards for workers.

Things to consider when using the guide

- If the physical demands vary from day to day, due to different products or services being produced or provided, ask workers if the activity being observed is more or less demanding than on a typical day.

- If less demanding, plan to come back when the demands are more typical.

- If more demanding, complete the checklist. It may be that the risk of ergonomics-related hazard is only increased when working with certain products or performing certain services. You should also reuse the checklist when the demands are more typical.

- If typical, but there are times when the demands are higher, reuse the checklist when the demands are higher, especially if an increased risk is not indicated by the checklist when observing typical demands.

- For non-repetitive activities, add up the total time spent performing the specific activity/demand over the day. Observe on the days when the duration is longest when using the risk assessment checklist.

- For repetitive activities (e.g. the same motion is done more than once every 6 - 30 seconds), add up the total time that the repetitive activity is performed per day. Observe on the days when the duration is longest when using the risk assessment checklist.

- Definition of force, refer to the Guide on the Prevention of Musculoskeletal Injury (MSI).

Estimating grip and push/pull forces:

The following method can be used to estimate grip, push and pull forces if you don't have a hand grip or push/pull force gauge.

Observe the workers performing the task (pinch or power gripping, pushing or pulling).

Ask the workers to stop doing the task.

Tell the workers that you want them to rank, on a scale from 0 to 10, how much force they need to exert when performing the gripping, pushing or pulling activity. Tell them that a 0 on this scale means no effort and a 10 means "as hard as you can, using as much force as you can generate".

Have the workers do the task again for a few more minutes or cycles.

Ask the workers to stop doing the task.

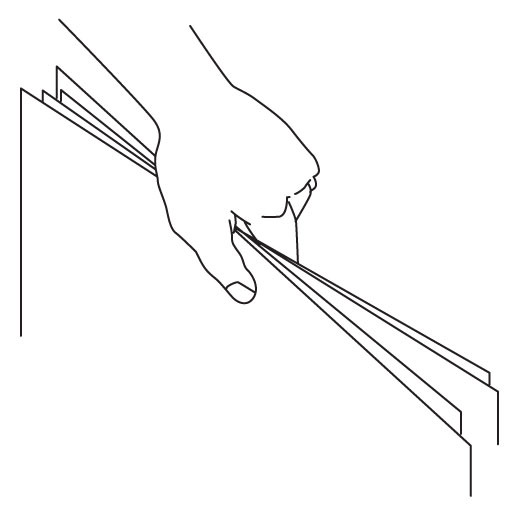

If looking at pinch or power gripping (page 5), have the workers pinch or power grip something solid as hard as they can for 3 to 4 seconds*-see note 1 below .

If looking at pushing or pulling (page 5), have them push or pull as hard as they can for 3 to 4 seconds on something that won't move*-see note 1 below .

Ask the worker to perform the gripping, pushing or pulling just once. As soon as they have done this, ask them to compare the amount of effort needed to do the task to how hard they gripped, pushed or pulled a few minutes ago when you asked them to grip, push, pull as hard as they could*-see note 1 below . Ask them, "If the hardest you can grip, push or pull is a 10, how much effort is needed, from 0 to 10, to perform the task?"

For pinch and power gripping, if one or more workers tell you that the effort required to perform the task is 5 or higher, and gripping is done for more than two hours total per day, then place a check mark in the appropriate box (page 5).

For pushing or pulling, if one or more workers tell you that the effort required to perform the push or pull is 5 or higher, place a check mark in the appropriate box (page 5).

* Caution required: There is a very small risk of injury from a one-time, short-duration high-level force exertion, in an awkward posture. If workers are experiencing any pain or discomfort then do not ask the worker to grip, push or pull something as hard as they can.

General guide for identifying ergonomics-related hazards

Job title or task:

Date completed:

Completed by:

Space for notes/comments is provided on the last page of this checklist.

| Grip force | Check here if required at this job/task | Notes | |

|---|---|---|---|

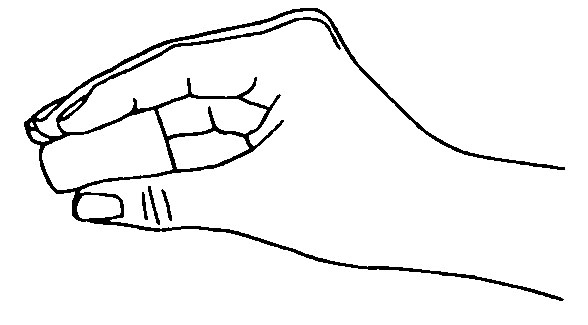

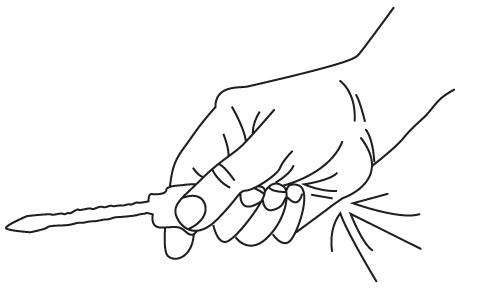

| Pinch grip |

Pinch gripping unsupported objects weighing 1 kg or more per hand for more than 2 hours total per day. or Pinch gripping with a force of 2 kg or more per hand for more than 2 hours total per day.

|

||

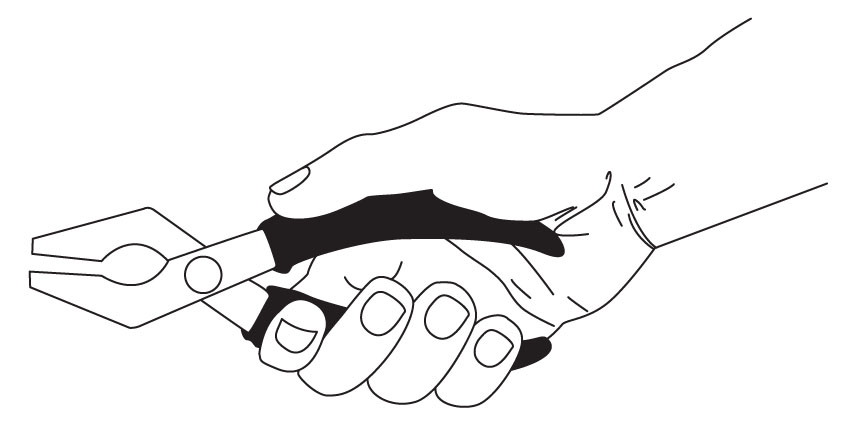

| Power grip |

Power gripping unsupported object weighing 5 kg or more per hand for more than 2 hours total per day. or Power gripping with a force of 5 kg or more for more than 2 hours total per day.

|

||

| Pinch grip: force is primarily between the fingers and thumb. Power grip: force is primarily between the fingers and the palm. |

|||

| Manual material handling tasks | Check here if required at this job/task | Notes | |

|---|---|---|---|

| Back/ shoulder |

Lifting/lowering is required for this job/task? If checked do weights exceed levels in tables 1 or 2? Pushing/pulling is required for this job/task? If checked do initial push forces exceed levels in tables 3 or 4? |

||

If lifting/lowering is required for this job/task, does the weight of the object exceed the value in the appropriate table?

-

Step 1: Choose the right table to use:

If the task is performed by males only, use table 1. If the task is done by females only, or both males and females, use table 2. -

Step 2: Determine whether the lift/lower is close or far:

- Close - hands are 17 cm or less from body at all times during the lift/lower.

- Far - hands are more than 17 cm from the body at any time during the lift/lower.

-

Step 3: Determine if the lift/lower is short or long:

- Short - the object moves up/down no more than 25 cm.

- Long - the object moves up/down more than 25 cm.

- Step 4: Determine where the worker's hands end up at the end of the lift/lower

- Step 5: Determine how often the object is lifted/lowered - once every 15 sec, 1 min, 2 min, 5 min, 30 min or 8 hours.

- Step 6: Compare the weight from the table to the actual weight of the object being lifted/lowered.

Example:

Only males do the job being assessed. The hands are more than 17 cm from the body, the item is moved up more than 25 cm, the worker's hands at the end of the lift are at just below shoulder height and the item is lifted once every 5 min. The value from table 1 for this example is 19 kg. To get this number:

- Look at numbers in table 1;

- Look at the numbers in the far-long row;

- Find the numbers in the far-long row, under the heading "Hands end between knuckle and shoulder height"; and

- Find the number for objects lifted once every 5 min - 19 kg.

Values in tables 1-4 are adapted from Snook SH and Ciriello VM, (1991), The design of manual handling tasks: Revised tables of maximum acceptable weights and forces, Ergonomics 34, 1197-1213.

| Type of lift/lower | Hands end below knuckle height once every… |

Hands end between knuckle and shoulder height once every… |

Hands end above shoulder height once every… |

|||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 15 sec. |

1 min. |

2 min. |

5 min. |

30 min. |

8 hr. |

15 sec. |

1 min. |

2 min. |

5 min. |

30 min. |

8 hr. |

15 sec. |

1 min. |

2 min. |

5 min. |

30 min. |

8 hr. |

|

| Far - long | 13 | 16 | 19 | 20 | 21 | 24 | 16 | 18 | 18 | 19 | 21 | 23 | 12 | 14 | 14 | 14 | 16 | 17 |

| Far - short | 15 | 19 | 22 | 24 | 24 | 28 | 20 | 23 | 24 | 25 | 27 | 30 | 15 | 18 | 18 | 19 | 21 | 23 |

| Close - long | 17 | 22 | 25 | 28 | 28 | 33 | 17 | 20 | 20 | 21 | 23 | 25 | 16 | 18 | 19 | 19 | 24 | 24 |

| Close - short | 21 | 26 | 30 | 32 | 33 | 38 | 21 | 26 | 27 | 28 | 31 | 34 | 20 | 24 | 25 | 26 | 29 | 31 |

| Type of lift/lower |

Hands end below knuckle height once every… |

Hands end between knuckle and shoulder height once every… |

Hands end above shoulder height once every… |

|||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 15 sec. |

1 min. |

2 min. |

5 min. |

30 min. |

8 hr. |

15 sec. |

1 min. |

2 min. |

5 min. |

30 min. |

8 hr. |

15 sec. |

1 min. |

2 min. |

5 min. |

30 min. |

8 hr. |

|

| Far-long | 9 | 9 | 10 | 10 | 11 | 14 | 8 | 10 | 11 | 11 | 12 | 14 | 6 | 7 | 8 | 8 | 8 | 10 |

| Far-short | 11 | 11 | 12 | 12 | 13 | 18 | 9 | 12 | 13 | 13 | 14 | 17 | 8 | 9 | 9 | 9 | 10 | 12 |

| Close-long | 11 | 12 | 13 | 13 | 14 | 19 | 9 | 11 | 12 | 12 | 13 | 15 | 8 | 9 | 10 | 10 | 11 | 13 |

| Close-short | 13 | 14 | 15 | 15 | 17 | 23 | 11 | 13 | 14 | 14 | 16 | 18 | 9 | 12 | 12 | 12 | 14 | 16 |

If pushing/pulling is required for this job/task, does the initial push force to move the object exceed value in the appropriate table?

-

Step 1: Choose the right table to use:

If the task performed by males only, use table 3. If the task is done by females only, or both males and females, use table 4. - Step 2: Determine where the worker's hands are on the object while it is being pushed/pulled - at or below knuckle height, between knuckle and chest height, at chest height or higher.

- Step 3: Determine how far the object is pushed/pulled - up to 2 meters, 2 - 7.5 meters, more than 7.5 meters.

- Step 4: Determine how often the object is pushed/pulled - once every 15/20/30 sec, 1 min, 2 min, 5 min, 30 min or 8 hours.

- Step 5: Compare the force level from the table to the actual amount of force required for the push/pull to the object.

Example:

Both females and males do the job being assessed. The hands are below the worker's knuckle height on the object when it is being pulled, the item is pulled 1.5 metres, once a minute. The value from table 4 for this example is 17 kg

To get this number:

- Look at numbers in table 4;

- Look at the numbers in the "At or below knuckle height" row;

- Find the numbers in the "At or below knuckle height" row that are under the heading for "Up to 2 metres";

- Find the number for an object that is pulled up to 2 metres, once per min -17 kg

| Height of hands on object being pushed/pulled | Up to 2 metres once every… | 2 - 7.5 metres once every… | More than 7.5 metres once every … | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 15 sec. |

1 min. |

2 min. |

5 min. |

30 min. |

8 hr. |

20 sec. |

1 min. |

2 min. |

5 min. |

30 min. |

8 hr. |

30 sec. |

1 min. |

2 min. |

5 min. |

30 min. |

8 hr. |

|

| Chest height or higher |

19 | 22 | 22 | 23 | 24 | 28 | 15 | 20 | 20 | 21 | 21 | 26 | 18 | 19 | 19 | 20 | 20 | 24 |

| Between chest and knuckle | 27 | 31 | 31 | 32 | 33 | 39 | 21 | 28 | 28 | 29 | 30 | 36 | 25 | 26 | 26 | 28 | 28 | 33 |

| At/or below knuckle height | 30 | 34 | 34 | 37 | 37 | 44 | 24 | 31 | 31 | 33 | 34 | 40 | 28 | 29 | 29 | 31 | 32 | 38 |

| Height of hands on object being pushed/pulled | Up to 2 metres once every… | 2 - 7.5 metres once every… | More than 7.5 metres once every … | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 15 sec. |

1 min. |

2 min. |

5 min. |

30 min. |

8 hr. |

20 sec. |

1 min. |

2 min. |

5 min. |

30 min. |

8 hr. |

30 sec. |

1 min. |

2 min. |

5 min. |

30 min. |

8 hr. |

|

| Chest height or higher |

18 | 21 | 22 | 24 | 25 | 27 | 19 | 19 | 20 | 22 | 23 | 24 | 17 | 17 | 17 | 19 | 20 | 21 |

| Between chest and knuckle | 18 | 21 | 22 | 24 | 25 | 27 | 18 | 20 | 20 | 22 | 23 | 25 | 16 | 17 | 17 | 19 | 20 | 21 |

| At/or below knuckle height | 15 | 17 | 17 | 19 | 20 | 21 | 15 | 17 | 17 | 19 | 20 | 21 | 13 | 14 | 15 | 16 | 17 | 18 |

| Awkward postures | Check here if required at this job/task | Notes | |

|---|---|---|---|

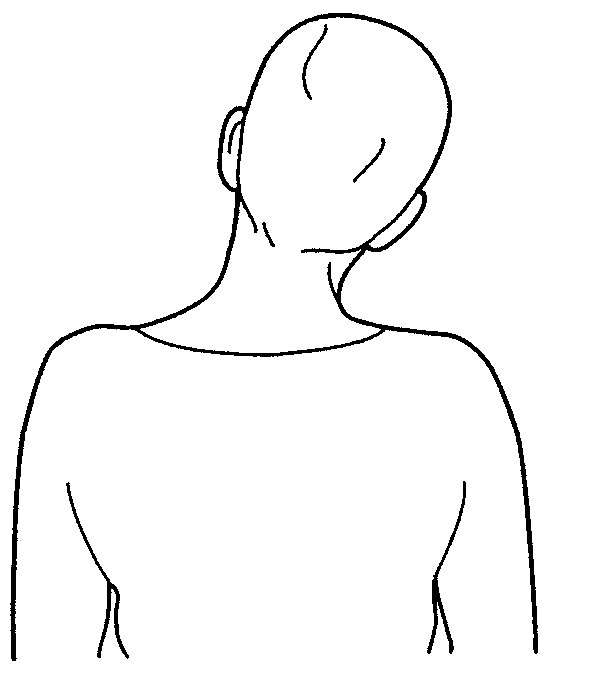

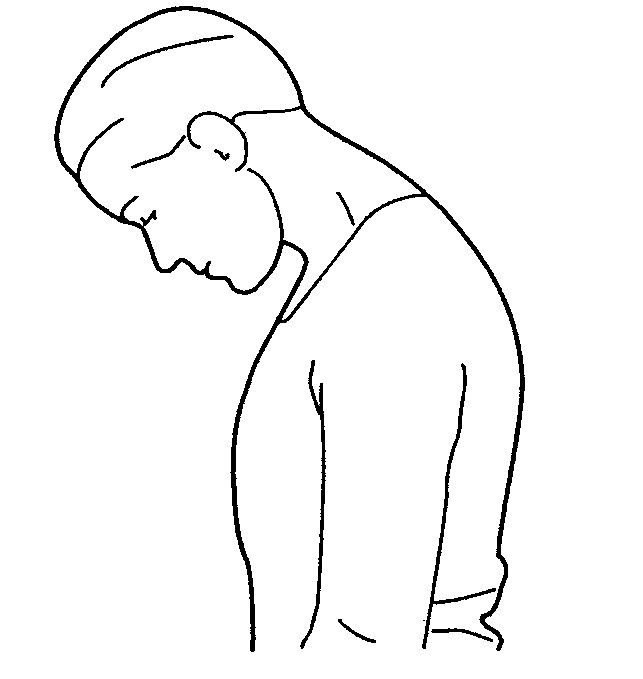

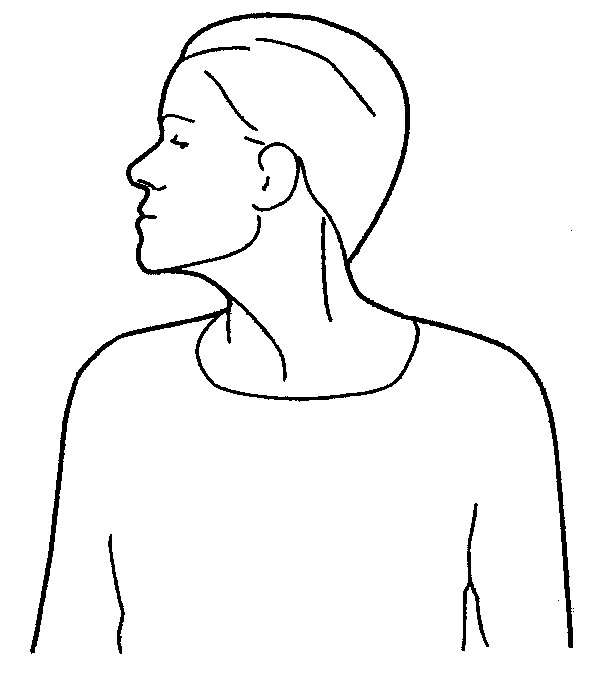

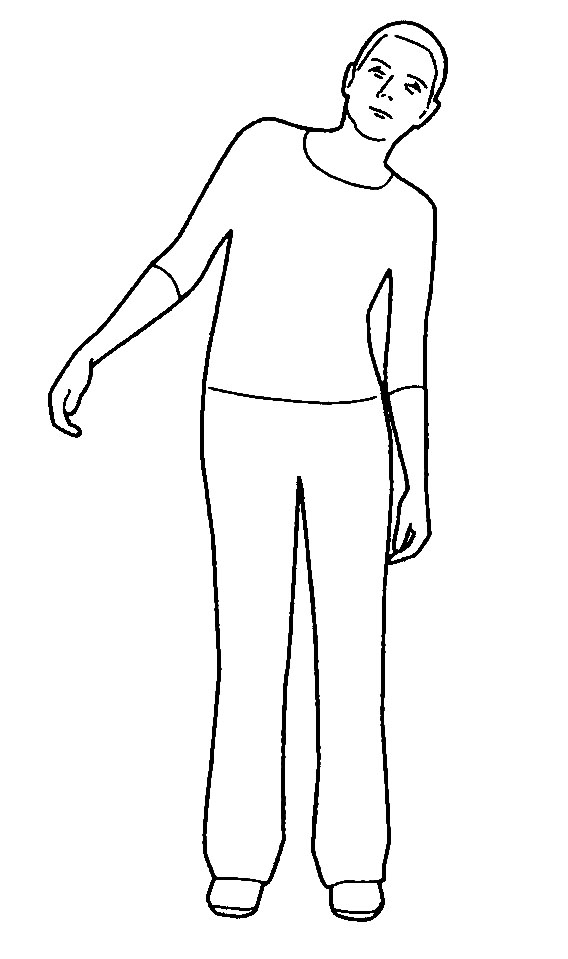

| Neck |

Working with the neck bent forward or to the side more than 30° for more than two hours total per day.

(circle the appropriate movements) |

||

|

Working with the neck rotated more than 45° in either direction for more than two hours total per day.

|

|||

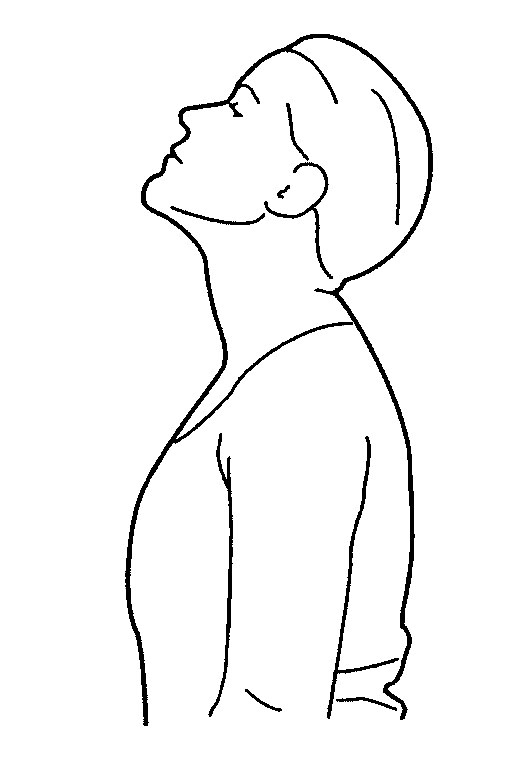

|

Working with the neck bent back/up more than 20o for more than two hours total per day.

|

|||

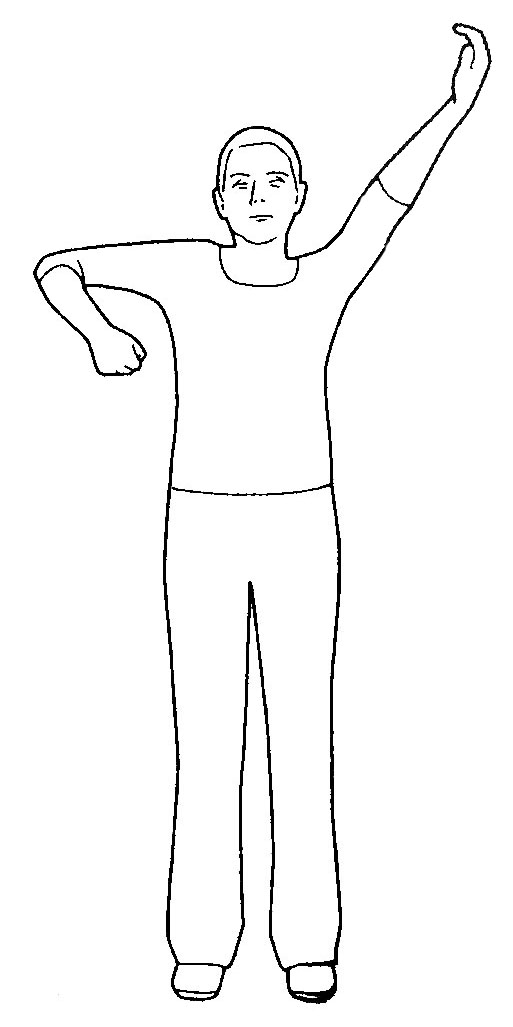

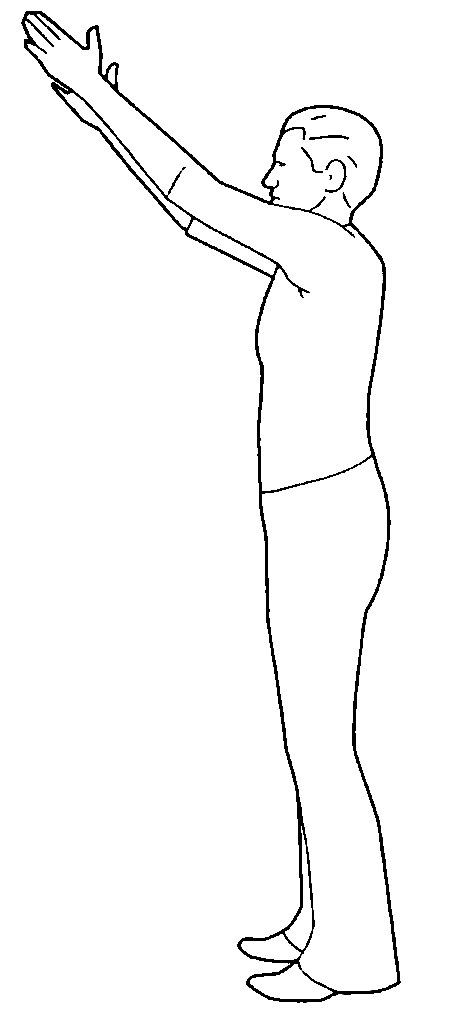

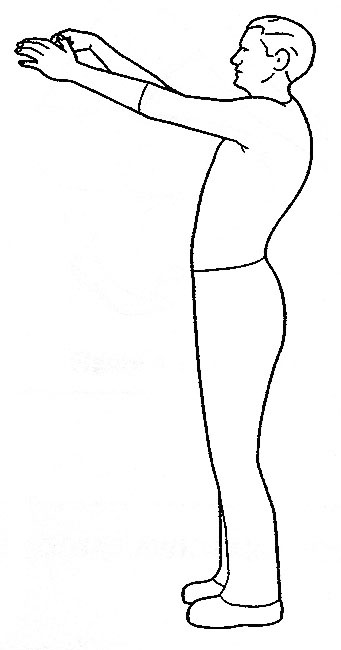

| Shoulder |

Working with the hand(s) at or above the head for more than two hours total per day.

|

||

|

Working with the elbow(s) at or above the shoulder for more than two hours total per day.

|

|||

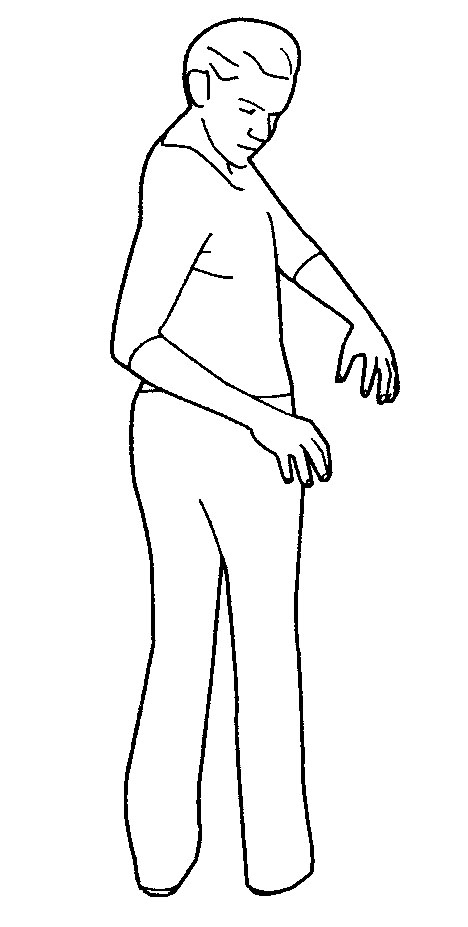

| Back |

Working while sitting or standing with the back bent forward, sideways, or twisted more than 30° for more than two hours total per day.

(circle the appropriate movements) |

||

|

Working while sitting or standing with the back bent back more than 20°, and with no support for the back, for more than two hours total per day.

|

|||

| Knees |

Worker squats/kneels for more than two hours total per day.

(circle the appropriate movements) |

||

| Static whole body postures | Check here if required at this job/task | Notes | |

|---|---|---|---|

| Prolonged sitting | Worker sits for more than six hours total per day. | ||

| Prolonged standing | Worker stands on a hard surface for more than four hours total per day (standing in one location without taking more than two steps in any direction). | ||

| Repetition | Check here if required at this job/task | Notes | |

|---|---|---|---|

| Neck, shoulders, elbows, wrists or hands |

Worker repeats the same motion with the neck, shoulders, elbows, wrists or hands every few seconds with little or no variation for more than two hours total per day (excluding keying activities). Check body parts that apply:

|

||

| Keyboarding | Worker performs intensive keying more than four hours total per day. | ||

| Repeated impacts | Check here if required at this job/task | Notes | |

|---|---|---|---|

| Hands/ knees |

Employee uses one of the following as a hammer more than 10 times per hour and for more than two hours total per day. Check body parts that apply:

|

||

| Hand/arm vibration | Check here if required at this job/task | Notes | |

|---|---|---|---|

| Hands/ wrists |

Use high vibration tools (impact wrenches, carpet strippers, chainsaws, jackhammers, scalers, riveting hammers) for more than 30 minutes total per day. | ||

| Use hand tools that typically have moderate vibration levels (grinders, sanders, jig saws) for more than two hours total per day. | |||