Nitrosamine impurities in medications: Guidance

Download in PDF format

(1.37 MB, 52 pages)

Organization: Health Canada

Date published: 2022-04-04

Date updated: 2025-08-01

Evaluating and managing the risks of N-nitrosamine impurities in human pharmaceutical, biological and radiopharmaceutical products

On this page

- Background

- General

- Safety

- Quality

- Appendices

- Appendix 1: Established Acceptable Intake (AI) limits for N-nitrosamine impurities

- Appendix 2: Guidance with respect to nitrosamine impurities and risk assessments for Post NOC Changes of new drug products containing chemically synthesized and semi-synthetic APIs (updated)

- Appendix 3: Enhanced Ames assay test conditions

- Appendix 4: Carcinogenic Potency Categorization Approach (CPCA) for N-nitrosamines

- Appendix 5: Bioequivalence studies for reformulated drug products (new)

Background

This guidance represents Health Canada's current thinking and recommendations on issues related to N-nitrosamine impurities (nitrosamine impurities or nitrosamines). This guidance may be subject to change as new information becomes available and if further guidance is needed for applicants and market authorization holders (MAHs).

A questions-and-answers (Q&A) document on nitrosamines was issued to MAHs on November 26, 2019. This document has undergone a number of revisions and has been further updated as a guidance document and to provide additional details to active pharmaceutical ingredient (API) manufacturers, drug product manufacturers, MAHs and importers of APIs and drug products.

In this guidance document, changes from the previous version are identified with the descriptors "new" or "updated" (as applicable). Information on a similar theme is grouped together under general headings (for example, General, Safety and Quality).

Queries about the Health Canada letters noted below can be directed as follows:

- "Information to MAHs of Human Pharmaceutical Products Regarding Nitrosamine Impurities: Request to evaluate the risk of the presence of nitrosamine impurities in human pharmaceutical products containing chemically synthesized active pharmaceutical ingredients" (October 2, 2019)

- Email to bpsenquiries@hc-sc.gc.ca

- "Information to MAHs of Human Pharmaceutical Products Regarding Nitrosamine Impurities: Request to evaluate the risk of the presence of nitrosamine impurities in biologics and radiopharmaceuticals" (December 15, 2020)

- Email to brdd.nitrosamines.dmbr@hc-sc.gc.ca

If you have queries about this guidance document, you may send an email to bpsenquiries@hc-sc.gc.ca.

General

Scope and responsibilities

1. Drug products that are within the scope of Health Canada's call for review

The request in Health Canada's call for review to evaluate the risk of the presence of nitrosamine impurities outlined in the October 2, 2019, letter applies to human pharmaceutical products with a drug identification number (DIN) containing chemically synthesized and semi-synthetic APIs. This includes:

- prescription and non-prescription (over-the-counter) drug products

- chemically synthesized excipients and raw materials used in the manufacturing of drug products

Also considered to be within the scope of Health Canada's call for review are:

- drug products that have been approved but are not yet marketed

- approved drug products with a DIN status reported as "dormant"

The request for conducting risk assessments for the potential presence of nitrosamine impurities was extended to all biological and radiopharmaceutical products for human use. This was outlined in Health Canada's letter dated December 15, 2020.

All human plasma proteins, vaccines and cell-based fermentation products are classified as biologics. They are, therefore, within the scope of the request for risk assessment.

Please refer to Health Canada's letter dated December 15, 2020, for further details.

All non-prescription products with a DIN, such as topical antiseptic products, grooming and personal hygiene products and sunscreens, are within the scope of products for assessment if they contain a chemically synthesized or semi-synthetic API. This is irrespective of the route of administration or any cosmetic properties.

Products that are not within the scope of the October 2, 2019, and December 15, 2020, letters include cosmetics (which do not have a DIN). The following categories of drug products are also excluded at this time: antimicrobial agents, veterinary products (including veterinary health products) and natural health products. Disinfectant products for use on hard surfaces are also not within the scope of products for assessment at this time.

2. Timelines for completing risk assessments (Step 1), confirmatory testing (Step 2) and changes to the market authorization (Step 3) (updated)

For drug products containing chemically synthesized and semi-synthetic APIs, the steps for actions relating to nitrosamines are expected to be completed as follows:

- Step 1: risk assessments by March 31, 2021

- Step 2: confirmatory testing by October 1, 2022

- Step 3: changes to the market authorization by August 1, 2025

For biological and radiopharmaceutical products, the steps for actions relating to nitrosamines are expected to be completed as follows:

- Step 1: risk assessments by November 30, 2021

- Step 2: confirmatory testing by November 30, 2023

- Step 3: changes to the market authorization by August 1, 2025

The following sets out Health Canada's expectations for MAHs regarding submitting and implementing necessary changes to their market authorizations effective August 1, 2025:

- For those nitrosamine impurities with an established Acceptable Intake (AI) limit published in Appendix 1 of this guidance document prior to August 1, 2025, MAHs are permitted to have a Corrective and Preventative Action (CAPA) implementation timeline of up to 3 years from August 1, 2025 (i.e., up to August 1, 2028).

- For those nitrosamine impurities with an established AI limit published in Appendix 1 on August 1, 2025 or later, MAHs are permitted to have a CAPA implementation timeline of up to 3 years from the publication date of the AI limit.

- The applicable publication dates of AI limits can be obtained from Appendix 1.

- Considering the risk profiles of nitrosamines and the possibility of an additive biological effect, the AI limits published in Appendix 1 are considered appropriate by Health Canada for lifetime and less-than-life (LTL) administration of a drug product, including during the 3 year CAPA implementation timeline. (i.e., LTL-based AI limits are not to be applied during or after 3 year CAPA implementation timeline).

It should be noted that despite the 3 year CAPA implementation timeline, it is Health Canada's expectations that MAHs implement risk mitigation measures to reduce the levels of nitrosamine impurities to below the AI limits as soon as possible.

3. Outcomes of risk assessments (Step 1) and what is provided to Health Canada

Risk assessment documentation should be retained by the MAH, unless nitrosamine impurities are detected in the API, drug product or both during confirmatory testing. Following the completion of confirmatory testing of the drug product, Health Canada must be informed if the nitrosamine impurity is detected above the established Acceptable Intake (AI) limit (refer to Appendix 1 for a listing of established AIs) for the nitrosamine impurity in question, or above the AI limit established using the Carcinogenic Potency Categorization Approach (CPCA) (refer to number 24 and Appendix 4) if an AI limit has not been established by Health Canada. The confirmatory testing results should be submitted at the same time that Health Canada is informed of the detection and the details of the risk assessment should be available upon request. Refer to the information in number 15.

For nitrosamine impurities listed in Appendix 1 that are classified as non-mutagenic, the submission of the risk assessment and confirmatory testing results is not required, and these impurities should be controlled according to ICH's Q3A and Q3B guidelines.

Please note that Health Canada may request to review the MAH's risk assessment for all products and will request this information directly from the MAH, as necessary.

Canadian importers that received terms and conditions (T&C) on their drug establishment licence (DEL) for nitrosamine testing of angiotensin II receptor blockers (also known as sartans) may provide supporting information to modify or remove the terms and conditions. They should submit the API and drug product risk assessments and testing results completed as per Steps 1 and 2 for consideration. Email to foreign.site-etranger@hc-sc.gc.ca.

MAHs may be requested by Canadian importers for a copy of the MAH's risk assessment and testing results to facilitate this request. Alternatively, MAHs may provide the requested risk assessment and related information to Health Canada on behalf of the Canadian importer. In this case, the MAH should specify on whose behalf the risk assessment and related information is being submitted.

4. Determining the priorities and order in which products should be reviewed

MAHs should use a risk-based approach to determine the order in which their drug products are reviewed. In order to prioritize the sequence in which products should be reviewed, MAHs should consider a number of factors, including the following:

- principles set out in the International Council for Harmonisation of Technical Requirements for Pharmaceuticals for Human Use (ICH) Q9 guideline on quality risk management

- maximum daily dose of the drug product

- route of administration

- duration of use

- indication and consideration of special populations, such as pregnant women and children

- toxicological profile of the API

- for example, evaluating the risk of presence of nitrosamine impurities in cancer therapies in which the API is a potent mutagen could be considered lower priority and sequenced for review after higher priority APIs

- market considerations such as the availability of product for sale on the Canadian market and number of patients being treated with the drug product

- emerging international or domestic information that 1 or more nitrosamine impurities has been identified in an API (or a structurally similar API) or drug product

- the presence of structural elements in the API or conditions in the manufacturing and packaging processes for the API or drug product, which are conducive to nitrosamine formation (for example, presence of secondary or tertiary amine groups in the API)

Appendix 1 should be consulted for APIs and drug products that may contain nitrosamine impurities. Peer-reviewed literature (for example, M.K. Parr, J.F. Joseph, Journal of Pharmaceutical and Biomedical Analysis 164 (2019) 536–549) and other sources of information (for example, regulatory communications) should also be consulted for APIs and drug products known to contain nitrosamine impurities.

5. MAHs co-operating with API and drug product manufacturers to perform risk assessments

After receiving authorization to market in Canada, MAHs are responsible for the safety, efficacy and quality of their drug products and for carrying out the risk assessments. They should:

- work with API and drug product manufacturers to review their API and drug product manufacturing processes to conduct risk assessments

- take into account the API and drug product manufacturers' knowledge of the manufacturing processes, potential sources of contamination and other root causes of the formation and presence of nitrosamine impurities

API and drug product manufacturers should make available to the MAHs the information necessary for conducting the risk assessments.

If the risk of nitrosamine impurity formation has been assessed during the development phase of the API or drug product manufacturing processes, the information from the assessment can be used to support the evaluation.

6. Responsibilities of API manufacturers, excipient manufacturers, drug product manufacturers, MAHs and importers

After receiving authorization, MAHs are responsible for ensuring the ongoing safety, efficacy and quality of drug products on the Canadian market. This would include implementing an ongoing monitoring program to detect trends in quality. Such a program should be based on appropriate controls for raw materials, all processing steps, critical process parameters and critical quality attributes.

To complete risk assessments for the potential presence of nitrosamine impurities, MAHs should complete robust risk evaluations using a holistic approach. A detailed assessment of all stages of the product's life cycle should be done and would include an evaluation of the risk factors and potential root causes for the presence of nitrosamines, including those identified in number 29.

MAHs are responsible for ensuring that personnel with acceptable qualifications and expertise (for example, relevant training, knowledge and practical experience) have conducted the risk assessments. Information should be made available to the MAH by API, excipient and drug product manufacturers.

In the context of control for nitrosamine impurities, manufacturers and importers must comply with any terms and conditions specified on their DEL. This could include restrictions or additional specific testing and investigational requirements for nitrosamine impurities.

7. Inability to meet specified timelines for risk assessment (Step 1), confirmatory testing (Step 2) or changes to the market authorization (Step 3)

Given the potential risks associated with nitrosamines in drug products, MAHs should take all necessary measures to complete the 3 steps as soon as possible and within the designated timelines.

In a follow-up letter issued to MAHs of drug products containing chemically synthesized active pharmaceutical ingredients on April 14, 2021, Health Canada requested that affected MAHs indicate their status for completing Step 1, risk assessments. MAHs should provide a completed Annex 1, Annex 2 or Annex 3, as applicable, as per the instructions in the April 14, 2021, follow-up letter. If risk assessments have not been completed for all marketed, approved and dormant products or have been partially completed, Annex 3 should be completed.

MAHs unable to meet the Step 2 or 3 deadlines due to exceptional circumstances may submit a request for extension to Health Canada. This should be done as soon as possible. The request should contain relevant information, including the progress to date, the reasons for not meeting the deadline(s), the remaining work and the expected timelines for completion.

To prioritize APIs and drug products for the completion of risk assessments, confirmatory testing or changes to the market authorization, MAHs are reminded to use quality risk management principles. Consult ICH's Q9 guideline, Health Canada's good manufacturing practices (GMP) guides 0001 (for drug products) and 0104 (for APIs). Also consult the information in number 4.

Requests for extensions will be considered on a case-by-case basis. Direct such requests as follows:

- for drug products containing chemically synthesized or semi-synthetic APIs: bpsenquiries@hc-sc.gc.ca

- for biological and radiopharmaceutical products: brdd.nitrosamines.dmbr@hc-sc.gc.ca

8. Statements or declarations by manufacturers and suppliers in lieu of completing risk assessments

Statements and declarations provided by manufacturers and/or suppliers are not a substitute for an overall robust risk assessment by the MAH. While the knowledge and expertise offered by manufacturers is valuable and is encouraged to support the risk assessment process, manufacturer/supplier statements or declarations do not replace a documented risk assessment by the MAH.

9. Skipping the risk assessment step (Step 1) and proceeding directly to confirmatory testing (Step 2)

The risk assessment step (Step 1) is necessary to identify risk factors, possible root causes and the scope of nitrosamine impurities that have the potential to be formed or introduced into the API or drug product. If a risk of 1 or more nitrosamine impurities is identified, this knowledge is used to guide the development and validation of appropriate test methods required for the confirmatory testing stage (Step 2).

This knowledge may also be useful for the establishment of a suitable control strategy and changes introduced to prevent the presence of nitrosamines.

As such, it is not appropriate to proceed directly to confirmatory testing (Step 2) without completing the risk assessment step (Step 1).

10. Applying the results of a risk assessment and confirmatory testing for a drug product marketed outside Canada to a drug product authorized for sale in Canada

MAHs are responsible for ensuring that risk assessments and, if applicable, confirmatory testing are relevant to the drug product authorized for sale in Canada.

If a risk assessment and confirmatory testing have been completed for a drug product approved for use outside Canada, it may be possible to use that information for the risk assessment and confirmatory testing of the drug product authorized for sale in Canada. In this scenario, the 2 drug products must be identical (for example, composition, strength, manufacturing process, API and excipient sources, manufacturing sites).

MAHs should prepare a written justification when the risk assessment and confirmatory testing results of a foreign product will be relied upon. MAHs should be prepared to provide this justification to Health Canada upon request. This justification should be included in communications to Health Canada if nitrosamine impurities are detected in the drug product following confirmatory testing where the nitrosamine impurity is detected above the established AI limit (refer to Appendix 1) for the nitrosamine impurity in question, or above the AI limit established using the CPCA (refer to number 24 and Appendix 4) if an AI limit has not been established by Health Canada. Refer to the information in number 15.

11. Nitrosamine risk assessment applicable to a drug product brought into Canada under the Special Access Program (SAP)

Companies may need to conduct nitrosamine risk assessments for drug products not authorized for sale in Canada that are being made available in Canada through the SAP. Refer to the approaches described in Health Canada's October 2, 2019, and December 15, 2020, letters and in this document.

If the nitrosamine risk assessment or confirmatory testing results (if applicable) indicate the risk of presence of a nitrosamine impurity, notify the SAP by email at sapd-pasm@hc-sc.gc.ca.

To protect the health and safety of patients accessing unauthorized drug products, significant new information on the safety, efficacy and quality of drug products released under the SAP should be made available to practitioners and the SAP.

12. Confirmatory testing where the risk assessment concludes there is no identified risk for the presence of nitrosamines or where nitrosamine impurities can be controlled according to the ICH Q3A and Q3B guidelines (updated)

MAHs are expected to conduct a thorough, robust risk assessment for the potential formation or presence of nitrosamine impurities. In Health Canada's letters dated October 2, 2019, and December 15, 2020, Health Canada shared some potential sources of nitrosamine impurities. Refer to number 29 for more information on risk factors and potential root causes for nitrosamine impurities.

MAHs should prepare a report that includes considerations, steps, conclusions and a rationale. The report should clearly identify which nitrosamine(s) is (are) at risk of formation, if applicable. If it is concluded that a risk for the presence of nitrosamines is not identified, then confirmatory testing is not expected.

If a risk of formation or presence of nitrosamines is identified, confirmatory testing should be carried out using appropriately validated and sensitive methods (refer to number 36). Following the completion of confirmatory testing of the drug product, Health Canada must be informed if the nitrosamine impurity is detected above the AI limit established by Health Canada or above the AI limit established using the CPCA (refer to number 24 and Appendix 4) if an AI limit has not been established by Health Canada. The reporting addresses are provided in number 15.

For nitrosamine impurities that can be controlled according to the ICH Q3A and Q3B guidelines (for example, refer to number 3 and number 25), confirmatory testing is generally not expected if their risk of presence can be sufficiently mitigated based on scientific considerations that demonstrate the relevant ICH Q3A and Q3B thresholds will not be exceeded. In such cases, the scientific justification should be documented in the risk assessment and controlled by the MAH's pharmaceutical quality system.

13. Managing and submitting Step 3 changes to the market authorization relating to risk mitigation measures (updated)

Step 3 changes to the market authorization relating to risk mitigation measures should be submitted to Health Canada in a timely manner in eCTD or non-eCTD format using the Common Electronic Submission Gateway (CESG).

Step 3 risk mitigation related changes are the result of potential safety concerns and therefore require Health Canada's critical review of scientific data and subsequent authorization prior to implementation by the manufacturer. Therefore, with the exception of certain minor changes (see further details described below in this section), Step 3 risk mitigation related changes for drug products containing chemically synthesized and semi-synthetic APIs should be submitted as Level I - Supplements or Post-Drug Identification Number (DIN) Change submissions, as applicable. For biological and radiopharmaceutical products, changes should be submitted as Level I – Supplements or Level II - Notifiable Changes, or Post-Drug Identification Number (DIN) Change submissions (PDCs), as applicable. For examples of risk mitigation related changes, refer to number 20 and Appendix 2.

When filing a Supplement, Notifiable Change or Post-DIN Change submission for the market authorization, applicants should clearly indicate in the covering letter that the proposed changes are being submitted to address risk mitigation for nitrosamines (Step 3 of Health Canada's call for review to evaluate the risk of the presence of nitrosamine impurities in approved drug products).

A summary of the root cause investigations and the conclusion regarding the confirmed root causes(s) for nitrosamine presence in the drug product should be included under section 3.2.P.2.

Where a proposal is made to add individual or cumulative nitrosamine AI limits to an approved drug substance or drug product specification (based on the use of the CPCA or other approaches), MAHs should manage these changes as Level I – Supplements.

For proposed changes unrelated to Step 3 of the call for review of approved drug products (that is, changes unrelated to risk mitigation for approved drug products), changes should be managed and, where applicable, submitted according to the Post-Notice of Compliance (NOC) Quality Document and Post-Drug Identification Number (DIN) Changes Guidance Document. Refer to number 20 and Appendix 2.

For drug products containing chemically synthesized or semi-synthetic APIs, where AI limits for individual nitrosamine impurities and, where relevant, limits for cumulative levels of nitrosamine impurities, had previously been included in an approved drug substance or drug product specification based on the approval of an application for market authorization, the following changes can be managed according to Health Canada's Post-Notice of Compliance (NOC) Quality Document as Level III changes (Annual Notifications):

- tightening of individual or cumulative nitrosamine AI limits in the approved drug substance or drug product specifications

- relaxation of individual or cumulative AI limits in the approved drug substance or drug product specifications to adopt AI limits listed in Appendix 1 of this guidance document

- deletion of a test for a nitrosamine impurity from a drug substance or drug product specification, with appropriate scientific justification

In addition, the following changes can be managed according to Health Canada's Post-Notice of Compliance (NOC) Quality Document as Level III changes (Annual Notifications):

- addition of a test and acceptance criteria to a drug substance specification for a nitrosamine impurity that is based on a valid Certificate of Suitability (CEP) issued by the European Directorate of Quality of Medicines and HealthCare (EDQM)

- addition of a test and acceptance criteria to a drug substance or drug product specification for a nitrosamine impurity that has been classified as non-mutagenic in Appendix 1

Where a proposal is made to relax individual or cumulative nitrosamine AI limits already included in an approved drug substance or drug product specification (based on the use of the CPCA or other approaches) when an AI limit is not listed in Appendix 1, MAHs should manage these changes as Level I – Supplements.

Bioequivalence studies for reformulated drug products

Reformulation of drug products to include nitrosamine suppressing agents, such as antioxidants and pH modifiers, is one potential strategy to reduce or prevent the formation and presence of nitrosamine impurities. Refer to Appendix 5 for recommendations regarding bioequivalence studies for reformulated drug products.

14. Selling a drug product if changes (specifications, controls) to the market authorization (Step 3) submitted as a Supplement, Notifiable Change or Post-DIN Change submission are still under review

The ongoing marketing of a drug product depends on the impurity levels and the risk of nitrosamine impurities that are detected upon notification to Health Canada. Some of the outcomes of the Health Canada assessment may include recalls or stop sale requests until the risks are mitigated and suitable corrective and preventive actions are in place to ensure that all lots being released to market meet the acceptance criteria for each nitrosamine impurity (and multiple nitrosamines, if relevant). Both outcomes would affect the ongoing marketing of the drug product while the Supplement, Notifiable Change, or Post-DIN Change submission is being reviewed. Refer to the information in number 13.

15. Contacting Health Canada if nitrosamine impurities are detected following the completion of confirmatory testing (updated)

Following the completion of confirmatory testing of the drug product, MAHs must inform Health Canada if nitrosamine impurities are detected above the established AI limit (refer to Appendix 1) for the nitrosamine impurity in question, or above the AI limit established using the CPCA (refer to number 24 and Appendix 4) if an AI limit has not been established by Health Canada. The confirmatory testing results should accompany the notification to Health Canada by the MAHs.

Health Canada recognizes the challenges faced by MAHs to decrease levels of nitrosamine impurities in their drug products while maintaining drug supply to Canadians. To minimize the impacts on drug supply within the Canadian market, MAHs are requested to engage Health Canada prior to taking any market action for a drug product due to a nitrosamine impurity issue.

Communications should be directed as follows:

| Location of firm | Reporting address |

|---|---|

| New Brunswick, Newfoundland and Labrador, Nova Scotia, Prince Edward Island, Québec | Health Product Compliance Unit East |

| Ontario | Health Product Compliance Unit Central |

| Manitoba, Saskatchewan, Alberta, British Columbia, Yukon, Northwest Territories, Nunavut | Health Product Compliance Unit West |

If nitrosamines are not detected during confirmatory testing (for example, less than the appropriate limit of detection of the validated test method) or are detected below the established AI limit for the nitrosamine impurity in question or the AI limit established using the CPCA (refer to number 24 and Appendix 4) if an AI limit has not been established by Health Canada, MAHs do not need to communicate this information to Health Canada. However, they should keep the risk assessment, analytical testing results and analytical method validation documentation on hand in case Health Canada requests them. Refer to number 13 for information on communicating changes to market authorization to Health Canada.

16. When information necessary to complete risk assessments is not provided by the API or drug product manufacturer

MAHs are responsible for ensuring the ongoing safety, efficacy and quality of products on the Canadian market. When manufacturers do not provide information that is essential for MAHs to complete the risk assessment due to confidentiality or other reasons, MAHs may engage a third party (such as a consultant) to work directly with the manufacturer to complete the risk assessment.

The third-party approach may also be appropriate when the MAH:

- has all of the required information to conduct the risk assessment from the manufacturer but

- does not have staff with the necessary qualifications (for example, relevant training and practical experience) to conduct the risk assessment

For additional guidance on outsourced activities, consult the:

Alternatively, MAHs should consider delegating the risk assessment to the API and drug product manufacturers. In this scenario, MAHs would continue to be responsible for ensuring the safety, efficacy and quality of their drug products.

MAHs should ensure through internal or third-party audit that:

- risk assessments have been conducted by personnel with acceptable qualifications (relevant training and practical experience)

- manufacturers have considered all possible risk factors and potential root causes of nitrosamine impurities (including those in the December 15, 2020, letter concerning biological and radiopharmaceutical products, and those identified in number 29)

17. Additional expectations of MAHs if nitrosamine impurities are detected in the API and/or drug product (updated)

Where 1 or more nitrosamine impurities are detected following the completion of confirmatory testing (for multiple nitrosamines, refer to number 27), in addition to notifying Health Canada (refer to number 15 for detailed guidance on when to notify), MAHs should have completed or be completing as necessary:

- a health risk assessment posed by the presence of the nitrosamine(s) along with intentions related to any actions, as necessary, for the batches on the Canadian market

- where product recalls are warranted, consult the Drugs and Natural Health Products Recall Guide (GUI-0039) for procedures

- an assessment to determine if the product is considered to be medically necessary or medically important and if any disruption to product supply is expected should market action be taken

- a detailed investigation report assessing all possible root causes of the detected nitrosamine impurity (or impurities) and describing corrective and preventive actions

- perform investigations in accordance with written procedures

- evaluate all potential changes to facilities, materials, equipment and/or process intended to reduce the levels of the nitrosamine impurities through a formal change control system

- a risk mitigation plan including the establishment of a suitable control strategy for detected nitrosamine(s) to ensure that, moving forward, nitrosamine impurity levels will be consistently below the Acceptable Intake (AI) limit at the end of the retest period for the API or the shelf-life for the drug product. Refer to Appendix 1 for a list of established AI limits. These AI limits are considered qualified for nitrosamine impurities in the drug product at the end of shelf life. In some cases, tighter limits in the API specifications and in the drug product release specifications may be warranted to ensure that the drug product shelf life specification will be met.

MAHs are reminded to submit changes to the market authorization as per Step 3 of the October 2, 2019 letter. Refer to number 13 on how changes should be submitted.

Health Canada may use such notifications to request additional actions and/or information. For example, the origin of nitrosamine impurities may be attributed to the type of process chemistry used and the risk mitigation plan may necessitate the establishment of a control strategy by manufacturers for each detected nitrosamine impurity according to ICH's M7 guideline.

We may request additional actions by other MAHs of the same products to mitigate any risks identified and protect people's health and safety if necessary.

For more information on the establishment of specifications and controls, refer to number 34 and number 35, respectively.

18. Assessing progress with the request to review the risk of presence of nitrosamine impurities

On April 14, 2021, Health Canada issued a follow-up letter to the October 2, 2019, letter. In the letter, we asked MAHs with drug products containing chemically synthesized and semi-synthetic APIs to provide their progress towards completing Step 1 (risk assessments).

Health Canada may also:

- verify progress, adequacy and robustness of the risk assessments, confirmatory testing results and any other supporting documents related to this request during GMP inspections, proactive risk management projects and compliance verification upon receipt of a complaint and/or notification or

- request information at such time as changes are made to either the existing market authorization for a product or for the drug establishment licence

We appreciate the significance of this request. We will continue to engage with stakeholders to consider all options to address the potential risks associated with nitrosamines.

19. Approach for drug products that are planned for submission or are already filed with Health Canada

Whenever possible for APIs and drug products that are under development, the formation or introduction of nitrosamine impurities should be avoided at the outset.

If the formation or introduction of nitrosamine impurities is unavoidable, manufacturing processes should demonstrate process capability to routinely reduce the levels of nitrosamine impurities below the AI limit. A control strategy, based on product and process understanding, should be established for each nitrosamine impurity present in the API and/or drug product.

For drug products that are planned for submission or have already been submitted, MAHs and applicants should proactively undertake a risk assessment for the potential presence of nitrosamine impurities in the drug product (if this has not already been undertaken) using the considerations and steps provided for approved products in Health Canada's communications. For planned submissions, the relevant sections of the Common Technical Document (CTD) in the drug application should include information on these risk assessments.

A summary and discussion of the risk assessment for nitrosamine impurities in the drug product should be placed in section 3.2.P.2 of the CTD. This summary is expected to include sufficient detail to allow Health Canada to assess the adequacy and robustness of the risk assessment. Expectations for the content of the summary and discussion of risk assessments are found under number 20.

Confirmatory testing results and the updated control strategy (where warranted) should also be included in the drug application (for example, under sections 3.2.S.2, 3.2.S.4, 3.2.S.7, 3.2.P.3, 3.2.P.4, 3.2.P.5, 3.2.P.8).

For submitted applications currently under review, MAHs and applicants may be asked to provide the risk assessment and confirmatory testing results as part of the assessment procedure. For further information, refer to number 20.

20. Risk assessments for the potential presence of nitrosamine impurities as part of the expected content for new submissions (updated)

Risk assessments for the potential presence of nitrosamine impurities should be conducted routinely during API and drug product development. The outcome of the risk assessment for nitrosamine impurities in the drug product and the justification for the proposed control strategy for nitrosamine impurities should be made available for assessment in New Drug Submissions (NDSs), Abbreviated New Drug Submissions (ANDSs), applications for a Drug Identification Number for a Pharmaceutical Product (DINAs) (with Chemistry & Manufacturing (C&M) data), applications for a Drug Identification Number for a Biological Product (DINBs), Supplements, Notifiable Changes and Post-DIN Changes submissions (refer to number 13). For more information on mutagenic impurity considerations and quality risk management principles, consult the following:

- Good Manufacturing Practices Guide for Drug Products (GUI-0001)

- Good Manufacturing Practices Guidelines (GMP) for Active Pharmaceutical Ingredients (GUI-0104)

- ICH's M7 guideline (PDF format)

- ICH's Q9 guideline (PDF format)

All NDSs, ANDSs, DINAs (with C&M data), DINBs, and as detailed below, certain Supplements, Notifiable Changes and Post-DIN Change submissions (for quality changes that may increase the risk of presence of nitrosamine impurities relative to the approved drug product) should include a summary and discussion of the risk assessment for the potential presence of nitrosamine impurities in the drug product.

For Supplements, Notifiable Changes and Post-DIN Change submissions where the quality changes do not increase the risk of presence of nitrosamine impurities relative to the approved drug product (for example, the addition of a proportionally-formulated strength), a summary and discussion of the risk assessment for the potential presence of nitrosamine impurities in the drug product is not expected to be provided in the drug submission. This approach is taken as the potential nitrosamine-related risks for the approved drug product are expected to be addressed and managed under Health Canada's call for review. In such cases, a brief justification for the conclusion that there will be no increased risk for nitrosamine presence relative to the approved drug product as a result of the proposed changes should be provided, for example, in the Notes to Reviewer or in Sections P.2 or P.5 of the drug submission.

This is required as follows:

- as of April 1, 2021, for NDSs, ANDSs, and Supplements for pharmaceutical products containing chemically synthesized and semi-synthetic APIs

- as of April 1, 2021, for DINAs (with C&M data) including Post-DIN Change Submissions for quality changes for pharmaceutical products containing chemically synthesized and semi-synthetic APIs

- as of November 30, 2021, for NDSs, Supplements and Notifiable Changes for biological and radiopharmaceutical products

- as of November 30, 2021, for DINBs and Post-DIN Change (PDC) submissions for biological and radiopharmaceutical products

The summary and discussion of the risk assessment for the drug product is expected to include sufficient detail to allow Health Canada to assess the adequacy and robustness of the risk assessment. It should include a discussion of the risk factors and potential root causes considered in relation to specific knowledge of the drug product and its components (including the API). Checklists lacking sufficient discussion and detail should be avoided. The summary and discussion should include the following:

- identification of any third parties (for example, suppliers, manufacturers, consultants) who have been authorized to perform the risk assessment on behalf of the applicant

- identification of intrinsic and extrinsic risk factors related to formation or introduction of nitrosamine impurities originating from all drug product components as well as quality/compliance considerations

- identification of those nitrosamines potentially formed and/or introduced

- information on the established process and/or analytical controls and how they may mitigate risk

- supporting scientific data (for example, confirmatory testing results) and calculations

- an overall conclusion on the risk of presence of nitrosamines in the drug product together with an appropriate scientific rationale/justification

For certain Supplements, Notifiable Changes and Post-DIN Change submissions (for quality changes that may increase the risk of presence of nitrosamine impurities relative to the approved drug product), the summary and discussion of the risk assessment need only address the impact of the proposed change(s) on nitrosamine impurities relative to the approved drug product. Examples of changes that may impact the potential presence of nitrosamine impurities relative to an approved drug product include, but are not limited to, changes in drug substance or drug product manufacturing processes, changes to the drug product composition (API, excipients), introduction of a new dosage form, and changes to the container closure system.

Refer to Appendix 2 for additional guidance with respect to nitrosamine impurities and risk assessments for Post NOC Changes of new drug products containing chemically synthesized and semi-synthetic APIs.

For Clinical Trial Applications (CTAs) (as described in section 9.1 of ICH's M7 guideline):

- For Phase 1 clinical trials of 14 days or less, include a description of efforts to mitigate risks of mutagenic impurities focused on Class 1 and Class 2 impurities and those in the cohort of concern (for example, nitrosamine impurities).

- For Phase 1 clinical trials greater than 14 days and for Phase 2 and 3 clinical trials, also include Class 3 impurities that require analytical controls.

Failure to include this information could result in requests for additional information, delays in the review process, and potentially the issuance of negative decisions.

21. Controls for nitrosamines in APIs purchased for compounding

The Policy on Manufacturing and Compounding Drug Products in Canada (POL-0051) provides a policy framework to help distinguish between compounding and manufacturing activities of drug products in Canada. In Canada, the compounding of drugs is done mainly by pharmacists as an integral part of their profession. It's regulated by the respective regulatory authorities in each province/territory.

This policy indicates that compounded products should be either:

- produced from an authorized API used in an authorized drug product for use in Canada or

- listed in a recognized Pharmacopoeia (for example, USP/NF, Ph. Eur., Ph. Int., BP, Codex - Schedule B, Food and Drugs Act)

Health Canada recommends, therefore, that principles outlined in the October 2, 2019, letter and in this guidance should be considered when purchasing APIs and producing compounded products.

Health care professionals and compounding firms are encouraged to access the nitrosamines webpage to stay informed on product recalls due to the presence of nitrosamines. This page is updated regularly and also includes general information on nitrosamine impurities, and what Health Canada is doing to address the issues.

Communications

22. Engaging stakeholders and ensuring ongoing communication with industry

Health Canada is committed to sharing information with stakeholders and maintaining transparency as we continue to analyze and better understand this evolving, global situation.

To date, we have shared information openly with stakeholders, including information on the potential sources of nitrosamine impurities, root causes, risk factors and new findings. We hosted stakeholder sessions in January 2020, February 2021 and October 2021, and may host more sessions in the future if necessary.

We also established a dedicated webpage on nitrosamine impurities in medications. The webpage includes the following:

- summaries of drug products that have been affected or recalled due to the presence of nitrosamines

- analytical testing results of several products for levels of nitrosamine impurities

Discussions are ongoing to determine the most appropriate and effective methods to continue to engage stakeholders as new information becomes available to ensure a coordinated and consistent approach in dealing with this complex issue.

23. Health Canada works with global regulators relating to issues associated with nitrosamine impurities in drug products

Health Canada regularly collaborates with international regulatory partners, including those in Europe, the United States, Japan, Switzerland, Singapore, Australia and Brazil, as well as the World Health Organization. Through collaboration, we hope to increase the understanding of the issues associated with nitrosamine impurities, align requirements and actions as appropriate, and share information under the terms of our confidentiality agreements.

Discussions amongst the consortium of regulatory authorities continued, with the "Nitrosamines International Strategic Group" (NISG), which was formed in 2018. The NISG began meeting regularly with a focus on knowledge sharing on market and other regulatory actions. Due to a mutual interest of the participating regulatory agencies of the NISG to have greater in-depth discussions on technical issues and scientific developments, a sub-group of the same regulators, the "Nitrosamines International Technical Working Group" (NITWG), was established in late 2020.

When determining appropriate regulatory measures to address the presence of nitrosamine impurities that exceed the AI limit in human drug products, individual jurisdictions must determine timelines and actions that will best protect patient safety and work within the relevant regulatory framework.

Safety

24. AI limits for nitrosamine impurities that Health Canada considers acceptable

AI limits have been derived for several nitrosamines (Appendix 1). These AI limits are considered appropriate for all routes of administration and should be applied to the maximum daily dose (MDD) of the drug product.

AI limits can be established using several approaches.

In cases where there is reliable compound-specific data for a nitrosamine impurity, MAHs and applicants may:

Establish an AI limit based on reliable compound-specific data

- Linearly extrapolate from the dose giving a 50% tumour incidence (TD50) to a 1 in 105 excess cancer risk, using the most relevant TD50 value from a sufficiently robust carcinogenicity study (refer to ICH's M7 Addendum for guidance on selecting an appropriate carcinogenicity study).

- Provide a negative, GLP-compliant, enhanced Ames test using the enhanced Ames test conditions described in Appendix 3 to justify a limit of 1.5 µg/day.

- Provide negative in vivo mutagenicity data (for example, a negative in vivo mutagenicity assay conducted per the Organisation for Economic Co-operation and Development (OECD)'s Test Guideline No. 488 "Transgenic Rodent Somatic and Germ Cell Gene Mutation Assays") to justify controlling a nitrosamine impurity per the recommendations in ICH's Q3A and Q3B guidelines.

In cases where there is insufficient reliable compound-specific data available for a nitrosamine impurity, MAHs and applicants may:

Establish an AI limit based on a structure-activity relationship (SAR) assessment and read-across to a surrogate with sufficient compound-specific data

To justify an appropriate surrogate for read-across, the SAR assessment should take into consideration structural similarity (both overall and at the local site of activation), similarity of physicochemical characteristics, steric and electronic factors impacting reactivity and metabolic similarity (for example, metabolic pathway, stability/reactivity of metabolites).

If an appropriate surrogate for read-across is identified, to calculate an AI limit, the TD50 should be derived from a sufficiently robust carcinogenicity study. Parameters to consider include adequate description of the study design and appropriate histopathological analysis, number of dose groups (i.e., single-dose studies are not considered appropriate), number of animals per dose group, duration of exposure, route of administration, observed dose-response relationship. Refer to ICH's M7 Addendum for guidance on selecting an appropriate carcinogenicity study.

Alternatively, in cases where an acceptable surrogate for read-across may be controlled to a limit as per the recommendations in ICH's Q3A and Q3B guidelines (when indicated in Appendix 1), this limit can be applied to the nitrosamine impurity.

Consistent with international regulatory practices, Health Canada will continue to use, and expect applicants and MAHs to use, mass-based calculations (rather than molar-based) to derive AI limits for nitrosamine impurities when a surrogate is selected for read-across.

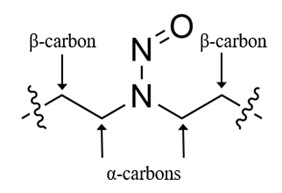

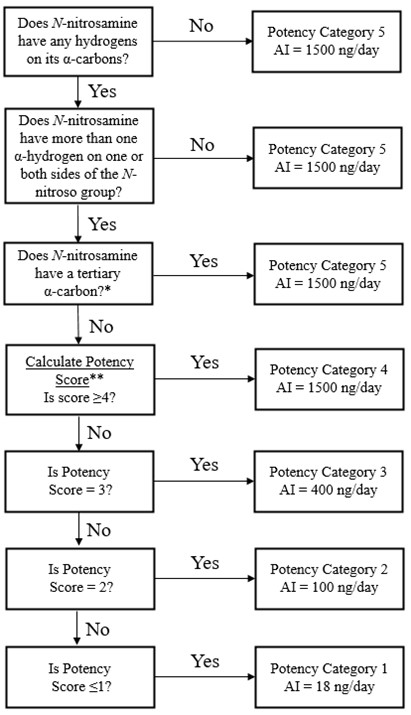

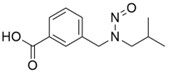

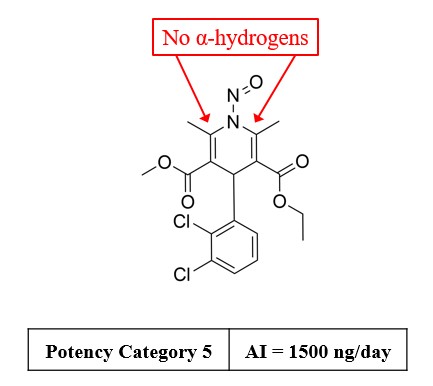

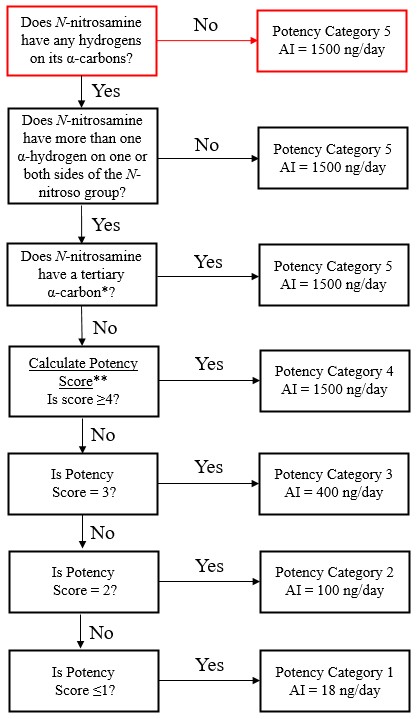

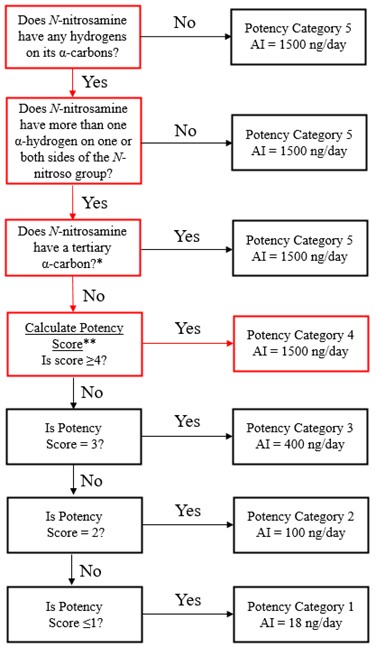

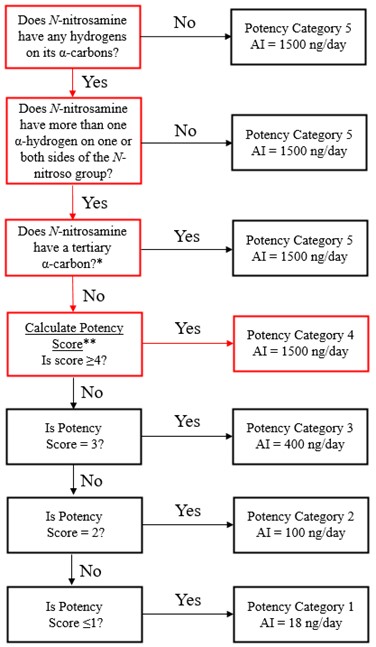

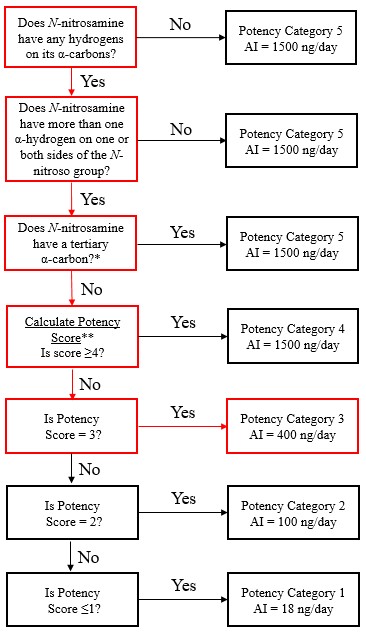

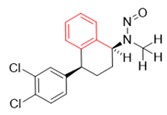

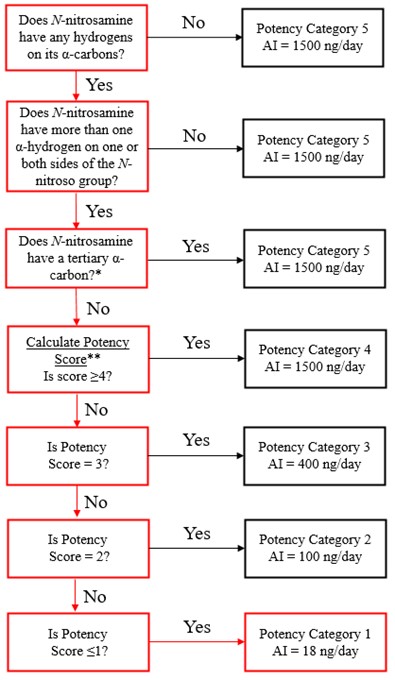

Establish an AI limit using the Carcinogenic Potency Categorization Approach (CPCA)

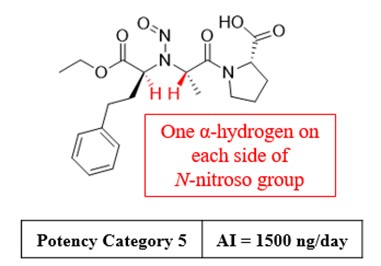

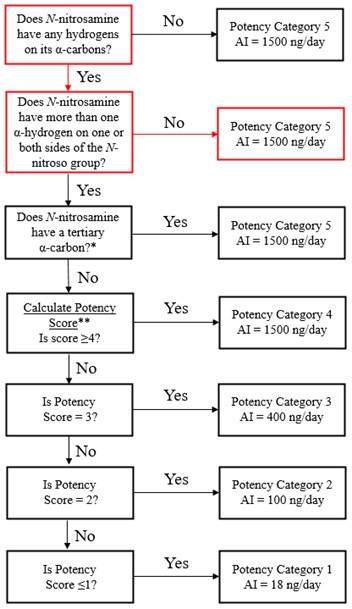

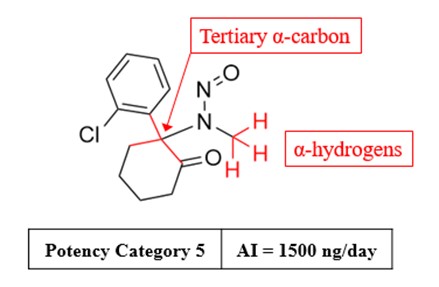

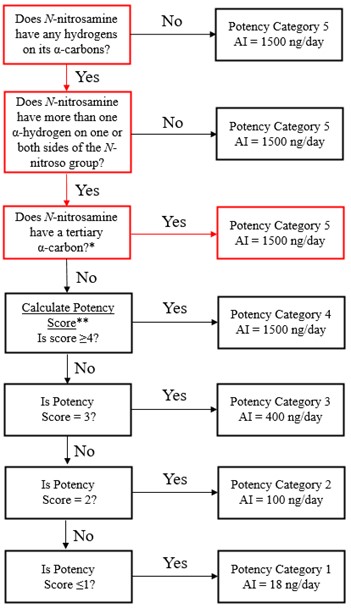

The Carcinogenicity Potency Categorization Approach (CPCA) is an approach for assigning a nitrosamine to a predicted carcinogenic potency category.

A total of five carcinogenic potency categories are available, each with a corresponding AI limit that ranges from 18 ng/day to 1500 ng/day.

A nitrosamine is assigned to a predicted carcinogenic potency category based on an assessment of alpha hydrogen atoms and activating or deactivating structural features present in the nitrosamine. Refer to Appendix 4 for a description of the approach which also includes case examples to illustrate application of the CPCA.

MAHs and applicants should also refer to the following items for more information:

- number 27 on the presence of multiple nitrosamines

- number 28 on applying a less-than-lifetime limit

- number 31 on which nitrosamines should be included in risk assessments and confirmatory testing

25. AI limits for nitrosamine impurities in drug products that fall within the scope of ICH's S9 guideline or where the API is genotoxic

If a nitrosamine impurity is identified in a pharmaceutical, biological or radiopharmaceutical product that is intended for advanced cancer indications (defined in the scope of ICH's S9 guideline), the impurity can be controlled per the recommendations in ICH's S9 questions-and-answers document.

If a nitrosamine impurity is identified in a drug product where the API is genotoxic at therapeutic concentrations, the impurity can be controlled at limits for non-mutagenic impurities. Refer to ICH's Q3A and Q3B guidelines.

26. Communicating if AI limits are revised in the future

Health Canada continues to work with international regulatory agencies to determine AI limits for nitrosamine impurities. We will communicate any changes to the AI limits for nitrosamine impurities to MAHs and applicants in a timely manner.

Interim AI limits were originally communicated to MAHs for 5 nitrosamine impurities in angiotensin II receptor blockers (also known as "sartans"). These were in place until September 30, 2020, and will not be reduced to a lower level.

27. Acceptable Intake limit if multiple nitrosamines are detected in an API or a drug product

If an API or drug product has the risk of containing more than 1 actual or potential nitrosamine impurity, total (cumulative) daily exposure should be limited to the nitrosamine with the most conservative AI limit at the maximum daily dose of the drug product.

Examples:

- If a drug product contains both NDMA and NMBA, the total/cumulative daily exposure of the 2 nitrosamines should be limited to 96.0 ng/day.

- If a drug product contains both NDMA and NDEA, the total/cumulative daily exposure of the 2 nitrosamines should be limited to 26.5 ng/day.

If an applicant or MAH proposes to control multiple nitrosamine impurities in an API or drug product using an alternative methodology, Health Canada will assess the acceptability of the approach on a case-by-case basis. Any proposed alternative methodology should ensure that excess cancer risk does not exceed 1 in 100,000.

For nitrosamine impurities that are considered non-mutagenic, the recommendations provided in ICH's Q3A and Q3B guidelines apply and such impurities do not need to be included in a limit for total nitrosamines.

28. Application of a less-than-lifetime (LTL) limit by considering the principles in ICH's M7 guideline if a nitrosamine impurity is present in a drug product that is administered for less than a lifetime

Considering the risk profiles of nitrosamines and the possibility of an additive biological effect, the AI limits outlined in Appendix 1 are considered appropriate for lifetime and LTL administration of a drug product.

If a nitrosamine impurity cannot be controlled at the AI limit, Health Canada may consider an interim limit higher than the AI limit. We will do so on a case-by-case basis and only in exceptional circumstances (for example, to avoid a drug shortage of a drug product that is considered medically necessary or medically important).

Where an applicant or MAH proposes an interim limit higher than the AI limit for a nitrosamine impurity, Health Canada will consider:

- the medical necessity or medical importance of the drug product

- levels of impurity observed in representative batches

- other risk management considerations (for example, the availability of alternative medications on the Canadian market)

We will consider an interim limit higher than the AI limit for a nitrosamine impurity as a transitory measure only, until appropriate changes to reduce the level of the nitrosamine impurity to at or below the AI limit have been implemented.

For nitrosamine impurities that are considered non-mutagenic, the recommendations provided in ICH's Q3A and Q3B guidelines apply and such impurities do not need to be included in a limit for total nitrosamines.

Quality

29. Risk factors and potential root causes to be considered for the presence of nitrosamine impurities in human pharmaceuticals when performing a risk assessment (updated)

Knowledge of risk factors and potential root causes for nitrosamine impurities continues to evolve. Applicants and MAHs should stay up-to-date on risk factors and potential root causes that Health Canada and other regulators have identified in their guidances and peer-reviewed publications. The collaboration of the quality technical experts of the international regulatory partners of the NITWG has led to the development and publication of the paper "Regulatory Experiences with Root Causes and Risk Factors for Nitrosamine Impurities in Pharmaceuticals" (Horne et al. J. Pharm. Sci. 2023, 112, 1166-1182). This publication is designed to share current information and experiences from a quality perspective on root causes, risk factors, and risk mitigation measures relating to nitrosamine impurities in pharmaceuticals for human use.

Inadequate process design and/or process controls, as well as gaps in quality and compliance oversight, may contribute to the presence of nitrosamine impurities in APIs and drug products above AI limits. Applicants and MAHs should consider both intrinsic and extrinsic factors when conducting risk assessments for nitrosamine impurities.

Potential and confirmed root causes and risk factors for the presence of nitrosamines in drug products include the following:

- Nitrosation of a secondary or tertiary amine during API or drug product manufacturing, with insufficient downstream purge of the nitrosamine formed, and/or during API or drug product storage (common nitrosation conditions involve the combination of amines and nitrite ion under acidic conditions)

- Sources of amines include APIs, API intermediates, starting materials, reagents, solvents, catalysts, reaction by-products and degradation products. Certain non-medicinal ingredients may also contain amines as part of their structure. Amines leading to stable nitrosamines include secondary amines and tertiary amines. Quaternary ammonium salts are also potential precursors to nitrosamines. Primary and tertiary amines may contain secondary amines as impurities. Amines may be present as impurities in amides or formed through the degradation of amides (for example, via hydrolysis). Tertiary amines may be nitrosated by a dealkylative pathway to produce one or more secondary amines, which may subsequently undergo nitrosation to produce multiple nitrosamines.

- Nitrosating agent precursors and sources include:

- nitrite ion intentionally used in a manufacturing process (for example, as used in diazotization chemistry or as a reducing agent for azide ion)

- nitrite present as an impurity in reagents (for example, sodium azide), common non-medicinal ingredients (for example, microcrystalline cellulose, magnesium stearate)

- nitrogen oxides (for example, NO, N2O3)

- nitric acid

- nitrosyl halides

- alkyl nitrites and nitro compounds (for example, nitromethane)

- potable and/or purified water containing nitrite

- Using a nitrosamine as a starting material or synthetic intermediate, with incomplete conversion of the nitrosamine and/or insufficient downstream purge

- Reaction of nitrite ion and an amine under process conditions with pH >7 under catalysis by a carbonyl compound, with insufficient downstream purge

- Oxidation of a hydrazine functional group in an API, starting material, intermediate or a reagent to produce a nitrosamine, with insufficient downstream purge

- Using certain materials in container closure components which may provide a source of nitrosating agents or amines, such as:

- nitrocellulose, found in certain lidding foils used for blister packaging

- certain types of vulcanisation accelerators (for example, dithiocarbamate, thiourea, thiruams) which are used in rubber manufacturing

- Using recycled materials (for example, solvents, reagents, catalysts) contaminated with nitrosamines and/or nitrosamine precursors

- Cross-contamination of materials with nitrosamines/nitrosamine precursors in multi-product facilities (for example, through the use of shared equipment)

- Poor operation of a process step (for example, during liquid-liquid phase separations), which is intended to purge nitrosamines

- Using certain manufacturing operations that could facilitate contact between nitrosamine precursors (for example, wet granulation) or introduce nitrosating agents/precursors (for example, nitrogen oxides during fluid bed drying)

30. Components of drug products to consider in risk assessments

All components of the drug product should be considered as potential sources of nitrosamine impurities, or their precursor nitrosating agents and amines, in the context of the designated process and storage conditions. For example, some excipients may contain residual levels of nitrite (see Wu, Y. et al. AAPS PharmSciTech 2011, 12(4), 1246-1263 and Boetzel et al. J. Pharm. Sci. 2023, 112, 1615-1624) or reactive amines as part of their molecular structure. Under certain manufacturing process or storage conditions, this may lead to the formation of nitrosamine impurities.

Refer to number 29 for more information on risk factors and potential root causes to take into consideration.

31. Nitrosamine impurities to consider in the Step 1 risk assessment and Step 2 confirmatory testing

Each API and drug product manufacturing process is unique. Thus, the nitrosamines listed in Appendix 1 of this guidance are not exhaustive and do not represent all nitrosamines potentially present in APIs and drug products. Conversely, the nitrosamines listed in Appendix 1 may not be potential impurities in all APIs and drug products.

MAHs and applicants should ensure that the risk assessments consider and identify the possibility of any nitrosamine impurity that may be formed or introduced. All nitrosamines that have been determined to be potentially formed or introduced should be included within the program for confirmatory testing (Step 2).

For nitrosamines not included Appendix 1, MAHs and applicants should refer to number 24 for guidance on how to establish an AI limit.

32. Testing methodologies provided by Health Canada

Several regulators, including Health Canada, Europe's network of Official Medicines Control Laboratories (OMCLs) and the U.S. Food and Drug Administration (FDA), have published and shared testing methodologies. These methods may be used, although there is no requirement to do so.

In all cases, companies should use appropriately sensitive, validated analytical methods and conduct the testing at a GMP-compliant facility. If other methodologies are used, there is no need to verify the method with Health Canada prior to use.

Analytical methods should be quantitative in nature (as opposed to limit-based tests) and should be fully validated before confirmatory testing begins. If limit-based tests are used, ensure that the appropriate scientific justification is provided in the risk assessment documentation. For example:

- demonstration that the limit test is valid at or lower than the AI limit

- supporting evidence that indicates there is no increase in the concentration of nitrosamine impurities over time

Unless otherwise justified, method validation should be performed using the drug product that is authorized for use in Canada.

Where multiple strengths of a drug product exist and the validation is to cover multiple strengths, the justification for the choice of product strength used for validation should be described in the validation protocol.

33. Validating the limit of quantitation (LOQ) for nitrosamine impurity analytical procedures (updated)

The LOQ for analytical procedures that are intended for quantitation of individual nitrosamine impurities in APIs and drug products should be equal to or less than the established AI limit (Appendix 1), the AI limit established using the CPCA (refer to number 24 and Appendix 4) if an AI limit has not been established by Health Canada, or the relevant ICH Q3A or Q3B reporting threshold for a nitrosamine impurity that has been classified as non-mutagenic in Appendix 1.

Where instrument sensitivity challenges exist to achieve the desired LOQ, some exceptions may be acceptable with appropriate scientific justification (for example, for drug products with a very high maximum daily dosage and nitrosamine impurities with very low AI limits).

Analytical procedures should be validated with a LOQ which is less than or equal to 10% of the acceptable limit for an individual nitrosamine, if a proposal to not routinely test for the nitrosamine in the drug product specification is anticipated (refer to number 34).

Analytical procedures should be validated with a LOQ which is less than or equal to 30% of the acceptable limit for an individual nitrosamine, if a proposal for periodic (skip) testing is anticipated.

34. Including routine testing for nitrosamine impurities in the API and/or drug product specification (updated)

The API specification should include a test and acceptance criterion for each nitrosamine impurity when:

- the risk for nitrosamine presence is considered to be high and/or

- the concentration of any nitrosamine is found to be at significant levels (for example, greater than 30% of the AI limit) during confirmatory testing

Examples where the risk of presence for nitrosamines in the API is considered high:

- potential for nitrosamine formation on storage is identified

- presence of nitrosamine precursor functional groups in the API structure

- late-stage formation/introduction of a nitrosamine impurity in the API manufacturing process

Where multiple nitrosamines are detected in an API, a cumulative limit should also be included in the specification using one of the approaches outlined in number 27.

Routine testing for nitrosamine impurities should be included in the drug product specification when:

- the potential for nitrosamine introduction during drug product manufacturing, packaging and storage is identified and/or

- a nitrosamine impurity is detected in the drug product during confirmatory testing and the root cause is unknown

If the root cause for the presence of a nitrosamine impurity in the drug product is well understood, then alternative control strategies may be acceptable when scientifically justified.

A test and acceptance criteria for both release and shelf life specifications should be included. Refer to Appendix 1 for a list of established AI limits. These AI limits are considered qualified for nitrosamine impurities in the drug product at the end of shelf life. In some cases, tighter limits in the API specifications and in the drug product release specifications may be warranted to ensure that the drug product shelf life specification will be met.

Where multiple nitrosamines are detected, control for total nitrosamines using one of the approaches outlined in number 27 should be included in the specification. Alternatively, control limits expressed on an individual impurity basis (for example, a limit for each nitrosamine set at a percentage of its AI limit such that the sum of the % AI limits for each specified nitrosamine does not exceed 100%) may be proposed with appropriate justification. Other approaches for establishing a suitable specification when multiple nitrosamines are concerned may be acceptable if appropriately justified.

The presence of one or more nitrosamines at <10% of their individual AI limits in a drug product constitutes a negligible toxicological risk; if the root cause for the presence of such nitrosamine impurities is understood and appropriate controls have been established to ensure such impurities will consistently be <10% of their individual AI limits, then such impurities do not need to be specified in the drug product specifications. Nitrosamines present below 10% of their respective AI limit do not need to be factored into the calculation of limits for total nitrosamines.

Where nitrosamine impurities can be controlled according to ICH Q3A and Q3B guidelines (refer to number 3 and number 25) and the risk of presence can be sufficiently mitigated based on a scientific justification that demonstrates the relevant ICH Q3A and Q3B thresholds will not be exceeded, then additional controls specific for nitrosamines in the API and drug product specification are not expected.

MAHs should test all new lots of drug product for nitrosamines and only release lots that meet the acceptance criteria for individual (and multiple nitrosamines, if relevant). Continue routine testing of all drug product lots until the root cause is identified and alternative controls/risk mitigation measures (such as process controls, raw material specifications) have been implemented. Ensure that nitrosamine impurities will be routinely below the AI limit in the future.

35. Potential control options for nitrosamine impurities in the API

Control options for nitrosamine impurities include:

- routine testing in the API (ICH's M7 Option 1)

- control in upstream intermediate specifications at the AI limit (ICH M7 option 2) (when the route cause, or causes, of nitrosamine presence have been established unequivocally)

- control in upstream intermediate specifications at acceptance criteria that exceed the AI limit (ICH's M7 Option 3) (when the root cause, or causes, have been established unequivocally and justification of the proposed limit is supported by demonstrated process capability (for example, spike and purge studies))

Proposals for an ICH M7 Option 4 control strategy for nitrosamine impurities in a new market authorization application will be evaluated on a case-by-case basis. An Option 4 control strategy proposal may not be appropriate when the concentration of any nitrosamine impurity in an API is greater than 30% of the AI limit. However, such a strategy may be acceptable when process understanding has been demonstrated by fate-purge studies, identification of process parameters that impact nitrosamine impurity levels and when supported by appropriate analytical data. Predicted purge factor calculations should be supported by appropriate analytical data.

This information should be provided along with copies of analytical procedures and method validation reports in the new market authorization application.

Refer also to number 34 for information on routine testing for nitrosamine impurities in the API and/or drug product specification.

36. Confirmatory testing expectations (Step 2)

During confirmatory testing, MAHs should test the drug product to determine the levels of nitrosamine impurities.

Testing the API is also recommended if the risk assessment indicated that the API is a potential source of nitrosamine impurities in the drug product. The API testing results may be used to support root cause investigations and the development of a justified control strategy for nitrosamine impurities in the API.

If a drug product is available in multiple strengths of the same dosage form with the same risk factors applicable to each, then testing could be rationalized by testing only the worst-case scenario strength. The worst-case approach should be justified by the MAH on a case-by-case basis. The justification should be documented in the risk assessment in the MAH's pharmaceutical quality system.

If, despite extensive efforts, it becomes apparent that a nitrosamine impurity cannot be synthesized or isolated and purified, then this could be an indication that the nitrosamine either does not exist, is unstable, or that there is no risk of it being formed. In such cases, it may not be necessary to conduct confirmatory testing. This should be justified thoroughly on a case-by-case basis according to appropriate scientific principles. A scientific justification including experimental data which summarizes the efforts made to synthesize and/or isolate and purify the impurity should be included in the summary and discussion of the risk assessment in the regulatory submission and documented in the MAH's pharmaceutical quality system.

37. Analytical laboratories conducting nitrosamine testing and listing on the DEL

The analytical lab used for nitrosamine confirmatory testing (Step 2) does not have to be listed on the DEL at this time. However, in all cases, the confirmatory testing must be conducted at a GMP-compliant facility. A foreign analytical lab, if used for conducting the nitrosamine confirmatory testing, must either:

- have been deemed GMP-compliant by Health Canada or

- have a valid GMP inspection by a competent or qualified regulatory authority demonstrating compliance with current GMP standards

Ethical drugs are those that do not require a prescription, but are generally prescribed by a medical practitioner as professional use products (for example, hemodialysis solutions, nitroglycerine). For testing ethical and over-the-counter drugs, if no inspection reports by regulatory/qualified authorities are available, a corporate or consultant audit report to demonstrate GMP compliance is acceptable.

For more information about acceptable GMP evidence and regulatory requirements, refer to the following guidance:

However, analytical labs must be listed on the applicable annex of the DEL if they are conducting:

- nitrosamine testing used to release APIs and drug products for the Canadian market or

- tests that are part of the API or drug product specification

- includes testing imposed through the sartan terms and conditions

For guidance on Health Canada's expectations for testing facilities or for other related questions, please send an email to foreign.site-etranger@hc-sc.gc.ca.

38. Number and types of drug product batches as part of confirmatory testing for marketed products and new market applications

For marketed products, the number of batches to be tested should be commensurate with the risk. Examples of high risk include:

- late-stage formation/introduction of a nitrosamine impurity in a manufacturing process

- presence of nitrosamine precursor functional groups in the API

- potential for nitrosamine formation on storage

MAHs and manufacturers should test a representative number of batches of the drug product as appropriate based on the risk assessment (for example, batches that are representative of sources of components, manufacturing processes/sites, manufacturing dates).

If the root cause for the nitrosamine presence has been identified and scientifically demonstrated, and impurity levels are expected to be consistent from batch-to-batch (for example, as demonstrated by spike-purge studies), testing should be conducted on 10% of annual batches, or 3 per year, whichever is highest. Testing should include both newly produced batches as well as retained samples of batches still within the expiry date. If fewer than 3 batches are manufactured annually, then all batches within the expiry date should be tested.

Testing plans or protocols (for example, a protocol for the number and type of batches to be tested) do not need to be submitted to Health Canada for assessment and approval before initiating confirmatory testing.

If nitrosamine impurities are detected at significant levels (approaching, at or above AI limits), additional batches of the drug product on the Canadian market and within the expiry date should undergo confirmatory testing. In such cases, MAHs may be requested to test all lots on the Canadian market that are within the expiry date.

For NDSs, ANDSs, DINAs (with C&M data), DINBs, Supplements Notifiable Changes and Post-DIN Change (PDC) submissions(for quality changes that may impact the potential presence of nitrosamines in the drug substance or drug product, refer to number 13), at least 6 pilot or 3 commercial-scale batches should undergo confirmatory testing where a risk of nitrosamines has been identified. A higher number of batch results should be submitted for assessment where the risk of nitrosamine presence is high. Examples include:

- the late-stage formation/introduction of a nitrosamine impurity

- nitrosamine precursor functional groups in the API

- stability concerns exist for nitrosamine formation over the retest period/shelf life

Testing of stability batches for a nitrosamine impurity should be conducted where:

- a risk has been identified that nitrosamine levels could increase in the API or drug product over time or

- the potential for increases over time is unclear

Where applicable, testing for the nitrosamine impurity for a minimum of 6 months of accelerated and long-term stability data in the proposed container closure system(s) should be provided in the drug application.

Appendices

Appendix 1: Established Acceptable Intake (AI) limits for N-nitrosamine impurities

- See separate Appendix 1.

Appendix 2: Guidance with respect to nitrosamine impurities and risk assessments for Post NOC Changes of new drug products containing chemically synthesized and semi-synthetic APIs (updated)

Appendix 2 - Text description

An image of a decision tree is providing advice to Market Authorization Holders about regulatory filing requirements related to nitrosamines. It describes some types of changes which may impact the possibility of nitrosamine formation when a change is being proposed. Are changes to a market authorization being filed specifically to address nitrosamine risk mitigation issues? If yes, a Level I supplement or a Level III annual notification is expected. A Level III annual notification is accepted only for certain specific changes (refer to number 13). For a Level I supplement, include a summary of root cause investigations and conclusion(s) regarding the confirmed root cause(s) for nitrosamine presence under 3.2.P.2. If no, refer to Post-Notice of Compliance (NOC) changes: Quality Document for the level of the change (Level I or III). Could the proposed changes increase the nitrosamine risk relative to the approved/marketed product? If yesFootnote *, assess the impact of the proposed change on nitrosamine presence and include a risk assessment summary/discussion relative to the approved product in the submission. If noFootnote **, a summary and discussion of a nitrosamine risk assessment is not expected in the submission but do include a brief justification for no increased nitrosamine risk relative to the approved drug product in the notes to reviewers, 3.2.P.2 or 3.2.P.5.

- Appendix 2 footnote *

-

For example, changes to drug substance or drug product manufacturing processes, changes to the drug product composition (API, excipients), changes in dosage form, and changes to the container closure system may increase risk relative to the approved drug product.

- Appendix 2 footnote **

-

For example, the addition of a proportionally-formulated strength would not be expected to increase risk relative to the approved drug product.

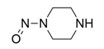

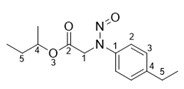

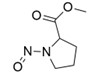

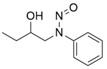

Appendix 3: Enhanced Ames assay test conditions

The Organisation for Economic Co-operation and Development (OECD)'s Test Guideline No. 471 "Bacterial Reverse Mutation Test" provides standard recommendations for the conduct of the bacterial reverse mutation test (also known as the Ames assay) to assess the mutagenic potential of a test compound. For N-nitrosamines, enhanced testing conditions for the Ames assay are recommended due to the reported reduced sensitivity of the assay under standard conditions for some N-nitrosamines such as N-nitroso-dimethylamine (NDMA). Moreover, very little is known about the sensitivity of the Ames assay to N-nitrosamine drug substance related impurities (NDSRIs), which are a recently recognized class of N-nitrosamine impurities structurally related to the drug substance. NDSRIs generally have a wider variety of functional groups present than typically found in low molecular weight N-nitrosamines (such as NDMA) historically studied.