Module 1 - Guide on the prevention of Musculoskeletal Injury (MSI)

Introduction

Many hazards in the work place can lead to employee injuries. Part XIX of the Canada Occupational Health and Safety Regulations outlines a hazard prevention program for employers under federal jurisdiction. In December 2007, Part XIX (commonly known as the Hazard Prevention Program Regulations) was amended to include ergonomics-related hazards, which can cause musculoskeletal injuries.

A musculoskeletal injury (MSI) is an injury or disorder of the musculoskeletal system. The musculoskeletal system includes muscles, tendons, blood vessels, ligaments, nerves, joints, spinal discs and related soft tissue.

Other common terms used for musculoskeletal injuries are:

- Musculoskeletal disorders (MSD);

- Cumulative trauma disorder (CTD);

- Repetitive strain injury (RSI);

- Occupational overuse syndrome;

- Sprain and strain.

This guide does not cover musculoskeletal injuries that result directly from:

- Falling, slipping or tripping;

- Being struck by an object or knocked against something;

- Being caught in or on something; or

- Being in a vehicle accident.

The hazards that can cause MSI s are usually associated with the physical demands of work activities. For example, employees may injure themselves by:

- Lifting or pushing loads that require excessive force;

- Reaching or bending in an awkward posture;

- Holding the same position for a long time; or

- Repeating the same movements over and over with little chance for rest or recovery.

Through the application of ergonomics principles, the risk of injury posed by such hazards can be eliminated or reduced.

Ergonomics is the scientific study of the relationship between people and their working environment with a view to improving safety, ease of action and efficiency.

For work places under federal jurisdiction, MSIs represent about 30% of all work-related injuries accepted for compensation. This reflects considerable pain and suffering for the injured workers. It also reflects significant costs to employers for compensation and other expenses as a result of employees being off work.

The incidence of MSIs in a particular work place may be much higher or lower than the average depending on factors such as the effectiveness of the health and safety program and the type of work done in that work place.

Implementing good MSI prevention strategies will help to reduce the number of MSIs and save employers money.

Employer costs due to MSIs include:

Insurance-related costs

- Insurance coverage;

- Premium surcharges for poor health and safety performance.

Wage costs

- Paying employees on the day they are injured;

- Continuing benefits while employees are away with injury;

- Paying replacement employees.

Administrative costs

- Training and orienting replacement employees;

- Investigating and reporting on injuries;

- Completing forms and reports required by government agencies and insurance providers.

Lower production, quality of service or product quality

- Loss of experienced employees;

- Disruptions to production while finding and training replacement employees;

- Assignment of production-line employees to other duties such as conducting hazardous occurrence investigations.

Lost business

- Damage to reputation;

- Negative impact on staff morale;

- Adverse labour relations environment.

An employer that is successful in preventing MSIs will not have to waste valuable financial resources paying these costs.

Purpose of the guide

The purpose of the Guide on the Prevention of Musculoskeletal Injuries (MSIs) is to help work places establish a MSI prevention program that is effective and will meet the requirements of the Hazard Prevention Program Regulations (HPPR) with respect to ergonomics-related hazards.

In each section of the Guide, the applicable sections of the Regulations are provided for reference. The Guide also includes best practices for developing and implementing an MSI prevention program. The words "should" and "recommended" are used to identify these best practices.

Some work places already have a MSI prevention program. In that case, the Guide can be helpful in evaluating whether the program includes everything the Regulations require with respect to ergonomics-related hazards. The Guide may also draw attention to areas where the program can be improved.

For work places that do not yet have a MSI prevention program, the Guide can be used as a roadmap for developing and implementing a program that will meet the regulatory requirements.

The Guide highlights only those aspects of the hazard prevention program that are specific to ergonomics-related hazards. It does not cover aspects such as record keeping and periodic review of the employee education program, which apply to all hazards.

MSI prevention - Getting started

For on-going success in preventing musculoskeletal injuries, work places need to take a program approach. The Hazard Prevention Program Regulations (HPPR) provides the framework for such a program.

Section 19.1 of the Regulations

The employer shall, in consultation with and with the participation of the policy committee, or, if there is no policy committee, the work place committee or the health and safety representative, develop, implement and monitor a program for the prevention of hazards, including ergonomics-related hazards, in the work place that is appropriate to the size of the work place and the nature of the hazards and that includes the following components:

- an implementation plan;

- a hazard identification and assessment methodology;

- hazard identification and assessment;

- preventive measures;

- employee education; and

- a program evaluation.

Subsection (1) applies in respect of every work place controlled by the employer and, in respect of every work activity carried out by an employee in a work place that is not controlled by the employer, to the extent that the employer controls the activity.

Under the Regulations, the program must be developed, implemented and monitored "in consultation with and with the participation of" the policy committee. (If there is no policy committee, the employer shall call upon the work place committee or the health and safety representative.)

In addition, the program must include a number of parts:

- An implementation plan;

- Hazard identification and assessment methodology;

- Hazard identification and assessment;

- Preventive measures;

- Employee education;

- Program evaluation.

The first step is to establish an implementation plan that includes all these parts, in a logical order that will make the process easier.

Section 19.3(1) of the Regulations requires several sources of information to be taken into account in developing the methodology. To ensure that information from these sources is useful and will make the program more effective, employee education should take place early in the implementation process. Employee education includes training for those who conduct work place inspections, such as health and safety committee members.

The flow chart below entitled Hazard Prevention Program for Ergonomics-Related Hazards gives an overview of the implementation process recommended in this Guide.

Implementation plan

Section 19.2 of the Regulations

The employer shall:

- develop an implementation plan that specifies the time frame for each phase of the development and implementation of the prevention program;

- monitor the progress of the implementation of the preventive measures; and

- review the time frame of the implementation plan regularly and, as necessary, revise it.

In implementing the prevention program, the employer shall ensure that ergonomics-related hazards are identified and assessed and that they are eliminated or reduced, as required by subsection 19.5(1), as much as reasonably possible and that any person assigned to identify and assess ergonomics-related hazards has the necessary instruction and training.

The implementation plan for the MSI prevention program must include the following components, in this recommended order:

- Step 1: Process for consultation with and participation of the policy committee (or the work place committee or the health and safety representative) during each step of the program.

- Step 2: Education of employees and health and safety committee members.

- Step 3: Methodology for hazard identification and assessment.

- Step 4: Hazard identification and assessment.

- Step 5: Preventive measures.

- Step 6: Program evaluation.

The implementation plan must establish time frames for each phase in the development and implementation of the program. Be realistic in establishing the schedule. If the hazard prevention program at the work place has never included MSI prevention, it may take a few years to address all the ergonomics-related hazards.

The size and complexity of the work place, as well as other health and safety priorities, will be factors in the time required. If most employees in the work place perform roughly the same tasks, it may not take as long to implement the program and address the ergonomics-related hazards.

The implementation plan must be monitored periodically to ensure that the process is on schedule. If for some unforeseen reason the time frames in the implementation plan cannot be met, they may need to be revised.

Description of Hazard Prevention Program for Ergonomics-Related Hazards Steps flow chart

- Step 1

- Consultation with and with the participation of the Health & Safety Committee. Establish framework and set-up the process for each step.

- Step 2

- Health & Safety Committee: education and training for members

- Employee Education

- Step 3

- Hazard ID and Assessment Methodology

- Investigation Reports

- Work Place Inspections

- First Aid and Claims

- Employee Reports/ Survey

- Other Sources

- Priority Setting Process

- Priority

- A, B, C, D, E, F, G, H, I

- (just started - reference to priority C)

- Priority

- Hazard ID and Assessment Methodology

- Step 4

- Hazard Identification and Assessment (Preventive measure not already known or not obvious)

- (in progress - reference to priority B)

- Hazard Identification and Assessment (Preventive measure not already known or not obvious)

- Step 5

- Preventive measure implementation and evaluation of the effectiveness of the preventive measure

- (completed - reference to priority A)

- Preventive measure implementation and evaluation of the effectiveness of the preventive measure

- Step 6

- Program Evaluation

End flow chart description

Step 1: Consultation and participation

The Canada Labour Code, Part II and the Canada Occupational Health and Safety Regulations are based on a system of internal responsibility. In such a system, the employer works in cooperation with employee representatives to address work place hazards and reduce risks to employees. This means the employer must consult and involve the policy committee (or, if there is no policy committee, the work place committee or the health and safety representative) at each stage in developing, implementing and monitoring the MSI prevention program.

It is a good idea for health and safety committee members involved in the work place program to have a good knowledge of MSI prevention principles, for several reasons. First, it will help them contribute more effectively when they take part in developing and implementing the hazard prevention program. Second, it will assist them during inquiries, investigations, studies and inspections they must help carry out pertaining to ergonomics-related hazards. Information from these activities is to be taken into account in the development of the methodology for hazard identification and assessment.

For the program to be successful, it is therefore recommended that the committee members who participate in the process be given the training that will enable them to carry out their responsibilities proficiently. These committee members should:

- Understand the implementation plan;

- Be able to identify ergonomics-related hazards in the work place in order to participate in MSI investigations, work place inspections and similar tasks;

- Understand and be able to conduct basic assessment of ergonomics-related hazards so that they can be effective in performing their duties as committee members; and

- Be familiar with the system being used by employees to report MSIs and ergonomics-related hazards in the work place.

If the committee members are also to be responsible for conducting detailed hazard assessments, they must be trained in the methods used for such assessments.

There is a third reason for making sure committee members know all about ergonomics-related hazards and MSI prevention: the employer can then have them deliver the employee education on ergonomics that is required under section 19.6 of the Regulations.

Step 2: Employee education

Section 19.6 of the Regulations

The employer shall provide health and safety education, including education relating to ergonomics, to each employee which shall include the following:

- the hazard prevention program implemented in accordance with this Part to prevent hazards applicable to the employee, including the hazard identification and assessment methodology and the preventive measures taken by the employer;

- the nature of the work place and the hazards associated with it;

- the employee's duty to report under paragraphs 126(1)(g) and (h) of the Act and under section 15.3; and

- an overview of the Act and these Regulations.

The employer shall provide education to an employee

- whenever new hazard information in respect of a hazard in the work place becomes available to the employer; and

- shortly before the employee is assigned a new activity or exposed to a new hazard.

The employer shall review the employee education program, and, if necessary, revise it

- at least every three years;

- whenever there is a change in conditions in respect of the hazards; and

- whenever new hazard information in respect of a hazard in the work place becomes available to the employer.

Each time education is provided to an employee, the employee shall acknowledge in writing that they received it, and the employer shall acknowledge in writing that they provided it.

The employer shall keep, in paper or computerized form, records of the education provided to each employee, which shall be kept for a period of two years after the employee ceases to be exposed to a hazard.

A booklet entitled Guide to Employee Education on Musculoskeletal Injuries from the Labour Program is available to help employers teach employees about ergonomics, with a focus on MSI prevention. It outlines:

- The regulatory requirements specific to ergonomics-related hazards;

- The program approach to MSI prevention;

- The components of the MSI prevention program;

- Common ergonomics-related hazards in the work place; and

- The employees' duty to report ergonomics-related hazards.

Step 3: Methodology for hazard identification and assessment

Section 19.3 of the Regulations

- The employer shall develop a hazard identification and assessment methodology, including an identification and assessment methodology for ergonomics-related hazards, taking into account the following documents and information:

- any hazardous occurrence investigation reports;

- first aid records and minor injury records;

- work place health protection programs;

- any results of work place inspections;

- any employee reports made under paragraph 126(1)(g) or (h) of the Act or under section 15.3;

- any government or employer reports, studies and tests concerning the health and safety of employees;

- any reports made under the Safety and Health Committees and Representatives Regulations;

- the record of hazardous substances; and

- any other relevant information, including ergonomics-related information.

- The hazard identification and assessment methodology shall include

- the steps and time frame for identifying and assessing the hazards;

- the keeping of a record of the hazards; and

- a time frame for reviewing and, if necessary, revising the methodology.

Key documents and information

Under the Regulations, the hazard identification and assessment methodology must take into account some key documents and information.

1. Hazardous occurrence investigation reports [section 19.3(1)(a)]:

For the information in these reports to be of value, the investigations must be conducted by people who know about ergonomics-related hazards and the problems and injuries that can result from exposure to these hazards.

The work place committee members who participate in these investigations must therefore receive the required education and training. For employers needing assistance, a Guide for Investigating Musculoskeletal Injuries is available from the Labour Program.

2. Results of work place inspections [section 19.3(1)(d)]

Again, for the information in inspection reports to be useful in this process, the inspections must be conducted by people who know how to identify and assess ergonomics-related hazards.

The work place committee members who participate in these inspections must therefore receive the required education and training. For employers needing guidance, a General Guide for Identifying Ergonomics-Related Hazards is available from the Labour Program.

Some ergonomics-related hazards are associated with lifting, reaching and/or repeating the same movements. These are also normal life activities that are considered healthy when performed in moderation.

To help in properly identifying the risks in the work place, the General Guide therefore suggests some basic assessment parameters, such as:

- Magnitude ("how much");

- Duration ("how long"); and

- Frequency ("how often").

In most cases, this level of identification and assessment is sufficient to arrive at preventive measures.

3. Employee reports [section 19.3(1)(e)]

Employees are required to tell the employer about anything in the work place that is likely to be hazardous to their own health or safety or to the health and safety of others.

Sometimes employees will themselves notice potential hazards in their environment or experience signs or symptoms of MSI. The education provided under Step 2 should further increase awareness in the work place and enable employees to identify potentially hazardous circumstances.

When trying to determine which jobs require preventive measures or detailed hazard assessment, the employer may wish to be proactive and ask employees for their input. To assist employers, a guide entitled Employee Input on Potential Ergonomics-Related Hazards is available from the Labour Program.

It is important for employees to be aware that their reports and input represent only one of several sources of information that will be considered in prioritizing tasks or jobs for hazard assessment and preventive measures.

Setting priorities

In most work places there are limited resources available, so it is helpful to have a way of identifying the tasks for which preventive measures are the most urgent. Situations where employees have already suffered MSIs or are reporting signs or symptoms of MSIs should be dealt with first. Each work place should establish a system for prioritizing tasks for preventive measures, based on the specific circumstances for the work site.

Once the order of priority has been established, the tasks should be assessed one by one so that preventive measures can be taken to reduce the risk to employees as much as is reasonably possible. Criteria for determining what is reasonably possible include:

- The number of employees affected;

- The availability of options and technology to reduce the hazard; and

- The severity of the hazard compared with the cost of the preventive measures.

Work places that have not previously had a MSI prevention program will find that there are many tasks with ergonomics-related hazards that must be looked at. The best approach is to work through them one at a time, in order of priority, at a pace that takes into account the severity of the hazards, the number of employees affected, and other health and safety issues that are being addressed at the same time in the work place.

Work places may wish to pick certain tasks on which quick action can be taken, to demonstrate their commitment to MSI prevention. This can be done where the preventive measures for a particular ergonomics-related hazard are obvious and have been proven by past experience in that work place or similar work places. In such cases, the process can be "fast-tracked" from Step 3 (Methodology) to Step 5 (Preventive Measures).

Step 4: Hazard identification and assessment

Section 19.4 of the Regulations

The employer shall identify and assess the hazards in the work place, including ergonomics-related hazards, in accordance with the methodology developed under section 19.3 taking into account

the nature of the hazard;

(a.1) In the case of ergonomics-related hazards, all ergonomics-related factors such as

- the physical demands of the work activities, the work environment, the work procedures, the organization of the work and the circumstances in which the work activities are performed, and

- the characteristics of materials, goods, persons, animals, things and work spaces and features of tools and equipment;

- the employees' level of exposure to the hazard;

- the frequency and duration of employees' exposure to the hazard;

- the effects, real or apprehended, of the exposure on the health and safety of employees;

- the preventive measures in place to address the hazard;

- any employee reports made under paragraph 126(1)(g) or (h) of the Act or under section 15.3; and

- any other relevant information.

Ergonomics-related factors

Many factors must be considered in hazard identification and assessment. The following are some ergonomics-related factors that can cause or contribute to MSIs. When an employee is exposed to two or more factors at the same time, the risk of injury is higher.

(a) Physical demands of work activities

The primary factors that impose physical demands on an employee are force, fixed or awkward postures, contact stress, and repetition.

Force:

Force is the effort exerted by the employee to do the work. All work requires some level of force and in most cases the work can be done without harmful effects. However, if the force exerted (for example, when lifting an extremely heavy object) is more than the musculoskeletal system can handle it can lead to injury.

The risk of injury increases if a fairly high level of force is exerted repeatedly over a long period. There is even more risk of injury if the work is also done in an awkward posture (for example, lifting objects repeatedly with a twisting motion).

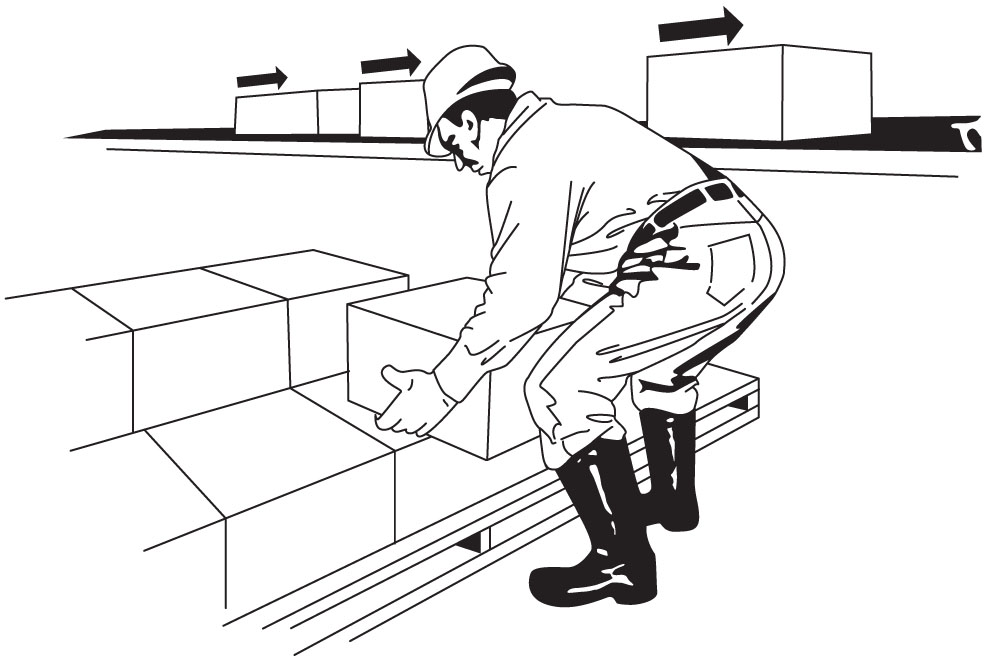

In addition to lifting, other common types of work associated with forceful exertion are pushing, pulling, gripping and carrying.

Holding things may be more difficult when the hands are cold or the object being manipulated is heavy. In addition, extra effort may be needed because of the nature of the task to be performed (for example, holding a knife to cut through a dense object).

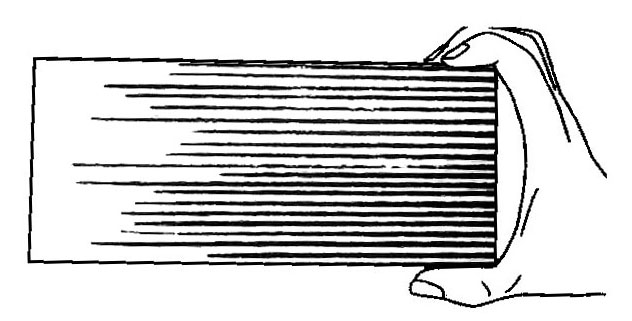

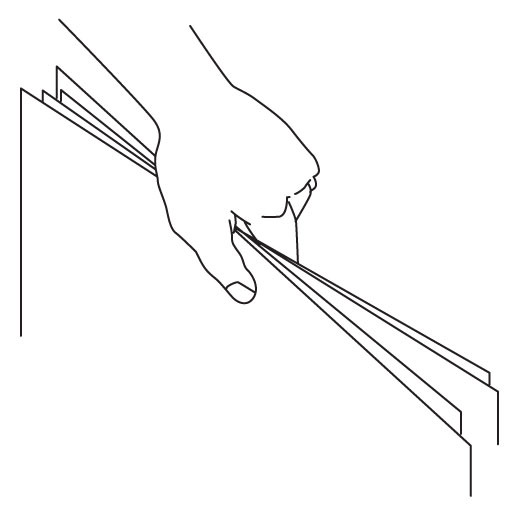

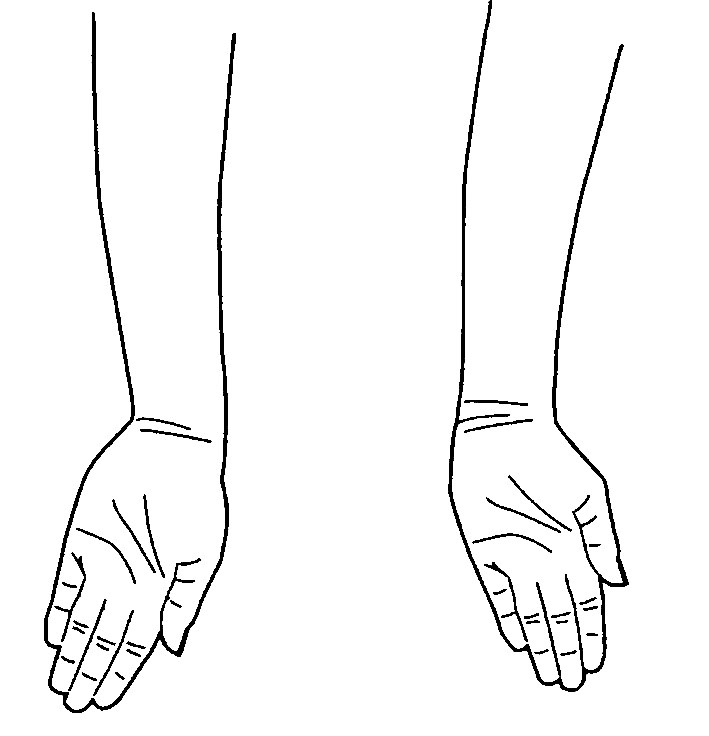

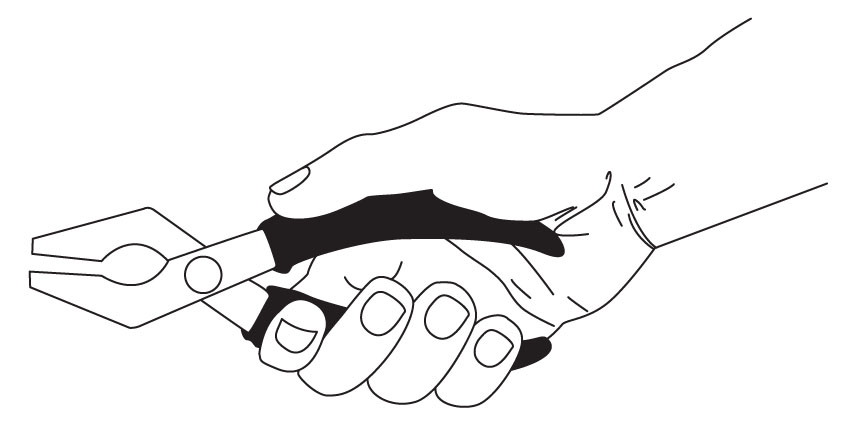

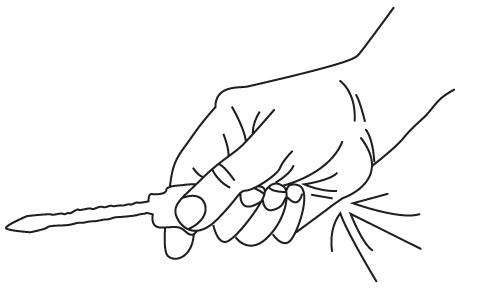

Here are some examples of tasks requiring increased grip force:

- Holding a slippery object ;

- Gripping a small tool or holding an object for precision work;

- Holding an object that is too large for a comfortable grip (i.e. fingers do not slightly overlap);

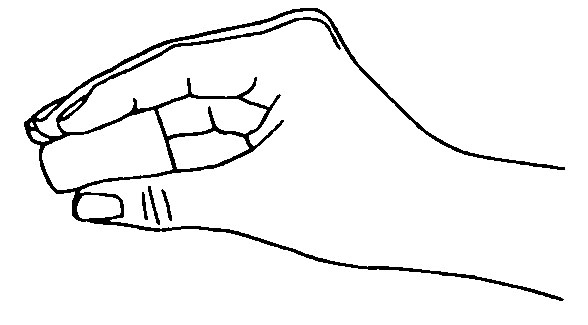

- Handling something using the fingers and the thumb (a pinch grip) instead of the whole hand (a power grip);

- Grasping an odd-shaped object that is difficult to hold;

- Holding vibrating tools or objects.

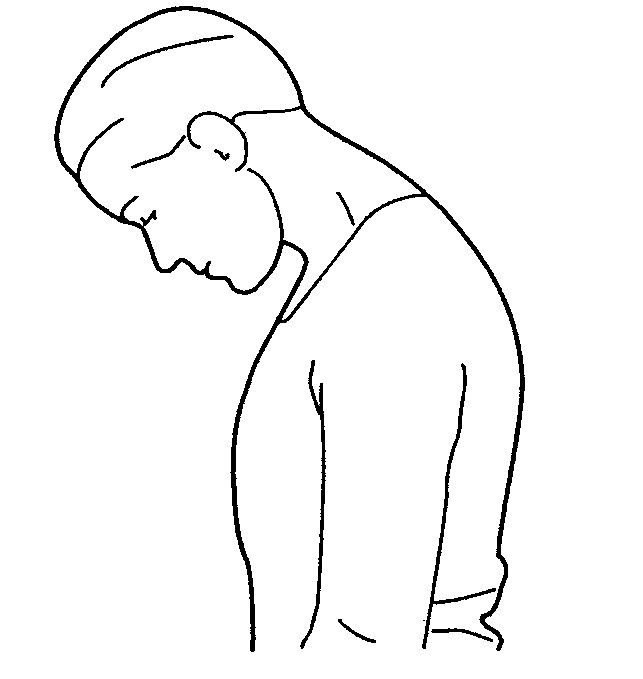

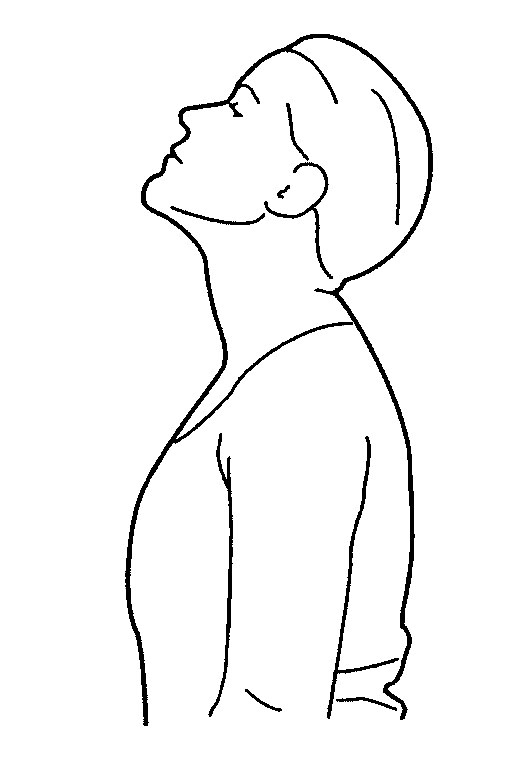

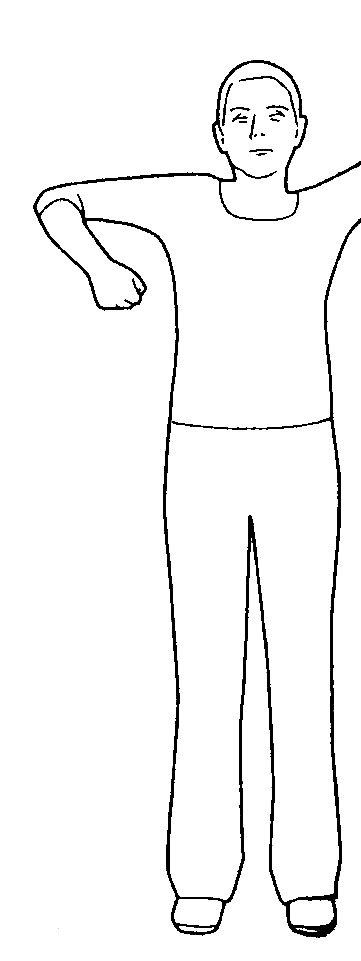

Static (fixed) or awkward postures:

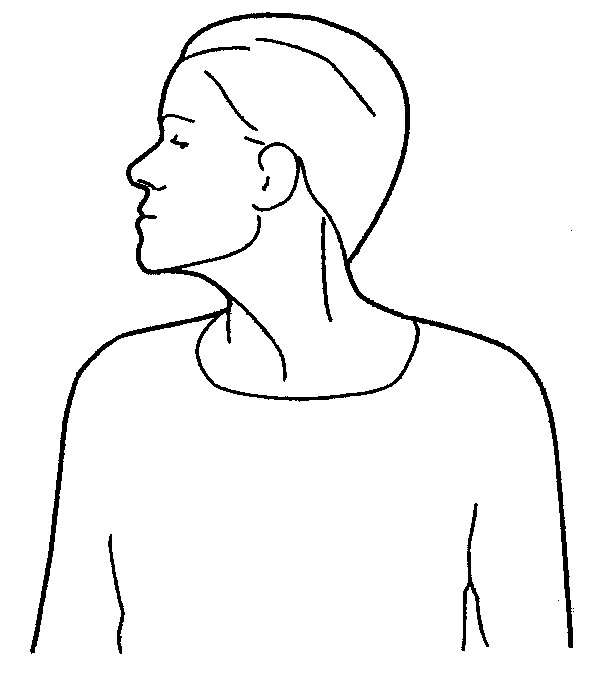

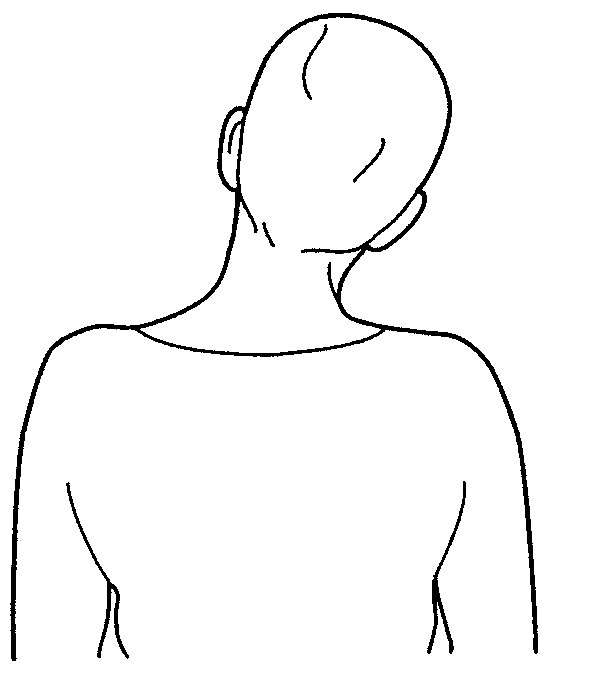

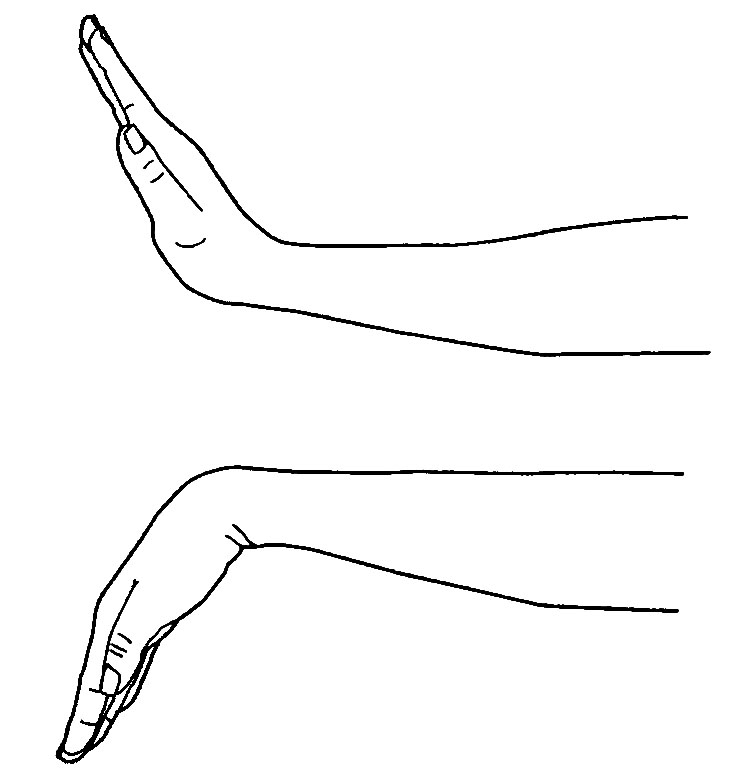

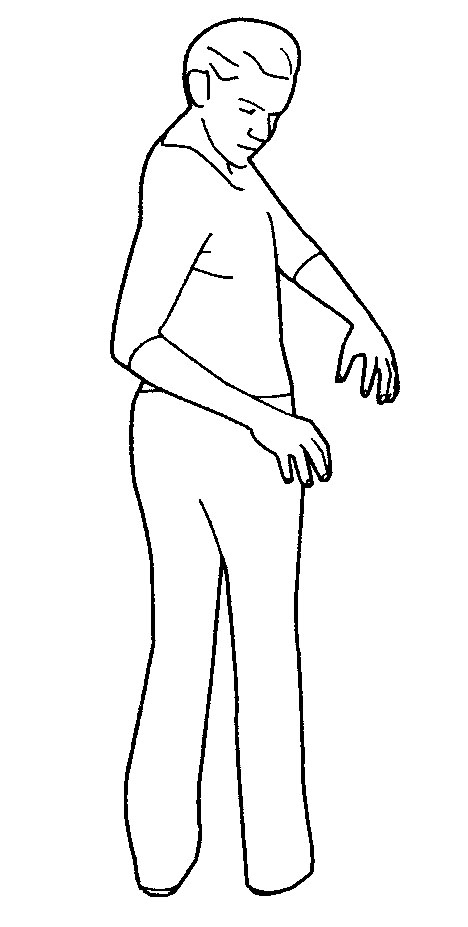

Posture refers to the position of a body part, in relation to nearby body parts, during an activity.

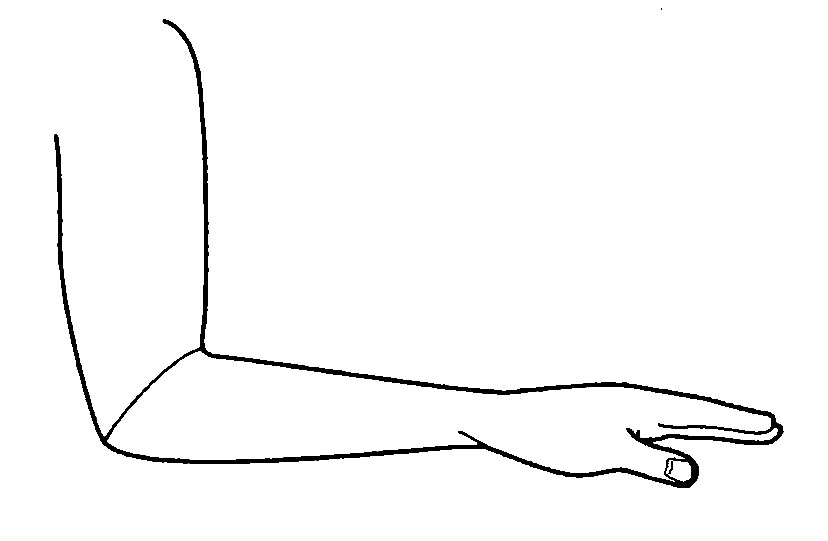

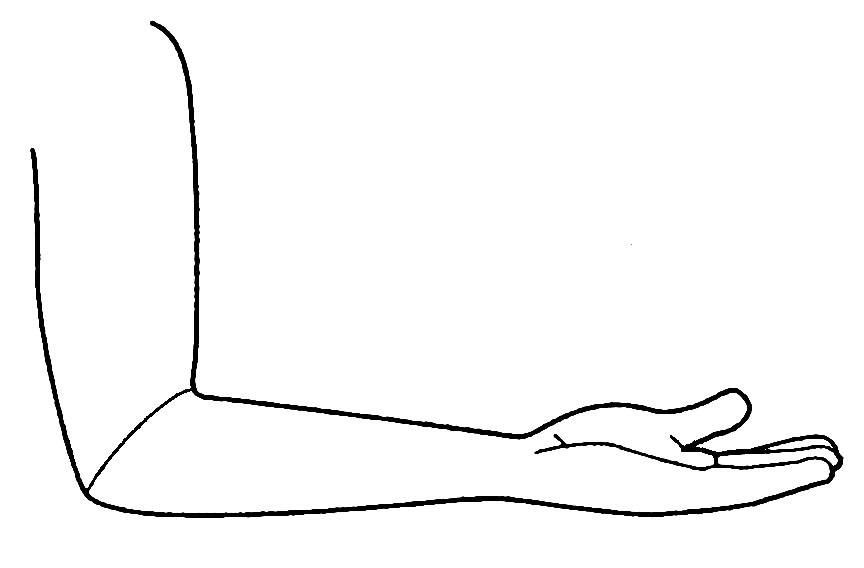

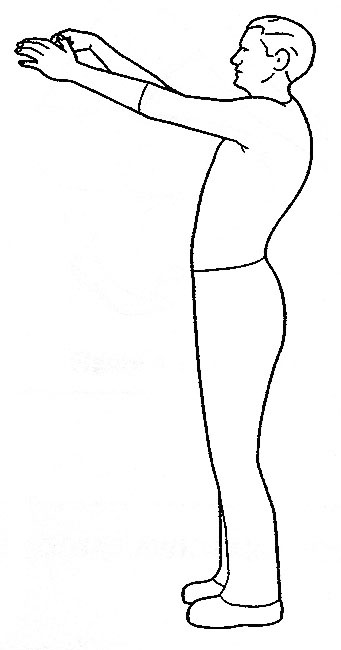

Joint position inside the comfortable range of motion is known as the neutral position. Awkward posture results when a joint in the body bends or twists excessively, outside the comfortable range shown in the diagram below.

Muscles, ligaments and tendons work harder to support the affected body part when in an awkward posture. The farther a joint moves away from the neutral position, the greater the effort required by the supporting soft tissues.

If a posture is held fixed, or static, for a long time, the muscles get tired because the lack of movement stops them from getting enough blood flow to keep them supplied with energy. This results in aches and pains.

Some common awkward postures are illustrated below:

Here are some examples of office tasks that can result in awkward postures:

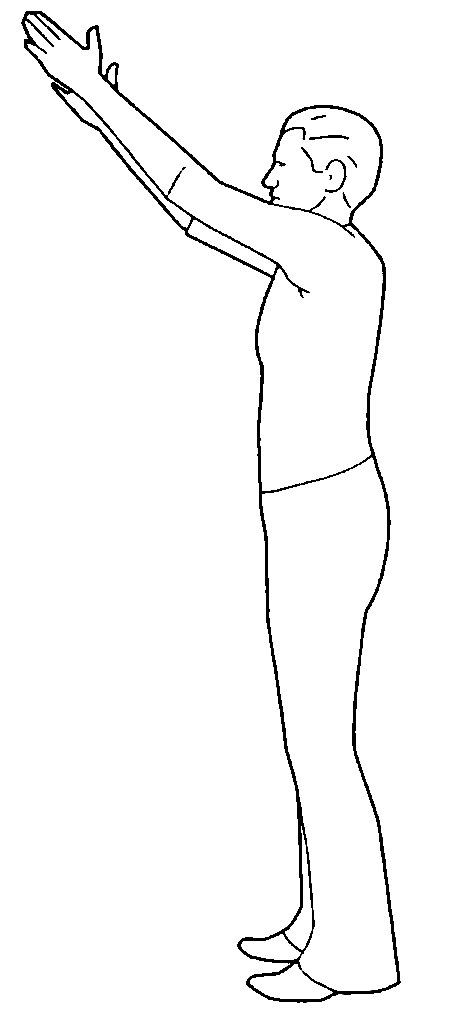

Awkward shoulder posture

- Reaching overhead to get books or files on a high shelf;

- Reaching across the desk to use a telephone placed on the far side;

Awkward neck posture

- Twisting the neck to talk to someone seated to the side while using a keyboard directly in front;

- Bending the neck down to do detailed drawings on paper laid flat on the desk;

- Looking up frequently at a security screen high on the wall to monitor access points to the building, while working on a desktop computer;

Awkward back posture

- Leaning sideways to reach into a low drawer while sitting;

- Bending down and sorting documents on the floor.

Contact Stress:

Contact stress occurs when a hard or sharp object comes in contact with the skin. Soft tissues, including nerves and blood vessels, can be injured due to the pressure caused by contact stress.

Here are some things that can lead to contact stress:

Using body parts to strike hard surfaces

- Using the hand to knock metal parts into place while assembling machinery;

- Kicking the carpet-stretcher with the part of the leg right above the knee when installing carpet;

Kneeling on hard surfaces

- Kneeling on cement while setting floor tiles;

- Kneeling on a metal surface while stacking baggage inside the hold of a small aircraft;

- Kneeling on wood flooring while putting together a piece of furniture.

Having the sharp edge of a desk dig into the forearm or wrist while typing

Having ridges on a tool handle dig into the hand when the tool is held tightly

Repetition:

Using the same muscles, tendons and other soft tissues repeatedly with little chance for rest or recovery can lead to musculoskeletal injury when the muscles get tired. Repetition increases the risk of injury when other factors such as forceful exertion and awkward posture are also present.

Highly repetitious tasks can affect large muscles (for example, repeatedly lifting and stacking heavy objects) as well as small muscles (repeatedly operating a small syringe assembly).

Other factors that impose physical demands:

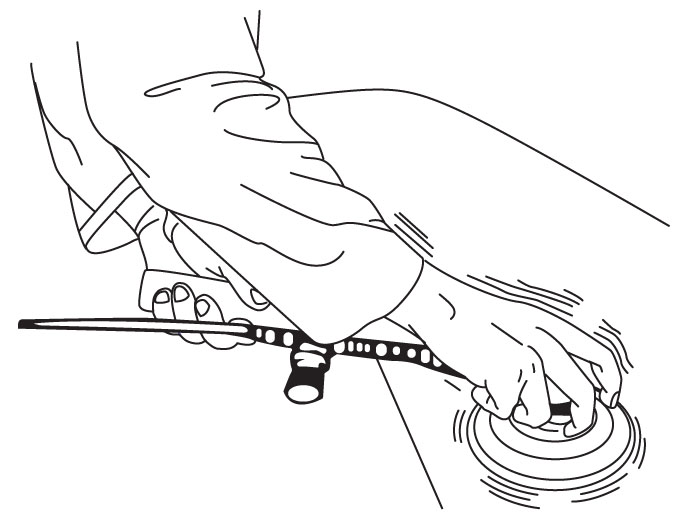

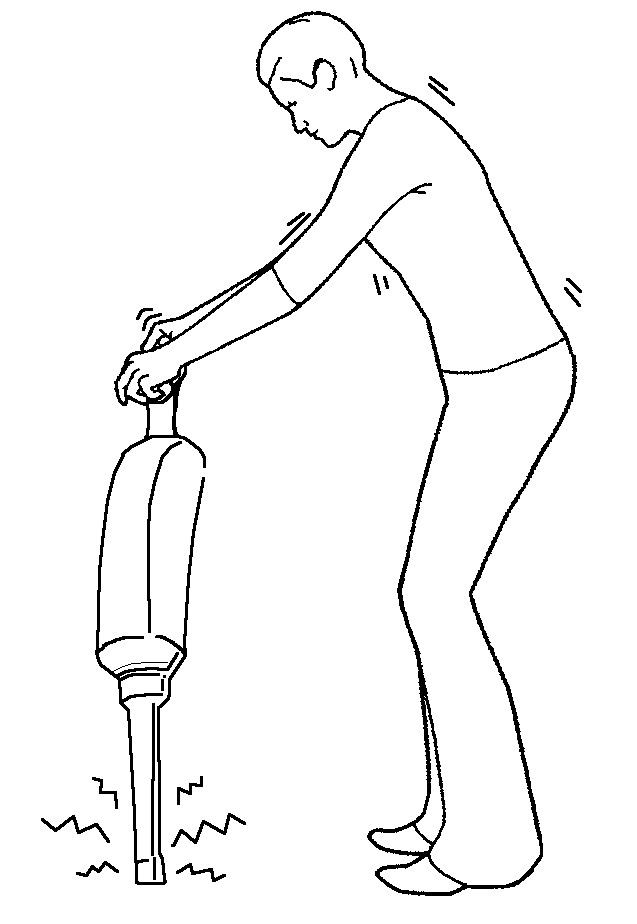

Hand-arm vibration (HAV)

Small hand tools such as drills and sanders produce vibrations that are transferred to the hands of the employee holding them. This also happens with larger tools such as chain saws and pneumatic chippers and drills. Depending on the level and frequency of the vibration and the duration of exposure, the nerve and circulatory system in the hands and fingers may be harmed.

Exposing cold hands to vibration (for example, using a chain saw outside in the winter) raises the risk of hand-arm vibration syndrome.

Whole-body vibration

When a worker is sitting or standing on a vibrating surface, such as a surface directly attached to a large diesel engine, the vibration can be transmitted to his whole body. The same thing occurs when driving vehicles over rough surfaces.

Depending on the level, frequency and duration of exposure, whole-body vibration can contribute to back pain and performance problems.

(b) Work environment

The primary factors to be considered are cold temperatures and hot working conditions.

When exposed to cold, muscles and tendons become less flexible and do not work as efficiently. The blood circulation in the hands and arms is reduced and the worker will lose some of the feeling in his hands and fingers.

The worker will have to use more grip force to grasp objects. The increased effort can lead to greater strain on muscles and tendons.

Cold can be an issue when handling cold objects or if the air temperature is low.

Here are some examples where cold is a factor:

- Handling tools that are stored outside during the winter;

- Handling frozen or refrigerated food;

- Working outside during the winter; and

- Having cold air from the exhaust of a pneumatic drill blow over the hands and fingers.

Working in a hot or humid environment also imposes strain on the body. It increases the body temperature and causes dehydration, leading to muscle tiredness. People working in commercial kitchens or working outside during the summer are exposed to hot, humid work environments.

(c) Work procedures and the organization of work

Work procedures and organization of work can minimize the harmful effects of the factors listed above. For example, physically demanding tasks can be spread among more employees through job rotation, thereby reducing the demands placed on any one person. Outside work during the hot summer months can be scheduled to begin early and finish early in the day, thereby reducing the heat load on employees.

Other possibilities are for employees to pace themselves when doing physically demanding tasks and for employers to phase out piecework.

When work procedures and organization of work do not take the work environment and the physical demands of the tasks into consideration, there is a higher risk of injury.

(d) Circumstances in which work activities are performed

When working in hazardous environments or responding to emergencies, workers must use various kinds of personal protective equipment. Waterproof coveralls that do not "breathe" can add to stress from heat. The filters in air purifying respirators increase the physical demands involved in breathing by cutting down on air flow. Using a self-contained breathing apparatus can add significant weight and bulk, making it harder to climb stairs and manoeuvre around objects.

(e) Characteristics and features that affect handling

Shape, bulkiness, surface texture and availability of handles are some of the characteristics that affect how easy it is to pick up and move materials, goods or things. For example, things that are wet and slippery can be hard to hold.

The characteristics of people and animals have a similar effect. Unfortunately, people and animals do not come with handles. They can be heavy and awkward to lift or move. In addition, both people and animals can be highly unpredictable. They may startle when touched or struggle to get away. This increases the risk to employees whose work involves manual handling of people or animals.

Characteristics of the work space, such as layout, can increase the physical demands of the work activities. For example, employees may have to reach to get materials they need, or they may use improper postures or body mechanics because they do not have enough space to move around.

Features of tools and equipment, such as weight, handle position and vibration, can increase the risk of MSIs.

Assessment methods and tools

The methodology used in Step 3 will identify the tasks with ergonomics-related hazards. These hazards may only be potential hazards, or they may already have caused an MSI, resulted in a minor injury or in first aid treatment, or been reported by an employee. In most cases, this level of information should be sufficient to proceed to preventive measures.

However, more complex assessment methods are sometimes required. This is true in cases where it is harder to assess the degree of hazard associated with a particular task or when comparing similar tasks.

Example:

An employee is assigned to transfer items from one conveyor to another. When is he most likely to injure himself?

- If he spends 4 hours moving boxes weighing 20 kg twice a minute?

- If he spends 4 hours moving boxes weighing 10 kg four times a minute?

- If he spends 2 hours moving boxes weighing 20 kg four times a minute?

Determining the relative hazard involved in performing the same quantity of work requires the use of fairly advanced or detailed assessment methods. So does evaluating the impact of exposure to a combination of factors, such as exerting force in an awkward posture repeatedly.

A list of in-depth risk assessment tools, along with brief descriptions, can be found in MSD Prevention Tool Box - More on In-Depth Risk Assessment Methods, which was developed by the Occupational Health and Safety Council of Ontario. It is important to note that to use these tools properly, people must have the necessary training.

It is the employer's responsibility to ensure that those assigned to identify and assess ergonomics-related hazards have the necessary education and training. They should be familiar with basic ergonomic principles and have experience applying them.

The ergonomics principles include:

- Adapting the work space and the work equipment to fit the operator and the kind of work being performed, to promote preferred body postures;

- Providing sufficient space for body movements;

- Providing variety in tasks and movements to avoid body tension caused by static postures;

- Designing work to allow machinery to do or assist with highly repetitive tasks, leaving more variable tasks to human operators;

- Placing controls within easy reach;

- Keeping loads close to the body and handling them with neutral postures;

- Keeping physical demands compatible with the physical capacities of the employee;

- Using mechanical assistance if the strength demanded exceeds the capacity of muscle groups.

Step 5: Preventive measures

Section 19.5 of the Regulations

The employer shall, in order to address identified and assessed hazards, including ergonomics-related hazards, take preventive measures to address the assessed hazard in the following order of priority:

- the elimination of the hazard, including by way of engineering controls which may involve mechanical aids, equipment design or redesign that take into account the physical attributes of the employee;

- the reduction of the hazard, including isolating it;

- the provision of personal protective equipment, clothing, devices or materials; and

- administrative procedures, such as the management of hazard exposure and recovery periods and the management of work patterns and methods.

As part of the preventive measures, the employer shall develop and implement a preventive maintenance program in order to avoid failures that could result in a hazard to employees.

The employer shall ensure that any preventive measure shall not in itself create a hazard and shall take into account the effects on the work place.

The preventive measures shall include steps to address

- newly identified hazards in an expeditious manner; and

- ergonomics-related hazards that are identified when planning implementation of change to the work environment or to work duties, equipment, practices or processes.

The employer shall ensure that any person assigned to implement ergonomics-related prevention measures has the necessary instruction and training.

The Regulations specify the order of priority for the types of preventive measures, or risk controls, that must be used to deal with ergonomics-related hazards.

(a) Elimination of the hazard:

It may be possible to eliminate the hazard by means of engineering controls. Common examples include:

- Having an adjustable work surface to eliminate awkward posture;

- Using a mechanical hoist to eliminate manual lifting;

- Using automation to eliminate repetitive manual tasks.

When preventive measures such as equipment modifications are implemented, the physical attributes of the employee(s) using that equipment must be taken into account. For example, modifying a work station to suit a very tall employee who is on the day shift may introduce new ergonomics-related hazards for a shorter employee on the night shift. Making sure that adjustability is built into the preventive measure can help overcome such challenges.

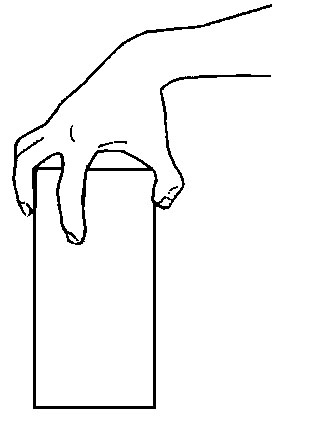

Use of mechanical equipment to transport materials rather than carry materials

(b) Reduction of the hazard

Ergonomics-related hazards can be reduced by making changes in the work place (for example, so the employee does not need to reach as far or bend down as often to get materials).

A hazard can be reduced by lowering the level (magnitude/amount), the duration of exposure or the frequency of exposure, or through any combination of these three methods.

(c) Personal protective equipment

Personal protective equipment includes things such as knee pads for kneeling on hard surfaces and vibration dampening gloves for using hand tools that vibrate.

There is a very limited range of personal equipment for protection against ergonomics-related hazards. This equipment is best used in combination with other preventive measures, such as administrative procedures.

For example, to reduce the risk to an employee assigned to set tiles on a large floor area, the employer may include different tasks in the employee's work day so he does not have to spend too long kneeling on a hard surface. However, during the time the employee does spend kneeling, using knee pads will improve his safety.

(d) Administrative procedures

A good example of an administrative control is having the employee monitor himself in order to change tasks when physical tiredness sets in while he is performing a physically demanding task.

Another example is having two or more employees alternate between a physically demanding task and less demanding tasks, to give them a chance to recover. Yet another possibility is for the employee to spread the physically demanding portion of the daily work over the entire shift rather than do it all at once.

The Regulations also say that when planning changes to the work environment or to work duties, equipment, practices or processes, the employer must be proactive in identifying and addressing potential ergonomics-related hazards.

As with hazard identification and assessment, the employer must ensure that any person assigned to implement ergonomics-related preventive measures has the necessary education and training.

Appendix 1 of the Guide outlines some common preventive measures that have proven successful in reducing the risk to employees due to exposure to ergonomics-related hazards. It does not, however, include all possible options. The specific preventive measure or combination of measures that will be effective will depend on the specific circumstances at the work site.

The following aspects should be considered in selecting the most suitable option:

- What experiences have others had with the solution? (Is there a proven or benchmark solution to the problem?)

- Will any new hazards be created?

- What are the costs and/or benefits of the preventive measure?

- Are there non-monetary benefits to one option over another?

- If there is disruption to work, productivity and/or quality of service during implementation, how will it be managed?

- What training is required?

- What feedback have employees provided? What option would they prefer?

- What maintenance requirements will there be?

- How will the success of the implementation evaluated?

It is recommended that a brief employee survey be conducted to collect and document employees' feedback on preventive measures implemented. This gives everyone who has used the control a chance to indicate their overall satisfaction with it, comment on its advantages and disadvantages, and make suggestions for improvement.

If a large number of employees are involved, the survey may be done using a sample of employees.

Step 6: Program evaluation

Section 19.7 of the Regulations

- The employer shall evaluate the effectiveness of the hazard prevention program, including its ergonomics-related components, and, if necessary, revise it

- at least every three years;

- whenever there is a change in conditions in respect of the hazards; and

- whenever new hazard information in respect of a hazard in the work place becomes available to the employer.

- The evaluation of the effectiveness of the prevention program shall be based on the following documents and information:

- conditions related to the work place and the activities of the employees;

- any work place inspection reports;

- any hazardous occurrence investigation reports;

- any safety audits;

- first aid records and any injury statistics, including records and statistics relating to ergonomics-related first aid and injuries;

- any observations of the policy and work place committees, or the health and safety representative, on the effectiveness of the prevention program; and

- any other relevant information.

As with other hazards covered under the Hazard Prevention Program Regulations, the ergonomics-related components must be evaluated to see whether they are effective. First-aid records and statistics for ergonomics-related injuries are useful for this.

The effectiveness of the ergonomics-related components can be evaluated when evaluating the hazard prevention program as a whole, and the findings can be recorded as part of the HPP evaluation report.

For employers needing assistance, a Checklist for the Evaluation of an Ergonomics-Related Hazard Prevention Program is available from the Labour Program.

Reports and records

Section 19.8 of the Regulations

- If a program evaluation has been conducted under section 19.7, the employer shall prepare a program evaluation report and submit a copy of it to the Minister as part of the employer's annual hazardous occurrence report referred to in subsection 15.10(1).

- The employer shall keep readily available every program evaluation report for six years after the date of the report.

Section 19.8 of the Regulations does not contain any specific requirements relating to ergonomics.

Appendix 1: Common options for preventive measures

This appendix outlines some common preventive measures that have proven successful in reducing the risk to employees due to exposure to ergonomics-related hazards. It does not however include all possible options. The specific preventive measure or combination of measures that will be effective will depend on the specific circumstances at the site. Priority must be given to preventive measures that will eliminate the hazard to employees.

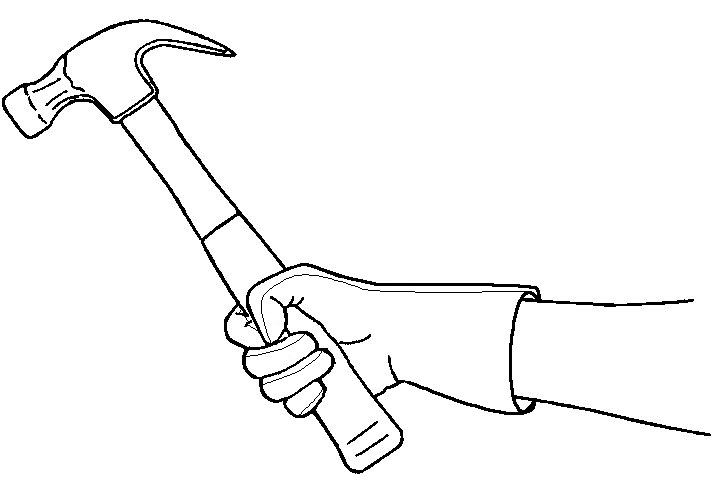

Force: Gripping tools, equipment or objects

Eliminate the need to manually grip or handle tools, equipment or objects by using engineering controls such as clamps and automated tools. If that is not reasonably possible, consider options such as the following to minimize the risk to employees:

- Use tools that allow employees to grip the tool using the whole hand (a power grip);

- Choose tools that have triggers that can be operated using several fingers rather than one finger or a thumb;

- Choose tools that can be used with the wrist straight;

- Choose tools with features that reduce vibration;

- Choose tools that are lighter and designed to reduce hand torque and kickback;

- Ensure the tool is balanced and does not require extra muscular effort to hold it in position ;

- Ensure the handle of a tool does not create pressure points in the palm of the hand;

- Use tools with handles that fit the hand (for example, use a smooth hand grip rather than one with hard ridges that space the fingers);

- Use rubber or sponge-type grips on tool handles;

- Choose tools that can be safely used by either left handed or right handed employees;

- Maintain tools regularly;

- Inspect tools regularly;

- Ensure worn or damaged tools are fixed or replaced;

- Improve grip while handling slippery objects by using friction-enhanced, well-fitting gloves;

- Reduce the total time the employee spends manually gripping objects;

- Rather than have the employee spend one long period continuously gripping a tool, break the time into shorter periods.

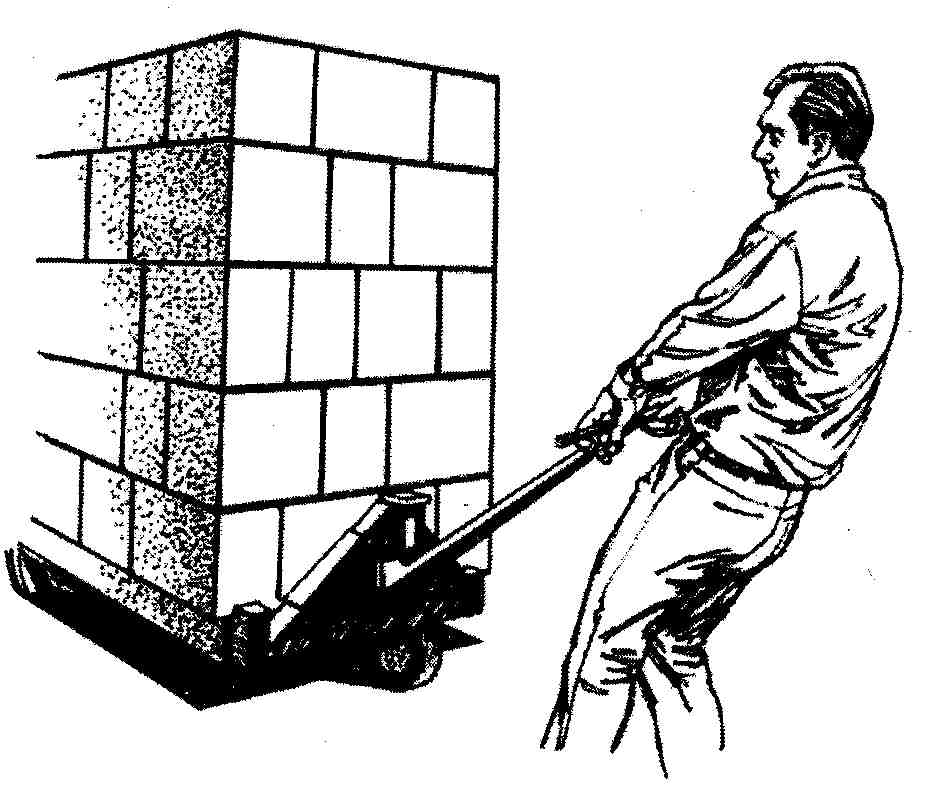

Force: Lifting, lowering or carrying objects

Eliminate the need to manually lift, lower or carry objects by using mechanical means such as cranes, hoists, pallet jacks, conveyers and carts. If this is not reasonably possible, consider options such as the following to minimize the risk to employees:

- Minimize the distance between the load and the employee by removing any obstacles between them or using a turntable;

- Use height-adjustable pallet trucks/scissor lifts to keep loads off the floor and above knee height;

- Organize the starting and ending location of the lifts to limit the overall vertical distance a load has to be lifted;

- Avoid lifts below knuckle level and above shoulder level (e.g. make sure shelf heights are not too high or too low);

- Tell employees not to lift loads heavier than 4 kg when seated; have them stand up and use larger, stronger muscles;

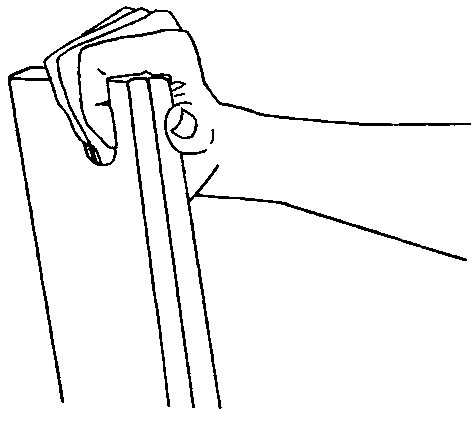

- Improve the grip/handles on objects being lifted;

- Split the overall weight of a load into smaller loads;

- Avoid handling uneven, unbalanced loads;

- Make sure the work space allows enough room for the employee to move about easily, without stooping or twisting;

- Use gravity as an assist whenever possible (lower rather than lift);

- Minimize the distance loads must be carried;

- Use carts, motorized buggies, conveyors or gravity-fed conveyors to transport loads rather than carrying them;

- Provide tools/devices to help with carrying tasks (e.g. carrying handles, extension handles);

- Train workers to assess all material handling tasks and to ensure that the path is clear of obstructions/trip hazards when carrying items;

- Do not carry objects up and down stairs if two hands are needed to hold objects; keep one hand free to hold the hand rail;

- Improve housekeeping to prevent trips and falls;

- Use shoulder pads when carrying loads on the shoulders;

- Organize the work so that physically demanding tasks are not performed continually for long periods; use job enrichment practices and pause periods to permit muscles to recover from applying force for long periods.

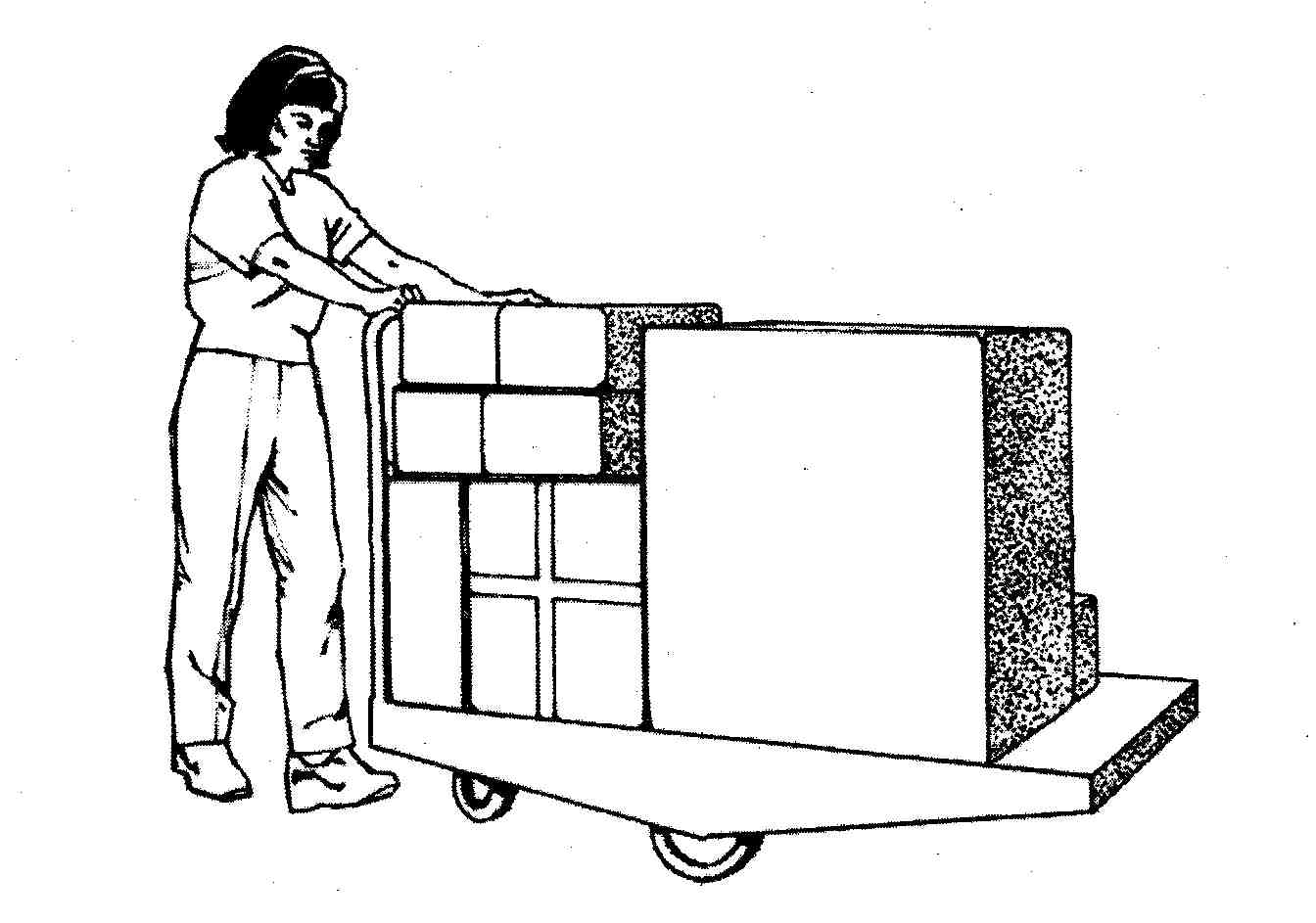

Force: Pushing and pulling

Eliminate the need to manually push or pull objects by using mechanical devices such as conveyors, cranes or gravity-fed systems. If that is not reasonably possible, consider options such as the following to minimize the risk to employees:

- Use carts that have vertical or height adjustable handles to enable different sized workers to position their hands between waist and shoulder height;

- Use larger wheels on carts and bins as this reduces push and pull forces and makes it easier to roll over cracks or holes in the floor;

- Ensure that wheels/casters are suitable for the load being transported and are compatible with the type of flooring;

- Determine the most suitable swivel arrangement of casters - 2 or 4, front or back;

- Ensure there is enough space so the worker does not have to use awkward postures to move the cart;

- Design/change the layout of the work area to eliminate the need to push wheeled objects up slopes or over uneven surfaces;

- Minimize changes in floor level in areas such as entrances to elevators;

- Ensure the flooring is smooth but not slippery, and in good condition;

- Ensure the floor is clean (no debris or clutter) and not covered with thick, plush or shag carpet;

- Ensure workers can see over the top of the cart;

- Push rather than pull carts;

- Ensure unrestricted work space so the employee can comfortably get the load moving and keep it moving;

- Maintain carts, especially wheels and wheel bearings;

- Provide brakes on carts where practical;

- Organize the work so that physically demanding tasks are not performed continually for long periods; use job enrichment practices and pause periods to permit muscles to recover from applying force for long periods.

Work posture: Fixed or awkward postures

Eliminate awkward postures through preventive measures such as having adjustable work heights, minimizing reach distances, and using proper tools, turntables, conveyors, tilted surfaces or spring-loaded surfaces. Note that even when the employee is able to work comfortably, periodic movement or changes in posture are required.

If elimination of awkward posture is not reasonably possible, consider options such as the following to minimize the risk to employees:

- Minimize awkward posture of the neck:

- Keep the monitor or objects that need to be viewed at a height that will not require tilting the head to look up or down;

- Avoid twisting the neck (e.g., using a keyboard in front and looking at a person seated to the side);

- Avoid bending the neck (e.g., to hold the telephone receiver);

- Minimize awkward posture of the shoulder:

- Reduce the need to reach forward or sideways by moving objects closer and by adjusting the work height (e.g., tilted position);

- Minimize reaching behind by moving objects to the front;

- Minimize reaching across the body by moving closer to the objects or by transferring objects from one hand to the other;

- Minimize forearm rotation by using power tools or mechanical turners;

- Minimize awkward posture of the wrist by using tools with appropriate handles (e.g., angled handles, drop down tools);

- Minimize awkward posture of the body:

- Reduce forward bending by increasing the work height or moving objects closer (i.e., improved work place layout);

- Minimize side bending by reducing the reach distance or moving objects to the front of the employee;

- Minimize twisting by improving the layout of the work area;

- Minimize squatting or kneeling by raising the task;

- Incorporate adjustability into tools and equipment:

- Have work surfaces whose height can be adjusted to suit the type of work being done (i.e., precision, light or heavy work);

- Use a tilted surface for drafting;

- Use tilted bins and bins with false bottoms for easier access inside;

- Have height adjustable chairs;

- Minimize static or fixed postures:

- Include a greater variety of tasks in the work;

- Encourage employees to move/walk around periodically;

- Use sit/stand stools and footrests at standing workstations;

- Use anti-fatigue matting for standing work areas with hard floor surfaces.

Contact stress

Eliminate or minimize exposure to contact stress:

- Change or modify equipment (e.g., use a long-handled screwdriver to prevent the butt from digging into the palm);

- Change or modify the work area to prevent sharp edges from digging into skin (e.g., pad sharp or metal edges);

- Use personal protective equipment (e.g., use knee pads while kneeling; use padded gloves when lifting heavy objects by means of narrow plastic strapping);

- Improve or change work practices to reduce resting or leaning against sharp edges;

- Avoid using body parts (e.g., palm or knee) as a hammer.

Repetition

Eliminate highly repetitious tasks by using preventive measures such as automation or mechanization (e.g., power tools). If that is not reasonably possible, consider options such as the following to minimize the risk to employees:

- Reduce the duration of exposure to repetition

(e.g., through well-designed job rotation or job enrichment); - Add different tasks to the job to increase the variety of activities;

- Include flexibility in the job so the worker can control the pace of work;

- Use a work schedule that allows for frequent changes of activity;

- Encourage employees to take micro-breaks;

- Use good work techniques and avoid unnecessary repetition.

Work environment: Cold temperatures

- Ensure employees wear high-friction, well-fitting gloves;

- Ensure employees wear clothing that keeps them warm without adding a lot of bulk;

- Ensure hand tools are stored in a warm place prior to use;

- Provide alternating periods of cold and warm work (employee rotation) and allow employees to take breaks in warm areas;

- Avoid having employees use tools that discharge cold gases over their hands;

- Provide local source heating (portable heaters) for employees;

- Educate employees about the harmful effects of cold and its influence on musculoskeletal injuries;

- Encourage employees to drink enough fluids.

Work environment: Heat and humidity

- Provide alternating periods of cool/shaded and warm work (employee rotation) and allow employees to take rest breaks in cool areas;

- Provide local source cooling (portable spot chillers) for employees;

- Educate employees about the harmful effects of heat and its influence on musculoskeletal injuries;

- Encourage employees to drink enough fluids.

Work organization and work methods

- Ensure that repetitive or demanding tasks incorporate opportunities for rest or recovery (e.g., allow brief pauses to relax muscles; change work tasks; change postures or techniques);

- Incorporate task variability so the employee does not have to perform similar repetitious tasks throughout the shift; provide the employee with the opportunity to vary work tasks by rotating jobs or increasing the scope of the job;

- Ensure that work demands and work pace are appropriate;

- Evaluate jobs to determine whether work methods are compatible with employee capabilities;

- Analyze the differences in work methods between individuals to find the best work methods;

- Ensure that the official work method is the best work method and corresponds to what employees are actually doing.